Order Goods

advertisement

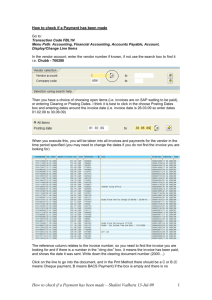

Three basic business activities in the expenditure cycle: 1. Ordering goods, supplies, and services 2. Receiving and storing goods, supplies, and services 3. Paying for goods, supplies, and services Order Goods Key decisions in this process involve identifying what, when, and how much to purchase and from whom. Weaknesses in inventory control can create significant problems with this process as demonstrated in the introductory Purchase Requests Whatever the inventory control system, the order processing typically begins with a purchase request followed by the generation of a purchase order. The purchase requisition is triggered by the inventory control function or an employee noticing a shortage. Advanced inventory control systems automatically initiate purchase requests when quantity falls below the reorder point. Generating Purchase Orders A crucial decision is the selection of supplier for inventory items. Several factors should be considered in making this decision: 1. Price 2. Quality of materials 3. Dependability in making deliveries Once a supplier has been selected for a product, their identity should become part of the product inventory master file. It’s important to track and periodically evaluate supplier performance. The purchasing function should be evaluated and rewarded based on how well it minimizes total costs, not just the costs of purchasing the goods. A purchase order (PO is a document or electronic form that formally requests a supplier to sell and deliver specified products at specified prices. The PO is both a contract and a promise to pay. Multiple purchase orders may be completed for one purchase requisition if multiple vendors will fill the request. A blanket purchase order is a commitment to buy specified items at specified prices from a particular supplier for a set time period. Improving Efficiency and Effectiveness The major cost driver is the number of purchase orders processed. Using EDI is one way to improve the purchasing process. EDI reduces costs by eliminating the clerical work associated with printing and mailing paper documents. The time between recognizing the need to reorder an item and subsequently receiving it also is reduced. Vendor-managed inventory programs provide another means of reducing purchase and inventory costs. Vendor-managed inventory essentially outsources much of the inventory control and purchasing. Suppliers are given access to point-of-sales and inventory data and are authorized to automatically replenish inventory. Reverse auctions provide another technique to reduce purchasing-related expenses. In reverse auctions, suppliers compete with one another to need demand at the lowest price. One other way to reduce purchasing-related costs is to conduct a pre-award audit, normally involving large purchases that involve bids. The internal auditor verifies the accuracy of the bids. Receiving and Storing Goods The Receiving Department accepts deliveries from suppliers. The Receiving Department normally reports to the Warehouse Manager, who reports to Vice President of Manufacturing. The Inventory Stores Department, which also reports to the Warehouse Manager, is responsible for the storage of the goods. The two major responsibilities of the receiving department are deciding whether to accept delivery (based on whether there is a valid purchase order) and verifying the quantity and quality of delivered goods. When goods arrive, a receiving clerk compares the PO number on the packing slip with the open PO file to verify the goods were ordered. The receiving clerk counts the goods and examines them for damage before routing to the warehouse or factory. Three possible exceptions to this process are 1. Receiving a quantity of goods different from the amount ordered 2. Receiving damaged goods 3. Receiving goods of inferior quality that fail inspection In all three cases, the purchasing department must resolve the situation with the supplier. Improve Efficiency and Effectiveness One way to improve the efficiency of the receiving process is to require suppliers to bar-code their products. Bar-coding enables receiving clerks to scan in the product number, description, and quantity of all items received, eliminating data errors. Radio frequency identification (RFID) tags are attached to each crate of goods and emit a signal that a receiving unit embedded in the gates near a company’s warehouse unit can read. EDI and satellite technology provide another way to improve the efficiency of inbound logistics. EDI advance shipping notices inform companies when products have been shipped. Finally, audits may identify opportunities to cut freight costs. For example, many companies have negotiated significant savings with specific carriers. Paying for Goods and Services There are two basic sub-processes involved in the payment process: 1. Approval of vendor invoices 2. Actual payment of the invoices Approve Vendor Invoices for Payment Approval of vendor invoices is done by the accounts payable department, which reports to the controller. The legal obligation to pay arises when goods are received; but most companies pay only after receiving and approving the invoice. This timing difference may necessitate adjusting entries at the end of a fiscal period. There are two basic approaches to processing vendor invoices: 1. Non-Voucher system—Each approved invoice is posted in the supplier’s records in accounts payable, filed, and is then stored in an open invoice file. When a check is written, the invoice is removed from the open invoice file, marked “paid” and then stored in a paid invoice file. 2. Voucher system—A disbursement voucher is also prepared which identifies the supplier, lists outstanding invoices, and net amount to be paid after discounts and allowances. The disbursement voucher effectively shows which accounts will be debited and credited, along with the account numbers. There are three advantages for using disbursement vouchers: 1. Several invoices may be paid at once (reducing number of checks). 2. Vouchers can be pre-numbered, which simplifies tracking all payables. 3. The voucher provides a record that a vendor invoice has been approved for payment and facilitates invoice approval separate from invoice payment. This makes it easier to schedule both activities to maximize efficiency. Accounting approves the invoice for payment by comparing the invoice to the purchase order and receiving report. A voucher package, which contains the approved invoice, and supporting purchase order and receiving report, is sent to the cashier. This voucher package authorizes issuance of a check or EFT to the supplier. Pay Approved Invoices The final activity in the expenditure cycle is the payment of approved invoices. The cashier reviews the voucher package, approves the payment, prepares the check for payment, and signs the check. Improving Efficiency and Effectiveness The accounts payable process, which matches vendor invoices to purchase orders and receiving reports, is a prime candidate for automation. Processing efficiency can be improved by: requiring suppliers to submit invoices by EDI and having the system automatically match invoices to purchase orders and receiving reports. Another option is to eliminate vendor invoices. This “invoiceless” approach is called evaluated receipt settlement (ERS). ERS replaces the traditional three-way matching process with a two-way match of the purchase order and receiving report. Procurement cards provide one way to eliminate the need for accounts payable to process many small noninventory invoices. A procurement card is a corporation credit card that employees can use only at designated suppliers to purchase specific kinds of items. Using corporate credit cards for travel expenses further reduces the number of invoices that need to be processed. Preparing careful short-term cash budgets is useful in taking advantage of early-payment discounts. For example, if the corporation purchased an item for $100,000 with the terms 2/10, n/30; the amount of the discount that could be realized by paying within ten days is $2,000. Even more important, if the corporation did not pay within the ten days, the 2 percent discount represents an annual interest rate of 18 percent (2% X 360/20). Finally, financial data electronic interchange (FEDI) can cut the costs associated with paying suppliers by eliminating the need to prepare and mail checks.