to find out more

advertisement

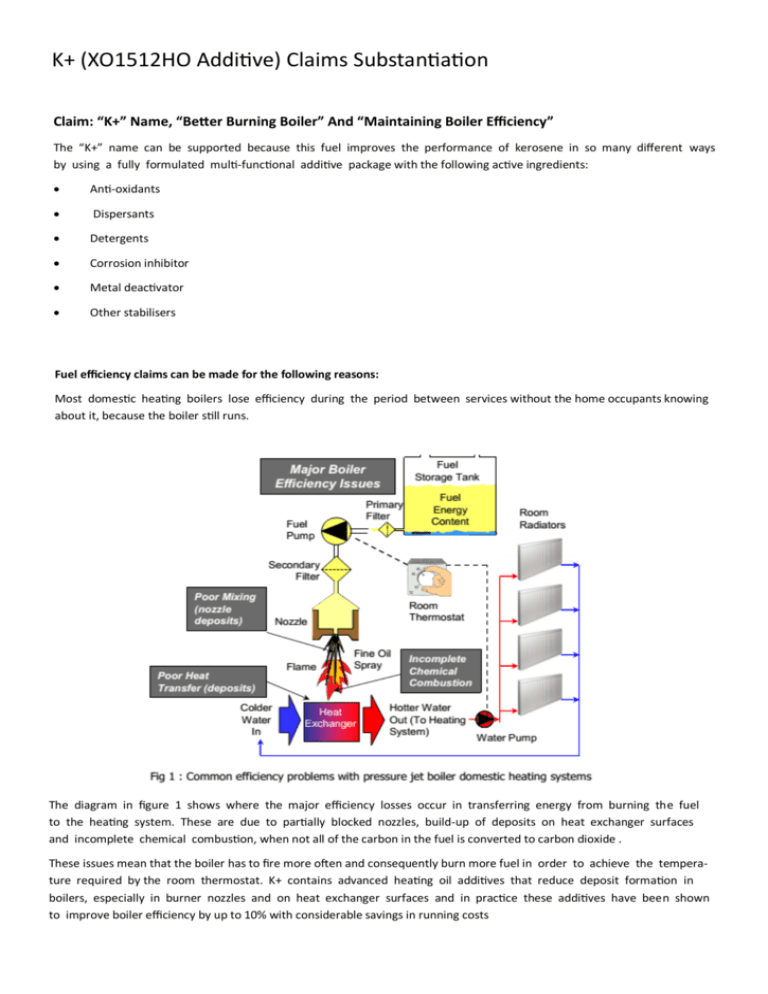

K+ (XO1512HO Additive) Claims Substantiation Claim: “K+” Name, “Better Burning Boiler” And “Maintaining Boiler Efficiency” The “K+” name can be supported because this fuel improves the performance of kerosene in so many different ways by using a fully formulated multi-functional additive package with the following active ingredients: Anti-oxidants Dispersants Detergents Corrosion inhibitor Metal deactivator Other stabilisers Fuel efficiency claims can be made for the following reasons: Most domestic heating boilers lose efficiency during the period between services without the home occupants knowing about it, because the boiler still runs. The diagram in figure 1 shows where the major efficiency losses occur in transferring energy from burning the fuel to the heating system. These are due to partially blocked nozzles, build-up of deposits on heat exchanger surfaces and incomplete chemical combustion, when not all of the carbon in the fuel is converted to carbon dioxide . These issues mean that the boiler has to fire more often and consequently burn more fuel in order to achieve the temperature required by the room thermostat. K+ contains advanced heating oil additives that reduce deposit formation in boilers, especially in burner nozzles and on heat exchanger surfaces and in practice these additives have been shown to improve boiler efficiency by up to 10% with considerable savings in running costs Deposits and sludge are normal, but can give all kinds of operating and efficiency problems: Nozzles, filters and pipes get blocked – Environment Agency Home Heating Guidelines “inspect your tank, its ancillary equipment and pipework at least weekly for corrosion, damage, interference and signs of leaks; use an OFTEC registered technician to service and inspect your boiler, tank, ancillary equipment and all pipework, at least once a year” (www.environmentagency.gov.uk/business/444217/590750/590821/174658/1158171/?version=1&lang=_e) and OFTEC boiler service advice in various documents at www.oftec.co.uk Deposits build up inside all boilers - This combustion of any fuel results in some degree of deposits – this is one of the reasons boilers require regular servicing www.oftec.co.uk Deposits occur on internal “post burner” surfaces – causing reduced thermal heat transfer, higher fuel consumption and higher CO2 per energy output unit The efficiency of an “in-service” boiler could be reduced by as much as 10% This comment is a very modest upper efficiency loss estimate based upon a review of a range of literature and practical observations: a) In a recent field survey (Appendix 2), the combustion efficiency of boilers running on an additive very similar to K+ kerosene averaged 93.42% i.e. 3.38% higher than those using regular heating oil. On cleaning, an increase of between 0.9% and 5.2% in combustion efficiency was found in boilers burning premium fuel. Clearly, these increased efficiencies are accompanied by improved efficiency and fuel economy, especially between boiler services. b) An average in-service efficiency degradation of 2% per year (“Potential energy savings in residential oil-fired heating systems…”, Kelly et al, NBS Building Science Series 163, 1985) c) A traditional burner/boiler, needs ideally a quarterly cleaning and service, to run with an yearly efficiency between 70% to 80%. With yearly service, its efficiency can degrade with 20% to 30% from beginning to end of service. Many will have longer interval and it is not uncommon to see equipment that runs constantly at 60% to 70% of its nominal efficiency (“Pulsonex Propulsion Burner/Boiler”, Hakan Falk, Energy Savings Now, Dec 2003) (http://energysavingnow.com/products/ pulsonex/) d) SEDBUK boiler efficiency database (reviewed March 2006 at www.sedbuk.com); efficiency range for new boilers is between 65% and 97%, with a reasonable spread of results and no dominant “outliers” that explain this