Carter Wind Snapshot

advertisement

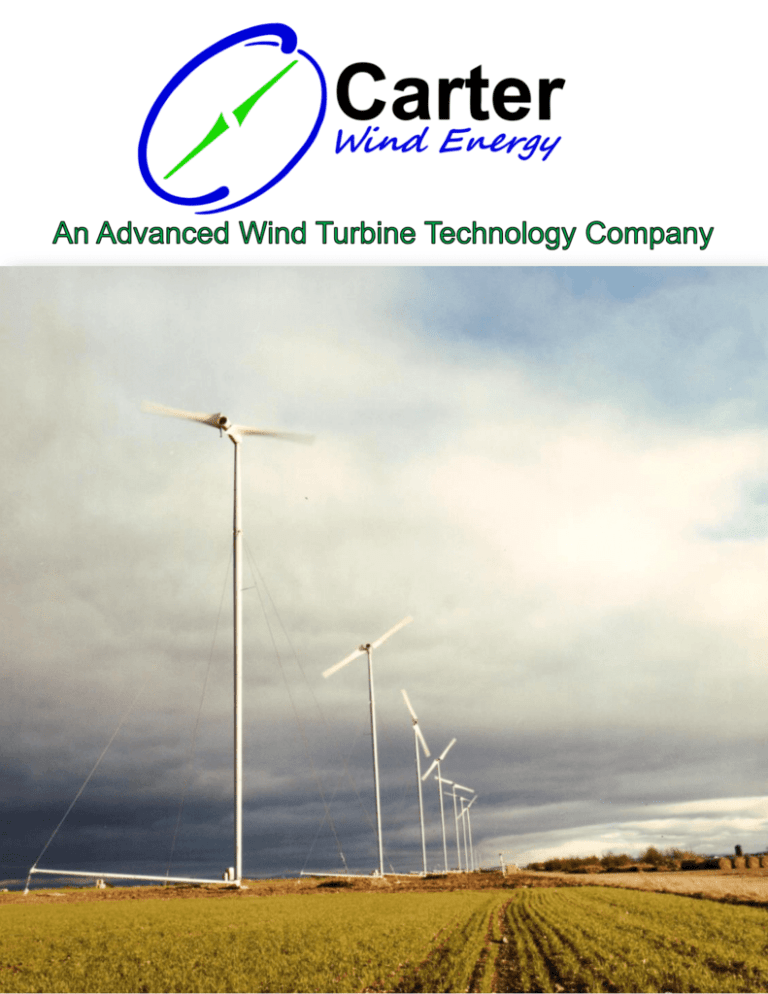

CARTER WIND SNAPSHOT as of July, 2014 35 300-500 60 7 50% 2 100 0 Building its first turbine in 1976, Carter Wind Energy is an industry leader and pioneer of the two-blade wind turbine design. YEARS OF DEVELOPMENT KW MILLION OPERATING HOURS The Company’s technology advantages and value proposition have been independently evaluated by U.S. National Renewable Energy Labs (NREL) and Garrard Hassan with partnerships having been developed thru Hamilton Standard (division of United Technologies), MAN in Germany, and EDF in France. Notable customers include Southwest Public Service, Newfoundland P&L, and TXU. Carter Wind Energy’s competitive advantage lies in its proprietary: • Two bladed design, which eliminate and reduce many of the loads encountered by three blade turbines; • Self-erecting guyed tower concept which eliminates the need for large expensive cranes for installation and maintenance . NEW PATENTS IDENTIFIED LESS COST By minimizing loads and utilizing a structurally efficient guyed tower, Carter turbines weigh a fraction of three bladed design. The lighter weight and self-erecting tower, results in a lower manufacturing, installation, and maintenance costs, and as a result, a dramatic reduction in the cost of wind generated renewable energy. BILLION PEOPLE LACK ACCESS TO ELECTRICITY The dramatic reduction in cost of energy afforded by Carter wind turbine technology creates vast new market opportunities for traditional wholesale power projects, but also portable stand-alone wind-diesel power generation in remote, harsh environments. BILLION DOLLAR MARKET LIKE COMPETITORS Power Solutions for: • • • • • • • • • Cooperatives / Municipalities Government/Military Mining Water desalinization Oil/Gas exploration Enhanced oil recovery Agricultural Resort Industrial Complex HISTORY First Prototype 1975 First Carter Windfarm 1980 > 60 Million Operating Hours MAN & EDF Partnerships 1985 1990 1995 Company Sold to Foreign Investor Initial Concept Initial Turbines Sold and Installed 300 KW Turbine developed Series A Financing 2000 IP Recovered U.S. Tax Credits Expire 2005 2010 2015 Carter Wind Reorganized 500 KW Preliminary Design Awarded Department of Energy Grant > 800 Tubines Installed Building its first turbine in 1976, Carter Wind Energy has 35 years of wind energy experience and is an industry leader and pioneer of the two-blade wind turbine design. The Company’s technology advantages and value proposition have been independently evaluated by U.S. National Renewable Energy Labs (NREL), with partnerships having been developed through Hamilton Standard (division of United Technologies), MAN in Germany, and EDF in France. Over 800 turbines have been installed worldwide in remote, harsh environments accumulating well over 60 million operating hours. COMPANY MANAGEMENT The Carter Family of engineers : Jay Carter Sr. is the inventor of filament winding technology which was used to fabricate all of the solid fuel cases for the Polaris and Minuteman missiles. Mr. Carter formed a company that produced continuous/seamless fiberglass pipe and then sold this company to Ciba-Geigy/Ameron, who is a world leader in this business today. Jay Carter Jr. is the Chairman of Carter Aviation Technologies and inventor of a unique vertical takeoff aircraft that flies like a fixed wing airplane. Textron/AAI has licensed this