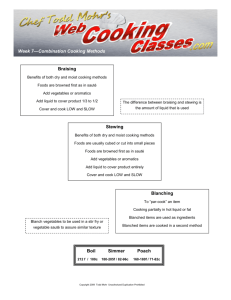

Cooking and Cooling of Meat and Poultry Products

advertisement