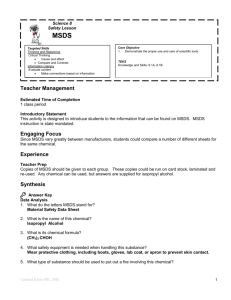

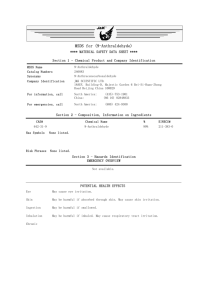

Chapter 5 - The Material Safety Data Sheet

advertisement