Recrystallization Preparation/Recrystallization of Acetanilide CHM

advertisement

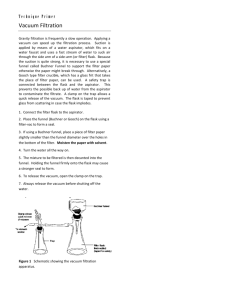

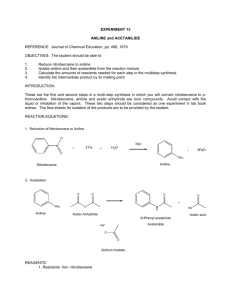

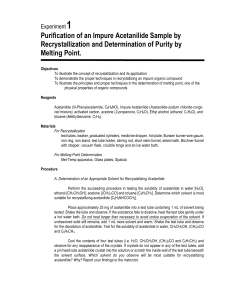

Recrystallization Preparation/Recrystallization of Acetanilide CHM 2201 (September 4 – 10, 2007) From Bell, Clark and Taber, pgs 30, 31 NHCOCH3 NH2 + Aniline H2O + (CH3CO)2O Acetic acid Acetic anhydride MW = 102.09 d = 1.08 g/mL 7 drops = ~220 µL 220 µL = ____ g = _____mole MW = 93.13 d = 1.02 g/mL 125 µL = ____g = ____mole CH3CO2H Acetanilide MW = 135.16 Theorteical Yield: _________ g Actual Yield: _______ g (___ %) Conduct this Experiment in your hood. Aniline is toxic and acetic anhydride is an irritant to the eyes and nasal membranes. 1. Have a TA place 125 !L of aniline into a dry 13 x 100-mm test tube. 2. Add 2 mL of water to the test tube containing the aniline. 3. Add 7 drops (~220 !L) of acetic anhydride to the test tube and stir the resulting mixture with a glass rod until a solid (the acetanilide product) forms. 4. Add 4 mL of water to the test tube containing the solid and heat the test tube in a hot water bath with occasional stirring until the solid dissolves. 5. Allow the test tube to cool for 5 minutes and then place it in an ice bath for 5 – 10 minutes to thoroughly cool the mixture and to complete the crystallization. 6. Use a glass stirring rod to break up any lumps of crystals that have formed during the crystallization process and to ensure that the crystals are evenly suspended in the water. 7. Set up a vacuum filtration apparatus using your small Hirsch funnel, a 50 mL filter flask, and a rubber adapter (place the funnel in this adapter which is fitted on top of the filter flask). To prevent the filter flask from tipping over, clamp it to a bar in your hood. 8. Using a vacuum hose (use the black thick-walled hose), connect the filter flask side arm to the house vacuum outlet in your hood. 9. Place a small filter paper on the Hirsch funnel (be sure all the funnel perforations are covered by the filter paper) and moisten the filter paper with a few drops of water. 10. Turn on the house vacuum and then pour the contents of the cold test tube onto the funnel. 11. Add a small quantity of ice cold water to the test tube and swirl or scrape loose the solids remaining in the tube and rinse the resulting suspension into the funnel. 12. Leave the vacuum on and allow air to draw through the collected solids on the funnel for ~10 - 15 minutes to remove as much water as possible from the solids. (continued) 13. While air is being drawn through the solid, use a spatula to carefully break up the solid cake of crystals to facilitate air drying. Be careful not to tear the filter paper during this scraping/breaking process. 14. When the solid appears to be dry and free flowing, use a spatula to remove the solids to weigh the dried material. If the weight of your product is MORE than the calculated theoretical yield, the acetanilide is still wet and requires additional drying 15. Determine the melting point of your material for comparison with the literature value and calculate the actual yield of your product. If you are running out of time and your acetanilide appears to still be not completely dry, place the material on a covered watch glass and allow it to dry for a week in your drawer. At the next class, weigh the dry product, determine its melting point and calculate the per cent yield of product. You must hand in this experiment for grading before you leave next weeks class. TMB 8/31/07