Slides PDF

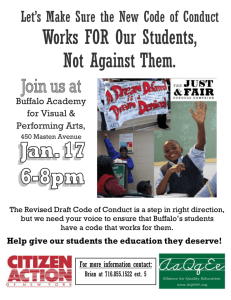

advertisement

1. II CONCURRENT ENGINEERING OF PRODUCT, PROCESS, SCHEDULE & FACILITIES Concurrent Engineering & Systems Approach • Concurrency implies different systems and engineering functions performed at the same time in a consistent manner • Facilities engineering is not a stand-alone process -- highly dependent on what, how, when & how much to produce. • What? = Products By Rakesh Nagi • How? = Process Department of Industrial Engineering SUNY at Buffalo • When? = Production scheduling • How much? = Production planning, forecasting UB UB State University of New York at Buffalo Department of Industrial Engineering Product, Process & Schedule Interaction With Facilities Design 2. State University of New York at Buffalo Department of Industrial Engineering Product Design • Functions Product Design • Dimensions and shape • Materials Facilities Design Schedule Process Design Design • Quality and aesthetics The product design is then described in: • Engineering drawings: specify materials, dimensions, quality, assembly structure SYSTEMS APPROACH Consistent & coordinated functioning of various functions State University of New York at Buffalo UB 2. – Multiview drawing: third angle projection – Perspective drawing State University of New York at Buffalo Department of Industrial Engineering – Assembly drawing UB Department of Industrial Engineering Product Design 2. Product Design • Parts list: Name, Descr., Drw. #, Quantity req., Material, Size, Vendor • Parts list: Name, Descr., Drw. # , Quantity req., Material, Size, Vendor • Bills-Of-Materials (BOM): Assembly structure Matl. Req. • Bills-Of-Materials (BOM): Assembly structure Matl. Req. Table 1 week Top (1) 2 weeks Leg Assem (1) 1 week Legs (4) 3 weeks UB UB State University of New York at Buffalo Department of Industrial Engineering Page 1 Frame (1) 1 week State University of New York at Buffalo Department of Industrial Engineering 3. 3. Process Design Process Design • Process selection • Make-or-buy decisions -- break even analysis – – – – C=px C=K+mx Define elemental operations from product design Identify alternative operations for each operation Analyze alternatives -- depends on production quantity Standardize process • Process sequencing K – Route sheet or routing (fig. 3.10, pp. 44-45) – Assembly chart (fig. 3.11, P. 46) – Operation process chart (fig. 3.12, p. 47) -- Combines above Break-even point Number of units (x) • Computer-Aided Process Planning (CAPP) UB 3. UB State University of New York at Buffalo Department of Industrial Engineering Process Design 4. Schedule Design • How much to produce at a time (lot sizing) • Process selection – – – – State University of New York at Buffalo Department of Industrial Engineering • How long to produce Define elemental operations from product design Identify alternative operations for each operation Analyze alternatives -- depends on production quantity Standardize process • When to produce (scheduling) 4.1 Market information • Less specific information => general design • Process sequencing • More specific information => optimized design – Route sheet or routing (fig. 3.10, pp. 44-45) – Assembly chart (fig. 3.11, P. 46) – Operation process chart (fig. 3.12, p. 47) -- Combines above • Volume, trend and life • Computer-Aided Process Planning (CAPP) CAD CAPP 4. CAM UB UB State University of New York at Buffalo Department of Industrial Engineering Schedule Design 4. State University of New York at Buffalo Department of Industrial Engineering Schedule Design • How much to produce at a time (lot sizing) • How long to produce • Uncertainty: most likely, optimistic, pessimistic • When to produce (scheduling) • Qualitative information (Table 3.4, p. 53) 4.1 Market information • Less specific information => general design 4.2 PARETO ANALYSIS • More specific information => optimized design • Variety vs. Volume (P-Q) analysis • Volume, trend and life UB UB State University of New York at Buffalo Department of Industrial Engineering Page 2 State University of New York at Buffalo Department of Industrial Engineering 4. 5. Production Quantity & Equipment Requirement Schedule Design • Uncertainty: most likely, optimistic, pessimistic DETERMINING CAPACITY REQUIREMENTS • Qualitative information (Table 3.4, p. 53) • Quantity requirements workload) 4.2 PARETO ANALYSIS • X = D [ I - B ]-1, D = end-item demand vector, X = prod. State University of New York at Buffalo reqmnts. 15% UB State University of New York at Buffalo Department of Industrial Engineering 5. Production Quantity & Equipment Requirement C (1) 5.2 DETERMINING INPUT REQUIREMENTS CONSIDERING SCRAP • Definitions – Pk : percentage of scrap produced on k-th operation – Ok : desired non-defective output from k-th operation – Ik : input requirement to k-th operation BOM M atrix B(2) D(2) A 0 0 0 0 0 B 2 0 0 0 0 C 1 0 0 0 0 D 0 2 0 0 0 E 0 3 0 0 0 1 -1 0 (I - B) = 0 0 0 2 1 0 0 0 1 0 1 0 0 4 2 0 1 0 6 3 0 0 1 E(3) Ik D = (100, 0, 5, 10, 15) ; X = (100, 0, 5, 10, 15)(I - B)-1 = (100, 200, 105, 410, 615) UB – Equip. Fraction = (Total time for operation) / (Total time available) – Total time reqd. = setup time × # of setups + run time × # of opns. – Reliability Factor (m/c efficiency) = uptime/(uptime + downtime) • DETERMINISTIC MODEL total time reqd. capacity per × efficiency × K-th operation O k = Ik+1 PkI k (K+1)-th operation UB State University of New York at Buffalo Department of Industrial Engineering 5.3 DETERMINING EQUIPMENT REQUIREMENTS INDIVIDUAL EQUIPMENT REQUIREMENTS • EQUIPMENT FRACTION: proportion of equipment reqd. for an op. # of machines required = Department of Industrial Engineering 5. Production Quantity & Equipment Requirement 5.1 DETERMINING QUANTITY REQUIREMENTS A B C D E => • BOM matrix,B = [bij], bij = # of item j required for 1 unit item i job shop arrangement (process layout) A time 5.1 DETERMINING QUANTITY REQUIREMENTS mass production arrangement (product layout) UB processing • Equipment requirements • Variety vs. Volume (P-Q) analysis 85% (& performance • PROBABILISTIC MODEL OVERALL EQUIPMENT REQUIREMENTS • combine equipment factors for identical equipment type • consider overtime and subcontracting UB Page 3 State University of New York at Buffalo Department of Industrial Engineering