SECTION 6.0 METHANOL SYNTHESIS AND DISTILLATION 6.1 6.1

advertisement

SECTION 6.0

METHANOLSYNTHESISAND DISTILLATION

(Areas 213, 214, 219)

DESIGN BASIS

6.1

6.1.I

6.1.2

Methanol synthesis w i l l be by the ICI low pressure process.

Three trains of equal capacity w i l l be provided for converting the upgraded synthesis gas to methanol.

6.1.3

6.1.4

Operating pressure wi~l be at lO0 atmospheres.

Purge and flash gas w i l l be collected and sent to a reformer

for converting CH4 to H2 and CO which w i l l

be returned to

the converter.

6.1.5

Each of the three d i s t i l l a t i o n columns w i l l

be designed to

produce 2,500 stpd of fuel grade methanol.

6.1.6

Bottoms water w i l l be directed to the wastewater treatment

area for cleanup prior to discharge.

6.2

PROCESS DESCRIPTION

6.2.1

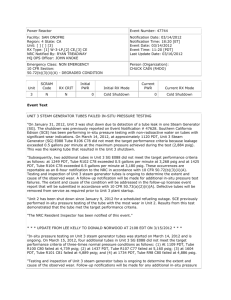

Methanol Synthesis {Area 213~ Dwg. 5530-213-Y-001)

The synthesis gas charged to the methanol converter is composed of makeup gas, reformed gas, and recycled loop gas. A

fraction of the synthesis gas is preheated to reaction temperature and enters the top of the converter as feed gas.

The following overall reactions take place over the copper

based methanol synthesis catalyst.

0815R

6/1

~,

..,.

.

"."L'~,~.,,.,-w

...............................

4 , ,

.

,

,,~,,'

'"'., " , '

-

'

'

•

°"," .........

,,.

, ..............

:.

CO + 2H2 ~-~

~

CH30H

C..,

CO2 + H 2 ~ C O

+ H20

The overall reaction from CO, CO2 and H2 to methanol is

exothermic. The remaining synthesis gas is preheated (to a

/../...

temperature substantially below reaction temperature) and is

injected into the converter at appropriate points along the

length of the converter. This "warm shot" gas is used to

quench the reacting gas passing down through the catalyst

beds. It moderates the reacting gas temperature and subsequently reacts to form methanol as it passes over the catalyst bed below.

:,.."

:w ;"

The converter effluent gas is cooled by heat exchange in the

warm shell interchanger, in the saturator water heater and in

.,...

the d i s t i l l a t i o n column gas reboiler,

The remaining heat is

removed in the cold shell tnterchanger. The a i r cooled crude

methanol condenser removes waste heat from the e x i t gas and

the Condensate (crude methanol) is knocked out in the methanol separator. A fraction of the gas from ti~e separator is

., ! ; " 14.

!L.

":

purged to maintain the proper inerts level in the loop. This

(

:t,

purge is used as part of the reformer feed and fuel.

ii ,

•

The

remaining gas is recycled through the circulator compressor

and the Interchangers back to the converter. The makeup gas

.?,:'i' ';'

addition is at the suction of the circulator compressor.

Crude methanol is flashed at a pressure above atmospheric to

remove some of the gases ph?sically dissolved at the loop

pressure. The crude methanol then passes under i t s own pressure to the crude methanol tank.

The flashed gases are sent to the rsformer as part of the

feed.

{

x.

0815R

612

•

,t

.,..

The methanol converter is a pressure vessel of stngle wall

design constructed of low alloy steel whtch holds a single

bed of catalyst. Temperature control is effected by injecttng "warmshot" gas at appropriate levels directly into the

catalyst bed using specially developed distributors called

L

lozenges.

The lozenges provide excellent gas mixing while

L

~

yi.: ~.

•

,,

.'i"

a11owlng free flow of catalyst between them, thus allowing

raptd catalyst charging and discharging. Catalyst chanqeout

times of less than 36 hours from hot shutdown to start of

reduction of new catal3st are consi~tantly achieved.

The synthesis loop also contains a steam heated start-up

heater which serves to heat the cl~culating gases at start-up

and for catalyst reduction.

i i~!¸

6.2.2

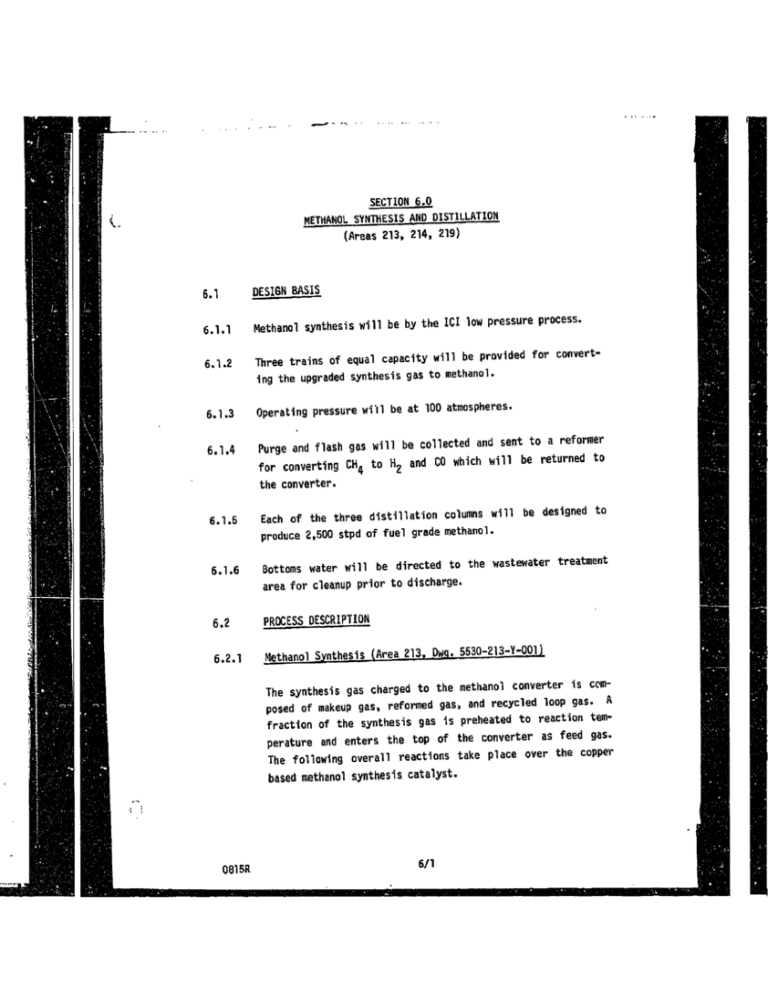

Reforming (Area 219,/)rawings 5530-219-Y-001~ Y-O02)

The purge gases prodLiced by synthesis and d i s t i l l a t i o n

are

steam reformed to supplement the makeup gas required from

gastfters as feed to the synthesls loops. In practice, not

all of the purge gases can be fed to the reformer and returned to the methanol synthesis loops because the synthesis gas

also contains nitrogen which would build up i f some purge

were not maintained. Thus 75% of loop purge and all of loop

flash and d i s t i l l a t i o n light ends are fed to the reformer as

feed and 25% of loop purge is used as fuel to the reformer

which is supplemented by No. 2 fuel oi1.

Purge gas feedstock

is supplied at IO0=F and 350 psig. The feedstock is mix~:d

with process steam and heated to 900°F in the mixed feed preheater.

Preheated mixed feed is distributed equally to tubes packed

with natural gas reforming catalyst.

.)

!

0815R

6/3

,i

/

q~

~

I

* . . . . . . . .

The reforming furnace is of "modular" design which combines

economical s t r u c t u r a l costs with s i m p l i c i t y of design. Heat

of reaction is provided by downfired burners, situated in the

roof of the furnace.

The burners are designed f o r f i r i n g

C.

purge gas and No. 2 fuel o i l .

Steam and purge gases enter the reforming tube centrally

through a top blind flange, pass through a 35 foot bed of reforming catalyst reacting to form reformed gas which leaves

through the outlet pigtail.

In the event of accidental tube f a i l u r e , i t is possible to

isolate individual tubes by a hydraulic nipping device which

pinches shut the " p i g t a i l "

connections at i n l e t and o u t l e t .

This operation may be carried out with the furnace on-line.

The reforming

reaction

is

basically

the

reaction

between

hydrocarbon and steam to produce carbon monoxide and hydrogen, The prusence of excess steam promotes the s h i f t reaction which w i l l a l t e r the f i n a l equilibrium composition of

the reformed gas. Typical equations representing the overall

~eactions are given below:

Reforming Reaction

CH4 + H20_eF__.~_C0 * 3H~

S h i f t Conversion Reaction

CO + H20

~

CO2 + H2

Heat is recovered from hot reformed gas by generation of

steam in the reformed gas boi]er, preheating the mixed feed

and boiler feedwater heating in the b o i l e r feedwater heater.

C

;.

0815R

6/4

Final cooling of the reformed gas to IO0°F is done in the air

cooled reformed gas cooler.

Generation of steam at the 1500 psig level has been selected

so as ~ be compatible with plant wide steam generating

system.

Steam generation is achieved by heat recovery from reformed

gas and radiant box flue gas, The steam generation boilers

and the superheater utilizes a common steam drum and, for

r e l i a b i l i t y o natural boller feedwater circulation.

The flue gas from the furnace is also used to produce superheated steam, and to preheat combustion a i r .

6.2.3

D i s t i l l a t i o n (Area 214, Dwg. 5530-214-Y-001~

One of the major advantages of the ICI low pressure methanol

process is the excellent s e l e c t i v i t y of the converter catalyst and the consequent low level of organic impurities. A

simple d i s t i l l a t i o n system can thus achieve high efficiency

without requiring high rebotl heat loads. A single column

d i s t i l l a t i o n system is therefore provided. A part of the reboil heat is provided by the effluent gases from the methanol

converter and effluent gases from the hydrolysis unit and the

rest ls provided by 50 psig saturated stets,

The crude methanol is pumped from the crude methat,ol tank to

the d i s t i l l a t i o n system and is heated with the d i s t i l l a t i o n

column overheads.

To prevent corrosion, a premixed aqueous

solution of 1% sodium hydroxide is metered into the crude

feed at a rate sufficient to neutralize any organic acids

present. The heated liquid is then fed to the d i s t i l l a t i o n

column.