technology for military UAVs. The rotor employed in the aircraft was first developed as an integral/unique part of the Carter Wind turbine design. Matt Carter is the President of Carter Wind Energy and following in the heritage of his family by reintroducing Carter Wind technology into the mid-size turbine market, initially focused on small wholesale and industrial DG installations for harsh and remote locations. TECHNOLOGY Carter turbines produce more energy with less equipment PROPRIETARY TECHNOLOGY Carter’s proprietary technology allows more energy to be produced with less equipment weight (the investment required to manufacture, transport, install, and maintain wind turbines, is a function of equipment weight). The result is a lower cost of energy. Carter’s unique patented design features include: Annual Energy/Tower Head Weight kWhr/Kg Data provided by Renewable Energy Systems Ltd. 7 m/s @ 30m: 100% Availability • • • • Propriety Two Bladed Teetering Rotor Flexible Composite Downwind Rotor Design Self-erecting, Tilt-up, Guyed Tower Simple unitized design, semi free yaw, stall regulated, and fail safe aero shutdown EASE OF INSTALLATION/MAINTENACE The Carter tilt up turbine design does not require cranes and can be installed faster than traditional turbines. Additionally, installation requires substantially less infrastructure than typical wind turbines (less excavation and concrete for foundations and less road infrastructure, as roads leading to the installation site need only support a regular pick-up truck). 1 Container, 1 Turbine Shipped Global Easy Transport No Crane Self-Erecting Easy Construction 12 Hours 2 INTEGRATED SOLUTION W IDE Wind Water Integrated Diesel Electricity Wind Farm Water Desalination From a maintenance standpoint, tilt-down service capability dramatically reduces the cost and complexity of service and increases safety for workers. Carter’s turbines have proven to remain operative in the most harsh climates with excellent survivability in severe weather, including tropical storm prone environments. A Wind Water Integrated Diesel Electricity (W 2IDE) solution combines a proven low cost, self-erecting wind turbine technology with advanced water and diesel power generation to create a hybrid energy storage system that is well-suited for operation on mini-grids in remote locations with limited infrastructure. Diesel Generator Sets W2IDE is adapted to meet the most stringent requirements of weak and isolated grids to ensure high reliability and grid stability with excellent power quality. MORE COST EFFECTIVE By utilizing W2IDE, project stakeholders are able to build new or expand existing generation capacity, thanks to optimized fuel savings and a significantly lower cost of power generation. Access to affordable and reliable electricity provides societies with the opportunity for clean water, healthcare, irrigation, educational opportunities, communications infrastructure, and other social and economic benefits which are desperately needed to enrich life and improve social productivity in developing regions of the world. PRODUCT SPECIFICATIONS MODEL 300 TECHNICAL DATA MODEL 300 Rotor Performance Type Number of Blades Area Diameter Speed Type of Hub Tilt Angle Pre-cone Horizontal Axis / Downward 2 2 4,778 ft 78 ft 30 - 65 rpm Teetering Hub 2º 8º Power at Windspeed Max. Power Cut-in Windspeed Cut-out Windspeed (adjustable) Design Max Windspeed 200 kW 27 mph 350 