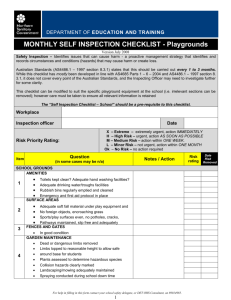

Appendix A - Building & Construction Authority

advertisement

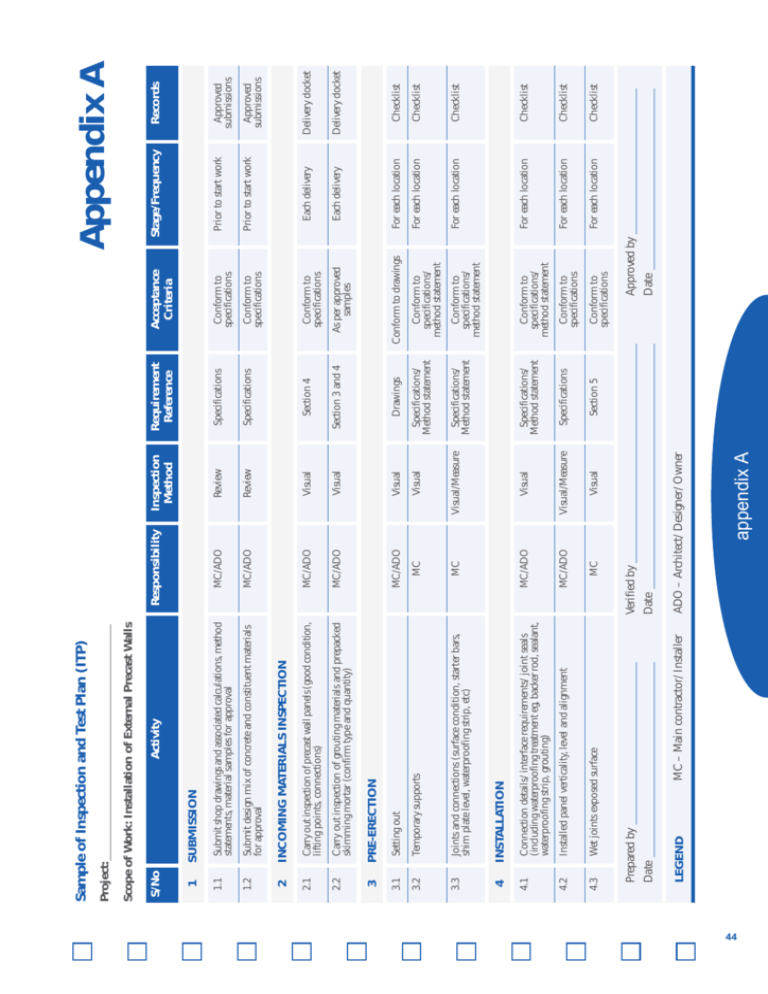

44 Joints and connections (surface condition, starter bars, shim plate level, waterproofing strip, etc) 3.3 appendix A ADO – Architect/ Designer/ Owner MC – Main contractor/ Installer LEGEND Visual Date MC Visual/Measure Date Wet joints exposed surface 4.3 MC/ADO Visual Visual/Measure Visual Visual Visual Visual Review Review Inspection Method Verified by Installed panel verticality, level and alignment 4.2 MC/ADO MC MC MC/ADO MC/ADO MC/ADO MC/ADO MC/ADO Responsibility Prepared by Connection details/ interface requirements/ joint seals (including waterproofing treatment eg, backer rod, sealant, waterproofing strip, grouting) 4.1 INSTALLATION Temporary supports 3.2 4 Setting out 3.1 PRE-ERECTION Carry out inspection of grouting materials and prepacked skimming mortar (confirm type and quantity) 2.2 3 Carry out inspection of precast wall panels (good condition, lifting points, connections) 2.1 INCOMING MATERIALS INSPECTION Submit design mix of concrete and constituent materials for approval 1.2 2 Submit shop drawings and associated calculations, method statements, material samples for approval SUBMISSION Activity 1.1 1 S/No Scope of Work: Installation of External Precast Walls Project: Sample of Inspection and Test Plan (ITP) Section 5 Specifications Specifications/ Method statement Specifications/ Method statement Specifications/ Method statement Drawings Section 3 and 4 Section 4 Specifications Specifications Requirement Reference Date For each location For each location For each location For each location For each location For each location Each delivery Each delivery Prior to start work Prior to start work Stage/Frequency Approved by Conform to specifications Conform to specifications Conform to specifications/ method statement Conform to specifications/ method statement Conform to specifications/ method statement Conform to drawings As per approved samples Conform to specifications Conform to specifications Conform to specifications Acceptance Criteria Checklist Checklist Checklist Checklist Checklist Checklist Delivery docket Delivery docket Approved submissions Approved submissions Records Appendix A 45 ADO – Architect/ Designer/ Owner LEGEND MC – Main contractor/ Installer Date Visual Date MC/ADO Visual Visual Visual Visual Visual Inspection Method Verified by Carry out watertightness test on - External wall panels - Joints between external wall and window frame 7.2 MC/ADO MC/ADO MC/ADO MC/ADO MC Responsibility Prepared by Check for any cracks on finished surface 7.1 FINAL INSPECTION Check application of skim coat (finished surface for evenness, squareness and plumb). All rectification works should be completed before painting works. 6.2 7 Skimming mortar mixing 6.1 APPLICATION OF SKIM COAT Check preparation of substrate to receive finishing, including M&E services 5.2 6 Hand over precast works to finishing works, including clearance from other trades PREPARATION FOR SKIMMING Activity 5.1 5 S/No Scope of Work: Installation of External Precast Walls Project: Sample of Inspection and Test Plan (cont’d) appendix A Section 6 Specifications Section 5 Section 5 Section 5 Section 5 Requirement Reference Date As per required Per location For each location In process For each location For each location Stage/Frequency Approved by - No dampness - No leakage Conform to specifications Conform to