0815R

615

. o .

The d i s t i l l a t i o n column is used to separate dissolved gases

and water from the product methanol. This column is f i t t e d

with an overhead condenser system, two gas reboilers and a

steam reboiler.

. . ,

C

The overheads from the d i s t i l l a t i o n column are partially condensed in the overheads condenser.

The remaining methanol

vepor is condensed in the l i g h t ends cooler at IO0°F. Such a

s p l i t cooling duty avoids subcooling of the methanol r e f l u x

more than is absolutely necessary and yet maintains very low

losses of methanol in the o f f gas purge from the secondary

methanol separation. This gaseous purge contains the remaining dissolved gases not separated in the letdown vessel and

l i g h t organic by-products such as dimethyl ether, aldehydes,

ketones, etc.

The l i g h t ends purge gas is compressed in the

l i g h t ends compressor and is used as part of the feed to the

reformer.

columns w i l l

compressor.

Light

e n d s from

three

separate

distillation

be recycled as feed through a common l i g h t ends

The d i s t i l l a t e is drawn as liquid from near the top of the

column. This product is cooled and passes to the fuel methanol storage f a c i l i t i e s .

A sidestream of fusel oil is extracted from near the bottom

of the d i s t i l l a t i o n column. The fusel oil contains the organic heavy ends such as ethanol, propanols a~d butanols

which are valuable as fuel. To remove these higher alcohols

from the d i s t i l l a t i o n system the fusel o i l , after cooling, is

pumped into the d i s t i l l a t e stream to y i e l d fuel grade methanol.

The bottoms water, which contains about 12 ppm alcohols, tim

bulk of which is methanol, is pumped t o the wastewater t r e a t ment area.

.

i

0815R

6/6

6,3

ENGINEERING DESIGN DATA

J~

Design dato pertinent to Reforming, Synthesis and D i s t i l l a t|on ts detailed in the Process Flo~ Otagrams immediately

following thts page, in the Equipment List beginning on Page

6/9, and in the Drawings following Page 6/22.

0815R

6/7

DRAWINGS RELATING TO METHANOL

SYNTHESIS AND DISTILLMION

TITLE

DRAWINGNO.

5530-213-Y-001

Methanol Synthesis

5530-214-Y-001

Methanol D i s t i l l a t i o n

5530-219-Y-001

Reforming

5530-219-Y-002

Reforming

EQUIPMENT LIST

5530-213-P-001

5530-213-P-OO2

Raw Gas and Methanol Areas - Overall Arrangement

Methanol Unit, D i s t i l l a t i o n and Synthesis - Plan

5530-213-P-003

at Base

Methanol Unit, D i s t i l l a t i o n and Synthesis - Plan

above 2Z'-O"

Methanol Unit, D i s t i l l a t i o n and Synthesis - Plan

5530-Z13-P-O04

above 38'-0"

5530-213-P-005

Methanol Unit, D i s t i l l a t i o n and Synthesis - Plan

5530-Z13-P-006

above 54a-0"

Methanol Unit, D i s t i l l a t i o n

vatio==

and Synthesis - Ele-

LIST OF CORRECTIONS

Equipment List

Reads

Should Read

213-1301-1

C

117,000

39,000

214-1621

T

Shell and Tube

Fin Fan

Shell--310

Tubes--400

Tubes--3]O

Shell--400

219-1604

C

Item

Des P/T

219-1607

T

Horizontal

Vertical

302-1103

C

D

200

350

670

1,065

0815R

618

t~

.,I

,.,,-,-,,

.."l'.!!]!!!!!!!l.!l'~t.!l.l~.~

,~l;l~.l.tI1.1:1:,:1.~,.~,.~,:,Zi

87RE~ DE~RI~|ON

l J J 11 t l I ~ J. [ ~ J.J. LJ. ~.~ [ J.Z~

,,,-r"l

P

£

~45

[

2' t'~-220",~

2L3-1616

CONVERTER

HBTER

f-

213-1615

213-1618

INTERC'-IRNP,ER

COL~

HATER HERT[R

i,

a

J

/

I

~s'llm4i

s I C

-'l)'-i

| ,;,o-v-oo~ ~F

~,

e,el a I

Iz,',lzzoTl' " I

| 21o.-'t-ool ~

SnTW~T,',~

NMF..q

i

I 2.,,~ooi 14 vo t o ~ ~s ccL.~,,, ~Eoazc. L

J 214-Y-OOI

.

i

213

CIRC"

LURt RF.OOILER I

A¢|II4|

OWlICISSI'TION

i¢~ I ..~

2

!

I

I

:

I

r

i

ii

~,-rm'ltill I tl ~ I ! !,LLL

',='F'=rL t [ I mt L L I L L !,

f

.~-~

.

.

.

.

.

|.

]i

213-|6t~

CRUDE NETHRNOL

CONDENSER

213-1614

COLD SHELL LOOP

INTERCHN~IOER

213-ZE0~

CRUDE HETH~NQL

SEPARATOR

2t3-2209

LET~OHN

VESSEL

213-1~05

FL~SH GAS

EDUCT3R

|

i

PUR~E O~S.I ~|~ Y OOt

TO REFOI~'~q F ' L ~ " ;''':':z=-t''u= J

,

)-----~ i

II,

-

L.... "I

:

-

-

I===l=~osl

= I

C01~INED

PLm~

A

I

-

~

(!

='~=~'-=

To

1=131t==zj 3 I

";-

i:,zr,]z=ot-ll := ]

i

¢ IRCULP,TOR

213-130t-!

C2 RCUL~TOJ~

TURB%NE

NOlrZz lrlzk I~.k~Io~ i=,mzn~ of DAVYMcKEE

I~OiR.zQUllQN.. I l mz.m.mlk.., l=~ld w t,.m~=.

In mf w

~ W.~ It N ~

I=

palk= ~ m m l r e t ~ ~ d t ~ t ~ ==~

=

It ildl k ,rod ¢ld/m i =

d mira

curer

C|NZIPLACER

BELUGPt HETHRNOL PROJECT

COOK ; h L E T - ALRSKA

DavyMcKee

E N G I N E E R S ,-~ND CONSTRUCTORS

__==~_

HIETHRNOL

SYNTHESZS

m=m

7

I

o

I

'

L

10

4"'[[11]1 I III/lll/llllllllllllillllllllllllllll!l

!

OG~.,.qiP1 ~C.~I

,,,'l'"J J J J J 1 [ 1 J 1 J.£ l £ ~ J,,L £ J,£ J,,L,[

•

CRUI~N

m

I

~

- - - - -

~

_ - - - - -

m

. ~

m

,

~

~

~

~

m

m

i

2|4m|SOe

LICHTENDS

COHPRESSOR

~]4"2213

HYD~OgS

SEPARATOR

214-182!

L ~ $

COO~ER

[ 2&5-¥'-001 jI_CRUDE HEI"HAHOL FRON CRLI~E I'ETHRHOt. 'rN~K

214-221:

REFLUX DRUH

214-1820

OVERHEADS

CONDENSER

214-1619

FEE~ADS

ZNTERCHRNgER

214.

OlSTIt

COLL~

REBO!

(~

'

D

214-2502

CfiU~INQ

SET

I

r

i

i

i

Iz-lz,~,fl 3]

i

u

I~z411esgl :b I

t*'J

,[

I

r

fl

)Bm_

,/v

i

.I

r

1~1.4111o=1,N

L2i~,¥-oo1

~

LooP CONYERTEROR9 TO DXfrgTZLLATXONCOLLIHNItESOttER 1

L2|3-~-OOl

~t LonP CONVERTEROR8 TO COL[] SHELL XmERCH/iNQF.R

I.~l*lte,~;I " I'''IL J

~-~|O-Y-OQI ,J- HYOROLY2EOOA8 TO OIBT|LUtTXON ¢OLtJ~l nrcm~l.ER 2

L

L~Y-ooi

.L¢_ ¢o~e,sa're

214-1103

REFLUX PUH?-

214-1104

BOTTOHS PUHP

214-1108

m

,

FUSEL OIL

PUHP

llczc3L

_m

-3

IIIII

----,4-

~-I~. I i II I L! i ! ! i,I.I.~

,,-r'~, ! ! ! [ ! ! ! ! ! ~.

_!

LI~0ILIER o~.

-----4%

2:4-~.b'2~

~I"STZLL,~T Z0N

C'~L.,~.I.IN P~,~S

ZZ.~-22~.0

~ :~::l~l

CCL~JI,~

2:4-~.S24

BOTT~J4S

CQCI...~

2:4.-IG22

HE THP.",~-'L

CL-'CLr."R

i

2%¢-1623

~ - - ~ L

~-ISr=O %Llg:l u2

214-*-62";

,"-"-'ST [LLAT I C..~I

214-2:*'2

5TF~H

RE'~31 ~LS.q

{~LLq

~

PIIC{I~. lq~'l'll~Ul3. TI~ l'rl:ll/iG~

1

I

!

~.-~_/

°

Y

/-'--'-~

i

I

|

' '

'I az;-,-~

'

!

:..~.

,+ ....

~,,

:,

F : ~

,, ,,

-~

¢;~]~[]I~TE

:.....

F(.a~

~

m

~

$,'~JIl,*

r

*~Tr.~P* ¢~'(~,(S.q'rE

~ - - - ~

="

¢:GNF'CRAllCL ~ u m t m t ~ " ~ m e m ~ m .

u~¢ It "a

t~r m

~

m. ram.

3¢, UG# --_".",-ANCL P ~ J - ' £ T

~ , a 1 , = ~ l i C,B m ~ ~

~

L'JL~.-T ,

~L.~SK~

bawMcKee

ENGINE.S AND ~

iIimlmll Ill. Illl

0 ; S T ZLLr~TI~.N

,t ,:;

'~#./

I

'

j

t

'

I

'

i

'°

.;,: ,

.,--.~

,,-r[!l!l!!!!!;.lil!1!.i,!l!li1!lilil!lilili111!lililil

~'1'"11 J ] l lll

,, . . . . .

~.~..,.,_,~.,~, ,,.,!,,.;;V.,,,,~,:.~5',;~.,~.%~.

ILLLLLLLLLilII

FL.UE

,=A~

h4o;.~.

