Single Point Sprinkler Design Criteria vs Traditional Density

advertisement

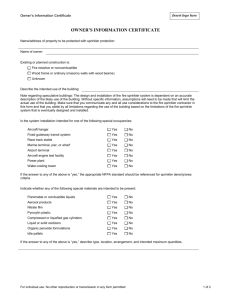

Supporting Data Needs for NFPA Automatic Sprinkler Committees Research Project Single Point Sprinkler Design Criteria vs. Traditional Density-Area Curves THE FIRE PROTECTION RESEARCH FOUNDATION CI .. "" - "".. r--- .."' -............"". --. .. -- . - . -- - . .. .. .. . - - . A. - . . . -- . . -- - AI -- ..... ... THE FIRE PROTECTION RESEARCH FOUNDATION ONE BATTERYMARCH PARK QUINCY, MASSACHUSETTS, U.S.A 02169 E-MAIL: Foundation (g NFPA.org WEB: www.nfpa.org/Foundation Supporting Data Needs for NFPA Automatic Sprinkler Committees Research Project Single Point Sprinkler Design Criteria vs. Traditional Density-Area Curves Prepared by: Garner Ä. Palenske, P.E. Daniel J. O'Connor, P.E. Schirmer Engineering Corp. (g Copyright The Fire Protection Research Foundation January 2007 FOREWORD The 2006 edition of NFPA 13 provides designers with a range of sprinkler densities and application areas. This report reviews the background and basis underlying the occupancy density-area curves of NFPA 13 and the storage protection curves. Observation from the review and gaps in the technical background of these curves are discussed and recommendations for further study and testing are presented. The Research Foundation expresses gratitude to the report authors Garner Palenske and Daniel O'Connor of Schirmer Engineering Corporation; Project Technical Panelists Kerry Bell, Edward Budnick, Christian Dubay, Morgan Hurley, Kenneth Linder, Joe Noble, John O'Neill and Rich Pehrson; and to the National Fire Protection Association for sponsoring the project. The content, opinions and conclusions contained in this report are solely those of the authors. Supporting Data Needs for NFPA Automatic Sprinkler Committees Research Project Technical Panel Kerry Bell, Underwriters Laboratories Inc. Edward Budnick, Hughes Associates, Inc. Christian Dubay, NFPA Morgan Hurley, Society of Fire Protection Engineers Kenneth Linder, GE Insurance Solutions Joe Noble, Clark County Fire Department John O'Neill, The Protection Engineering Group, PC Rich Pehrson, Futrell Fire Consult & Design, Inc. Sponsor National Fire Protection Association SCHIRMER 11770 Bernardo Plaza Court, Ste. 116 ~jrlYl ..lY~~~.j ~ Phone 673-5845 Fax (858) 673-5849 ~_.G'._.~~"'.N~ San(858) Diego, CA92128 Fire Protection. Code Consulting. Risk Control. Security Consulting SINGLE POINT SPRINKLER DESIGN CRITERIA VS. TRADITIONAL DENSITY-AREA CURVES A REPORT SUPPORTING DA TA NEEDS FOR NFPA AUTOMA TIC SPRINKLER COMMITTEES SEC Project No. 1806119-000 Prepared for: Fire Protection Research Foundation Prepared by: Garner A. Palenske, P.E. Daniel J. O'Connor, P.E. January 18, 2007 Schirmer Engineering Corporation ww.schirmereng.com TABLE OF CONTENTS INTRODUCTION ..........................................................................................................................1 LOSS HISTORY........................................................................................................................... 2 LITERATURE REVIEW - NFPA 13 OCCUPANCY DENSITY-AREA CURVES .....................4 LITERATURE REVIEW - STORAGE PROTECTION CURVES......................................... 11 RECOM MEN DA TIONS .............................................................................................................. 16 Storage Curves....................................................................................................................... 16 LH, OH 1 AND OH2 Density-Area Curves............................................................................... 17 Miscellaneous Storage............................................................................................................ 17 CON C LUSION ............................................................................................................................ 17 RESULTS OF INDUSTRY MEETING ........................................................................................18 TABLES TABLE 1 - WOOD'S SUMMARY TABLE FOR DEVELOPMENT OF 1974 CURVES .............6 TABLE 2 - COMPARISON TABLE .............................................................................................7 TABLE 3 - SUMMARY OF CHANGES .....................................................................................10 TABLE 4 - SUMMARY OF VARIABLES ...................................................................................16 TABLE OF FIGURES FIGURE 1 - 1972 CU RVES ..........................................................................................................4 FIG U RE 2 - 1991 CURVE................................................. ............ ...............................................9 FIGURE 3 - CLASS II COMMODITY CURVE DEVELOPMENT .......................................14 FIGURE 4 - CLASS II AND IV CURVE DEVELOPMENT ............................................15 APPENDICES APPENDIX A - JACK A. WOOD, LETTER DATED MAY 7,1974 SEC Project No. 1806119-000 -i- January 18, 2007 INTRODUCTION The 2006 edition of NFPA 13 provides designers with a range of sprinkler densities and application areas. Based on a September 13, 2006 meeting with a group of sprinkler and research industry experts, it is apparent that two viewpoints exist regarding single or multi-point design criteria. 1. The user of NFPA 13 benefits from the options available with multi-point design criteria which allows for cost effectively matching water supplies to the building occupancy hazard. 2. Converting to single-point design criteria would assure better sprinkler performance by limiting design to higher densities and simplify the design and review process. FM Global, a leader in the development in storage sprinkler design, believes this complexity to be unnecessary as in recent years they has revised their data sheets to a single point criteria which is presented in tabular format, versus the traditional graphical presentation. The design criteria applicable to typical residential and commercial buildings is based on matching the building occupancy to one of five classes of occupancy hazard - Light, Ordinary Hazard Group 1 and 2; Extra Hazard Groups 1 and 2. NFPA 13 graphically describes multiple potential design points for each of these five occupancy classes. This report examines the basis and development of these curves which date back to 1972 in the time period when hydraulic calculated sprinkler systems were rapidly becoming recognized as a valid alternative to the pipe-schedule method of design. At this time (70's and prior) pipe schedule systems were considered to have performed effectively over the years and a means of relating pipe schedule system performance to hydraulic calculated system was a next step towards quantifying and engineering sprinkler system performance for the future. At the same time that hydraulic calculation methods were developing, there was significant interest in the hydraulic criteria needed to protect storage occupancies with using increasing higher storage arrays with varying hazard levels of combustible contents. \ The design criteria found today in NFPA 13 for storage occupancies can be traced mainly to fire tests conducted in the 1970's 1. As with most historical data, one must view this in proper context. In the 1970's, standard 165 degree rated, Y2 inch orifice sprinklers were the only sprinklers commonly available. The performance characteristics of sprinklers, such as response time index or droplet size, were largely unknown. In addition, the world was just being introduced to plastics, as both packaging material and products themselves. The majority of the material found within a typical warehouse consisted of wood and paper products. From this vantage point the baseline testing makes more sense. For rack storage, multiple area and density baseline testing was conducted on Class II commodity. Standard 165 degree rated, Y2 inch orifice sprinklers were used in the majority of the tests. Specific application curves for various other commodities were developed by single design criteria testing and simply creating parallel curves to that of the Class II testing. No tests were performed to validate this concept of parallelism. 