47 Molar Mass Determination from Freezing Point Depression When

advertisement

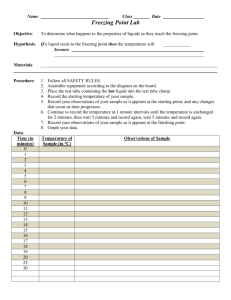

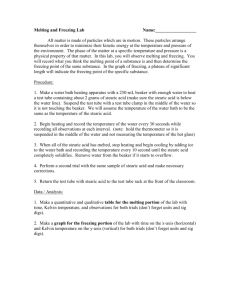

A GREENER APPROACH TO COLLIGATIVE PROPERTIES Molar Mass Determination from Freezing Point Depression When a nonvolatile solute is dissolved in a solvent, the solvent’s boiling point is increased, its freezing point is decreased, and its osmotic pressure is increased. These characteristics of a solution are termed the colligative properties. Colligative effects are observed in many phenomena such as the melting of ice on winter roads from “salting”, addition of antifreeze to a car’s radiator to prevent “freeze up”, and the rising of water in trees, due to osmotic pressure. This procedure deviates significantly from normal “colligative properties” labs. The driving force behind the change in procedure stems from a desire to reduce waste and use less toxic materials. Previously, compounds such as p-dichlorobenzene, biphenyl, benzil, and naphthalene were used. As these compounds are toxic and therefore potentially hazardous, they have been replaced with naturally occurring non-toxic fatty acids. One of the green objectives of this lab is to reduce waste by converting the used fatty acids into useful products such as soap, candles or bio-diesel fuel. For this reason, waste disposal directions should be followed carefully. The amount the properties of a mixture change due to colligative effects depends on the number of moles of solute particles dissolved in the solvent and not the nature of the particles. It is therefore imperative to know whether the dissolved solute produces one mole of particles for every mole dissolved, or whether the solute dissociates into two, three or more particles on dissolving. Ionic compounds when dissolved in water produce more than one mole of particles (ions). NaCl produces two moles of ions, while CaCl2 produces three moles of particles (i = 2 for NaCl; 3 for CaCl2) The relationship between the boiling point elevation (BPE) and the freezing point depression (FPD) to the corresponding change in temperature is given by the following equations: BPE : ΔTb = ikbm FPD : ΔTf = ikf m Where, ΔTb is the difference between the boiling point of the solution and the boiling point of the solvent and ΔTf is the difference between the freezing point of the solution and the freezing point of the solvent. The change is temperature, ΔT, is always a positive value. The number of particles is represented by the Van’t Hoff Factor, i. In this experiment the solute is molecular (non-ionic) and i will equal one. The concentration of the solution is determined in molality, m. The molal boiling point constant, kb, and the molal freezing point constant, kf, are specific for each solvent. Some representative values are shown below. 47 Solvent water benzene camphor stearic acid kb (°C kg/ mole) 0.52 2.53 40.0 kf (°C kg/ mole) 1.86 5.10 5.95 4.50 One use of colligative properties is the determination of the molecular weight of a substance. In this experiment, the freezing point of pure stearic acid will be measured. A weighed quantity of an unidentified sample will be added to the pure stearic acid and the freezing point re-determined. The difference between the freezing points of pure stearic acid and the mixture is the freezing point depression, ΔTf. Knowing the molal freezing point constant for stearic acid, the molecular weight of the unidentified sample can be determined by using the following equations. Hazards Stearic, lauric, myristic and palmitic acids are non-hazardous, but prolonged skin contact may cause irritation. If fatty acids are spilled on skin, students should wash affected areas thoroughly with soap and water. 2-propanol is flammable and should be kept away from an ignition source. Prelab Questions: 1. 2. 3. 4. 5. Do colligative properties depend on the number of particles dissolved, the identity of the particles dissolved, or both? If 1.00 g of arachidic acid (CH3(CH2)18COOH) is added to 9.00 g of stearic acid, what is the resulting molality? For the same solution described in question 2, what is the expected FPD (recall, i = 1 and Kf = 4.50 °C/m)? If a second 1.00 gram addition of arachidic acid is added to the 9.00 g sample of stearic acid what is the expected total FPD? Write a specific reaction, using full Lewis structures, that illustrates the formation of soap from a fatty acid (use stearic acid as the specific example fatty acid). 48 Experimental: 1) Prepare an insulating jacket by wrapping a piece of paper towel around an 18 x 150 mm test tube, A, and fitting it in a 25 x 150 mm test tube, B. Remove the 18 x 150 mm test tube , A, and reserve the 25 x 150 mm test tube, B, and the paper towel as the insulating jacket (see Figure A). The insulating jacket prevents premature cooling due to contact with the skin or other surface. 2) Determine the mass of the 18 x 150 mm test tube removed from the insulating jacket on an analytical balance. 3) Fill the test tube approximately 3/4 full, about 9 grams, with stearic acid and reweigh the test tube and its contents to determine the exact amount of stearic acid employed. Thermometer (0-110°C) Paper Towel 18 x 150 mm (inner tube-A) 25 x 150 mm (outer tube-B) Fatty Acid Mixture Figure A. Schematic for the construction of an insulating jacket. 4) Prepare a hot water bath by filling a 600 ml beaker 3/4 full with tap water and heating with either a Bunsen burner or a hot plate. If a Bunsen burner is used, the beaker should be supported on a ring stand with wire gauze. The beaker should also be supported using a chain clamp. 