I COlVl~uI51"lOM

TI

AU=I

I

I

IRIIP'~

(3t41~

Ilv101.JI4n.IMOl,.~'~

IMOI.,A411LIMOt-.~;.AI,~a

I

'

I

7o,~?,e 11433o.lsl ?e.nl

@,o,"~ 11~-'.o,'9~

I,,,,,,ol,-

z..~9~,am.I,"O,IZ) Lz0n

!

]

,

*.

~-~

~oo.oo I,o,,~l,oo.ooi,s~,,

219-1501

REf-', .;.". : N~

~', ~N;;CE

FUEL OIL

DAY TANK

~rt-----~--~

~- L

i-~.- ~

219-1602

219-1601

R/ADIN,IT

SHIELD

BOILER

STERH

SUPERHERTER

/--~

~

lztaltl

0,s,,L,.~,,0,

J

I

/

21S-1603

REFDRHER

STERH

RI"I"EHPORRTOR

II (LF-T

I

~4."t99

I

.4"=~,oSI

~.e'~

I

~ ~'

219-1604

,

oc

219-220t

STERH

DRUH

H|XED FEED

PREHERTER

2Lg-LG

REFORH

CRS

BO]LE

12,olz".'od I I

4,

3_

•

l

II

tlzel'isoll ~"I

,

~,~

,,,

k

lalslzsozl I I

lai~hr~o~l I I

L--~'lzlsi16c~ I 11

i

t

1

BFH 140RHO-

21~-1 !01

FUEL OIL

PUHP

I~¢',1 '

otecs~vm.

b-wIF-'1[

l:~"

J Jiil',,,a[ ° Z; ~ ~ l l r j ' / 7 / ' J

I "t,I, ~- I ""~o~1 17~';'~i;l~

~"

"~

I"~l

i,1,,

I ,

°

I I I~['~

I j

'---i'" I.-.li:i:;,:_,' :i_.,

I

i

ii

-I

'~'i""

L I |

mi~m,im..i....

NNN

s

m

m

-

|

[

[

~ ;

:

L :

• ,

a

m

/

i

m

n

m

i

°r

i

w

;°

•',

2_

•

219-|807

219-1605

COHBUSTION

RZR

PREI-E~TER

~ZbER

2tS-1~08

H . P . BFH

HIERT~R

2tg-lGOS

FLU~ GAS

BOILER

I=lslz~l

219-1609

215-2401

219-2202

R~-IP~'ORHE~ ~RS

COOLER

F].U~ CRS

5TRCK

REFORHEDCRS

SEPRRRTCR

v

LI

• e*i

'

Iz~911..~_la.l

N~'[r~Tr'l

.i

• :2

~,

i!!?!

)

i'.

i~:i:i

21.q-13C'2

F.O. FAN

219"13C3

l . n . FAN

..,:!

DavyMcKee

!

:£ ].i

ENGINEF.RSAND CON~'I~UC'I'ORS

gll*tKl ~

ItI~II

i

I

6

I

'

I

°

I

, i

5S30-21S-Y-O01

REFORNING

'

I

,o

:ii: %

,,,-'ILILLLIlII.,.L~,

tit Ill....till L Itt[lllllltlltlltll~l.t.l~

.....

....

II~tUlIa RUUUI

~-l'llJ]fill 11 J. ~. L L ~, L J,,L L J.~ J.,!

I

i.

• " ~...',~,.'~"-

~_,_'Z~j

~o¢.,.~,~

~o~.~ .~_

w~-~.~

"1

I,.~m~T,E

i

I

_~_;,

...."'~"'~ ~ ..... ~;'.:~,'.-1

;~I "5~-.~-I

: ~ - ~ =_-~__~)_=

~

........

"" ,,.~,'.=~,

.......

--,,-.-r~-'

: ~

o~;,'~:

• -,.,~ I,

.~ " : ;:'~ '-;~-.1

~.".-'".~;1.....

~ I

...............

~

.................

l ~----~

............

P ";h ....

-':'

;. " " , L , ; ; . ~

", r : t ~ : ~ l ~

.:;,~;.

.... ~'~:,-,~.

....

:',:,.~:F.I

,~,,.:*

I

-~-~.~:

.. . . . . . . . . . . .

.:.,,. ..... ,.'~,;c~.

~0'.,~', ~,

"I4.19..~'.5G?.'J?.

':,;:~[|

"~'~.~';-~

.......

,~s~.s~

_~...I~

I ~-~--'-'-

~:9,,~)11

".~" -. "

". "':.:.

".'~-.:

.'--

:.."

~.h .."l~l]

I.~ i: r;

...................

.

. . . . . . . . . . .

"

""

.

.

.

.

..

. .....

..............

"~..~.=

.

' ~" *-~" I ~*I.~,

":;,'1 "

, .' ". ,';.

.............

.5, ~J.__~.~9.5~.

"

.....................

r.:~"~,-c ..........

1_~,.¢.~__1~,~,~7,.~

~

......

,,~o.i

..............

.

.

._

| . . . . . . . t,

.

|

....

.

.1 . . . . . . . . . . . . .

i

•

.... ,.

. . . . . .

,.::

,..',~:~:..

~,!~',~

~"

.,

. . . .

.

i

t"i'al

Ih" I i

~ "'?,C*;~

''.' '.' , t" ~.,

";'"

= . r .:;.*'

[ i~'l.l~R

I r':lP

I ":

I

•

"

•

=.,¥r

',"

,, .v ......

f

I llll. = 't.l~

l~, ~,- ,',',~

.

" "";'Z.lS~'Sl8

GG4GI$P-.

-" ~5~'"

.... l~O'"

.

.

.

-."i

.

.

.

! . . . . . . . . . . . . .

_3-_2.2_-.2.12 ..... ' 2 6~4oi3'P-

"

•. . . . . . . . . . . . . . . . . . . . . .

: •

~"

!i -£-~-:--~

.;-2

.........

~c=

~.~S

too

.

.

l.oo .....

l

-

,'I',

~.'."l

,'I.¢~

I.,"~. F 6 - " ' I :~ r,n~=

,.f., :.!; [ . r o ; ~

:' . . | ;G*: "~Z~°F~I~;!"~',

I:~0|

;l,~-16tt

~.l'FO~':f.'l lJ ('.,~5

f;O~..~ ~1" ~,';SOI~

319-22;.;__

F:RI3 t

[NTEI<L, ! =OF.

r, Of'jEER

219.-16'-2

F|RST

: NTER-¢,I" nGf',;r, pFRF.TO;'<

sr:CONO

1NTERST=G[COOLER

6

I

Iz,,l'lsl,I

I .,~-'~,_~

"" ' :

~,,

' "1

~"~

,.~

m

p,911oo,

i

ISSU~'D

FOR

D||CSIPTION

OIBCRIPTIOM

P/HAl..

R~'PORT

m

I

J

•

~

I

q

I , I

~

',.

LL!LLLL~

tLLLLLiLL.L!,L

-

>~

r

_-__.-.

""

.....

" .:'.~'.'2.1

.....

+i -

,

.......

..

i--.

.-.

, ......

I

, ..,

..

.'_2.". --.'.

............

. ....

,+--.-

o,

..

,.

'

"'~/' /&

•

..

. . . . . .

ti';:l

I

-|

-.--4.

•

I

"°

/+!+

. . . . . ......

. . . . l- . . . . . . .

t ...........1

i

,:;,?+g

. . . . .

(';I

.... ii-_----I i+;~-:

~,, !Z:]

~t9-220~

S~CONO

INTERST~G[

SEpPRFTOR

21~

:tO

".'S~;

RL'FORI'I ;I G n ~

[ ~ . , 0 ~ r ".','.OR

FF fliP. " ~ , . ~ . L R

:'£ ;.,~R~ TOR

t C,t'!

R E F ORM('I.! ( : n S

CO~,;~F~F '..5OR

FF'IER

COGL, L R

:

r.

:

i:+q

C ~ , ~ . = r l ' Y.CO~;

~R6:

P£.:"

,..

•

~'-'

• ~.

!

' i ~'~

•

1

C~R

i~it

~t:~

"2

:,

i

7

;i

•

•

.~-~

!.i

..,<

.+,

:-3

it,

-,.

......

....

~|

I

t.-,:,t-,.:_:_:'.__l

.T,L

!

: ° ~i

¢ O B p a I ~ T I O M . I t I m l t m t be I~m¢~ nat I*~m*

C I R" IP"

r'CI~-P-'-

-rl

IL

~w~dml~d

Qr t a ~ l W

:;,

~

q

I

"

lO

I

&'!),~. :.

lIO~l

T

¢

8

Plf

METHANOL SYNTHESIS - AREA 213

| NCL&TUlill

t

- TYPI[

" CAPACITY

" t|i~l¢

" OPKN4TINI

PIIEIIUIOI

"rill4PRN&'rUII

IK

ll4 - l l 4 A T e r l l | d l , l~

eliCANIgON

liTItlEI.

l i b * ImTdlLINL01[IJlII I T I l [ g r L

GI

GAIIT iNON

O - DNIlYI[

I - tlrlllN1r

AI=¢ = AC¢~1¢1101111¢1

-

EQUIPMENT L.IST

TEM

213-1301

,,

NO. REqUXRED

DESCRIPTION

3

Circulator

i

Single stage centrifugal

S - 6000 hp

Pi/TJ - Suction - 1394 psig/lOO°F

D - Steam t u r b i n e

T

213-1301-1

3

C i r c u l a t o r Turbine

T m Condensing

C

117,000 l b / h r steam

Pt/Ti/Po - 855 psJg/840°F/2 '' Hg Abs

213-1705

3

Flash Gas Eductor

m

Jet e j e c t o r

C - 4365 l b / h r with NW23.44

M - Carbon Steel with SS nozzle

Des P/T - S u c t t o n - 60 psig/lOO=F

Discharge - 370 psig

N3ttve gas @ 1394 psig, IO0°F

WIMW = 14.69

T

213-1614

Cold Shell Loop Interchanger

Shell and Tube

29,500 sq f t / s h e l l

Shell - Carbon Steel

Tubes - Ebrite

Des P/T - Shell - 1663 psig/3OO°F

Tubes - 1663 psig/320°F

T

m

SM-

08!5R

619

I

METHANOL SYNTHESI~ - AREA 213

C

EqUIPMENTLIST

ITEM

DESCRIPTION

NO. REQUIRED

W_arm Shell Loop Interchanger

213-1615

Shell

T

and

Tube,

2

shells

in

series

S - 14,800 sq f t / s h e l l

M - I s t Shell - Shell/Tube - C-I/2 Mo

2nd Shell - Shell - Carbon Steel

Tubes - Ebrite

Des P/T - Shell - 1663 psi9/515 °c

Tubes - 1663 pstg/570~'f

213-1616

Loop Start-Up Heater.