1 Schirmer, Chet - Rack Storage Test Report, 10.19.70. SEC Project No. 1806119-000 - 1 - January 18, 2007 For other storage arrays, such as solid pile, palletized, and shelf storage, approximations of design criteria were made based upon a reduction of the rack storage criteria. This seemed to make sense as such arrays were generally thought to be less severe than rack arrays due to their reduced exposed surface area. This report reviews the background and basis underlying the occupancy density-area curves of NFPA 13 and the storage protection curves. Observation from the review and gaps in the technical background of these curves are discussed. Recommendations for further study and testing are presented. Resolution of these issues is consistent with fire protection's present direction of developing protection parameters based upon scientific data. The reader should note that recommendations towards maintaining the design curves verses changing to a single point approach were not made. The authors believe it is first more important to establish the accuracy of the design criteria and then decide on the presentation format of the information. LOSS HISTORY To determine if storage does in fact present a fire protection exposure, available sources of applicable fire history were reviewed. Data from the National Fire Incident Reporting System (NFIRS) Version 5.0 was reviewed. This data is presented in an analysis prepared by John R. Hall, Jr., Ph.D. of the National Fire Protection Association. Dr. Hall's paper, "An Analysis of Automatic Sprinkler System Reliabilty Using Current Data" was the primary source of data. For storage arrays in general, sprinklers are quite effective, controlling or extinguishing the fire 90% of the time when activated. The data also shows a strong correlation between number of sprinklers operating and sprinkler effectiveness. Ten or fewer sprinklers operate in 97% of the wet pipe sprinkler system activations. The percentage of fires where performance is effective decreases as the number of sprinklers operating increases, rising from a low of 5% of fires where 1 sprinkler operates to a high of 19% when more than 10 sprinklers operate. A higher initial density and lower design area, might have advantages, therefore. Note however, the data is not specific to storage occupancies only and could be biased to fires in occupancies with less severe fire challenges which historically open fewer sprinklers. FM Global Loss Prevention Data Sheet 8-9 "Storage of Class 1, 2, 3, 4, and Plastic Commodites" provides the most detailed discussion of fire losses in storage occupancies found in modern literature. The FM Global information states that loss experience demonstrates that there are no major problems with the current protection, and therefore the existing protection standards are adequate. A study of approximately 228 rack storage losses which occurred 1972-1990 provides insight to this issue2. Note that the study included losses in which no protection defects (E.g.: inadequate water supplies, closed valves, obstructed sprinkler piping, missing sprinklers, or flammable liquid deficiencies) were identified and all fires studied involved standard spray sprinklers only. Data regarding suppression mode sprinklers was not found. From these fires it can be generalized that: 2 FM Global Loss Prevention Data Sheet 8-9, "Storage ofC/ass 1,2,3,4 and Plastic Commodities." SEC Project No. 1806119-000 - 2 - January 18, 2007 1. Rack sprinklers, used in conjunction with ceiling sprinklers performed exceptionally welL. 2. Damage and number of sprinklers activated increased with increasing storage/building height. 3. For ceiling sprinklers only, the average number of sprinklers which opened was eight. For systems with both rack sprinklers and ceiling sprinklers the average number of sprinklers which activated was three each. In response to a series of large loss warehouse fires in the 1980's, an NFPA task force was created. The purpose of this effort was to compile loss data such that fires in storage occupancies could be better understood. FM Global, IRI, and Kemper provided loss data for review. It was found that storage occupancies incur an average loss three times greater than other insurer facilities. This large property damage was in part due to the large amount of combustible materials and damageable products within such facilities. It was found that facilities which were unsprinklered or had inadequate sprinkler protection had losses five times larger than those with adequate sprinkler protection.3 Review of this data appears to show the existing sprinkler design standards are adequate. However, there are several variables which complicate this picture. For sprinkler system design purposes, the supplementation of the water supply by the fire department apparatus is not considered. This additional supply can greatly enhance the sprinkler system's capacity and therefore performance. Fire tests are almost always conducted using a constant design density. In real applications, a declining density usually occurs. The first few sprinklers discharge a higher density and the density declines as more sprinklers activate. Application of more water early in the growth of fire can greatly improve sprinkler performance. Interestingly, small hose streams were employed in 87% of the losses in which 10 sprinklers or less activated. In addition, 50% of the time the small hoses were used prior to sprinkler activation or prior to fire control. This data suggests that application of small hoses has a significant effect on the average number of sprinklers which activate,4 In summary, adequately designed and installed sprinkler systems appear to perform well in storage fires. However, other factors have been identified which could have a substantially positive affect on sprinkler performance. Not considering same in the design process is a testament to the conservative nature of sprinkler design, but also clouds our understanding of sprinkler performance. 