pdf - Civil Aviation Safety Authority

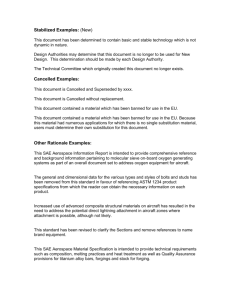

advertisement