3

T N Shell and Tube

S - 1700 sq f t

Shell/Tube - C-I/2 Mo.

Des P/T - Shell - I020 psi9/9OO°F

Tubes - 1663 psig/9OO°F

Crude Methannl Condenser

213-161

T

m

SMDes PIT D-

Fin fan

23,350 sq f t bare area

Tubes - Stainless Steel

Tubes - i663 psig/250°F

20-30 hp e l e c t r i c motors

Loop Saturator Water. Heate,r.

213-1618

Shell and Tube

T

S - 21,480 sq f t

M - Shell/Tubes - Carbon Steel clad

w/304L SS/Carpenter 7 Mo SS

Des P/T - Shell - 930 psig/470°F

Tubes - 1663 psig/570°F

Methanol Converter

213-2207

T

m

Vertical,

Cylindrical,

catalyst packed

M - C-1/2 Mo

Des PIT - 1663 psig/6OO°F

Catalyst ICI Type 51-2

C

0815R

5/10

6

bed

METHANOL SYNTHESIS - AREA 213

.EQUIPMENT LIST

ITEM

NO. REQUIRED

DESCRIPTION

Crude Methanol Separator

213-2208

T - Horizontal, Cylindrical, double

barrel

S - I0' ID x 30' T-T top barrel

6' ID x 30' T-T bottom barrel

M - Shell - Carbon S t e e l ,

304 SS

l i n e d top b a r r e l

Bottom barrel a l i carbon steel

Des P/T

1663 psig/150°F

-

213-2209

3

Letdown Vessel

T - Horizontal, Cylindrical

mounted

w/demister

S - 8'6" ID x 30' T-T with 6" TK

demister pad

Demister - 304 SS

Des P/T - 150 psig/15O°F

0815R

6/11

METHANOL DISTILLATIONi iil i AREA

214

i =

EQUIPMENT LIST

ITEH

214-1103

NO.

R.EqUIRE,P

G " CAPAC~YV

• " 8lIE

PlY - OP~nPLTIIOIS PRKmlUmIKI

TEWOPIN mTU Ill(

HHA?llOlJ~l.

GI¢&milON

1Tt:~L

!1 " ITA~NIJZII

Qfll

L

C1 - C A l ?

1NON

0 - DIe|VII

IIW • I I l K I Q N T

&¢G

- A¢¢lilOllla

DESCRIPTION

3+3

Reflux PumE

T - H o r i z o n t a l , Centrifugal

M - Casing - Cast 3Leel

Impeller - Cast Iron

D - 100 hp, E l e c t r i c

214-1104

3+3

Bottoms,Pump

T - Horizontal, Centrifugal

C - 85 GPN @ 60 psi &P

H - Casting - Cast Steel

Impeller - Cast Iron

D - ]0 hp, E l e c t r i c

214-1105

3+3

Steam Condensate Pump

T - H o r i z o n t a l , Centrifugal

C - 330 SPH @ 20 psi ~P

M - Casing - Carbon Steel

I m p e l l e r - Cast Iron

D - 10 hp, E l e c t r i c

214-1106

3+3

Fusel 0 t l

T

C

M

D

-

214-1306

Pump

Reciprocating

3 GPM @ 60 psi ~P

S t a i n l e s s Steel

] hp, E l e c t r i c

L i g h t Ends Compressor

T 1 3 stage r e c i p r o c a t i n g compressor

C - ]29,277 SCFH

Des P/T - Suction - 1 psig/lOOl"F

Discharge - 370 psig/lOO°F

D . 1000 hp, E l e c t r i c Rotor

214-1619

3

Feed. Overheads Interchange.r

T

1

Shell and tube

S - 1945 sq f t

M - Shell/Tubes - Carbon Steel

Des P/T - Shell - 75 psig t o FV/3OO'F

Tubes - 150 pstg t o F~/3OO©F

0815R

6112

METHANOL DISTILLATION - AREA 214

EquIPMENT LIST

ITEM

,i= •

i

i

N,o. REQUIRED

DESCRIPTION

Overhead Condenser

214-1620

T

SMDes P/T -

m

D-

214-1621

3

Fin fan

30,500 sq f t bare area

Tubes - Carbon Steel

Tubes - 75 psig to FV/3OO'F

20-40 hp electric motors

Liqht Ends Cooler

T m

CSMDes P/T D214-1E22

Shell and Tube

15.39 MM Btulhr

1350 sq f t bare area

Tubes - Carbon Steel

Tubes - 75 psig to FV/3OO°F

2-15 hp e l e c t r i c mGtors

Methanol Cooler

T

CSMDes P/T D-

214-1623

Fin fan

8.79 1~

2200 sq

Tubes Tubes 2-30 hp

Btu/hr

f t bare area

Carbon Steel

75 psig to FV/300°F

e l e c t r i c motors

Fuse; Oil Cooler

Double Pipe

C - 0,13 NM Btu/hr

S - 25 sq f t

N - Carbon Steel

Des P / T - Outer pipe - 150 psig/3OO°F

Inner p t p e - 150 psig/170°F

T

214-1624

m

3

Bottoms Cooler

T

CSM-

m

Des

0815R

P/T

-

Shell and Tube

4.69 MM Btu/hr

390 sq f t

Shell/Tubes - Carbon Steel

Shell - 75 psig to FV/3OO°F

Tubes - 150 pstg/170°F

6/13

METHANOL DISTILLATION - AREA 214

(

EQUIPMENT LIST

ITEM

NO. REQUIRED

DESCRIPTION

214-1625

Distillation

No._.__~l

T 1

SMDes P/T 214-1626

Column Gas Reboiler

Shell and Tube

11,634 sq f t

Shell/'Tubes - Carbon Steel

Shell - 75 psig t o FV/3OO°F

Tubes

1663 psig/410°F

Distillation Column Gas Reboiler

NO,_____22

T

.

Shell and Tube

S - 17,145 sq f t

Shell/Tubes - Carbon SLeel/304 SS

Des/P/T - Shell - 75 psi9 t o FV/3OO°F

Tubes - 730 psig/520°F

214-1627

Distillation

Column

Rebotler

T m

CSMDes P/T 214-2210

3

Shell and Tube

125 MM B t u / h r

9470 sq f t

Shell/Tubes - Carbon Steel

Shell - 75 psi9 t o FV/3OO°F

Tubes - 75 psig/360°F

Distillation

Column

T

m

Valve Tray

M - Shell/Trays - Carbon Steel

Des P/T - 75 psi9 t o FV/3OO°F

21¢-2211

3

Reflux Drum

T

SMDes P/T -

Horizontal, Cylindrical

8'6" ID x 27' long T-T

Carbon Steel

75 psig to FV/3OO°F

C

0815R

0114

Steam

METHANOL DISTILLATION - AREA 214

EQUIPMENTLIST

x rEM

214-2212

,

NO......REQUIRED

DESCRIPTION

3

S_team Condensate Drum

T

SMDes P/T -

214-2213

Horizontal, Cylindrical

6 c ID x 13' long T-T

C~rbon Steel

75 psi9 to FV/3OO°F

Hydrolyzed Gas Separator

T

SMDes PIT -

214-2502

Vertical, Cylindrical

8' ID x 15' High

Carbon Steel w/304$S l i n i n g

775 pstg/320°F

Caust.tc. Oosing,S,et

T - Skid mounted

tank, pump

and

agitator for pH control {1% NaOH

solution)

C - lO0 GPH @ go psig discharge

Tank - lO00 gal

M - Carbon Steel, polypropylene lined

08]5R

8/]5

NQMI N¢LACUN

T " T Y P IE

•

• 85|il

- OP|IATINO

Pi|llUIz/

TICMPRNAT~IIR

M - MATERIA

L

¢1E- C:mlmmON IrrlEEL

II " ETAINLRII

IT[EL

¢| = CART INON

O * ONIVR

t~MEIOI4T

i C I~' " i I ~ ¢ E I C R I R I

PIT

REFORMING - AREA 219

C

EQUIPMENT LIST

ITEM

219-1101

NO. REQUIRED

DESCRIPTION

1+1

Fuel O i l Pump

T

C

H

D

219-1102

-

1+1

Reciprocating

4 GPM, ~P = 50 p s i

Cast I r o n

1 hp, E l e c t r i c

T.uP,bine Steam Condensate Pump

T

C

H

D

-

219-1301

Horizontal, Centrifugal

280 GPH @ 46 psi

Ap

Cast I r o n

10 hp, E l e c t r i c

Reformed Gas Compressor

T

S

C

Pt/Tt

-

3 Stage C e n t r i f u g a ]

19,100 hp

6.85 HM SCFH

240 psig/lOOOF

Po/To - 1394 psig/lOO°F

D - Steam Turbine

219-1301-1

Refm~ed Gas ComPressor Turbine '

T - Extraction

C - 228,113 l b / h r Steam

P i / T i / P o - Steam Turbine, 1500 psJg,

350 p s i g / 4 " H9 Abs

219-]302

219-1302-1

-

Centrifugal

120,954 ACFM @ 14.5" w . c . &P

H o u s i n g / I m p e l l e r - Carbon Steel

Steam Turbine

F_~.D.. Fan Turbine

T - Condensing

C - 2600 l b / h r Steam

P i / T i / P o - 350 psig/590OF/4" Hg Abs

0815R

900=F,

Forced D r a f t Fan

T

C

H

D

6/16

|:

REFORMING -

AREA 219

.EQUIPMENT LIST,

ITEM

NO. REQUIRED

DESCRIPTION

219-1303

Induced Draft Fan

T C MD-

219-1303-1

Centrifugal

233,562 ACFM @ 23" w.c. AP

Housing/Impeller - Carbon Steel

Steam Turbine

I.D. Fan Turbine

T Q Condensing

C - 7630 Ib/hr Steam

PIITi/Po - 350 psig/590°F/4 " HgAbs

219-1501

Reforming Furnace

T - Down f i r e d co-current

C - 293.88 MM Btu/hr

S - 58'6 = long x 47' wide X 35' high

Tubes - 312 t o t a l required, 13

tubes/bank, 4 banks/ro~, 6 rows

t o t a l 4.3" ID x 0.375 thick x

35' long ( p u l l bored)