5) Immerse the 18 x 150 mm test tube containing the fatty acid sample in the hot water bath to melt the fatty acid. After the fatty acid sample has completely melted, place the thermometer in the fatty acid sample and heat until the sample reaches 85 °C. From this point on, the thermometer is not removed from the fatty acid sample to prevent loss of material and contamination of bench tops with fatty acids. Remove the test tube from the water and dry the outside. 6) Place the 18 x 150 mm test tube containing the fatty acid sample in the previously prepared insulating jacket. Stirring constantly with the thermometer, record the temperature of the sample every 30 seconds for 8-10 minutes. Temperatures are collected until the temperature of the sample remains constant, changing by less than 0.1 °C per reading, for 3 minutes, 6 readings. Perform a second trial using the same sample. 7) To the fatty acid sample used above, add approximately 1 g of an unidentified sample. Exactly 1 g is not needed, but you must know the mass added to the nearest 0.1 mg. 8) Repeat steps 5 and 6 on this fatty acid sample. Two trials of this sample are performed. 9) To the same fatty acid sample, an additional 1 g of the same unidentified sample is added. Again, exactly 1 g is not needed but you must know the mass added to the nearest 0.1 mg. 10) Repeat steps 5 and 6 on this fatty acid sample. Two trials of this sample are performed. 49 Clean-up procedure 1) After you have completed your final trial, use the hot water bath to reheat the test tube and the fatty acid sample to 85 °C until all of the fatty acid has melted. 2) Pour all of the melted fatty acid mixture out into a clean beaker container labeled “PRIMARY FATTY ACID WASTE”. You will use this waste to make soap (see below). 3) At this point, you must shut off your Bunsen burner due to the flammability of the 2-propanol to be used in the next step. 4) In the fume hood in your lab, you will find a large beaker filled with 2-propanol. If you wish to wear gloves for this procedure, you should put them on now. 5) Dip your test tube into the beaker of 2-propanol (labeled “SECONDARY FATTY ACID WASTE”) and dump the contents back into the same beaker. Continue to do this until your test tube is “mostly” free of fatty acid residue. Do a final rinse of your test tube with CLEAN 2-propanol taken from the bottle (not the waste beaker). This clean 2-propanol should remove the final film of fatty acid from the test tube. Pour the 2-propanol mixture into the waste beaker labeled “SECONDARY FATTY ACID WASTE”. Converting the Fatty Acid Waste to Soap Conversion of the fatty acid waste stream to soap is accomplished as follows: 10 g (39 mmol assuming 100% stearic acid) of fatty acid mixture is placed in a 600 mL beaker. The fatty acid is heated until completely melted. Applied heat should not exceed 85 °C to prevent boiling of the subsequently added water/base mixture. The melted mixture is magnetically stirred, and 19.5 mL (39 mmol) of 2 M sodium hydroxide is added over 20 minutes in 5 mL aliquots. Stirring is adjusted as needed to avoid excess sudsing. The solution is stirred at 75 °C for an additional 5-10 minutes to aid removal of excess water. The warm mixture is transferred to a food grade mold such as an ice cube tray, candy mold, or a large container lined with plastic wrap. The soap you made today is ready for use as a general-purpose laboratory soap for washing hands or glassware. The soap we have prepared has not been found to be irritating, but monitoring the pH during the neutralization reaction is recommended to prevent addition of excessive amounts of base. A pH of 8 - 9 for the final mixture is recommended. The soap is not recommended for washing faces. If future experiments were planned on this “product”, the mixture would be cured for at least 2 weeks in a well-ventilated area. After 2 weeks, the soap should be checked for hardness: the soap usually is reduced to approximately 1/3 of the original volume. Further experiments to add emollients such as glycerin, to prepare the soap in flake form specifically for washing glassware, and to change the base from NaOH to KOH to investigate the preparation of a liquid soap could be done. 50 Data Treatment To accurately determine the freezing points of pure stearic acid and each of the solutions, “cooling curves” of temperature (y-axis) versus time (x-axis) are plotted. Data where the temperature changes by more than 0.5 °C per 30 seconds is plotted as one series and data where the temperature changes by less than 0.5 °C per 30 seconds as a second series. A best fit line is then calculated for each series and the freezing point is obtained by finding the intersection of the two best fit lines, see Figure B. Three graphs are needed. The two trials for each sample may be recorded on the same graph. From these graphs determine the freezing point for the pure stearic acid and each of the stearic acid and unidentified sample mixtures. The plot for pure stearic acid will be the same as the plots for the mixtures except the melting point will appear at a higher temperature for the pure stearic acid then it does for the mixtures. Figure B. Colligative properties data obtained using a mixture of stearic and myristic acids. The figure illustrates the data analysis process for determining the freezing point of the mixture. Calculations 1) Average the freezing points for each of the three samples tested. Find the change in freezing points, ΔTf, for the mixtures by comparing the freezing point of each to the freezing point of pure stearic acid. 2) Use this to find the molality of each solution 3) Use the molality to determine the moles of unidentified sample added in each trial. NOTE: for the second addition of unidentified sample, the total number of moles added is found. 4) Determine the molecular weight of the unidentified sample. 5) Determine the average molecular weight and identity of your unknown from this list. Myristic Acid C14H28O2 Palmitic Acid C16H32O2 Lauric Acid C12H24O2 51 52