Methods for Design and Management of a Fast

advertisement

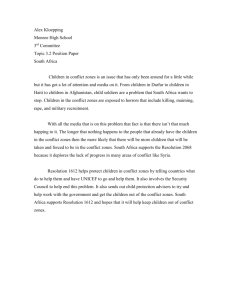

Proceedings of the 2008 Industrial Engineering Research Conference J. Fowler and S. Mason, eds. Methods for Design and Management of a Fast-Pick Area in a Warehouse Chenying Kong and Dale Masel Department of Industrial and Systems Engineering Ohio University, Athens, Ohio 45701, USA Abstract The fast-pick area of a warehouse is used to fill orders for the most popular items in a facility. In this paper, buffers are placed in each zone of the fast-pick area to allow pickers to work ahead. Heuristics are described to assign SKUs to the zones and then to sequence the orders for picking so that the full benefits of the buffers can be obtained. The performance of the system with the heuristics is shown to produce better throughput per worker than the same system with random assignments or a traditional system where orders are picked in waves. Keywords Distribution centers, Order picking, Fast-pick area, Lean warehousing 1. Introduction Order picking is the process of fulfilling customer orders through retrieving items from storage. Among all warehousing operations, order picking makes up approximately 55% of the cost [1] because it is a labor-intensive activity for traditional manual warehouses. One strategy that is used to improve the efficiency of the order picking operation is a fast-pick area (also referred to in some cases as a fast-pick line). The fast-pick area is a portion of the forward picking area where only a limited quantity of the most popular SKUs are stored. This allows the pickers to fill a large portion of the orders while traveling in a small space. This research studies an order picking system that was developed to apply the principles of lean manufacturing to warehouse operations. Lean manufacturing is a method developed from JIT manufacturing in Toyota 0, which promotes principles including waste reduction, customer-orientation, product flow, line balancing, and lower batch size [2]. Today, lean principles are not only for manufacturing, but are also used in many other areas, such as sales, purchasing, medical service, warehousing, and distribution [3-5]. Lean principles are widely applied because they help organizations achieve higher throughput, lower operation cost, faster response, and better quality. Consequently, customers are more satisfied with the service. The system being studied in this paper was initially proposed by Kong and Masel [6]. In this paper, further study will be conducted on the optimization of the system performance. In a lean system, it is important to balance the workload to keep all operator cycle times at or below the takt time, so heuristics for managing the storage assignments and the order assignments will be discussed. 2. System Description In the proposed system, the fast-pick area is divided into separate zones, where all products are stored on flow racks (See Figure 1). In each zone, there is one order picker who processes one customer order at a time. A “pick-to-light” system on the rack indicates to pickers where, what, and how many to pick. There is also a “put-to-light” system on the buffer trays that tells the pickers where to place items after they are picked. Each tray temporarily holds items from one order, which provides a buffer for the time difference between the picker’s availability and the container’s arrival. When the right shipping carton comes to the tray, the tray tilts to transfer items into the carton automatically. In addition to the fast-pick area, there is another portion of the facility that is used for order picking. It has the layout of a traditional forward area and stores the SKUs that are not assigned in the fast-pick area. This area will be called the traditional area in this research. In the traditional area, items are stored on shelves along aisles and the aisles are 1367 Kong and Masel separated evenly into zones, with one picker who is responsible for picking all the items in his/her zone. The requested items in the traditional area are picked in waves. One wave of orders in the traditional area corresponds to a certain number of orders in sequence for the fast-pick area, although orders are still picked one at a time in the fast-pick area. Figure 1: Layout of the proposed system The shipping cartons are transported out of the fast-pick area by the main conveyor, and there are two branches for two kinds of cartons. Conveyor I is for the shipping cartons that do not need items from the traditional area. The items requested for those orders are all located in the fast-pick area, and orders can be fully completed there. Those cartons go directly for sealing and then are shipped out. Conveyor II is for the shipping cartons that need items from the traditional area, which are transported out from the traditional area by sorting conveyor and then are sorted to individual lanes. The workers at the end of the lanes put the items into the right trays, which are controlled by the computer system. The trays transfer items into the right shipping cartons coming from the fast-pick area. 3. Methodology 3.1 Heuristics for Storage Assignment A storage assignment method is a set of rules that is used to assign the SKUs to storage locations. Since routing in the fast-pick area is not considered in this research, the storage locations within a picking zone make no difference. Consequently, the storage assignment methods make decisions about SKU selection (which SKUs should be stored in the fast-pick area) and space assignment (how many zones a SKU is located in and which zones it is placed in), but do not decide which individual