Grippers 2-finger parallel gripper KGG

advertisement

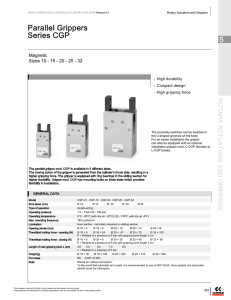

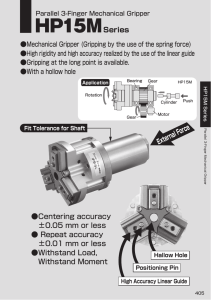

Grippers 2-finger parallel gripper KGG Description Operating principle Double piston drive, synchronized movement. Material The housing is made of a high-tensile, hard coated aluminium alloy. Functional components are made of hardened steel. Benefits: ·· long stroke 30 mm ·· compact and light design ·· light weight ·· high reliability and long service life ·· robust T-groove guide ·· suitable for inside and outside gripping ·· multiple mounting options Type Order numbers 2-finger parallel gripper KGG 80 050.012 2-finger parallel gripper KGG 80 incl. 2 sensors (inductive proximity switch INW 5/S shutter) 050.030 2-finger parallel gripper KGG 80 incl. mounting kit to monitor 3 positions with flexible position sensor AS-KGG 80 050.031 2-finger parallel gripper KGG 80 incl. mounting kit to monitor 3 positions with flexible position sensor AS-KGG 80 050.032 Technical data KGG 80 Stroke per finger 15 mm Gripping force at 6 bar* 88 N Opening/closing time 0.045 s / 0.060 s Repeat accuracy** 0.05 mm Max. finger length 70 mm Air connection M5 Operating pressure 2.5...8 bar Quality of compressed air filtered (10 µm) dry or lubricated Temperature range 5°C...60°C Fastening screw thread M4 / 5.5 deep Weight 0.25 kg *1 Gripping force is the arithmetic sum of the individual forces occurring at the gripping jaws at distance „P“ at 6 bar. *2 Spread of end positions at 100 consecutive swivel cycles. Maximum admissible forces and moments Gripping force diagram Maximum admissible forces and moments at the gripping fingers which might occur in addition to the gripping force Gripping force depended on length L at 6 bar 160 140 L max. gripping inside gripping force in N 120 Mz Mx 100 My Fa 80 60 gripping outside 40 20 Type L max. Fa Mx My Mz KGG 80 70 mm 200 N 5 Nm 6 Nm 1.75 Nm 08/2010 0 0 10 20 30 40 50 60 70 80 90 length of gripping finger (L) in mm 71 Suggestion for connection dimensions of gripper fingers compressed air connection proximity switch INW 5/S 12 10.3 + 0.05 – 0.05 20.6 6 .5 5 R2 thread ±0.1 Y M4 5.5 deep (2x) Ø 6 H7 2.5 deep (2x) 32 ± 0.02 0.8 6 6 5 17 21 + 0.02 0 fitting range M4 through (2x) 3 34 46 3 20 24 0 -0.1 51.5 0 41.5 -0.2 hole for lateral mounting with screw M 3 x 30 mm (accessories) 26 52 x) proximity switch 9.5 (2 10.5 12 P 4.3 15 ° 21– 00.05 80 64 46 Ø thread ±0.1 21.5 16 ± 0.02 26 M4, 6 deep (2x) 34 36 6 H7 3 2.7 14 26 M3 »Closed« 19 5.4 90 tubeless direct connection M3 »Open« 26 centering sleeve (accessories) 52 Tubeless direct mounting 0.5 gripper 38.5 31 Optional mounting kit AS-KGG 80 with flexible position sensor FPS The mounting kit includes: ·· flexible position sensor FPS to monitor up to 5 positions 27 5 12.5 29.1 6 7 8.2 25.5 40.3 O-ring Ø 3 x 1 M3 Ø 3 Ø 5 adapter 13.1 39.1 mounting kit for flexible positioning sensor Note · To maintain the mechanical gripping force, a 5/3-way valve with blocked middle position is to be used preferably. · Please note that the service life of the gripper can be reduced considerably if you use it in extreme conditions (e.g. where coolant is used or dust from casting or grinding processes are present). We cannot be held responsible in these cases. However, in most cases we can offer a solution; please contact us. 72 08/2010

![Electrical Safety[]](http://s2.studylib.net/store/data/005402709_1-78da758a33a77d446a45dc5dd76faacd-300x300.png)