kW 7.8 mph 75 mph 160 mph Control System Blades Material Blade Design Fiberglass Composite Non-linear Twist & Taper, NASA-LS Airfoils Fixed – Except Shutdown Blade Pitch Type Overspeed Aerodynamic Stall Controlled Deep Stall, by Twisting the Spar & Increasing Blade Pitch. Brake Backup Yaw Drive Transmission Type Type Ratio (at 60 Hz) Two Stage Planetary 1 : 27.82 Active Outside ±15º Window, Inside Window Free Yaw with Dampening Shell Generator Type Rated Power Voltage Speed Induction – AC 400 kW 480 V, 60 Hz 1827 rpm, 60 Hz Tower Type Number of Guy Wires Height Foundation Tubular / Tilt-up 4 164 ft 3 20 - 30 yd concrete Material Size (LxWxH) Type Number of Blades Area Diameter Speed Type of Hub Tilt Angle Pre-cone Weights Blades/Hub Assembly Tower/Gin Pole Nacelle Miscellaneous (control box, guy wires, etc.) Total Weight 2,950 lbs 18,400 lbs 6,800 lbs 3,350 lbs 31,500 lbs MODEL 500 Performance Horizontal Axis / Downward 2 2 11,310 ft 120 ft 10 - 45 rpm Teetering Hub 2º 8º Material Blade Design Blade Pitch Max Power at Windspeed Cut-in Windspeed Cut-out Windspeed (adjustable) Design Max Windspeed Fiberglass Composite Non-linear Twist & Taper, Custom Airfoils Fixed – Except Shutdown Type Two Stage Planetary 1 : 40 Type Rated Power Voltage Speed Induction – AC 500 kW 480 V, 60 Hz 1836 rpm, 60 Hz Tower Type Number of Guy Wires Height Foundation Tubular / Tilt-up Two Sets of 4 149 - 260 ft 3 30 - 40 yd concrete Aerodynamic Stall Controlled Deep Stall, by Twisting the Spar & Increasing Blade Pitch. Brake Backup Active Outside ±15º Window, Inside Window Free Yaw with Dampening Shell Material Size (LxWxH) Generator 160 mph The Model 500 is an efficient and powerful turbine specifically designed and optimized for low to medium wind sites, without comprising the robust design features required for installation in the most harsh tropical and artic conditions. It is based on the proven and reliable Model 300 turbine, and retains the easy shipping, self-erecting, portable attributes required for low-cost distributed power generation. Yaw Drive Transmission Type Ratio (at 60 Hz) 500 kW 32 mph 4.0 mph 60 mph Control System Type Overspeed Blades The Model 300 is ideal for standalone portable wind diesel or industry applications where height restrictions are a concern. Fiberglass Composite 11 x 4 x 4.5 ft TECHNICAL DATA MODEL 500 Rotor The Model 300 turbine is one of the most versatile and modern turbines designs on the market today having proven itself reliable in harsh tropical and artic conditions. Suitable for high and medium wind speed sites, the turbine is compact and portable, with easy shipping. The complete turbine assembly is shipped quickly in a standard cargo container anywhere in the world and can be erected in one day. Fiberglass Composite 16 x 4 x 4.5 ft Weights Blades/Hub Assembly Tower/Gin Pole Nacelle Miscellaneous (control box, guy wires, etc.) Total Weight The Model 500 is ideal for standalone wind diesel or single turbine installation applications for industry and small wholesale power projects that require the lowest cost of energy. 3,500 lbs 27,800 lbs 9,800 lbs 8,900 lbs 50,000 lbs ENERGY PRODUCTION Carter’s proprietary technology allows more energy to be produced with less equipment weight resulting in a lower cost of energy. Carter Wind Energy, LLC 2730 Commerce Street, Suite 600 Wichita Falls, Texas 76301 Tel. (940) 264-4417 – Fax (940) 691-5977 www.carterwindenergy.com