specifications/ method statement Conform to specifications/ method statement Conform to specifications/ method statement Conform to specifications Acceptance Criteria Test records Checklist Checklist Checklist Checklist Checklist Records Appendix A 46 Carry out concrete receiving inspection (check slump & concrete cube sampling) Carry out inspection of prepacked mortar mixes for finishing works (confirm type and quantity). - For on-site mixing of cement/sand, inspect plastering sand (silt content), cement and admixtures 2.3 2.4 LEGEND MC – Main contractor/ Contractor Visual Visual Visual Visual Visual Visual/Measure Visual/Measure Visual Visual Review Review Inspection Method appendix A ADO – Architect/ Designer/ Owner Date MC Date Seal form tie holes and repair joints/cracks 4.3 MC/ADO Verified by Concrete strength (analysis of cube test results) 4.2 MC Prepared by Post-pour inspection (formwork stripping, finished concrete surface, verticality, concrete curing) 4.1 MC MC/ADO MC/ADO MC MC/ADO MC/ADO MC/ADO MC/ADO Responsibility INSPECTION OF CAST IN-SITU CONCRETE WALL Monitor concrete placement (confirm that vibration, spread, discharge rate complies with specs, monitor delivery interval, waste & cumulative quantity) 3.2 4 Carry out inspection prior to closing formwork 3.1 PREPARATION AND CONCRETING Carry out inspection of grouting materials for form tie holes and joint repair 2.2 3 Carry out inspection of rebar 2.1 INCOMING MATERIALS INSPECTION Submit shop drawings and method statements for approval 1.2 2 Submit design mix of concrete and constituent materials for approval SUBMISSION Activity 1.1 1 S/No Scope of Work: External Cast In-Situ Reinforced Concrete Walls Project: Sample of Inspection and Test Plan (ITP) Drawings Drawings Drawings Specifications/ Method statement Drawings Section 3 and 4 Approved design mix Specifications Mill Certs Specifications Specifications Requirement Reference Prior to wall finishing Date After casting/ Every storey After casting/ Every storey Every casting For each casting area One sample per delivery Each delivery Each truck load Each delivery Each delivery Prior to start work Prior to start work Stage/Frequency Approved by Method statement Specifications Specifications/ Method statement Conform to specifications/ method statement Conform to drawings As per approved samples Silt content of plastering sand ≤ 5% by mass Conform to specifications As per approved samples Mill Certs Conform to specifications Conform to specifications Acceptance Criteria Checklist Test records Checklist Checklist Checklist Delivery docket and Test records Delivery docket Delivery docket Delivery docket Approved submission Approved submission Records Appendix A 47 LEGEND MC – Main contractor/ Contractor Visual Measure Visual Visual Visual Visual Visual/ Measure Inspection Method ADO – Architect/ Designer/ Owner Date MC/ADO Date Carry out watertightness test on - External wall panels - Joints between external wall and window frame 7.3 MC/ADO Verified by For plastered surfaces, carry out pull-out test on completed plasterwork and check for hollowness 7.2 MC/ADO MC/ADO MC/ADO Prepared by Check for any cracks on finished surface 7.1 FINAL INSPECTION Check application of skim coat (or plastering, if required). For plastering, check undercoat (scratched and sufficiently cured), second and final coat. Inspect finished surface for evenness, squareness, plumb and hollowness (for plastered surface). All rectification works should be completed before painting works. 