M - Tubes - Manau~ite 36-X

C~talyst - I137 f t

on natural gas

reforming c atal 3st:

57-3 long

rings or equal

219-1601

Radiant Shield Boiler

T

m

CSMDes PIT -

219-1602

Vertical tubes in duct

20.88 MM Btu/hr

900 sq f t

Carbon Steel

1760 psig + s t a t i c h~ad/670°F

Steam Superheater

T

Horizontal coil in duct

C - 66.68 MR 8tu/hr

S - 6250 sq f t

M - 2-114 Cr 1Mo

Des PIT - 1760 pslg/llOO°F

0815R

6/17

REFORMING - AREA 219

(

EQU,I,PMENT L,IST

ITEM

N0. REq.UZRED

DESCRIPTION

219-1603

Reformer Steam Attemporator

C . 272,200 l b / h r , 1550 psig

Steam to 920°F by injection of

BFW

219-1604

Mixed Feed Preheater

Shell and Tube

C - 106.91MM Btu/hr

S - ]4,360 sq f t

M - Shell - 2-1/4 Cr 1 No

Tubes -310 SS

I n l e t channel refractory lined

"Des P/T - She]] - 310 psig/lO5OOF

Tubes -400 psig/950°F

T

219-1605

Combustion Air Preheater

Rotary

75.19 MR Btu/hr, 465,173 l b / h r

air

Des P/T - Air in @ 10" w.9./62 ° DB to 700°F

D - 20 hp e ] e c t r i c motor

T !

C-

219-1606

Flue Gas Boiler

T

CSMDes P/T -

Horizontal tubes in duct

71.13 MR Btu/hr

50,035 sq f t (finned)

Carbon Steel

1760 psig & s t a t i c head/670=F

(

0815R

6/18

REFORMING - AREA 219

E~UIPMENT LIST

ITeM

NO..REQUIRED

DESCRIPTION

219-1607

Reformed Gas B o i l e r

T CSM-

Firetube

]16.69 MM B t u / h r

2920 sq f t

Shell - Carbon Steel

Tubes - Carbon Steel

Inlet

channel

&

tubesheet

refractory lined i n t e r n a l l y

Des P/T - S h e l ]

1 7 6 0 psig + s t a t i c

head/660=F

Tubes - 300 psig/660°F

?19-1608

HP BFW Heater

T CS M-

Shell and Tube

28.23 MM Btu/hr

4310 sq f t

Shell - Carbon Steel, SS clad

Tubes -304 SS

Des P/T - Shell - 300 psig/470=F

Tubes - 1760 psig/4OOOF

219-1609

Reformed Gas Cooler

T CS P/TD-

219-1610

Fin fan

121.18 MM B t u / h r

11,200 sq f t bare area

Tubes - 300 psig/425°F

10 x 30 hp e l e c t r i c motors

Turbine Steam Condenser

T - S h e l l and Tube

C - 140 MR B t u / h r

S - 5200 sq f t

M - S h e l l - Carbon S t e e l

Inhibited

admiralty

bronze

Tubesheet - 90/I0 Cu/Ni clad

Carbon Steel

Des P/T - Shell - 75 psig + f u l l vac/350°F

Tubes 150 psig/IZO:F

0815R

6/19

REFORMING - AREA 219

<i

EQUIPMENT LIST

ITEM

N0. REQUIRED

DESCRIPTION

F i r s t Interstage Cooler

219-1611

T

C

S

M

-

Shell and Tube

15.53 MM B t u / h r

1830 sq f t

Shell - Carbon Steel

Tub~s - 304 SS

Des PiT - Tubes - 850 psig/3OO°F

Shell - 150 psig/170°F

219-1612

Second Interstage Cooler

T C S M-

Shell and lube

15.28 MM B t u / h r

1780 sq f t

Shell - Carbon Steel

Tubes - 304 SS

Des P I T - Tubes - 850 psig/3OO°F

Shell - 150 p s i g / 1 7 0 ° F

;=

219-1613

Reformed

6as

Compressor

L'.

T

C

S

M

Des P/T

-

Shell and Tube

16.44 MM Btu/hr

1850 sq f t

Shell - Carbon Steel

Tubes - 304 SS

1560 psig/3OO°F

Shell - 150 psig/17O°F

t

!

.i

!

219-2201

Steam Drum

T m

CSMDes P/T -

Horzontal, Cylindrical

Normal - 236,700 lb/hr steam

52'6" T-T x 6' ID

Carbon Steel

1720 psig/650°F

C

0815R

6/20

REFORMING - AREA 219

EQU,IPMENT LIST

ITEM

NO: REQUIRED

DESCRIPTION

219-2202

Reformed Gas.Separator

T _ Vertical,

Cylindrical

wlSS

demister

S

6'6" ID x 12' T-T

M - Carbon Steel W/304 SS lining

Des P/T - 300 psig/2OO°F

219-2203

Reformed Gas Compr@ssor Suction

.Separator

T

Vertical, Cylindrical w/demister

6'6" ID x 12' T-T

M - Carbon Steel w/304 SS lining

Des P/T - 300 psigi~OO°F

219-2204

First Inters.tage Separator

T . Vertical,

Cylindrical

w/SS

de~11sLer

S m 5'6" ID x I0' T-T

M - Carbon Steel w/304 SS lining

Des P/T - 850 psig/3OO°F

219-2205

Second Interstag e Separator

T m

SMDes P/T -

219-2206

Vertical, Cylindrical

5' ID x 8' T-T

Carbon Steel w/304 SS lining

850 psig/3OO°F

Reformed

Gas

Compressor

AftercoG1er Separator

T . Vertical,

Cylindrical

wIGS

demister

S

4'6" ID x 8' T-T

M - Carbon Steel w/304 SS lining

Des P/T - 1560 psig/3OO°F

0815R.

6/2i

m

REFORMING - AREA 219

.

EQUIPMENT LIST

ITEM

219-2207

NO. REQUIRED

DESCRIPTION

1

Fuel 0 i l

T S MDes P/T Acc -

219-2401

1

Day Tank

C y l i n d r i c a l , Vertical

20'ID x 18' T-T

Carbon Steel

Atm/Amb

I n t e r n a l Heating Coil

Flue Gas Stack

T - Self-supporting,

Vertical

Cylindrical

C - 11.02 MM ACFH f l u e gas w/mol wt

= 27.37

M - Carbon S t e e l , Gumite lined

S - 80' tall

x 10' ID

Des P / T - Abmient/335°F

\.

0815R

6/22

,~o'.c;'

:o

-'o

8d-d'

r

;

i

ii

7~-d'

so: o"

II

~o'-o"

i

~o'=f e,

t

ri"l I I1 ; ,,,]

]

,

so'.d'

t

If

I

i

I

!_

I

i

'i'I

~s:o"

_LI

I I,,I

r--

PIPE~

,

|

i

I

,.,F

I

i

I

!

[~0.

".evxszoq~

DESCRIPTION

'~ [~ I=letAt, UPO,itE

|l

BY

~H.J,S,!

~.W. i

....

CHK. DATE NO,

"Z,q,jrl

&.lmifl

REV[SXbNS

DESCRI[PTCON

BY " CHK. IDATE .fJH_e.ND.

REFERENCES

TITI-e~

,

I

.I

1

!

i

I

I

I,,

L II

!

t

t

I

i

,

PlPEWA.Y

, ,,

!

!

:

'

}

II

!

]

~,TE

r_.,,I~.EI~E,~I.,,15 ,S...'~_['. A,,~cE T,',~IU-..t.- F 0 2 E/,,,.Cr'i H~'~-,~JLE

LXE.NI' ~_C I ~'l i "~'';-~'~'E ~"

DavyMcKee

ENGINEERS

AND

CONSTRUCTORS

TITLe

IAI

Z,,~.EA,~..

5530-

'ZI3- P - 001

l/o\l

i. m,

G e,A"t'.~ ~

~-~

,"

~.5'=

I~O

I

~ ~

\

w

I

-"

._ S ~ v i s z o . s

l•I ANO. p R e ~ . RnESCRIPrION

~.vte~0

I

nEViSmKS

BY CHK. iP~TI~ NP.

,.pEg'CRIPT|OH

w,,l~

ll.$.~_! o ! S S U L " ~ I ' ~ . ' E e P o ~ T

....

BY

~

C~F. DATE'DNg.NO.

REFERENCES

TITLE

#/zolll ~

I

m m m

. lT>'p

L.

• ,

\

,.

::%

,

\

j

'

I>

'Z14- 2,S~Z

.

..

,, !,

]

%

//

\

r

\

Q

/

oJ

/

t

|l

'2.t~,

....

•

\

't

!

)

'1'"'

\\

_~

_...

"!

tn

' i

[

•

.~

•

l r ~ - Jr..is

->

21~-

.)-

:

L_

CI.IF.liT

G I~i/PLACP-~

'

DavyMcKee

. r'~

.......

,,r

i.

..

ENGINEERS A N D CONSTRUCTORS

BY

nit4=•

'

il:X,O

I , . i,~,',~.

BATE

s,,.E 1" :, ~'

!TITLE

MG.'I'HAi4OL, Ul,.i i T

' ~ | ~ T I L L A T I Q N ~, ,~'I"N'rHF..,~I~

.I

"

.~o-'LI3- P-oog

ii

i

I .,v-

DRAN|NG NO-

A

......

ii:! .~

,"IO

'Zi4.

b

~ 1 I..,.__

C)

!

/i...

<

!

i'

I

i

L

,.ol

r

I

_@

I

-I

--. 4...-,.-

RE¥1SZOkS I i v.... t~,~. [ , ^ ~ |n.o.I

REVIS~LONS I "V ;CHK- IBATE BaNG

.ESCRIrTIO.

I A I PR~L. R LvI~.W/

IW.J.~J

II.S.611 0 Ilss.E:oT~_~.*I.~,~:po~- I ~

~#.'11

l,o.I

nEScRZrTIO.

!c!,~....v,,s,:~

a

~

,I

I~<,,,,, I

I

,~.N-. t

~

!

.....

/i

D

J

~-(~

~ • IC=15

•'l°

o

..

"

I

"l

t

;)

".~~ .... ..