efficiency range. e) Not all home owners have their boilers serviced every year. Most owners are unaware of this efficiency loss until the boiler breaks down – Home owners are not capable of accurately checking the efficiency of their boilers (even if they wanted to) due to the many variables present. Boiler efficiency measurements are only possible by standard SEDBUK tests as detailed at www.sedbuk.com. Claim: “Optimised Boiler Performance” This claim can be supported due to the XO1512HO deposit and sludge control performance (Appendix 1). Partially blocked burners cause the operating problems previously detailed. The presence of the XO1512HO additive ensures the burner operates as it was designed to. Preventing fuel oxidation deposits and sludge accumulating (e.g. F21-61 test) helps keep nozzles clean Sludge and fuel oxidation deposits cause burner deposit problems and increased black smoke and particulate emissions (“Residential oil burners with low input and two stage firing”, Butcher et al, Brookhaven National Laboratory 1997) Claim: “Reduced Sludge Formation” These claims can be supported due to the XO1512HO deposit and sludge control performance (Appendix 1). XO1512HO contains powerful dispersants that both inhibit sludge precursors (fine, black deposits) and break up existing sludge into smaller particles, so that they pass through the filter and burn. The reduction in fuel related “breakdowns” (Appendix 1) when using XO1512HO demonstrates that this sludge handling capability works in the field. Claim: “Reduced Fuel Degradation” “Reduces fuel degradation” claims can be supported by the F21-61 Accelerated Stability and metal deactivation tests shown in Appendix 1. In this a standard quantity of test fuel is heated and then passed through a filter to catch the oxidation deposits. It can be clearly shown that K+ degrades much less as there are fewer deposits shown on the F21-61 filter paper and the column of the K+ fuel is a much lighter colour when copper is present. Claim: “Protects And Promotes A Clean Fuel System” The fuel stabilisers and dispersants present in XO1512HO take care of sludge and deposits in the fuel system. Claim: “Inhibits System Corrosion And Reduces Fuel Related Service Problems” The NACE TM-01 rust test results shown in Appendix 1 clearly demonstrate the effectiveness of K+ in preventing corrosion occurring – providing an effective surface coating to leave the steel finger looking “as new”. The reduction in fuel related “breakdowns” (Appendix 1) when using XO1512HO demonstrates that there are less fuel related service problems. Claim: “Kinder To The Environment” K+ is kinder to the environment because it keeps the boiler running as it was originally designed to: Burner deposits increase emissions (e.g. smoke and particulates) Burner and heat exchanger deposits reduce efficiency and increase CO2 Claim: “Lowers Operating Costs”, “lower energy costs” and “Significant overall savings in most households” These claims are based upon several cost elements as follows: 1. Lowering energy costs by maintaining boiler efficiency: These calculations are based upon inputting values into the cost calculators contained on the www.sedbuk.com website and inputting today’s heating oil prices. Other key inputs into the calculations: Kerosene density = 0.810 Kg/m3 Kerosene low price assumption = 56 pence/litre = 56/0.810 = 69.1 pence/Kg Energy content = 43 MJ/Kg (http://www.convert-me.com/en/convert/energy) = 11.94 kWhr/Kg Key SEDBUK energy efficiency calculation input = 69.1/11.94 = 5.79 pence/kWh Output from SEDBUK database calculations using 5.79 pence/kWhr as a key input: Efficiency Increase In Cost Fuel Used @ Higher K+ Premium Example Reduction For Detached House Efficiency (litres) 3p/litre 4p/litre Saving 65%* to 55% 2132–1804 = £328 3221 75% to 65% 1804–1563 = £241 2791 £97 £129 £231 £84 £112 £157 [*There are still a significant portion of new boilers in the database that have 65% as new efficiency] If K+ was priced at 3 pence/litre above regular kerosene prices then the net saving of using K+ for thermal efficiency alone in a medium sized house could be over £120 per year Avoiding the cost associated with unexpected breakdowns: The field test results on the last page of Appendix 1 show that XO1512HO reduces boiler breakdowns that were caused by fuel issues by 20% A survey of service Engineers suggests boiler breakdown minimum callout fees are often in excess of £50. 