6.2 7 Cement mortar mixing 6.1 MC/ADO MC/ADO Responsibility FINISHING WORKS (IN-PROCESS INSPECTION) Check preparation of substrate to receive finishing - If plastering is required, check application of spatterdash coat, setting out and level packs, angle beads, groove line, etc 5.2 6 Hand over RC works to finishing works - Check verticality/horizontality of off-form RC surface and decide thickness of plaster/skim coat - Check clearance from other trades PREPARATION FOR FINISHING WORKS Activity 5.1 5 S/No Scope of Work: External Cast In-Situ Reinforced Concrete Walls Project: Sample of Inspection and Test Plan (cont’d) appendix A Section 6 Section 6 Section 5 Section 5 Section 5 Section 5 Section 5 Requirement Reference Date As per required As per required Per location Per location In process Per location Per location Stage/Frequency Approved by - No dampness - No leakage Conform to specifications Conform to specifications Conform to specifications/ method statement Conform to specifications/ method statement Conform to specifications/ method statement Conform to specifications/drawings Acceptance Criteria Test records Test records Checklist Checklist Checklist Checklist Checklist Records Appendix A 48 Carry out inspection of prepacked mortar mixes for plastering (confirm type and quantity) - For on-site mixing of cement/sand, inspect plastering sand (silt content), cement and admixtures 2.3 Build remaining brickwalls to 1/2 height and then full height 3.4 LEGEND MC – Main contractor/ Contractor Visual Visual Visual Visual Visual Visual/ Measure Visual Visual Review Inspection Method appendix A ADO – Architect/ Designer/ Owner Date Date MC/ADO Verified by Carry out inspection of completed brickwork - proper packing up of all gaps above last course of bricks - Opening for door/window/other services Prepared by 4.1 INSPECTION OF BRICKWORK MC/ADO Check completed 1st course brickwall 3.3 4 MC/ADO Cement mortar mixing 3.2 MC/ADO Structural clearance and setting out MC/ADO MC/ADO MC MC MC/ADO Responsibility 3.1 PREPARATION AND INSTALLATION Carry out inspection of jointing materials (bonding bars, lintels, etc) and damp-proof materials 2.2 3 Carry out inspection of brick, sand & cement for brickwork (confirm grade, type & quantity) INCOMING MATERIALS INSPECTION Submit material samples, shop drawings, method statements for approval SUBMISSION Activity 2.1 2 1.1 1 S/No Scope of Work: External Brickwalls Project: Sample of Inspection and Test Plan (ITP) Section 5 Section 5 Section 5 Section 5 Section 5 Section 3 and 4 Section 4 Section 4 Specifications/ drawings Requirement Reference Date Per unit Per unit Per unit Per unit/ Prior to start work In process One sample per delivery Each delivery Each delivery Each delivery Prior to start work/ each sample Stage/Frequency Approved by Conform to shop drawings Conform to shop drawings Conform to method statement Conform to shop drawings/ method statement Conform to shop drawings/ method statement As per approved sample Silt content of plastering sand ≤ 5% by mass As per approved sample As per approved sample Conform to specifications/drawings Acceptance Criteria Checklist Checklist Checklist Checklist Checklist Delivery dockets and Test Register Delivery dockets Delivery dockets Approved submissions Records Appendix A 49 Check preparation of brick substrate to receive plastering. Check setting out and level packs, angle beads, metal lath, groove line, movement joints, etc 5.2 