STAT3365 – Exercise 15

advertisement

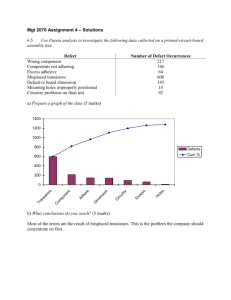

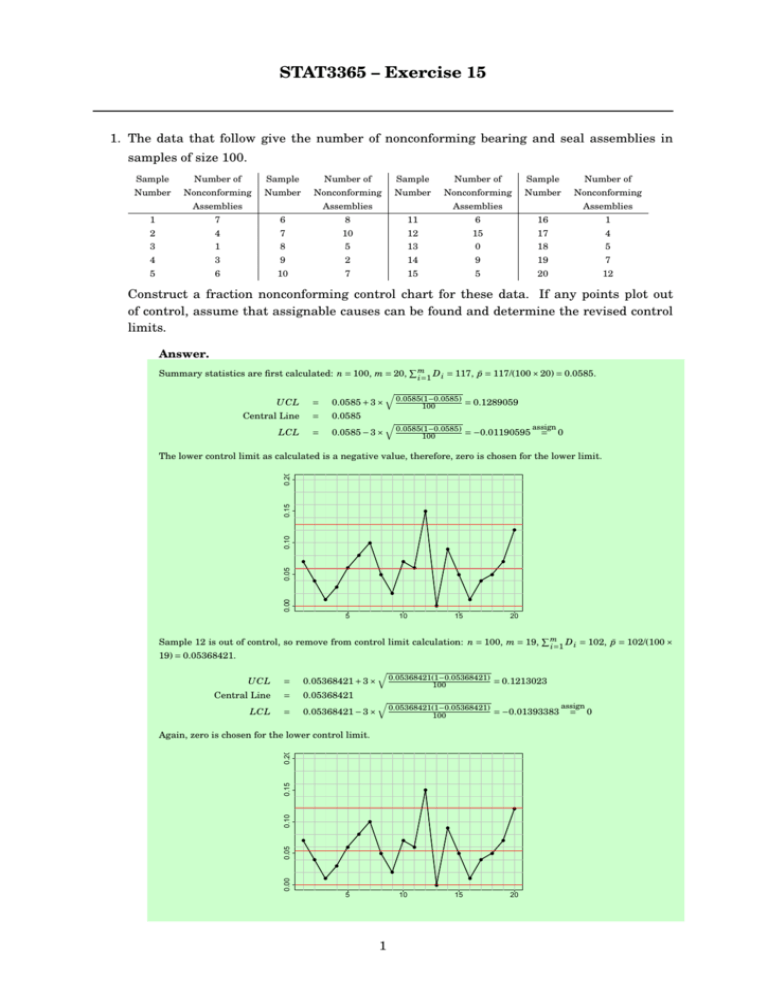

STAT3365 – Exercise 15 1. The data that follow give the number of nonconforming bearing and seal assemblies in samples of size 100. Sample Number of Sample Number of Sample Number of Sample Number of Number Nonconforming Number Nonconforming Number Nonconforming Number Nonconforming Assemblies Assemblies Assemblies Assemblies 1 7 6 8 11 6 16 1 2 4 7 10 12 15 17 4 3 1 8 5 13 0 18 5 4 3 9 2 14 9 19 7 5 6 10 7 15 5 20 12 Construct a fraction nonconforming control chart for these data. If any points plot out of control, assume that assignable causes can be found and determine the revised control limits. Answer. Summary statistics are first calculated: n = 100, m = 20, UCL = 0.0585 + 3 × Central Line = 0.0585 LCL = 0.0585 − 3 × Pm i =1 D i = 117, p̄ = 117/(100 × 20) = 0.0585. q 0.0585(1−0.0585) = 0.1289059 100 q assign 0.0585(1−0.0585) = −0.01190595 = 0 100 0.15 0.20 The lower control limit as calculated is a negative value, therefore, zero is chosen for the lower limit. ● 0.10 ● ● ● ● ● ● 0.05 ● ● ● ● ● ● ● ● ● ● 0.00 ● ● ● 5 10 15 20 Sample 12 is out of control, so remove from control limit calculation: n = 100, m = 19, Pm i =1 D i = 102, p̄ = 102/(100 × 19) = 0.05368421. UCL = 0.05368421 + 3 × Central Line = 0.05368421 LCL = 0.05368421 − 3 × q 0.05368421(1−0.05368421) = 0.1213023 100 q assign 0.05368421(1−0.05368421) = −0.01393383 = 0 100 0.15 0.20 Again, zero is chosen for the lower control limit. ● 0.10 ● ● ● ● 0.05 ● ● ● ● ● ● ● ● ● ● ● 0.00 ● ● ● ● 5 10 1 15 20 2. The following data represent the results of inspecting all units of a personal computer produced for the last 10 days. Day Units Nonconforming Fraction Inspected Number Nonconforming Day Units Nonconforming Fraction Inspected Number Nonconforming 1 80 4 0.050 2 110 7 0.064 6 120 6 0.050 7 70 4 3 90 5 0.057 0.056 8 125 5 4 75 0.040 8 0.107 9 105 8 5 130 0.076 6 0.038 10 95 7 0.074 Does the process appear to be in control? Answer. The summary statistics are m = 10, 1 3 4 5 6 7 8 9 10 i =1 n = 1000, Pm i =1 D i = 60, p̄ = 60/1000 = 0.06. LCL Sample Number 2 Pm UCL Central Line q −0.06) 0.06 − 3 × 0.06(180 q 0.06(1−0.06) 0.06 − 3 × 110 q −0.06) 0.06 − 3 × 0.06(190 q 0.06(1−0.06) 0.06 − 3 × 75 q −0.06) 0.06 − 3 × 0.06(1 130 q 0.06(1−0.06) 0.06 − 3 × 120 q −0.06) 0.06 − 3 × 0.06(170 q −0.06) 0.06 − 3 × 0.06(1 125 q 0.06(1−0.06) 0.06 − 3 × 105 q −0.06) 0.06 − 3 × 0.06(195 = 0.1396555 0.06 = 0.1279304 0.06 = 0.1350999 0.06 = 0.1422679 0.06 = 0.1224869 0.06 = 0.1250385 0.06 = 0.1451553 0.06 = 0.1237244 0.06 = 0.1295290 0.06 = 0.1330969 0.06 q −0.06) 0.06 + 3 × 0.06(180 q 0.06(1−0.06) 0.06 + 3 × 110 q −0.06) 0.06 + 3 × 0.06(190 q 0.06(1−0.06) 0.06 + 3 × 75 q −0.06) 0.06 + 3 × 0.06(1 130 q 0.06(1−0.06) 0.06 + 3 × 120 q −0.06) 0.06 + 3 × 0.06(170 q −0.06) 0.06 + 3 × 0.06(1 125 q 0.06(1−0.06) 0.06 + 3 × 105 q −0.06) 0.06 + 3 × 0.06(195 = −0.019655508 ⇒ 0 = −0.007930446 ⇒ 0 = −0.015099933 ⇒ 0 = −0.022267855 ⇒ 0 = −0.002486922 ⇒ 0 = −0.005038450 ⇒ 0 = −0.025155320 ⇒ 0 = −0.003724407 ⇒ 0 = −0.009529028 ⇒ 0 = −0.013096908 ⇒ 0 0.15 Here is the p-chart 0.10 ● ● ● ● ● ● ● ● ● 0.00 0.05 ● 2 4 6 8 10 The process appears to be in statistical control. 