3. Increases the life of metal parts: The metal deactivation and corrosion inhibition properties of K+ avoids the costly replacement of metal parts such as fuel tanks, fittings and fuel pumps. The combined cost of these is often in excess of £50/year over the lifetime of the components. Claims: “Kinder To The Environment” and “Better For The Environment” K+ is kinder to the environment because: It keeps the boiler running as it was originally designed to Burner deposits increase emissions (e.g. smoke and particulates) Burner and heat exchanger deposits reduce efficiency and increase CO2 A lower CO2 claim is possible due to the improved fuel efficiency provided by K+ 1. Lower Fuel Consumption Calculations Lowering energy costs by maintaining boiler efficiency: These calculations are based upon inputting values into the cost calculators contained on the www.sedbuk.com website and inputting today’s heating oil prices. Other key inputs into the calculations: Kerosene density = 0.810 kg/m Kerosene price assumption = 56 pence/litre = 56/0.810 = 69.1 pence/kg Energy content = 43 MJ/Kg (http://www.convert-me.com/en/convert/energy) = 11.94 kWhr/kg Key SEDBUK energy efficiency calculation input = 69.1/11.94 = 5.79 pence/kWhr Output from SEDBUK database calculations using 5.79 pence/kWhr as a key input: Efficiency Decrease In Cost Fuel Saved Fuel Saved Improvement For Detached House (litres) (%) 55% to 65%* 2132–1804 = £328 586 15.4 65% to 75% 1804–1563 = £241 430 13.4 [*There are still a significant portion of new boilers in the database that have 65% as new efficiency] 2. Lower CO2 Emissions Calculations Boiler combustion equation: CxHy + O2 + N2 CO2 + CO + H20 + HC + NOx + PM Fuel ( Air ) The average oil fired boiler CO2 emissions are 2.7 tonnes/year (http://www.esru.strath.ac.uk/EandE/Web_sites/01-02/ heat_pump/auxiliary.html). As most of the fuel carbon is converted into CO2, the CO2 saved is proportional to the fuel savings as follows: Efficiency Fuel Saved Fuel Saved CO2 Saved Improvement (litres) (%) (tonnes) 55% to 65%* 586 15.4 0.42 65% to 75% 430 13.4 0.36 In conclusion we can say that the annual CO2 reduction per average household operating on K+ can achieve is in the range of 0.25 to 0.5 tonnes/year. 3. Fewer Trees Calculations Different tree species absorb CO2 at different rates (http:// savetheplanet.co.uk.nz/carbon-wavepower-whatis.html). For example an average 25 year old maple has absorbed 27.5 Kg; whereas the comparable figure for a pine tree is 170.5 Kg. In conclusion we can say that the annual CO2 reduction per average household operating on K+ could be the equivalent of planting between 1.5 and 18 trees per year. Appendix 1: XO1512HO Technical Information Sheet XO1512HO Heating Oil Additive That Is In K+ Fuel Description Liquid, multi-component, premium heating oil additive with extensive field experience Application This additive can be used to upgrade standard kerosene to premium products. It contains a combination of components to help maintain quality, reduce fuel related service problems as well as enhance performance. A treat rate of 1:5000 is recommended. This product is suitable for batch treatment in tanks (e.g. bottle dosing and splash blending) or continuous injection into a flowing stream (e.g. in-line additive injection). This product will clean up existing dirt and sludge in the distribution system, depending upon the condition. For a very dirty system, this may require some filter changes until it is clean. Typical Heating Oil System Problems