LEGEND MC – Main contractor/ Contractor Visual Measure Visual Visual Visual Visual Visual Inspection Method ADO – Architect/ Designer/ Owner Date MC/ADO Date Carry out watertightness test on - External wall panels - Joints between external wall and window frame 7.3 MC/ADO Verified by Carry out pull-out test on completed plasterwork and check for hollowness 7.2 MC/ADO MC/ADO MC/ADO Prepared by Check for any cracks on finished surface 7.1 FINAL INSPECTION Check application of undercoat (scratched and sufficiently cured), second and final coat. Inspect finished surface for evenness, squareness, plumb and hollowness. All rectification works should be completed before painting works. 6.2 7 Cement mortar mixing 6.1 MC/ADO MC Responsibility PLASTERING WORKS (IN-PROCESS INSPECTION) Hand over areas from brickworks to plastering works including clearance from other trades 5.1 6 PREPARATION FOR PLASTERING WORK Activity 5 S/No Scope of Work: External Brickwalls Project: Sample of Inspection and Test Plan (cont’d) appendix A Section 6 Section 6 Section 5 Section 5 Section 5 Section 5 Section 5 Requirement Reference Date As per required As per required Per location Per location In process Per location Per location Stage/Frequency Approved by - No dampness - No leakage Conform to specifications Conform to specifications Conform to specifications/method statement Conform to specifications/method statement Conform to specifications/method statement Conform to specifications/drawings Acceptance Criteria Test records Test records Checklist Checklist Checklist Checklist Checklist Records Appendix A Appendix B Sample Checklist for Installation of External Precast Walls Project: Location: Inspection Checklist Date Result ✓/✗ Remarks Signature RECEIVING INSPECTION Dimensions (within tolerance) Overall conditions - No chipped/ cracked sections - Flatness - Cleanliness Lifting points/inserts (position, physical condition) Sleeve system/connections - Starter bars (length, size, spacing) - Loop and lapping bars (length, size) - Corrugated sleeve (position, cleanliness) M&E services present, if any (position, physical condition) Gridline position (setting out lines and level) Temporary supports (adequate propping bracing) Surface condition of joint (cleanliness from dust, debris) Starter bars from lower floor (number, spacing, size, length) Shim plate level Backer Rod / Waterproofing strip position Standby grout materials INSTALLATION OF PRECAST WALLS appendix B CHECKS PRIOR TO HOISTING Connection details (including proper grouting at horizontal joints) Interface requirements/ loop bars/continuity bars/backer rod/formwork Verticality of installed panel Alignment between panels Level of installed panel Joint and seal Wet joints exposed surface PREPARATION FOR SKIMMING Clearance from precast works (including other related trades) Wash surface thoroughly with high pressure water jet Check cleanliness and dampening of substrate APPLICATION OF SKIM COAT Mixing of skimming mortar (mixing proportion, use of mechanical mixer, consistency of mix) Application of skim coat (thickness, evenness, curing) FINAL INSPECTION Surface condition/evenness No visible cracks or damages Watertightness Test (no leakage or dampness) - External wall panels - Joints between external wall and window frame 50 Appendix B Sample Checklist for Construction of External Cast In-Situ Reinforced Concrete Walls Project: Location: Inspection Checklist Date PREPARATION M&E SERVICES appendix B REBAR