3 Zalosh Robert- Industrial Fire Protection Engineering, Chapter 5 4 FM Global Loss Prevention Data Sheet 8-9, "Storage of Class 1,2,3,4 and Plastic Commodities." SEC Project No. 1806119-000 -3- January 18, 2007 LITERATURE REVIEW - NFPA 13 OCCUPANCY DENSITY-AREA CURVES The 1972 Edition of NFPA 13 contains the first appearance of density-area curves to be used for the design of hydraulically calculated sprinkler systems. The graph of the curve appeared as follows in the 1972 Edition of NFPA 13. , Q . l-~~ø: .: CI N I& . - cc .J J: a U) , zo )- a: '0 . .)- a; C -- cc - Z c( . - N P. o--~ a: :r 4( 0: C\ z ~ - N DC ~.o a: :r o o. 5000 )- (C 0 c( a: I' Zc(Q. ã N CC a: ~ o :: - 1-. 04' . a: 4000 bJ a. o a: bJ .. 3000 x: -a: Z a. 2000 U) .. o 1500 .. 04 LL a: 0.05 oc 0.25 0.15 0.20 DE~SfTY~.GPM / SQ, FT. 0.10 0.30 Jie. :n13. A &uide for determmni~ density. area of eprlnkler ~pertton and watee . . supply requlremeø.h. . '. FIGURE 1 -1972 CURVES Members of the NFPA 13 Committee report that the curves were based on studies of a number of pipe schedule systems. Chet Schirmer, a past Chairman of the NFPA 13 Committee, reports the following explanation of the curves: "The basis for the NFPA 13 curves was a study by Jack Wood and one other (can't at this moment recall who) of a number of pipe schedule system arrangements. These were evaluated to determine the area density characteristics of light, ordinary and extra hazard pipe schedule systems. The consideration here was the fact that historically pipe schedule systems had a good (or excellent) performance record. A wide variety of system arrangements SEC Project No. 1806119-000 - 4- January 18, 2007 were reviewed to determine their density/area characteristics. This information, along with fire test data, provided the foundation for the curves. " To confirm and further understand the development of the curves, the NFPA 13 work folder of Chet Schirmer was investigated in an effort to locate specific documentation regarding the basis for the density-area curves. From this folder are several key pieces of correspondence. First is a 1974 memo from the Insurance Services Office (ISO) citing comments of the Factory Insurance Association - Travelers, regarding proposed changes to the original 1972 NFPA 13 density-area curves. The comment as it appears in the 1974 correspondence is quoted as follows: "5. It is interesting to compare the curves proposed and the hydraulic calculation results submitted to the Chapter 2 sub-committee. The curves were drawn from the results of hydraulic calculation of schedule systems with 1500 square feet, 3,000 square feet and 5,000 square feet areas of application. With three curves (Ordinary Hazard 1, 2, and 3) and three pre-selected areas, this gave 9 points to graph. The intent of these calculations appears to be to determine what density over these specific areas of application wil result in top line pressures of 15 psi, 30 psi, 45 psi, 60 psi and 75 psi. This apparently in an effort to be competitive with table 2.2.1 (A) which asks for 15 psi or higher for Ordinary Hazard Group 1 and 2. Interestingly enough only 1 out of the 9 points were based on 15 ft. which is less than 7 psi psi top line pressure (.08 gpm/sq.ft. ~ 5,000 sq. end head pressure per comment #2). Two points were the result of 30 psi top line, three with 45 psi top line, two with 60 psi top line, and one at 75 psi top line." . As a follow-up to the comment by Travelers, Jack Wood of the Viking Corporation provided a detailed explanation of the calculation for one 8-inch supplied pipe schedule tree system. It is apparent in Wood's letter that it was arbitrarily assumed that O.H. Group 1, O.H. Group 2 and O.H. Group 3 pipe schedule systems would be supplied, respectively, by 15 psi, 30 psi and 45 psi top-of-riser residual pressure to sprinklers assumed operating over 5000 fe. The central explanations of Wood's study are found in Items 1(a) and Item 5 of Wood's May 7, 1974 letter (see Appendix A). "ltem 1 (a). If we used the hydraulically most remote area in our calculations the end sprinkler density would be 0.062, 0.090 and 0.110 GPM per square foot for Groups 1, 2 and 3 (5000 square feet) respectively. We moved the operating area to the center of the system where the cross main sizing is 6-inches and the densities increased to 0.081, 0.12 and 0.15 GPM per square foot for Groups 1, 2 and 3. These values are the top points of our three proposed curves and would be used over the hydraulically most remote area per chapter 7. This amounts to about a 30% increase over the values we could have proposed had we selected the hydraulically most remote area." "Item 5. The pressures at the top of the sprinkler riser were selected arbitrarily; however, the only case in which we used the minimum pressure allowed in Table 2-2.1 (A) is Class I with 5000 square feet operating. These various pressures were used in order to provide a slope to the curves. In my opinion this slope is as accurate as the #231C curves and really makes more sense. We have used the calculated amount of water an ordinary hazard system wil deliver in the center of the system to produce these curves." SEC Project No. 1806119-000 - 5- January 18, 2007 An attachment to Wood's 1974 letter contained a table that lists Wood's data for the operating area calculated at the center of the system for 15, 30, 45, 60 and 75 psi top-of-riser residual pressure for operating areas of 1500, 3000 and 5000 ft. Wood's Summary Table is repeated below along with the resulting 1974 NFPA 13 Density-Area curves. The curves are annotated to show how Wood's data served to anchor the tops and bottoms points used to form the curves. TABLE 1 - WOOD'S SUMMARY TABLE FOR DEVELOPMENT OF 1974 CURVES OPERATING AREA Average Pressure 15 PSI 80 PSI 45 PSI 60 PSI 75 PSI 1500 s . ft. 13 SPRKS) Density Pressure GPM 3000 sq.ft. (25 SPRKS) 5000 s .ft. 42 SPRKS) Density Pressure GMM Density Pressure GPM GPM/ft2 PSI GPM/ft2 PSI 0.086 14.52 182.5 0.083 14.66 0.127 29.82 265.2 0.123 30.23 0~160 45.72 331.0 0.155 46.30 59.82 380.6 0.180 61.02 75.67 429.9 GPM/ft2 PSI 0.081 14.65 574.0 354.6 516.2 643.8 742.8 0.20 74.13 821.6 '~ r- 29.71 829.0 44.95 1028.1 59.20 1186.1 74.53 1336.8 ~ 5000 SQH (42 SPRKS) I 5000 \ .. . ò- . .. 4000 'i c ~o ~ ~ .,a. .. ~ Q) 3? c 3000 , ~ (" ~,. ~i \~ ~ ~., ~., Õ 'C 51 0~ " \'.~ 0 o ¡¡ .. ~ 2000 1500 0.05 i\. , . . 