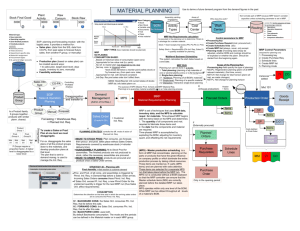

MANUFACTURING EXECUTION

advertisement

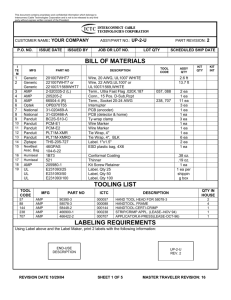

MANUFACTURING EXECUTION Finished Goods stock Plant Activity 10000 10000 2 2 Raw Consumption 5000 Cost Elem ent Assembly painting engineering Areas of responsibilities Who does the work? Activity Types Cost Center Work Center Raw Stock 5000 1 Routing contain the list the sequence of steps for producing a material, that is: Operations, Operation Sequences Usage Time elements Work Centers. Component allocations Basic data Default values Cost center Capacities Scheduling HR assignment 1 BOM FI Variances settled Material Sales Info Syst Controlling Profitable Analisys CO-PA SOP Product Group Sales & Operation Planning Product Group Disaggregation and transfer to Availability Check: Checks for: MD04: Stock/Req.list: info current status of stocks MRP list: info latest plann run Demand Management (from Rout+BOM or manually) E (inhouse production) MRP MPS (Admin of Ind Req.) ` Material Requirements Planning Planned Orders Sales Order (Created in SD) Items = Customer Ind. Req. F (Externally procured) Order Creation Options: Without BOM – Routing With BOM – Routing With Routing With Planned Order Planned Orders Purchase Requisition Release If a BOM is changed after a Pln Order is created but before is converted into a Prod. Order: BOM is not re-read and the Prod. Order uses the old BOM Items Manual Forecast Forcasting = Warehouse Req. = Planned Ind. Req. -Material components -Capacities -PRT’s Header + Items Schedule Lines Purchase Order Only in the opening period Elements of a Prod. Order: Order Header Settlement rule Costs Operations Operation sequences Material components PRTs Trigger points Documents links CO Releasing orders: levels _Individual operation _Whole order _Several orders together 2 Mvt 101 Goods Receipt Production Order 1 OP Items OP C.O.T Items Costs debited to Prod.Order Cost Object Controlling (COC): Order settlement: _Debits the stock account _Credits the order Order related .flexible production environment .flexible product range .Cost mgt of ind. production lots .if controlling is required for each order .High setup costs .Manufacture o co-products Goods Issue Status Prod. Order: CRTD MM FI CO Product related Production Order: GI - Goods Issue Posting: Is executed for a consumption of a material component for a prod. order. List the application modules that integrate with Manufacturing Execution: Inventory Management Quality Management FI - Financial Accounting CO -Controlling SD - Sales and Distribution Order PS -Project Systems HCM -Human Capital Management MM - Material document: describe the g. movt. from the MM (stock) point of view. FI - Accounting document: describes the goods movt. from the FI point of view. CO - Cost accounting document: serve various cost analysis purposes _ Account affected: .Consumption is debited .Raw material Stock is credited . NON Finished goods stock, Plant activity Q + $ (value) in Material master data is updated Reservations is Reduced (for planned withdrawal) Determination of actual costs (evaluation) and update of order When you display the material document, you can branch to the other documents GI doc. can be printed. The GI posting is controlled via a movement type 261. Production Order: GR - Goods Receipt Posting Realizes the stock receipt of a product produced using a production order. MM - Material document: FI - Accounting document: CO - Cost accounting document: serve various cost analysis purposes _ Account affected: .Finished good stock is debited .Plant activity is credited . NON consump, raw mat. When you display the material document, you can branch to the other doc. GR doc. can be printed Delivery quantity in an order is Updated lant activity is Updated Evaluation of the receipt Credit to order The GR posting is controlled via a movement type 101.