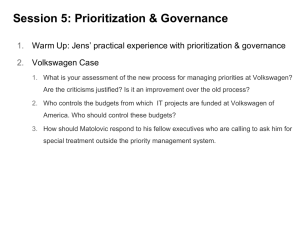

Acquisition of Škoda Auto Company by Volkswagen Group

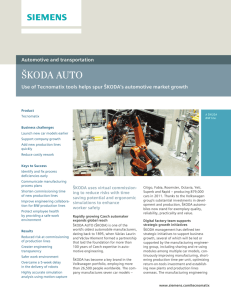

advertisement