0.15 ~ 0.10 Density -GPM/sq. ft. 1500 SQ.FT. (13 SPRKS) I The effect of Wood's 1974 analysis is that the 1972 Ordinary Hazard Density-Area curves are shifted to the left, slightly reducing the design requirements for sprinkler density at any given area. Wood provides a comparison of the curve generated from his data to the NFPA 13 (1972 Edition) and the single point density and area recommendations of Factory Mutual's Loss SEC Project No. 1806119-000 - 6- January 18, 2007 Prevention Bulletin 3-26 dated November, 1973. The handwritten notes of Chet Schirmer also provide for a comparison to the 1974 Edition of NFPA 231, "Standard for General Storage". TABLE 2 - COMPARISON TABLE 0.15 - 2500 NFPA 13 1974 0.133 - 2500 0.155 - 2500 NFPA 231 1974 0.126 for CCII 0.15 - 2500 0.17 - 2500 0.215 - 2500 0.150 for CCIII* 0.20 - 3000 0.18 - 3000 0.25 - 3000 0.189 for CC IV* FACTORY MUTUAL O.H. Group I NFPA 13 - 1973 Food ProcessinQ Glass Products O.H. Group II Mercantiles Textile Manufacturing O.H. Group III Tire Manufacturing *cc = Commodity Class Class I commodities are noncombustible products stored in ordinary single layer cardboard cartons. This includes metal and glass Also noncombustible products placed directly on wooden pallets and noncombustible products shrink wrapped or paper wrapped as a unit load (with or without pallets) are Class i. products as well as noncombustible foods. Glass jars in compartmented cardboard cartons are considered a benchmark Class i commodity. Class Ii commodities are the same as Class I, but in more substantial packaging such as wooden crates, solid wooden boxes or multiple thickness cartons. Metal lined double triwall cartons are a benchmark Class II commodity. Class ill commodities are products fashioned from ordinary combustibles such as wood, paper, cloth and leather. Group C Plastics are also defined as Class ILL commodities. Class Iii commodities are allowed to have a "limited amount" of Group A or B Plastics. A "limited amount" is defined as a maximum of 5% by weight or volume. Paper cups in compartmented cartons are considered a benchmark Class Iii. Class iv commodities are those Class i, ii or ill commodities with an "appreciable amount" of plastic or with plastic packaging. An "appreciable amount" of plastic is defined as between 5 and 15 percent by weight or between 5 and 25 percent by volume. Group B Plastics are also defined as Class iv commodities. Polystyrene and paper cups in compartmented cardboard cartons are considered a benchmark Class iv commodity. In 1972 the NFPA 13 Light Hazard curve extended to an operating area of 5000 ff with an amounted design density of 0.075 GPM/ff. The revision for the 1974 edition resulted in a reduction of the allowable operating area from 5000 ff down to 4000 ft., at which 0.05 GPM/ft. was indicated as the required design density. The apparent basis for this change was related to the work done in the United Kingdom by the Fire Offices' Committee (FOC). A letter from H. W. Marryatt of the Australian Fire Protection Association responds to correspondence of an NFPA 13 Committee member's concern for the degree of light hazard and extra light hazard systems (per the FOC, "extra light hazard occupation included hospitals, hotels, institutions, libraries, museums, nursing homes, office buildings, prisons, schools, colleges). Marryatts response to the NFPA 13 Committee member is quoted as follows: "In reading the copies of correspondence from members of the N. FP.A. 13 Committee it appears that several people are concerned about two questions in particular regarding the design of systems for light hazard and extra light hazard occupancies. The point is whether the design density of discharge of 0.05 ft. per minute is adequate, and one correspondent suggested that this figure should be doubled. Bearing in mind that the figure used in both the Australian standard and the F.O.C. Rules is in imperial gallons, i know that the gallons per sq. SEC Project No. 1806119-000 - 7 - January 18, 2007 research work carried out in the u.K. prior to the introduction of the 29th Editon of the F. O. C. Rules establishes pretty clearly that this density or discharge would establish control in an extra light hazard occupancy, and in fact it gave a reasonable factor of safety as tests indicated that control was reliable down to 0.05 gallons per sq. ft. per minute. Additionally, insight into the 1974 change to the 0.05 GPM/ft1 density for Light Hazard occupancies is provided by Wood in his May 7, 1974 letter. Wood comments on the F.O.C. density requirements as follows: "i know the F. O. C. water supplies are considered too light by many, but they require a density of 5 mm per minute (0.12 GPM per square foot) regardless of whether the hazard is Ordinary i, 1/, 11 or 11 Special. They increase the area of application as follows: i - 775 square feet, 1/ - 1550 square feet, 11 - 2324 square feet, and 11 Special - 3874 square feet. Our proposed curves exceed their requirements in all cases. " The 1974 Edition of NFPA 13 and the density-area waiver remained unchanged until the 1991 Edition of NFPA 13, with one exception. In 1978 the Extra Hazard Group 1 and Group 2 areadensity curves were added to the Appendix of NFPA 13 as guidance for occupancies involving a wide range of variables which could produce sever fires. The following explanations and examples of Extra Hazard (EH) Occupancies were provided in the 1978 NFPA 13 appendix as follows: "Extra Hazard Occupancies (Group 1) include occupancies as described in 1- 7.4.1 with litle or no flammable or combustible liquids. These include occupancies having conditions similar to: Combustible Hydraulic Fluid use areas Die Casting Metal Extruding Plywood and particle board manufacturing Printing (using inks with below 100°F (37. 8°C) flash points) Rubber reclaiming, compounding, drying, millng, vulcanizing Saw Mils Textie picking, opening, blending, garneting, carding, combining of cotton, synthetics, wood shoddy or burlap Upholstering with plastic foams Extra Hazard Occupancies (Group 2) include occupancies as described in 17.4.1, but with moderate to substantial amounts of flammable or combustible liquids or where shielding of combustibles is extensive. Extra Hazard Occupancies (Group 2) includes occupancies having conditions similar to: Asphalt saturating Flammable liquids spraying Flow coating Mobile Home or Modular Building assemblies (where finished enclosure is present and has combustible interiors) Open Oil quenching Solvent cleaning Varnish and paint dipping SEC Project No. 1806119-000 - 8- January 18, 2007 The Extra Hazard Occupancy density-area curves remained in the Appendix for 13 years until the printing of the 1991 Edition of NFPA 13. For the 1991 Edition a number of changes were instituted affecting all of the density-area curves. The 1991 Edition density-area curves are the curves currently found in the 2006 edition of NFPA 13. The graph of the 1991 curves is provided below showing a Light, OH1, OH2, EH1 and EH2 density-area curve. It is noted that an OH3 curve no longer appears as the prior OH2 and OH3 curves of prior editions were combined resulting in a revised OH2 curve in 1991. Also, the curves are no longer "curved", but are all represented as straight line relationships. Table 3 summarizes the changes to the density-area curves since they first appeared in 1972 through to the 1991 Edition which, again, are the curves found in the current edition of NFPA 13 (2006). Denslty-( L/mln)/m2 4.1 2.0 8.1 6.1 14.3 12.2 10.2 16.3 465 5000 .. &; I c: o .¡: .." 2 ~.~ 3 "" ~ 4000 .'\ ;, '" 0. a.. Q~ ~ II ~ o ,, '" .. ~ '" O ~ 2600. oc 2000 1600 0.05 , ~. 0. q. %"~ 3000 279 a.. '" :; .E .L ~ t: ~ E a -; i' "' N i c: ~ '.! .!: 372 'Q~ 232 ~.. 4 186 II ~ a "'" \~ 139 0.10 0.16 0.20 0.26 0.30 0.35 0.40 Density-gpm/sq ft FarS,! Units: 1 sqft=O.0929 m2; 1 gpm/sq ft=40.746 (L/min!