storage locations a SKU should be placed in. The objective of the storage assignment is to evenly balance the expected demand among picking zones. If the number of picks is not balanced across zones, some zones will be idle while other zones are still busy. If the expected demand is evenly distributed, the idle time of zones can be reduced, which matches the lean principle of eliminating idle time. 1368 Kong and Masel 3.1.1 SKU Selection The SKUs to be stored in the fast-pick area are based on the demand and ordering frequency of the SKU. The demand of a SKU is the number of units requested by all the orders during a time period. The ordering frequency of a SKU is the number of orders that request the SKU. In order to reduce travel, if two SKUs have the same demand, the SKUs with higher ordering frequency will be put in the fast-pick area. This is because the SKU with the higher order frequency is likely to be visited more often, so more travel is required if the SKU is put in the traditional area. The number of SKUs assigned to the fast pick depends on several factors. The number of storage positions in the fast pick area provides an upper limit, but to balance the workload between zones in this area, the number of SKUs should be significantly less than the number of storage locations. In general, class A SKUs should be placed in the fast pick area along with selected class B SKUs. A balance is needed between maximizing the number of items that can be retrieved (by assigning lots of SKUs to the fast pick area) and allowing flexibility in the pick assignments (by assigning just a few SKUs to the fast pick area). Further study is needed to determine the appropriate balance. The SKUs that are not chosen to be put in the fast-pick area will be stored in the traditional area. If those SKUs are needed, they will be retrieved from the traditional area and they will be combined with the ones picked in the fastpick area before the shipping carton is sealed. Since those are low demand items, the picking labor in the traditional area will be less than for the high-demand SKUs. 3.1.2 Space Assignment The SKUs chosen to be stored in the fast-pick area will be assigned to one or more zones. Two decisions are made for space assignment: 1) how many zones each SKU will be located in; 2) which zone(s) each SKU should go to. The space assignment approach begins by allocating each SKU that was selected (as described in 3.1.1) to one zone. The average number of picks per zone (APZ) for SKU i is the ratio of the total demand of SKU i to the number of zones it is assigned to. The number of picks made for a SKU (rather than the number of orders containing the SKU) is used for this ratio because the workers’ time in the fast pick area is spent mainly on retrieving items, so the number of units of each SKU that are picked is the main parameter that needs to be balanced in making assignments. After allocating one zone to each SKU, the APZ for every selected SKU is calculated and the SKU with highest APZ should be allocated one more zone. Then the APZ is recalculated for each SKU and again one more zone is allocated to the SKU with the highest APZ. This is repeated until the total number of assigned locations reaches the capacity in the fast-pick area. The goal of this step is to minimize the maximum number of picks per zone, which is the first step toward balancing the workload across zones. After determining the number of zones for each SKU, the next decision to make is which zone to assign each SKU to. Inflexible SKUs are those items with low demands that have been assigned to only one location. Those SKUs should be assigned first and spread among zones to balance the average picking frequencies and quantities. Flexible SKUs are those items that have been assigned to multiple zones in order to make workload balancing easier. A SKU should not be assigned to the same zone twice because doing this is not helpful for splitting the picking load for the SKU across zones. Also, several zones should not have the same combination of SKUs, since this reduces flexibility in making pick assignments, and a mix of flexible and inflexible SKUs should be located in a zone, to prevent the chance of having multiple items in a batch that must come from the same zone. 3.2 Heuristics for Sequencing After assigning zone(s) for each SKU, the next step is to sequence the orders, which includes two decisions: putting the orders into batches and then assigning each pick to one of the zone(s) where the needed SKU is stored. 3.2.1 Order Batching It is difficult and usually impossible to evenly distribute the workload for a single order among all zones due to fewer requested items than number of zones. Imagine an order that consists of nine items and a fast-pick area with ten zones. In this situation, there is no way to balance the demand among zones for this order without leaving at least one of the zones idle. By batching several orders together, the workload of the large order is more likely to be balanced. Therefore, rather than attempting to balance an individual order, orders are batched for scheduling purposes. The goal will be to evenly distribute the workload of a batch, and by using buffer trays the orders will still be picked one by one. 1369 Kong and Masel There are two limits on the maximum size of a batch. One constraint is on the number of orders per batch, which in general should be less than or equal to the number of buffer trays in a zone; otherwise there may not be enough places to hold the picked items. Because most orders will not require items from all zones, this constraint can be relaxed somewhat if necessary, but doing