3. A control chart indicates that the current process fraction nonconforming in 0.02. If 50 item are inspected each day, what is the probability of detecting a shift in the fraction nonconforming to 0.04 on the first day after the shift? By the end of the fifth day following the shift? Answer. Given that p̄ = 0.02 and n = 50, we compute the control limits, UCL = 0.02 + 3 × Central Line = 0.02 LCL = 0.02 − 3 × q 0.02(1−0.02) = 0.07939697 50 q 0.02(1−0.02) = −0.03939697 ⇒ 0 50 Since p new = 0.04 < 0.1 and n = 50 is large, we use the Normal approximation to the binomial with mean p new = 0.04 and variance p new (1 − p new )/ n = 0.000768. P (detect|shift) = P (D / n > UCL) + P (D / n < LCL) = 1 − Φ((0.07939697 − p p 0.04)/ 0.000768) + Φ((0 − 0.04)/ 0.000768) ≈ 0.1520263. P (detected by 5th sample) = 1 − (1 − 0.1520263)5 ≈ 0.5615582 2 4. Diodes used on printed circuit boards are produced in lot of size 1000. We wish to control the process producing there diodes by taking samples of size 64 from each lot. If the nominal value of the fraction is p = 0.10 determine the parameters of the appropriate control chart. To what level must the fraction nonconforming increase to make the β-risk equal to 0.50. To what level is the minimum sample size that would give a positive lower level control limit for this chart? Answer. Given that p̄ = 0.01 and n = 64, we compute the control limits, UCL = 0.1 + 3 × Central Line = 0.01 LCL = 0.1 − 3 × q 0.1(1−0.1) = 0.2125 64 q 0.1(1−0.1) = −0.0125 ⇒ 0 64 The beta risk is determined with the following: β = P (LCL < D / n < UCL| p) = P (D / n < UCL| p) − P (D / n < LCL| p) = P (D /64 < 0.2125| p) − P (D /64 < 0| p) = P (D < 13.6| p) − P (D < 0| p) D has Bin(64, p) distribution and we compute the probability of P (D ≤ 13) and P (D ≤ 0) with various p. Here we give 0.0 0.2 0.4 0.6 0.8 1.0 the following plot of β against p, 0.0 0.1 0.2 0.3 0.4 From the figure, we could identify that β = 0.5 with 0.21 < p < 0.22. Then we do further computation, p P (D ≤ 13) P (D ≤ 0) β 0.210 0.5192784 2.806298 × 10−7 0.5192782 0.211 0.5114091 2.587785 × 10−7 0.5114088 0.212 0.5035536 2.386041 × 10−7 0.5035533 0.213 0.4957148 2.199798 × 10−7 0.4957146 0.214 0.4878955 2.027883 × 10−7 0.4878953 0.215 0.4800987 1.869210 × 10−7 0.4800985 0.216 0.4723270 1.722773 × 10−7 0.4723268 0.217 0.4645831 1.587643 × 10−7 0.4645829 0.218 0.4568697 1.462959 × 10−7 0.4568696 0.219 0.4491895 1.347926 × 10−7 0.4491894 0.220 0.4415450 1.241808 × 10−7 0.4415449 The fraction of non-conforming would need to increase to 0.212. Assuming L = 3 sigma control limits, the minimum sample size to achieve a positive lower control limit is: n > = = 3 1− p 2 L p 1 − 0. 1 2 3 0.1 81