/m2. Figni:e 5-2.3 Ara/density curve~. FIGURE 2 - 1991 CURVE SEC Project No. 1806119-000 - 9- January 18, 2007 , " ", "",' ,,:','" i' ",' " ':'fl,\;' ,'" 'i i ", ",', ",', , L,s .'ft.,J, ,/ 0.21 5000 5000 0.12 5000 0.15 150Q, ,',i, 5000 0.12 5000 0.15 , 3000 ,' ,w""",'\i I";," ,', N/A N/A 0.15 4000 4000 N/A 0.10 ',' ","'" \, '"',, "'" ,,' " ,,1, 500 '"".',",,, ,,", """ I,,"" ,,""',i' ,,',,","', 500 5000 0.20 'ii25ÖÖ ,""'" ," I( ','.' ',," ",i"" " '" c" I",i', 8t 5000 0.30 desi prio ',', """",'" Th 2500 ,""'", , .. """"""'" "', aree( 0040 N/A 0.15 0.20 0.30 6000 5700 5000 5000 5000 , "i"",," ''',~~,.. .' ,c,'"',,,,: ,",,".,1 "',' ,', "",,' "',, " ",',"""',',',,', ,," 4000 d 81 ( Cur 'f"", """""""'."";."';11.,,", " - "',,' """.' 0.275 "i,,',i' " ¡i"l Appendix) Appendix ""',,, """",', """,' Appendix) 6000 (shown in 5700 (shown in 0.275 (shown in 0.20 (shown in Appendix) Appendix) Appendix) 0.20 ,,' Appendix) 2500 (shown in Appendix) 2500 (shown in 0.37 (shown in 0.29 (shown in N/A N/A N/A ""I'I " ",.: ",'i C' ",",i."'.""..''.""."'.,.,,' '""", 1"",,,,,,-- ',,'N/Ä, " ",' ," " N/A ,".',"", "."'.;,',."."",' ",' "I,',' " N/A 0.15 '.' ,'," ";,,,.',"'..'.' , '.'."""" ,..v~ ,'.' "."'.',. "',., ,,',',,' ,.l::~U ',' " ,"" I,",."'.. ,'"":,,' ,'" ,d,) " ,,,,,1".." "',"",,", ',", """"',',)i. ",,:,,' ""', ",' "',", ",',"'" "',-,~ ,..","', ",';, ',"'1"'" """lJ",?,. I""",, "c"D.t,!:'" ' ,"",'" """11..",'.,'".,,..' "...",..,.,.""."..""", "",', " ,'" ""A¡"" ;"",'-","",'""","',' T :t' 5000 0.08 ',' ,', ,,", "",'" ','" ,,' ,. ',,"',',"',', "',,i ' """.)' " " , ",,' ",':, , ,:'..,;;',.r~", "","", ~ -""'77 ',""','" ",,' " " ,150Ö,i'( ,'I,",. ,I' ",:' ' ,',,', ',,,I ,','.', ','.,',,"" ""'U. 16,",:',C,',' ,'",",","1 """"",,' ,,"",' "021",( ,', ',' """,' ,',"'""'" "",'i\ """;,',,,' :',:'.-., ,,)' , ',,', ",,' "" ":, """"':;,,' " "'ic' """, ',,',',,',",", ':'""""".,, 5000 0.08 '" """";,,, ,il\ ':,...""',, "",1""""'" ,.N/A" ; ,!, ',' '" I' ,'",' N/A 0.12 ~.ft.S " ,', ,,' ',' ,"'" ,,' 1500, I sq. ft. ) p area q. ft.) 0.19 5000 ",' "'," ",.-""""1",.,1"""'."""',,, ""","'"""..',.,',", ," "', """,,"."."",,'..,. ,,',., " 1500 """""-"/'",.""',",:,,,.,'IO~t)\ "":/i',,, "",1~00.....""", 0.16 5000 0.13 0.175 0.22 N/A N/A ",', ,', "",' """""'1500 ',,"'", .'.',i''''i'',N/A "'," ,', ."'",,, ""~/A ,', " """"",',,1,,', '..""'1500,,"". "",,' ",,' '," ",' "", '"',,,..,..."'" """',, ",' ,',,'.,., ""'" 1500""'" ",,""'..'.,!",' ,. ,,',,' "', ."'."",."..", ' ",0.18 ,.", 'i I,,\), t4 ,,'\: ," ".. ",'."", ',." ,',. ',' '.., " ,,"',f" ,.iN/ A""" ' ,I..,.. .""I,t~)A;; .' "'" ,'..'.',,'.,. 0.08 )måreá" ,,' ',' ", ',""" density, 0.07 l$q.,Jt:) .", ,',' ,",'," N~ N~ N~ N~ N~ Hazard Group 1 Hazard Group 2 Hazard Group 3 Group 1 Group 2 Ordinary Ordinary Ordinary Extra Hazard Extra Hazard 0.05 , 1~Op, " ",' .'A~;", ","":~','.)i,' 4000 0.05 1500 ",', " Jr?~?$ity, ,,' ,"""i ""'9:10 ' ',", ~. ft. ) I sq. ft. ) p area density 4000 0.05 ,"",,','" 1500 " 0:10, 5000 0.075 1500 ,,'," "",'" , ' " '", ,,'0,10 '", " , ",',.',',,' '", ," P,""""',,',',I,',p,,,e,'.'",r:,."""",.'~',i",tY, ',.",:', ""/'.".?". i """",' P area ~. ft. ) I sq. ft. ) density . ft. P area I sq. ft. ) density ~¡,fb"f, " )rr;area. ,'", ",'" ',' 0.10 N/A Light Hazard ,',',,' ,'" /sq.ft.) ,""",1""" naen~itY, :1. ft. ) ) area, I sq. ft. ) density, d.ff)., ' ,', )m,"',,'" a"""rea ,', ",,""',', Z~q :¡,ft,y". n,g~n~ìty ,', I, ""',",' N/A Points the previous edition L.L..;I\,I.. VUn,VL..;IL.. i..rrl" i~ LITERATURE REVIEW - STORAGE PROTECTION CURVES An extensive review of available literature was conducted. This review included: . . Rack Storage Fire Protection Committee Historical Records . . FM Global Rack Storage Fire Test Data National Fire Protection Association Committee on Rack Storage Historically Records FM Global Loss Prevention Data Sheet 8-9 "Storage of Class 1,2,3,4, and Plastics Commodities" . . . FM Global Loss Prevention Data Sheet 8-33 "Rack Storage of Materials" National Fire Protection Association Standard 13 "Installation Of Sprinkler Systems" National Fire Protection Association Standard 231C "Standard for Rack Storage of Materials" The Rack Storage Fire Protection Committee was organized in August, 1967, by representatives of rack manufacturers, fire protection equipment manufacturers, and fire insurance interests5. They were joined shortly by representatives from a wide cross-section of the industry. All are interested in finding ways and means of providing effective protection for racked storage through a comprehensive, full-scale, fire test program. The representatives serving on the Main Committee include executives, engineers, and technical specialists, with worldwide reputations as authorities in their respective fields. The Main Committee formed a Steering Committee responsible for developing and conducting the program. This subcommittee monitors progress and compiles and analyzes results. The Steering Committee consisted of those members (known as sponsors) of the Main Committee who have contributed cash, services, materials, or equipment in the amount of $10,000 or more to the project. Many organizations, some of which are members of the Main Committee and some not, also very graciously contributed - but in amounts less than that which would have qualified them as sponsors. These contributions, which have included cash and burnable stock (plywood pallets, plastics and cartons), are indicative of the fine cooperation which has been one of the factors in the success of this very costly project. The combining of the facilities and talents of not only the fire protection fraternity, but also, and more importantly, users and suppliers to solve this critical problem was a major step forward in the entire fire protection field. In 1968 the NFPA Committee on Rack Storage was organized. The data from the Rack Storage Fire Protection Committee was given to the NFPA committee to develop a standard that was "supported entirely by actual fire test data". This new standard, NFPA 231C "Standard for Rack Storage of Materials" was first adopted in May 1971. The requirements found in NFPA 231 C were eventually integrated into 1999 Edition of NFPA 13. The sprinkler design requirements found in both NFPA 231C and more recently in NFPA 13, are shown via curves. 5 Schirmer, Chet - Rack Storage Test Report, 10.19.70. SEC Project No. 1806119-000 - 11 - January 18, 2007 Sprinkler system design criteria for rack storage were also developed by FM Global for use by their insured's. These requirements were found in FM Global's Loss Prevention Data Sheet 833 "Rack Storage of Materials" (1976-1984). In this publication, sprinkler design criteria were presented by curves which included a variety of areas and densities. The presentation of the requirements is very similar to that found in the recent edition of NFPA 13. In addition, the base curves are the same in both documents. This comes as no surprise as FM Global representatives were on both the Rack Storage Fire Protection Committee and the NFPA Committee on Rack Storage In November of 1995, FM Global expanded Loss Prevention Data Sheet 8-9 "Storage of Plastics and Elastomers" to include all storage requirements, including rack storage of Class 1IV and plastic commodities. In addition, design curves were replaced with a single point densityarea approach. In general, the single point chosen was the largest sprinkler density and the smallest design