•7 . r ~ -

ic.,iI~

@.-

/

'2,13. I~=L~

~ ' ". . *. . . . . .

:

Imm,

!

•.

Ic~'P I

I

.:

I.^ee. I "~.

17tzo/et

-

:-

CIRI/PLACEP--

~ETI-~ANoL UNIT

OISTII..LATIQH ~ ~YIwI'I'i,4f,,

-~IS

Pu,~N

,',.~;,o,,,e

9,2'..o"

~

~

a y McKee

ID

I .NO,.--~~N, COHSTRUCTORS

V

IscA-e t" : I ~'

IIRAIIXWSWO.

l

55~o-"L~-P-oo3

m

r

i

\,

/

/

.I

f,'

/;"

.

.

.

.

.

.

.

.

.

.

.

~

. . . . . . . . . . . . . . . .

°

. . . . . . . . . . . . .

.

. . . . . . . . . . .

~

:

0"1 !,

i

I

.

I

!

i

i ,

i

'

1

REV][S|OH$

"'

REV lS|DHS

~'il~-I

DESCRTPT[ON

B Y . CHK. DATE NO,

DF_-q__r'R|PTI[OH

A IPREL.R[VteW

d.J.$.

11,5-81 0 Is,~E~T-c~"~t,~.~,,.'ll~r.lp~.'I"

"

1311~'iI"t~'L- UPDA,'i'~

C

i

|

~W

~-~,~1

I lt(vlse~>

"

,,

~

,

IrN~'

BY

~

CHIC.' DATE! I)Nl;~.N0..

PI~'I

REI:EREHCE5" '

TITL'E

nJ

;~

~I

l_

,,

il

~i,i.~ •

i~i ~, ~

i~ ~ ~

....-"

.. ",

"%

t

. . . .

o-/

. . . . . . . . .

t

,

/

/

~°

- ( )-I

~I.IENT

i

DavyMcKee

Ct&I/PLACER.

ENGINEERS A N D C O N S T R U C T O R S

ill

[

--+

__

.lls-+, ;:

i

tOES

|Y

iORMN

~rr '~/.~ •

/,rr'

DATE

tm.++

'

"CAL.+ L" = tO'

'

tvt~.T~iAI~ o L U N I T

I

I mev,

]RAHING NO.

OISTILL.A~TIQN ~r ,~YNTHF.~|~

PLAt4 ABov~ ~8'- o"

i

a

.

i

" 4 , . . , ~ "at

I

I

,,#]•

q.tZ

I

.q

I ~'?..i,

t.:

i 5,:

i

,

e

.

;:

(

o

i?

..:."

i

"?.t4.- IG?.O i

1~,9.2.

it.:blENT

CIRI/PLACEP,.

i

--.;-,_

,

pEs

DUN

CK.IB

APP

APP

~ATE

ll~olar l

TITLE

METRANOL UNfT

OiT~'rlLLATI ON ~ ~'¢14"rH~.~lS

PLAN A~oV~. 5 4 ! 0 ~

i

i

i

Ill

DavyMcKee

ENGINEERS AND CONSTRUCTORS

SCALE i n= IO t

. . . . .

REV.

DR.~HIN6tO.

5S~o-9.1~-P-oo5

..u

S

t

I q %'- 0"

~ 14-t~'z'E

'ZI ~.-I~,'?.. I

LI

54.;o"

mS

I lye,

- - , o , . _ .

?..14,,, IG?.,~

?.14- I G'LC..,

_o

?-14-IG'~.7

0¢

2 I~j~e'Z'~

,,dr

'T.L.

-

o o

%i4 - %"¢i'?-

II

i

__

u - , , , I m ~ . ~ *1~111

;.... -L-L_

........

1

L_

.. L J_

I

o.

; 'Pl

r

- - I'114.. I~2.0

9.15.1d, I ~

'

"i

.?

_

"'1

~

W

i

*

I~-~ro15

~.~ ~i

I

/

...

m

,~.

,. ,~,~.:

m

i

|

I

/

/

\

/

'i

J

J

.-~.,

-.~

,

J

i

,!

I

LL

¸

L

I

I

r.

m

C I RI/o LAC,~.l~

¥

rE

;TLE

~'T~A~o L. U~'~

OI ,STILI.A'I"IGH Pi-,5,.,'tlTHE£~I.5.

El. EVATIOI'4

DavyMcKee

ENGINEERS AND CONSTRUCTORS

MNKi4G NO.

55~o-~1~- p.oo~

i

SECTION 7.0

,OXYGENt NITROGENAND COMPRESSEDAIR

(Areas 101, 102)

7.1

DESIGN BASIS

7.1.1

Three air separation plants w i l l be provided. The capacity

of each plant shall be 2500 STPO of 99.5% purity oxygen by

volume.

7.1,Z

Oxygen required for reaction with steam and coal w i l l be supplied by the three air separation plants at 75 psig and 257°F.

7.2

PROCESS DESCRIPTION

7.2.1

Air_Separation Plants .(Area I01~ Dw9. 5530-I01-Y-001)

Oxygen w i l l be supplied by three air separation plants. Nitrogen from the air separation plants will be used for blan-keting, pressuring lock hoppers, pneumatic conveying and

backup for instrument air.

Liquid oxygen and nitrogen storage tanks plus vaporizers are

also provided in the air separation area. These are provided

f o r emergency use during unscheduled shutdown of one or more

of the three air separation plants.

7.2.2

Nitrogen and Plant Air S~stem (Area 102, Dwg. 5530-I02-Y-001)

Nitrogen from the air separation plants is compressed and

cooled to 105 psia and lO0°F in a two-stage compressor, and

is then distributed for use in pressurizing coal feed and ash

lockhoppers, conveying char and ash, and purging s i l o s .

0816R

7/1

Instrument and u t i l i t y a i r is supplied from a u t i l i t y air

package which compresses 180,000 scfh of air from atmospheric

conditions to 105 psta. The compressed air is dried in a

desstcant type drier to a -40°F dew point. The drier is a

dual unit, one section of which can be regenerated while the

other sectton is dwi~lg. Operation is completely automatic.

A ] t n e from the co~,qpressed nitrogen system provides emergency

backup f o r the instr, m ~ t a i r system.

4i

7.3

t

ENGINEERING DESIGN DATA

:!

Design data pertinent to the air separation plants and n i t r o gen/plant a i r systems is detailed in the Process Flow Diagrams immediately following this page, in the Equipment List

beginning on Page 7/4, and in the Drawings following Page 7/6,

':i

3

#,.

L

0816R

712

,DRAW,INGSRELATING TO OXYGEN~NITROGEN~COMPRESSEDAIR

_ Drawin~ No.

5530-101-Y-001

5530-102-Y-001

TITLE

Air Separation Plant

Nitrogen/Plant Air System

EQUIPMENT LIST

5530-]02-P-001

Air Separation, Plant

- General Arrangement

5530-102-P-002

Air and Separation, Plant Air and Nitrogen Systems Plan

5530-102-P-003

Air and Separation, P:ant Air and Nitrogen Systems Plan

0816R

7/3

Air

and

Nitrogen

Systems

. , , . _

i

"*'

,,.-i,!ii!i lilll~Ll,1~l,!,q,1~q,l~t1.1~I~I~I~I1.t_~I.~1.11~I~I

l

i

I..

l

.*

,

II

.

I '

• Jl

I

_

I

_

~-!i"!j !,.! !! l ! ! !!~!!LL~!~

RIR SEPRR~ ~IOll

PRCI<Agl '

REVERSINO EXCHRNgERS

I

[ IO2-Y-O0! J'CO'PRESSOR

I

I

. ~ r ~ K - v ' i n A T i ~ l . TO |OAIN GAS|F |~,I

"

3-"

t 2os-Y-OOl ~ T " ~ ' ~ ~nst~,s,'R

L,

GR$rouI

I~SrE

~t vl~r NITROGEN

$ I L~NCER

!

E

L'j~

d

m

,

m

R£VERS ! t

VRLVE5

EXPANSION TURB]

/

I

,+,-l"m"l,I

+-£_,..,

llllll

+

II

I I II

I I I

.

Ot-250!

to+

m

I-- I

,~"

)I

"~

,,

i

(

1

I

HRIN

VRPORIZER|

I

--'--

We--"-.---.--- ,q

e--i

++'-~'

I

L IQUil

.r'--I

P,ux IL ! ~RY

VRPgR ! Z£R

I

-t4

--~ -t---~+4

i

d

I

LIGUlO

OXYGEN

FILTERS

i

.,.,~ lLmutr

m

/t

~,~.

I I

-ioomw,.rmo=:,,

IPROClUCTI ('l't¢'~e-, I

L.jSLLIBCOOLL~X ~

,I

C

HIGH

PRESSURE

;f

COLUHH

TURBINES

1!

!

!

I

I

!

BOIE= lll~l'dMIIhpmOt~Mn~WltmKItE

I

~i~ii¢~iilotl. it tl+,mtnot bl tnRq~I~ r ~mlx.o.

¢1===In lett earmm ~

~.~

=

~

~tlon

It b,J -,t,.mitt=lto

~ = d t oar ~

I t M b l l a = d o a l l t l e l l l ' ~ l m d l M l t , lml

I

CIRI/PLI~CER

BELUP.FI METH/tNOL PROJECT

C00£ INLET,, RLRSKR

DavyMcKee

ENGINEERS AND CONSmUCTIDRS

lt=4-1MI I1~I'/111

AIR ,~pI~RRTION PLRNT

•

.

,

s

,

,

I

.

"

'

I

..,,,9

I

'

I

IO

.

~..

~..

• I.! I I;,,l~,l!,,I,,,,

...,..

~

.

.

.

'~'111 J J 1111

.

.

.

. . . .

1 Lt l LLL[

.

.-

,I

t

,

I

-i ...... i-i

(H[Ti I

IO0 O013]Io.trc tlo oo i1,8o.3o

E11~2*"~'*°'~_~"i,-~,-i------i

~'~nrt~L

~l~O""n"

.....i

E

! !.. I..,'!

| .,ot~ a o l~,o'f~ I I I a o o oo ? l i..~ I s~o o o I ~ ?,I 3 ~ 1

i

N|TROaENCOHPRESSOR

ZNTERCOOI.ER

C

Y 00~ ]

v~nEo.1~n~

F

.