so will add complexity to the workload scheduling process, which is described in Section 3.2.2. The second constraint on batch size is the number of items to be picked for a batch. There is a maximum cycle time per batch that is allowed in this system, which is tied to the speed of the conveyor. If a zone has more work than can be completed before the cartons for an order arrive, the items won’t be picked in time to be moved from the tray to the carton. This maximum cycle time represents the takt time of the process—the production time at each station to meet daily throughput requirements. The order batching heuristic begins by sorting all orders by demand in descending sequence. The largest order goes to the first batch, and the second largest order goes to the second batch, and so forth. After each batch has received at least one order, the next order should be assigned to the batch currently with smallest demand; all the remaining orders continue to be assigned following this rule. The purpose of doing this is to balance the picking load among batches; therefore, it is possible that all batches do not have the same number of orders. To check the feasibility of the order batching, the average workload per zone (AWSij) is calculated. AWSij is the number of picks of SKU i in Batch j divided by the number of zones having SKU i. The AWSij values are used as a standard to evaluate the current batching and they should be recalculated after each order is put into a batch. They should always be less than or equal to the takt workload, which is the maximum number of picks that can be completed within takt time, including extraction, travel, and placement. If one of the AWSij values is bigger than the takt workload, this means that multiple orders with the same SKU are all in the same batch, so that the zones can’t pick all of the units of that SKU that are needed and still keep up with the takt time. In this case the order which has just been put into one batch should be taken from it and given to the next batch in the sequence. 3.2.2 Workload Scheduling If a SKU is assigned to multiple storage zones, the zone that it will be picked from has to be selected each time that SKU appears in an order. Since it is assumed that travel distance is constant in the fast-pick area, a balanced workload is achieved by making the number of retrievals from each zone the same. Workload scheduling is done separately for each batch, since the batches will be processed sequentially in each zone. If necessary, the picks for a SKU can be split among multiple zones. The heuristic for scheduling the workload in a batch requires three steps. Step 1: Calculate the average workload per zone (AWi) for the batch, which is the ratio of the number of items in batch i to the number of zones. If AWi is not an integer, the value is rounded up to the next integer and this value serves as the target workload for each zone, since it represents a balanced workload across zones. The value of AWi should not exceed the takt workload, since the takt workload was used when the batch assignments were made. Step 2: Sort the SKUs needed for a batch in ascending sequence by the number of zones they have been assigned to. This puts the inflexible SKUs (only assigned to one zone) at the top of the list and the most flexible SKUs (assigned to many zones) at the bottom of the list. The SKUs will be scheduled in the same sequence, which means the SKUs assigned to the fewest zones are assigned first and SKU with the most zones are assigned last. Step 3: Schedule the picks required for the batch in the sequence produced by Step 2. If the demand of a SKU is smaller than or equal to AWi, all the demand of this SKU should be put into one zone. This is done to reduce the travel distance for the picker. For SKUs whose demand in batch i is bigger than the AWi, the demand should be assigned to the fewest number of zones possible. When assigning a SKU, the choice should be the zone that has the fewest picks remaining on the sequence list that could be assigned, since there are fewer opportunities left to assign picks to that zone. 4. Testing To evaluate the effectiveness of the heuristics, the performance of the fast-pick area using the heuristics was compared to the system without heuristics and to a traditional system. For testing, the performance of each system in 1370 Kong and Masel the tests was estimated using analytical model of each system. Before testing the heuristics, the accuracy of the analytical model was verified with a simulation model of the fast-pick system. The models calculated the total labor time required by using standard times for each operation in the system (extraction, travel, etc.) and the number of times that each operation is performed. For the traditional system, labor time included the work required for packing, but since items are placed directly into the containers in the fast-pick system, no labor time is added for this operation. Generally, it is assumed that 20% of the SKUs account for 80% of the demand, so it was assumed that 20% of the SKUs were located in the fast-pick area. In addition, Hinojosa [7] described the most active SKUs as 5% of the total SKUs which account for around 50% of demand. For other 80% of SKUs, they follow ABC classification that 30% of SKUs account for 15% of demand and the last 50% of SKUs account for 5% of the demand. Based on the above description, the demand distributions shown in Table 1 were used for generating orders in the experiment. Table 1: Demand Distribution for Experiment of Heuristics Percentage Number of Probability that the SKU Class of SKUs SKUs is included in an order A (most