area. The purpose of this change was to make the document user friendly and to provide easy access to all design options (suppression mode sprinklers, control mode sprinklers, etcl The Rack Storage Fire Protection Committee began by conducting over 70 small scale commodity tests in an attempt to find a commodity which was representative of the broad range of combustibles which might be found in a warehouse situation. It was necessary that a commodity be selected which not only represented the burning characteristics of this range of combustibles, but that it also be readily available and be inexpensive enough to be used throughout the full series. A double tri-wall carton (the equivalent thickness of six layers of corrugated cardboard) was selected as the burnable. The first four full scale tests (60, 61, 62 and 63) were conducted using this commodity. These tests opened a large number of ceiling sprinklers and produced water demands considerably in excess of the validity limits which had been established at that time. It was determined that these test fires progressed in a normally expected manner until the fire penetrated the cartons. At that time, the entire interior of the carton started to burn and was shielded by the carton from sprinkler water discharge. Full scale Test No. 64 (Hallmark products - consisting of a mixture of various paper products, including greeting cards, paper party favors, cups, negligible amounts of table flatware, etc.) was conducted to observe fire conditions with a real life commodity and compare these conditions with previous tests. Results more closely approximated real life burning characteristics than previous tests. Small scale tests were also run with Hallmark products for comparison with the double tri-wall carton and with a double tri-wall carton containing a 24 gage 38" x 38" x 36" high metal liner. The presence of this metal liner in the double tri-wall carton results in a commodity whose fire development characteristics very closely resemble the Hallmark products as well as those which might be found in many warehouses within the broad range of ordinary combustibles. This then became the standard commodity to be used in future full scale tests. Average weight per pallet load of this standard commodity was 226 Ibs. Average weight per pallet load of Hallmark products was 500 Ibs. and of 3M products - 900 Ibs. (Weights include pallets). Full scale tests were run on the standard commodity (double tri-wall carton with metal liner), Hallmark products and 3M products (abrasives, pressure sensitive tapes of plastic fiber and paper, etc.). The committee reviewed these results and developed a new guide or relative scale, to classify products as follows. 6 FM Global Loss Prevention Data Sheet 8-9, "Storage at Class 1,2,3,4 and Plastic Commodities." SEC Project No. 1806119-000 - 12 - January 18, 2007 Non-combustible products on wood pallets or in ordinary paper cartons or wrappings on wood pallets, such as - metal parts; empty cans; glass containers; Class i non-combustible food stuffs or beverages; stoves; washers; dryers; metal cabinets with plastic handles or knobs. Class II Class I products in slatted wood crates or solid wooden boxes, on wood pallets. Class III Wood, paper, natural fiber cloth, or products thereof, containing no more than a negligible amount of plastics in the product or in the packaging material, on wood pallets, such as - natural fiber clothing or textile products; wooden furniture or wood products; bicycles; luggage (except plastic); combustible foods or cereal products; paper products; leather goods, wooden cabinets with plastic knobs or handles. Class iV Class i, Ii and/or ILL mixed with more than a relatively negligible amount of plastics used in the product or packaging material, on wood pallets, such as small appliances with thermosetting plastic cabinets; typewriters, cameras or electronic parts in plastic packaging in cartons; plastic backed tapes. High heat release products, such as plastics and flammable liquids were considered outside the scope of this project. At the outset of the program it was decided that 20 ft tests should be conducted to determine the following: 1. Density of ceiling sprinkler discharge necessary to protect rack storage to a height of 20 ft. 2. Height of rack storage which can be protected by a density of 0.3 gpm/sq. ft. Pass/fail criteria were established as: 1. Fire Spread - produced damage in the main rack array to a distance in excess of 12 ft. (or three pallet loads) from the point of ignition, or ignited combustibles in the target piles. 2. Total Water Demand - produced a water demand in excess of 1500 GPM. 3. Building Exposure - produced air temperature at the ceiling exceeding 1000°F for 5 minutes within any 400 sq. ft. ceiling area. 4. Racks - did not maintain rack steel integrity. Validity was later changed to indicate a test was valid if it did not: 1. Burn beyond the first two rows of cartons in the target racks. 2. Burn to the end stack in the main racks. 3. Open sprinklers to the outside walls of the test facility. SEC Project No. 1806119-000 - 13 - January 18, 2007 The concept of parallelism was agreed upon. This involves the establishment of a base curve for a standard commodity with all variables constant except sprinkler discharge density. Additionally, curves Class ill and iV were constructed through a single point parallel to the base curve. For Class ILL commodity, Test No. 64 (Hallmark products) was used. For Class iV, Test No. 78 (3M products) was used. Class i commodity densities were reduced 12% less than Class II, based upon a Class III/Class II comparison. If the slope of the developed curve was different than the base curve, the slope of the developed curve was changed to agree with the base curve. Although the Class II curve was able to be constructed utilizing several fire tests, the Class III and Class IV curve relied essentially on single data points - Test No. 64 and Test No. 78. Review of the specific test results for Test No. 64 and Test No. 78 tend to be poorer measures of sprinkler performance and, therefore, are questionable as valid anchor points for the Class III and Class IV curves. See Figure 3 and Figure 4. 20 Foot Rack Storage Fire Test Data: Class II lStandard Commodity) 14,000 -r - \ \ .. Cu rent FPA 3 cur e 12,000 '" i: ' o :¡ := 10000 '\ ø Test 72 ~ 8,000 QI \ m i,est C. 75 o 'õ 6,000 ct e c: 4,000 Te ~6~ ~ Test 65 Te~ 2,000 o ~ ieSt .. Te ;s ii """" 0.10 0.15 0.20 0.25 0.30 0.35 0040 0045 0.50 0.55 0.60 Design Density (gpm/W) FIGURE 3 - CLASS II COMMODITY CURVE DEVELOPMENT SEC Project No. 1806119-000 - 14- January 18, 2007 20 Foot Rack Storage Fire Test Design Curves 14,000 .. 12,000 .