Q[

/~T| OOLER

N[TROOF.NCOHPRE[~;0R

~

i'iol

-

I

1

~mm"

i~

il

m

~

m

m

N

m

. . . .

W

.

.

.

.

.

.

N

I%

/

~

\

y

--

m

~

m

~

m

m

. . . . . . . . .

--4

/

--

wmmm

-,~

j

l

!

--~mJ

f-

,~

..,,

~ i

/~.,~i

~

ii~:iii:~"'~il¸ i

•

•

~

/;~

1

~H.~/:

~ i:,~. ~~

m

~ E

IGOOL.ER

U ~ R

PRCKRgE

N~ T o

co,q/, r ~ o

LOCKHO#P~R

.'~ 205-Y-OOt }

,

,.

.

*

• ,r-

~L~

Nd? TO CO,qLD#Y~rR

.

".:

.

:

I)~-204-Y-OOJ.'~

:

a

m

I

II

I~T~4EflT AIH II,

T

I

I

I

I

I!

UrILIYY

!

i~lra: T,k I~r~t~,~,~epmpmyd DAVY i~X r.r

¢OF.FORAi"IOLIt r ~ t mt I~ h ~ l mr mx~.

• =~ b mlf mm~ r ~ ~ ! h be wbmltml ~

I~nk,.Cm. ,m,ml,',W~ wl~c,h , ~ ~

cIR I/PLACER

BELUGA ,~EItlENOL PROJECT

NITROGEN/PLANT AI R

• SYSTEM

A I R ~

r

DawMcKee

ENGINEERS AND CONSTRUCU'3R "cz

": -,.

m

NQMKNCI.ATURF.

T

-

C "

g -

:

TYPE

I=&PAClTY

BsIiR

PIT

AIR SEPARATION PLANT - AREA 101

• oprlIATING

PRlilIURarl

•

T E M P I E N A * l ; a N ar

M - M/ILTIKRI/%~

GIICANIIION

IEYECL.

18 - IIITAINLIINII

IIb'll'llL

Cl - CAIn"

INON

D

-

OnIVl

W - WRImHT

ic~q~ - A(:CIEIIONIKI

,EQUIPMENTLIST

ITEM

DESCRIPTION

NO...,,RERUIRED

Air Separation and Oxygen

Compress,!.on Package

101-2501

This system ts to produce 2500

STPD of oxygen with a purity of

99.5% by volume. The oxygen is

to be de]ivered at 75 psig.

£

0816R

7/4

NOM Ii NCt, ATIJR It:

T - TYPE

C -

CAPACtTY

S • ll~K

P/T - OPI~RAI'ING

PR;iIURE/

Tit MPI~II ATUII[

NITROGEN/PLANT AIR SYSTEM, - AREA 102

EQUIPMENT LIST

ITEM

IOZ-1301

N0 .

M CS"

lib "

¢:1 13 W AC(: -

MATER|AI.

G&NBON

liTIKIt L

IT/tINS*KEg

BTI¢KI.

OAIT

ImON

DMtVlC

WEi6HT

ACeI[IIIOII|

a*&

DESCRIPTION

REQUIRED

First-Stage Nltrogen Compressor

3

Centrifugal

1025 hp

8,820 ICFM

0.5 psig/60°F

30 pslg/315°F

0--- E l e c t r i c

T

SCPi/Ti Po/To

102-1302

Second-Stage Nitrogen CompressRr

3

T ~e Centrifugal

S - 1030 hp

C - 3,560 ICFM

Pi/Ti

25 psig/1OO°F

Po/To - 90 psig/355°F

D - Electric

102-1601

-

F i r s t - S t a g e InterF. o o l e r

3

T C S M-

Shell and Tuke

6.52 MM Btulhr

Z,800 sq f t

Shell - Carbon Steel

Tubes - Carbon Steel

Des P/T - Shell - 50 psig/350°F

Tubes - 75 psig/150°F

102-1602

Second-StageAftercooler

3

T - Shell and Tube

C - 7.60 MR B t u / h r

S - 3,000 sq. f t .

M - Shell - Carbon Steel

Tubes - Carbon Steel

Des PIT - Shell - 75 psigll50°F

Tubes - 200 psigl3OO°F

0816R

7/5

NITROGEN/PLANT AIR SYSTEM - AREA 107

EQUIPMENT I.,IST

ITEM

DESCRIPTION

NO. REQUIRED

Utilit~ Air Pac,kage

102-2501

This system is to produce

180,000 SCFH of dry air (-40°F

dew p t . ) at 90 psig.

~:.

0816R

716

i1| ii

,

,

m

•

4.~'~,°-O"

r

~TS:o"

I

---- IOI-D

tOl-~

i

;

....... i

I--,I.--I

i ..... i

i ..........!

i..i

0

!.,,1

in

3

?

for-e,

111

_

~.L.,..

REV|S|ONS

I~EVlS|OHg

~

~i" NO.

DESCRIPTION_.

BY CHK. DATE KD.

~I~BCR|PTIrOH

| In" CHK. DATE DNG.NQ.

j IA P.~e..,/M. R~'vtew

.=o.K

~/~18/ o Is_~_,_='~'~eIR~,,~,~R=~Ti,~,.J

"p,~.~-_:

I

i

l

I I

i

I

d

.....

lClEFFU~;S~

~

..,..+p.~.

......

I

~

~

Yr'!

="

'

. . . .

I

.

I

I

HI

rS~.O"

- ----..-4m

_

~.L--

IoZ.A

~

~. . . .

,5,

_

"'%,

I0'~. ;~( ,IC,

IO?.iSOIA

,"

•

~

!-1-

I02.1GOI

~-h. ,~~

i I'

i' i

_.

_L-~i ,o~-~ _c

JOZ-IGO~A

"

/~, /.,@.

"

I

I

I

I

,3

rJ

o

I"

4.

0

1.

F

I

CLIENT

• CIr.

PLA~'~

"-

DavyMcKee

ENGINEERS A N D C O N S T R U C T O R S

T

nl Y

A I P--

.~"PA,e,~ r / O A / ,

PLAN'I" AIR A N D

AI/7".eOG~'/V SY~T&M~

,:

!. "2- -

T| TLE

IAz, P I

s(c*,, = I ' , 4o'. o"L

~.N|HG HO-

55.~0- I O E - P - O 0 /

/

loi

I

E I

1502

ii,

.Li , , / ~ , ~ ¢ ,

. I~-1~oe..'I[-

+.,.~,.,...

,++,

I~

I

I

[

i,'

l',

'2 .,,x

I

:'"'4

,,,IOl.

:

1:301

• .'!

"'. i

+,

4

i

TYPICAL

- MODUt.,&'S

I01D

¢,

DavyMcKee

I~.ZEHT

CIRI "/PLACE,e

g~LUGAMt~THAMQLPBOJ~CT E N G I N E E R S A N D

--UOOE 1WLET,-ALASKA

tr~l • 1% I0"0"1

,,

':' •

' .~' ~ ' - - ~

'"'-~

oEs

TITLE

BY

A I ~ S6PA~ATIOI~,

PLAMT" A I ~ AMD

Cl('n

APp

.

PLAId"

CONSTRUCTORS

,,

i

,

REV.

5550-t02-P-002

DR~HIHg

HO-

i

t

I

--#-..

I.-.-

w

I01-

,

.

~0'2C

tot-

:30tC

J_J_

I

:1

PIP~

RRC,~-..----..~

-I

I

J

I

"1

'.'~ .'. ',

.

.'

.

W --

"

V

-I

I

....

Io~.-15olA

!o~.

_t~i~ ~._:-I_~_~i_~

I 5 o~.A

-LI-io~. T6,o~c,

"1 I_

t i

t¢

Xoq.. 1~o2¢.

to'l.l:lotC

I~9.. I~o2A-1.J

i

I

I

loq..t5 o15__ .to2, 1302~

I

I

I

I

Io2.25o1

I

I

%0 "L.IG=o I 5--1-~.

II

•

t|

~IEXT

•

C~m+/PLAC+~

"

BF:EUGA /46TI~AIVOLP£oJ~cT

• CO0~ llVL~T, ,ALASZA

I

i"IILE

CK'DI

A I F~ 5£-'PA,~A TIO/J,

P L A I t T A/~P. AtL/D

MITaO~M

~Y'3T£M5

PLAM

DavyMcKee

ENG~IEERS AND CONSTRUCTORS

SCALE t aw | O I T

ORAN|KS MO-

'

5 5BO-IO2-P-005

i

REY.

SECTION 8.0

UTILITIES

(Areas 103, 300, 30l, 30Z, 305, 309)

8,1

PLANT STEAMSYSTEM(Dwq 5530-305-Y-00]

Steam for the entire plant is supplied from three different

plant areas, and at several different pressure levels, as described below.

8.1.1

power Plant (Area 300~ Dw9 5530-300-Y-00)~

o

DesignBasis:

The primary power production f a c i l i t y for the process

plant will be a conventional pulverized coal fired and

steam turbine generator system with three boilers and

three steam turbine generators. Its maximum design capacity w i l l "be 2,700,000 pounds per hour of htgh pres-

sure steam at 1255 pstg and 165 Mw of e l e c t r i c a l power.

o

ProcessDescription - Steam Generation:

A fuel supply consisting of a mixture of coal and char

ts received from the process plant, and is transferred

by conveyor belt to the coal bunker. The coal bunker,

is a silo type storage device which supplies fuel to the

pulverizer f o r reduction of the parttcle size of the

fuel mix to a fine powder. The powder is mixed with

preheated combustion a i r and injected into the boiler

where i t is ignited. Boiler exhaust gases are circulated through heat recovery devices which preheat air f o r

combustion and preheat boiler feedwater,

f

1058R

8/1

Part of the steam produced by the boilers is utilized by

the steam turbines for production of electric power, and

the remainder is sent to the process plant as high pressure steam.

The steam turbines selected for this operation are extraction type units which allow removal of part of the

steam from the turbine after some energy has been utilized. The extraction steam is

plant as low pressure steam.

sent to

the process

Ash from the combustion process is removed from the bottoms of the boilers, and from the baghouse exhaust gas

cleaning unit, then pneumatically conveyed to a r a i l car

loading station,

8.1,2

Reforming (Area 219)

o

Design Basis=

The reformer is designed to recover heat from reformed

gas to produce 236,700 pounds per hour of high pressure

steam at 1500 psig and 900=F. In addition to the process requirements of the reforming reactor this steam is

used for turbine drives in the methanol synthesis area.

