Mechanical Engineering Technology Major

advertisement

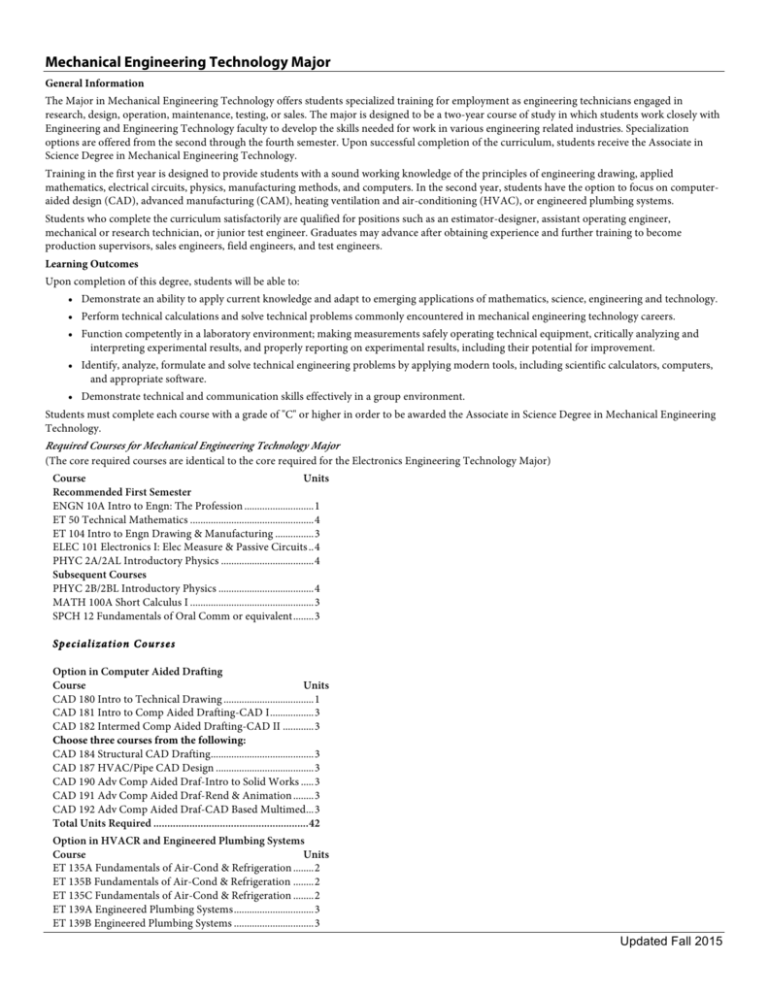

Mechanical Engineering Technology Major General Information The Major in Mechanical Engineering Technology offers students specialized training for employment as engineering technicians engaged in research, design, operation, maintenance, testing, or sales. The major is designed to be a two-year course of study in which students work closely with Engineering and Engineering Technology faculty to develop the skills needed for work in various engineering related industries. Specialization options are offered from the second through the fourth semester. Upon successful completion of the curriculum, students receive the Associate in Science Degree in Mechanical Engineering Technology. Training in the first year is designed to provide students with a sound working knowledge of the principles of engineering drawing, applied mathematics, electrical circuits, physics, manufacturing methods, and computers. In the second year, students have the option to focus on computeraided design (CAD), advanced manufacturing (CAM), heating ventilation and air-conditioning (HVAC), or engineered plumbing systems. Students who complete the curriculum satisfactorily are qualified for positions such as an estimator-designer, assistant operating engineer, mechanical or research technician, or junior test engineer. Graduates may advance after obtaining experience and further training to become production supervisors, sales engineers, field engineers, and test engineers. Learning Outcomes Upon completion of this degree, students will be able to: • Demonstrate an ability to apply current knowledge and adapt to emerging applications of mathematics, science, engineering and technology. • Perform technical calculations and solve technical problems commonly encountered in mechanical engineering technology careers. • Function competently in a laboratory environment; making measurements safely operating technical equipment, critically analyzing and interpreting experimental results, and properly reporting on experimental results, including their potential for improvement. • Identify, analyze, formulate and solve technical engineering problems by applying modern tools, including scientific calculators, computers, and appropriate software. • Demonstrate technical and communication skills effectively in a group environment. Students must complete each course with a grade of "C" or higher in order to be awarded the Associate in Science Degree in Mechanical Engineering Technology. Required Courses for Mechanical Engineering Technology Major (The core required courses are identical to the core required for the Electronics Engineering Technology Major) Course Units Recommended First Semester ENGN 10A Intro to Engn: The Profession ........................... 1 ET 50 Technical Mathematics ................................................ 4 ET 104 Intro to Engn Drawing & Manufacturing ............... 3 ELEC 101 Electronics I: Elec Measure & Passive Circuits .. 4 PHYC 2A/2AL Introductory Physics .................................... 4 Subsequent Courses PHYC 2B/2BL Introductory Physics ..................................... 4 MATH 100A Short Calculus I ................................................ 3 SPCH 12 Fundamentals of Oral Comm or equivalent ........ 3 Specialization Courses Option in Computer Aided Drafting Course Units CAD 180 Intro to Technical Drawing ................................... 1 CAD 181 Intro to Comp Aided Drafting-CAD I ................. 3 CAD 182 Intermed Comp Aided Drafting-CAD II ............ 3 Choose three courses from the following: CAD 184 Structural CAD Drafting ........................................ 3 CAD 187 HVAC/Pipe CAD Design ...................................... 3 CAD 190 Adv Comp Aided Draf-Intro to Solid Works ..... 3 CAD 191 Adv Comp Aided Draf-Rend & Animation ........ 3 CAD 192 Adv Comp Aided Draf-CAD Based Multimed... 3 Total Units Required ........................................................ 42 Option in HVACR and Engineered Plumbing Systems Course Units ET 135A Fundamentals of Air-Cond & Refrigeration ........ 2 ET 135B Fundamentals of Air-Cond & Refrigeration ........ 2 ET 135C Fundamentals of Air-Cond & Refrigeration ........ 2 ET 139A Engineered Plumbing Systems ............................... 3 ET 139B Engineered Plumbing Systems ............................... 3 Updated Fall 2015 ET 139C Engineered Plumbing Systems ............................... 3 Choose 6 units from the following Technical Elective Courses: ENGN 24 Design Graphics ..................................................... 3 ENGN 38 Introduction to Programming Concepts and Methodologies for Engineers ...................................... 3 ET 86 Intro to Comp-Aided Manufacturing - CAM I ........ 2 WELD 140 Manufacturing Processes .................................... 3 WELD 144 Welding Processes ............................................... 2 WELD 145 Intermediate Welding Processes........................ 3 Total Units Required ........................................................ 47 Up to 6 units of course work can be taken from courses not on the above technical elective list with approval of an engineering advisor. These could include electronics courses, engineering courses or courses in other departments. Updated Fall 2015