-. N :¡ 5 10,000 ~ CI g 8,000 -o CI ~ 6,000 cc 4,000 - aass II Curve - Class III Curve - aass rv Curve 2,000 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50 0.55 0.60 Design Density (gpm/ft2) FIGURE 4 - CLASS II AND IV CURVE DEVELOPMENT The committee acknowledged at the time that the concept of parallelism was somewhat arbitrary and that testing through three data points per curve was preferred; however, the project budget did not allow such effort. Several key variables were studied to determine the correlation between the test data and the resulting NFPA 13 requirements. The base line testing utilized 165 degree rated sprinklers. Tests were run to evaluate the difference in performance of 286 degree sprinklers. Of the 60 tests conducted with 20 ft. storage, 10 used 286 degree rated sprinklers. Tests No. 67 (165 degree), 69 (286 degree), 76 (286 degree) and 94 (286 degree) were used to evaluate this variable. Test 67 was considered invalid due to mechanical problems. Test Nos. 65 (165 degree) and 66 (165 degree) were compared to 69, and showed a reduction of area of 55% and 52% respectively. Test 94 was compared to Test 93 and resulted in a reduction of area of 55%. To evaluate 212 degree rated sprinklers, one test was conducted. Test No 84 (212 degree) was compared to Test Nos. 65 and 66 and showed an increase of operation of area of 15.5 and 8 respectively. A 40% reduction in area was used to form the curve for the use of 286 degree sprinklers. 212 degree rated sprinklers were assumed to operate in a similar fashion to 165 degree rated. The standard configuration used was 8 foot aisles between racks. Test Nos. 89, 90, and 93 used 4 ft aisles. However, multiple variables were changed as slave type pallet were also used (standard configuration used standard pallets). Committee members surveyed indicated this was done as a 4 ft aisle condition was assumed to occur only when an automated storage system was used, thus requiring slave pallets. Comparing Test No 90 to baseline Test No 65 an increase in operation area of 198% was found. Comparing Test No 68 to Test No 89 no increase in operation area was seen. Comparing Test Nos. 74 to 93 an increase in operation area of 300% was seen. This data shows an average area increase of 166% when 4 foot aisles SEC Project No. 1806119-000 - 15- January 18, 2007 4 foot aisle tests. A 190% were used. This data is inconclusive as slave pallets were used in all increase in operation area was used for the 4 foot aisle curve. Test 96 was conducted to investigate multiple row rack protection. A 33% increase in operation area was seen. A 30% increase in operation area was used in the development of curves for multiple row racks. A tabular summary of this data is shown below. TABLE 4 - SUMMARY OF VARIABLES Temperature Rating 286 vs. 165 212 vs. 165 Aisle Width* Multiple Row Racks Clearance CURVE ADJUSTMENT TEST RESULTS VARIABLE 54% reduction in area 11.75% increase in area 166% average increase in area 33% increase in area Further study needed 40% reduction used Considered same as 165°F 190% Used 30% Used - *Tests considered invalid due to use of slave pallets RECOMMENDATIONS STORAGE CURVES . The existing curves should be validated. Additional testing should be conducted for Class III and iV commodities. The testing should mirror the existing testing in sprinkler type, clearances, commodity, array, etc. Three points should be tested per commodity, at the top, middle and bottom of the existing curves. . . The following variables should be tested: ~ Sprinkler Temperature rating ~ ~ ~ Clearance Aisle width Sprinkler K factor The issue of new technology should be examined. This should include large orifice control mode sprinklers. SEC Project No. 1806119-000 - 16- January 18, 2007 LH, OH1 AND OH2 DENSITY-AREA CURVES In general the loss experience and sprinkler performance records for the LH, OH1 and OH2 occupancy classes are indication of successful performance. One area in question are those occupancies that would have relatively close continuity of combustibles and high-ceilings. Testing should be conducted to explore what combination of combustible load continuity and increasing ceiling height would jeopardize the occupancy density-area curves. MISCELLANEOUS STORAGE The miscellaneous storage requirements of NFPA 13 allow the use of the OH and EH curves in lieu of storage requirements. Full scale testing of miscellaneous storage arrangements with sprinkler protection requirements per OH and EH density-area curves should be conducted to validate the use of these curves for miscellaneous storage. CONCLUSION This report presents the historic technical basis for the sprinkler design criteria found today in NFPA 13. From review of many sources of information one finds that given the time period in which the work was completed, 1960 - 1970's, and the budget constraints of the test programs, the analysis for the most part is appropriate. However, many gaps exist which must be filled to truly confirm that the design criteria is in fact accurate and scientifically based. A prime example being the use of the theory of parallelism to develop design curves. In addition, sprinkler technology has changed drastically since this early time period. Such technological changes as sprinkler K factor increases and response time improvements make this original work less meaningfuL. Further research, specifically fire testing, is needed to confirm the accuracy of the design criteria, and equally important, its application to new sprinkler technology. SEC Project No. 1806119-000 - 17- January 18, 2007 RESULTS OF INDUSTRY MEETING The attendees of the industry meeting provided the following suggestions for future work or testing: 1. Existing Class III and IV commodity test data using large K factor sprinklers should be reviewed with the intent of validating existing Class III and IV commodity curves. 2. The majority of the group believed use of new technology was more important than verifying the performance of % inch orifice sprinklers. 3. Simplification of commodity classes should be explored. Fewer classes which are broader in scope were suggested. 4. All major sprinkler manufacturers should be contacted for applicable fire test data. SEC Project No. 1806119-000 - 18- January 18, 2007 APPENDIX A JACK A. WOOD, LETTER DATED MAY 7,1974 " I, '. ~II~I~~ RECEIVE D MAY 8 ~ 1974 THE VlKIf' CORPORAJIa210N.INOU-mIALPARKROD ..-,. F. r., 1-1A1\, MlGG., U.S.A 4WJ8 TELEPHE (616) 945-9501 CABlE: VlKIt\ TELEX: 22-6 AIR fVIL May 7, 1974 Mr. Chester W. Schirmer ,./ SCHIRMER ENGINEERING CORPORATION 5940 West Touhy Avenue Niles, I1lnois 60648 ~0' Dear Chet: ) I have received your letter of May 1, 1974, and the material enclosed from the enough, they are criticizing areas where we applied factors of safet, which leads me to believe they don't understand hydraulics too well. At any rate, I will try to answer their questions one by one. Rating Bureau Group's discussion. Strangely Item 1 (a) If we used the hydraulically most remote area in our calculations the end sprinkler density would be 0.062, 0.090 and 0.110 GPM per square foot for Groups 1, 2 and 3 (5000 $quare feet) respectively. We moved the operating area to the center of the system where the cross main sizing is 6 inches and the densities increased to 0.081, 0.12 and 0.15 GPM per square foot for Groups 1, 2 and 3. These values are the top point of our three proposed curves and would be used over the hydraulically most remote area per Chapter 7. This amounts to about a 30% increase over the values we could have proposed had we selected the hydrauli- cally most remote area. (See attched sheets Section 1 