FORMWORK Setting out / level Formwork condition Dimension Alignment and plumb Bracing and strutting Service opening, etc Construction joint No. of rebars Rebar size (diameter) Rebar cover Position and spacing Anchorage / lap length Links / stirrups / starter bars Rebar condition Installation Secured properly Bent properly No visual damage Check quality of concrete before placing e.g. water-cement ratio, slump test, etc. CONCRETING STAGE Concrete placing (ensure thorough compaction) INSPECTION (FINISHED CONCRETE) Dimension Alignment / plumb / level Exposed surface Concrete joints Sealing of form tie holes PREPARATION FOR FINISHING WORK Clearance from RC works (including rectification of RC alignment, brickworks and other related trades) Wash surface thoroughly with high pressure water jet FINISHING WORKS (IN-PROCESS) Application of skim coat For plastered RC walls, check: - setting out - application of spatterdash coat - reinforcement lathing (where applicable) - application and thickness of undercoat (compactness and scratched), second and final coat, including proper surface preparation and adequate curing for every coat 51 Result ✓/✗ Remarks Signature Appendix B Sample Checklist for Construction of External Cast In-Situ Reinforced Concrete Walls (cont’d) Project: Location: Inspection Checklist Date Result ✓/✗ Remarks Signature FINAL INSPECTION OF FINISHING appendix B Plumb Straightness of corners/joints Surface condition/evenness No visible cracks or damages No hollowness and good adhesion of plaster on RC walls Watertightness Test (no leakage or dampness) - External wall panels - Joints between external wall and window frame 52 Appendix B Sample Checklist for Construction of Plastered Brickwalls Project: Location: Inspection Checklist Date PREPARATION Condition of brick units (no physical damage) RC surface receiving bricks Moisten bricks Structural clearance and set reference lines Mixing of bedding mortar and mixing proportion appendix B FIRST COURSE Type of bricks Type of bond Wall thickness Brick joint width First course setting out Provision of stiffener ERECTION OF BRICKWALL Damp-proof course (if any) Bonding bars Reinforcement lathing Joint width Lintels Laid in two operations in half heights Gap between top course of brickwork and beam soffit properly grouted INSPECTION OF COMPLETED BRICKWORK Surface and edge are plain and vertical No cracked and chipped bricks Joints properly filled with mortar PREPARATION FOR PLASTERING WORK Clearance from brickwork and other related trades Wash surface by high pressure water jet (loose particles, organic growth etc, removed thoroughly) Check: - setting out / level pack - cleanliness and dampening of substrate - Angle beads, groove line, etc - reinforcement lathing (where applicable) PLASTERING WORK (IN-PROCESS) Plastering mortar (Mixing proportion, use of mechanical mixer, consistency of mix) Application and thickness of undercoat (compactness and scratched), second and final coat, including proper surface preparation and adequate curing for every coat 53 Result ✓/✗ Remarks Signature Appendix B Sample Checklist for Construction of Plastered Brickwalls (cont’d) Project: Location: Inspection Checklist Date Result ✓/✗ Remarks Signature FINAL INSPECTION appendix B Plumb Straightness of corners/joints Surface condition/eveness No visible cracks or damages No hollowness Good Adhesion Watertightness Test (no leakage or dampness) - External wall panels - Joints between external wall and window frame 54