A common steam drum is utilized for the steam generation

boiler and superheaters using natural boiler feedwater

circulation.

o

ProcessDescription:

Steam is generated by recovering heat from the reformer

flue gas using a radiant shield boiler.

This unit forms

a vertical waterwa11 screen across the entrance to the

C

1058R

8/2

main convection duct, and performs an important function

in protecting the steam superheater from the cavity radiation of the reforming furnace rear wall. The radiant

shield boiler comprises a vertical natural circulation

system connected to lower and upper horizontal

headers.

The steam generated in

the boiler

is

water

then

superheated in two sections~ a high temperature section

and a low temperature section.

The superheater tube

bundles are arranged horizontally to permit drainage of

the coils.

Most of the exit steam at 1500 psig and 900°F goes to

the

steam turbine

pressor.

uses.

dr ,er

on the

reformed gas com-

A smaller portic~ is exported for other plant

Some steam is extract~ ~ from the compressor tur-

bine at 350 psig for use on other drives in the methanol

synthesis area and the remainder is condensed.

8.1.3

Gasifier Waste Heat Boilers (Area 206)

o

DesignBasis:

Each gasification train includes a waste heat recovery

section capable of producing 152,814 pounds per hour of

high pressure steam at 855 psig and 840°F for use in

steam turbines.

Steam drum internals are designed to

minimize entrainment losses. The output from each waste

heat recovery unit is manifolded into a common steam

header with suitable valves and controls.

o

ProcessDescription:

Steam is generated by recovering heat from gasifier raw

gas.

1058R

The raw gas leaves the gasifier and enters the

8/3

I'

waste heat recovery unit. This unit contains additional

steam boiler tubes, hlgh and low superheater sections,

and a boiler feed water heater section.

(~,..

The waste heat recovery unit on each gasifier acts as an

individual

steam generator, and is tied into a common

855 psig header. The steam is used for the steam turbine drivers on the process gas compressors.

8.1.4

Condensate

All condensate is returned for reuse.

Three deaeratinglheaters

are provided for the process area

steam generators, and three are provided with the off-site

boilers.

Demineralized water makeup is supplied from the raw water

treatment area as shown on Drawing No. 5530-301-Y-002.

8.2

ELECTRICAL POWERSYSTEM (Area 309)

8.2.1

Desisn Basis

Electrica] power for the plant and associated f a c i l i t i e s is

supp]ied by an in-plant

generation station

consisting

of

three equally rated steam turbine generators. The generator

outputs are transformed from ]3.8 KV to 69 KV. A single c i r cuit, 161 KV, transmission line to the Beluga Power Company

is provided for startup and standby purposes. The generators

and u t i l i t y power are paralle]ed in an outdoor 69 KV switchyard,

C

1058R

8/4

Power for the mines is transformed to 161 KV and transmitted

on a single c i r c u i t overhead transmission llne. One single

tap type substation is supplied at each mine. The generation

station load is normally fed from auxiliary transformers connected to the generators,

Power for

the remaining plant

loads is distributed at 13.8 KV from double-winding secondary

• ,,,

,

transformers.

The total power requirement for the proposed f a c i l i t y is estimated to be 165 megawatts, detailed as follows=

1.

Coal Area

2.

Gasification & Gas Prep.

16 MW

49 MW

3.

Water

15 MW

4.

Lights

5 MN

5.

Mine

50 MN

6.

7.

PowerHouse

Miscellaneous

15 MW

15 MW

'i

'i

"£

:

8.2.2

Electrical System Description

The electrical system consists of three major load centers:

I.

Power Plant

2.

Capps and Chuitna Mines

3.

Process Plant

The total power requirements for these loads have been estimated to be 165 megawatts.

1058R

8/5

t

L.,

Power Plant:

Three steam turbine generators supply prime power for

the f a c i l i t y .

A single circuit, 161 KV transmission

line to the Beluga Power Company and 69KV to 161KV

transformer is provided for start-up and standby power,

The 13.8 KV output of the three generators is transformed to 69 KV and paralleled with the Beluga Power

Company in an outdoor 69 KV switchyard.

Power for the power plant operating is normally provided

from three 7500 KVA auxiliary transformers. A source of

standby power is provided by one ID,OOO KVA transformer.

0

Transmission Line to Mines

The power to the Capps and Chuitna mines is trensformed

from 69 KV to 161KV and transmitted by a single circuit

transmission line. There is a tap type substation located at each mine. The step-up transformer feeding the

transmission line is rated 70 MVA and is equipped with

automatic load tap changing equipment to provide acceptable voltage regulation at the mines. The 161KV transmission line runs alongside the railroad corridor.

o

Process Plant:

The power requirements for the process plant are estimated to be IO0 megawatts. Power for use within the

process plant is transformed from 69 KV to 13.8 KV by

three transformers rated 50 MVA each. In the event of a

sing]e transformer failure, the two remaining transformers have sufficient capacity for the entire plant

load, when auxiliary transformer coo]ing is utilized.

(i

1058R

8/6

The main 13.8 KV distribution substation for the methanol plant consists of three secot,dary selective switchgear lineups equipped with automatic transfer systems.

Each switchgear lineup operates with the t i e breakers

normally open.

Substations

The majority of the 480 volt and 4160 volt substations

u t i l i z e a secondary selective distribution system with

automatic transfer. Where reduced levels of r e l i a b i l i t y

and longer outage times are permissible, a radial distribution system may be used. The present design includes twelve 480 volt radial

substations, t h i r t y - f i v e

480 volt secondary se]ective substations, two 416D volt

radial substations and five 4160 volt secondary selective substations.

~

Transformers for the 480 volt sub-

stations are rated 1000 KVA and transformers for the

4160 volt substations are rated 7500 KVA. Both are

equipped with auxiliary fan cooling.

I D

P

Equipment f o r the 480 v o l t and 4160 volt substations is

installed in prefabricated bu;ldings.

The substation

vendor supplies and i n s t a l l s

including v e n t i l a t i n g

all

equipment,

necessary accessories

lighting,

annunciators

and a DC contro] power system as required to operate the

substation.

The 480 v o l t

prefabricated

substation

bui]din9s are installed on modules at the point of

module fabrication.

Where an entire 480 vo]t substation

is not required on a module, individual motor control

centers are installed on the module. The 480 volt substatiUn wirtng is completed to the extent possible before the modules are shipped to Alaska.

substations will

4160 v o l t

be shipped directly to Alaska where

they will be mounted apd wired.

1058R

All

8/7

L.

All motors larger than 3500 hp are rated 13,200 volts, 3

phase. A l l motors in the size range of 200 hp to 3500

hp are 4000 volts, 3 phase. Motors smaller than 200 hp

are 460 v o l t s , 3 phase except f o r f r a c t i o n a l horsepower

motors which are rated 230/115 volts, single phase.

8.3

RAWWATERTREATMENT(Area 301)

All water used in the plant is drawn from wells.

requirements f a l l into three categories of usage:

2.

General Plant and Potable Use

Boiler Feed Water

3.

Cooling Tower Water

I.

The water

A different type of treatment is required in each case to

supply water of suitable quality for each use. The several

requirements and treatme~ts are described below.

8.3,1

General Plant and Potable Use

Raw water will be softened by the "Cold-Lime" process, neutralized, and chlorinated before distribution.

),

J

Estimated requirements for this use category are:

GPM

C

1058R

Plant Processing Uses

Pump Seal gater

Make Up to Coal Dryer Scrubber

L,co Shop

real Handling & Storage Area

Drinking and Sanitary

5OO

175

255

5O

40

Miscellaneous Uses

TOTAL

140

15

1175 GPM

8/8

,!

%.!

•

P

Lr

Water treatment f a c i l i t i e s using the "Cold-Lime" process w i l l

be designed to produce up to 1400 GPM of softened water to

account for peak demands and to provide a nominal excess capacity.

i

8.3.2

Boiler Feed Water, (Owg 5530-302-Y-001)

'4

Water of boiler feed quality is required for producing high

pressure steam, and for use in the gasifiers and reformer

waste heat recovery boilers.

Due to the presence of high concentrations of silica in the

wel] water, make-up water for boiler use is f i r s t softened

using the "Warm-Lime" process for partial removal of silica,

and then is demineralized using a combination of cation and

anion exchange beds.

Water treatment f a c i l i t i e s w i l l be designed to supply up to

2600 GPM of make up water to the high pressure and process

area boilers. This includes an a11owance for nominal excess

capacity.

8.3.3

Coolinq Tower Make-Up Water

Cooling tower make-up water w i l l require alkalinity control

and chemical additions to prevent scaling and bio]ogical

growth within the recirculating cooling system. These requirements are accomplished by adding appropriate chemicals

directly to the cooling tower basins. Sulfuric acid is added

for alkalinity control.

Inhibitor and dispersant chemicals

are added for scale control. Chlorine is added for control

of biological growth.

]058R

8/g

The cooltng tower blowdown w i l l be discharged d i r e c t l y to the

e f f l u e n t storige pond f o r blendtng with the treated process

wastewaters f o r f t n a l discharge to Cook I n l e t .

8.4

COOLINGWATERSYSTE.M(Area I03~

Cooling water is supplied through a forced draft, open recirculation coollng tower system. There are flve cooling

towers. Each has Its own set of recirculating cooling water

pumps, and each represents 20~ of the t o t a l plant cooling

water capaCity.

Each tower has two speed reversible motor

fan drives and adjustable louvres - a combination which provide~ maximum f l e x i b i l i t y

in adjusting to changing climatic

conditions.

Each tower Is designed to cool 66,000 gallons of water per

minute from 95°F to 65°F with a 7° approach to the wet bulb

temperature. Design summer time wet bulb ten~eraure is based

on 69°F which w i l l not be exceeded more than 5~ of the time.

(Date Source: The Fluor Co.).

CoDlin9 tower water is distributed throughout the plant by

means of distribution headers. To prevent fouling on heat

exchanger surfaces, reduce scale formation and prevent the

growth of algae, provision Is made for the addition of certain chemicals such as chlorine, s u l f u r i c acid, dispersant,

etc.

Makeup water is supplied from wells, and controlled blow down

will be sent to the wastewater treatment area prior to discharge from the plant.

1058R

8/10