active) 5% 2 80% A (less active) 15% 6 16% B 30% 12 4% C 50% 20 0.8% For testing, orders were generated in a wave, since it was assumed that the traditional warehouse that was used for comparison would pick the orders in a wave. The SKUs in each order were randomly generated using the probabilities shown in Table 1 and the number of units required of each SKU that was included in an order was also randomly generated, using a uniform distribution from 1 to 10. The system parameters are shown in Table 2. Parameter Number of zones Number of locations per zone Number of orders in one wave Table 2: Parameters and Values used in the Experiment Value Parameter 5 Number of SKUs in the fast-pick area 5 Total number of SKUs in the facility 50 Value 8 40 70.00 Labor Time per Wave (min) Labor Time per Wave (min) 4.1 Lean with heuristics vs. lean without heuristics For the testing without heuristics, the number of zones for each SKU was still calculated using the heuristic, since a random number of zones would certainly provide poor performance. Then each SKU was randomly assigned to the appropriate number of zones. The orders were sequenced randomly and the picks were assigned randomly to zones, without exceeding the takt time in any zone. Since there was more imbalance without the heuristics, fewer orders per batch were usually processed, so more batches needed to be used for a wave than were needed with the heuristics. Figure 2 presents the results from the fast-pick system with random assignments and with the heuristic, using the same wave of 50 orders for both assignment methods on each trial. 60.00 50.00 40.00 30.00 20.00 10.00 0.00 1 6 11 Random/Lean 16 21 26 Trials 70.00 60.00 50.00 40.00 30.00 20.00 10.00 0.00 1 6 11 Random/Lean Heuristic/Lean 16 21 26 Trials Heuristic/Lean (a) (b) Figure 2: Labor time comparison: random vs. heuristics: (a) Small warehouse; (b) Large warehouse 1371 Kong and Masel The labor time result is the same for all waves when using the heuristics, so it is shown as a straight line in the figure. The scattered dots are labor time of the proposed warehouse with 30 different random assignment and scheduling results. The labor required without the heuristics is always larger than the labor with the heuristics. Therefore, using only the proposed layout design is not enough to achieve a more effective system. The developed heuristics are needed to assign the storage locations and schedule the workload to gain the benefit of the new system. By using the heuristics, the workload assigned per zone per batch can be maintained at or below the takt workload, which allows the system to achieve the necessary throughput. 4.3 Lean with heuristics vs. traditional The performance of the proposed warehouse was also compared with a traditional warehouse. Two warehouses process the same customer orders, and the performance measurement is the labor time they need to finish processing the orders in one wave. Two different sizes of warehouse were used, with the larger warehouse capable of processing more orders per day. Each warehouse still stores 40 different SKUs, but it was assumed that the warehouse filling more orders per day would require a larger forward area to hold a larger amount of each SKU, which would increase the travel time in picking. Because the flow racks in the fast-pick area can be replenished throughout the day, they are not subject to an increase in size with increased throughput. Four different tests were set up, as shown in Table 3, and five waves of orders were used for each test. Tests 1 and 2 have 50 orders per wave, so the same five waves of orders were used in both tests, and Tests 3 and 4 have 100 orders per wave, so the same five waves were used in both of these tests. Test 1 2 3 4 Table 3: Parameters and Values used in Four Tests Total Labor Time (minutes) Number of Warehouse capacity orders per wave (orders/day) Traditional Fast-Pick 50 1000 41.5 24.1 50 2500 50.7 26.0 100 1000 76.2 47.7 100 2500 85.3 49.7 Table 3 also shows the labor time results for the proposed warehouse and the traditional warehouse for four tests. In all four tests, the labor time per wave of the traditional warehouse is much larger than that of the proposed warehouse, so this demonstrates that the performance of the proposed warehouse appears to be better than a traditional warehouse. 5. Conclusions In this research, heuristics for storage location assignment and workload scheduling for a fast-pick area were presented. The fast-pick system was tested with and without the heuristics and the system with heuristics was compared to a traditional system. From the results of this testing the heuristics do help the proposed system to achieve a higher efficiency and the use of these heuristics allows the system to fill orders with a lower labor cost than a traditional system. References [1] Bartholdi, P.P. and Hackman S.T., 2005, Warehouse & Distribution Science, Available: http://www.warehousescience.com [2007, January 17]. [2] Alukal, G., 2006, “All about lean,” Quality Progress, 39(2), 74-75. [3] Schroer, B.J., 2004, “Simulation as a tool in understanding the concepts of lean manufacturing,” Simulation, 80(3), 171-175. [4] Baudin, M., 2005, Lean Logistics: The Nuts and Bolts of Delivering Materials and Goods, Productivity Press, New York. [5] Bradley, P., 2006, “The skinny on lean,” DC Velocity, 4(3), 31-36. [6] Kong, C. and Masel D.T., 2007, “A high-throughput pick line for split-case order picking,” Proceedings of the 2007 Industrial Engineering Research Conference, May 20-23, Nashville, Tennessee, 860-865. [7] Hinojosa, Arturo, 2003, “Picking up the pieces,” Industrial Engineer, 35(2), 39-44. 1372