and 2.) Item 1 (b) The sprinklers we calculated were as indicated because of the computer program. The end heads were used as this produces the greatest pressure loss in the branch llnes. In reality the same flows wil be reached at a lower total pressure. This procedure provides for a margin of safety in the branch line calculations. Item 1 (c) We were demonstrating what an ordinary hazard system will deliver with a residual pressure of 15 PSI at the top of the riser. The resulting end sprinkler pressure is about 3.5 PSI with a densily of 0.81 GPM per square foot over a 5000 square foot operating area. Item 2 I am perfectly aware that a density of 0.81 GPM per square foot applled over 130 square feet results in a flow of 10.5 GPM from the end sprinkler. And that pressure required to produce this flow is 3.45 PSI. This same condition can occur in a i ight hazard occupancy where you have to reduce the sprinkler coverage below 150 square feet with a density of 0.10 GPM per square foot. The choice is to either overdesign or use smaller orifice sprinklers. We are not advocating reducing the end sprinkler pressure below 7 PSI just because a few areas of these curves won't work. t1 - 2- Mr. C. W. Schirmer May 7, 1974 Item 3 An of Factory Mutual's hydraulic curves assume an end sprinkler ~re of 5 PSI. I don't know if actual fire testing has been done at this pressure but as mentioned above we are not advocating the reduction of the end sprinkler pressure at this time. If some testing is done in this field we may want to consider it. Item 4 The 1974 Standard has been revised so 10 PSI no longer appears in Chapter 8. Item 5 The pressures at the top of the sprinkler riser were selected arbitrarily; however, the only case in which we used the minimum pressure allowed in Table 2-2.1 (A) is Class I with 5000 square feet operating. These various pressures were used in order to provide a slope to the curves. In my opinion this slope is as accurate as the #231 C curves and really makes more sense. We have used the calculated amount of water an ordinary hazard system will deliver in the center of the system to produce these curves. I would hate to see Table 2-2.1 (B) 1974 returned to subcommittee because I don't believe additional deliberation wOuld accomplish anyhing. The single point density and area recommendations from Factory Mutual's Loss Prevention Bulletin 3-26 rather well with these curves. Much better than the (November 1973) compare ,i.l 1973 N.F. P.A. ¡tV 1''14 i.~1 ,l."li. DÆ l.U,- Factory Mutual N.F. P.A. '74 N,F .P.A. '73 0.15 - 2500 0.133 - 2500 o . 155 - 2500 ;2,1.0 0.15 - 2500 o . 17 - 2500 0.215 - 2500 . v L,~ d 1 Group II ,/9.. 0.20 - 3000 o . 18 - 3000 0.25 - 3000 lJ9 tJPtt~1 VD~0 c,l. ;; Group I Food Processing Glass Products ; /2-" Group II :n MercantHes , l.Jo Textile Manufacturing lJ . Tire Manufacturing' , III As you can see, we are slightly lower for Groups I and III but higher for Group II. N.F. P.A. 1973 is higher on all three Groups. I know the F .0. C. water supplies are considered too light by many, but they require a density of 5 mm per minute (0.12 GPM per square foot) regardless of whether the hazard is Ordinary I, II, III or III Special. They increase the area of appl ication as follows: I - 775 square feet, II - 1550 square feet, III - 2324 square feet, and III Special - 3874 square feet. Our proposed curves exceed their requirements in all cases. .3øii Mr. C. W. Schirmer - 3- May 7, 1974 The new #231 limits the discharge per sprinkler to 15 GPM for any class or 0.15 GPM per square foot density since the maximum spacing allowed is 100 square feet. If the 60% rule is applied for storage under 12 feet high the densities CNer 2000 square feet of area of application become 0.13 GPM per square foot for Class I, 0.14 GPM per square foot for Class II, 0.17 GPM per square foot for Class III, and 0.23 GPM per square foot for Class iV. With the exception of Class iv, these all fall within the proposed curves. In summary, I feel that if ordinary hazard pipe schedule systems have been performing satisfactorily, then systems properly calculated using the proposed curves wil do just as well. I do think we win have to be careful in describing the hydraulically most remote area in Chapter 7. We don't want systems to be throttled down to the point where they won't perform as intended. I have no doubt that this can be accomplished satisfactorily. If you have any questions, please cal l. I intend to bring 8~" x 11 II mylar sheets to Miami should we have to defend the curves. These sheets work very wen on an overhead projector. . Yours very truly, THE VIKING CORPORATION ~ Q.. uu -L /d" Jack A. Wood, P. E. Vice President jb Attachment PS - We used 120 square feet coverage per sprinkler in developing the proposed curves instead of the allowale 130 square feet. This provides another factor of safety. . -",.. . . ,- I I . 114 ,42 42 ;2 2 2 2 2 --/dL '. 2 11£ i// '. I / ~ TYI' II , SF?t:710N 1 , ?- ;. 't .' - g COtJ~IPJFI?g=.D" III~rE.I/) oP e.:/ 't -- CL'pEB&Dr.(/.LÑ¡;/1 _BELLG¡__L!Clff--ttr.€- '' --,----- '_.Aljl:--._.....--..._---,. ~. i~ . .f "T N07c~: .f. /3'1( 10'.. /20 ~.rTJHEI1D ? 1;1' ~R/'. wITrlJ(= :5iE5 3. c ~ /20. 4. ó)):J. H//%. PIP.Æ ~HG:lj¿ß. . E't:Gp;r 3Yz" /?ep/JaP 6/ . .4" ,:/:td. 6. 400" 5p//K.'. o¡J. 6.ý~irIY.;' h ~_.- - II ,.E/Ø c,,~ t; TcP of Æ'~. :ZlJi:l.Ui:)(~.s ¿;l.,ßD/I 5V¡7I7ARY Or l?t:50i.7"S: ope,t /1 J' /le; /50o~q.r;"(/3 SP/f)(s) /¡.£$5()11~.P¿=N~IT)' PIfF.#t. qpn¡ 1~6'l ,176.4 i~ ?J/ .c:.083. App,,/( 11 t;/i ßo P~J 4-5 PJJ eõo P$/ '75 p;si o.jL'L ..3..AL. g,i:kll. _.i§.i--. .ò,.I14 ,dJÙß., .odzL 59.. '10 :J.?4~~L _4..J.!4. .74..!1 '??M~ /tliiM 3000 .:a.rr(¿s .:P..K5) $J"'AI~/rl PI?..~Stl~ ~PP1 ...0:7- /4:.ø.t3D?.!! .Qê£. o.l.!O. .af2~- p",,~,,N .le~st/.e a;¡pm. -- ei../§ . .4~.I. .0.,otó2 .,Q.. ~ÃA6.~.' .0..120 ?9AQ ~~7..'L .544:.2. a.Q. .__.._,-- 52../:.2. .4'Z4:i o-" I;J:? iECJ.23 n ".-. '- ~_. 45.,1211. 4.JJZL' . Z-'22 .~ 6000 :JG:",r( 4¿:,'.1P''I($.) .Z£7. c:. ,_~3..14. ..~----~ .7'ZL .... .'Z4!¿ Q.--(4L 75.20 /.t£6/1- .:" .. ," I I i 1/4 tk /k .2 --/z!l. 2 2 Z. 2 2 IZe ilk t?+ I . I , . '" ?- . " 't TVP. C\ __o.PE/iATÜVt?_.~ . 11 S¡:~7101Ý .2 't -L-.;~0: ~r 't . . ~Z:Hë._. 5)'.ST£LK.-.--,..... ,. . ---- , CO¡J:$JPE,qpP ,. IN::TE//P () !$jr tt~. .~~ . .f -r f ~e:IM,.¡¡JG AI2€.4. , NOTê5: /. ¡¿"1( 10':: 120 ~.rTJ .I,¡/1D ? j2' ~PR/'. J.VlTH I(=:s 1$5 .3. c:: /¿O. A. OÆP. H4Z. PIP¿: ~1(G.1)))¿¿, E")C$PT p~" /?PP¿ga. ßj . A" .:IZP" s. '400 .5PÆJ(!. o;J ~Y$71'", . ~ --E/u' c/l~ (j TcP oF' K.l$$. F#eei.oe-;. Et.~CJt.U 50/111/1/(Y - O¡= I?ESOITS: ope/?,4T//'q IIKe.4 AveF?114ß /500 ~q.rr (/3 51'/7/(S) PiFN:$lrf 1'1?¡f#()ß¿ IS f?J/ o.o8i1 M.SZ 182.5. aoP~1 Q.IZ.L.. Z2.82_' . ZG.£.Z: ~... .. _.. ~o PSI o.lk.Q. 4Æ-ZiL .331LO.. l).I.85.. 5'1.82. 38(¿.t; 75 PJI ....~LD. 45 PSI 75.61. .5000 ;jG:~'( -+eSP,RK$) 3000 :s~.p (£5 ~.PAK5) Ph'Fß(/ ql'l1 42'1:!. ZJe/ý~/Tl 0..0.83 .14. (Pi1. .g£.4.fi - ...I?~ ::o. 25. - ._-~L6z. .D..!.-£ 44ßl).t64~8. _o_~ !8.Q° "ZQ-- p¿I/$/n' 4:e~sdA'£ PIiPS$tJr t:PP/ .-G?l~ l)./£ . .z.4£ ..74,13 -_&LG : t:PH/. ..0,C?13/. J4.G5 .574.0 .0.../9 x; 71. .. 8_~i.o. .o.L4.'L ..A!1".95..~--_..-- ./Q4ß.! aJJ.2- -59.20. 1lß6./. O.I!læ. 74.5"=?- /32.lJ.