MMI_WP-516.QXD

6/9/05

4:29 PM

Page 5

MICRO MOTION WHITE PAPER

Measuring Oxygen Gas Using Coriolis Technology

KNOWLEDGE

.micromotion.com

Key Benefits

•Direct mass measurement achieves high

accuracy over a wide turndown.

Independent of changes in pressure and

temperature. Uncertainties of volumetric

measurement and conversion to standard

conditions (inferred mass) eliminated. Thirdparty testing at 100:1 turndown and 60:1

operating density range confirms accuracy

and repeatability. Flow accuracy specification of ± 0.5% of actual rate ± sensor zero

stability applies to all gases.

•Lower routine maintenance costs because

Coriolis technology uses no moving parts.

Calibration factor does not shift over time,

eliminating need for routine proving. Mass

calibration factor applies to any gas.

Molecular weight changes do not affect

metering accuracy. Gas meters can be

proved using liquid medium and traditional

proving devices.

•Wider usable flow range/turndown than

other gas measurement technologies. Third

party testing verifies 100:1 performance

range.

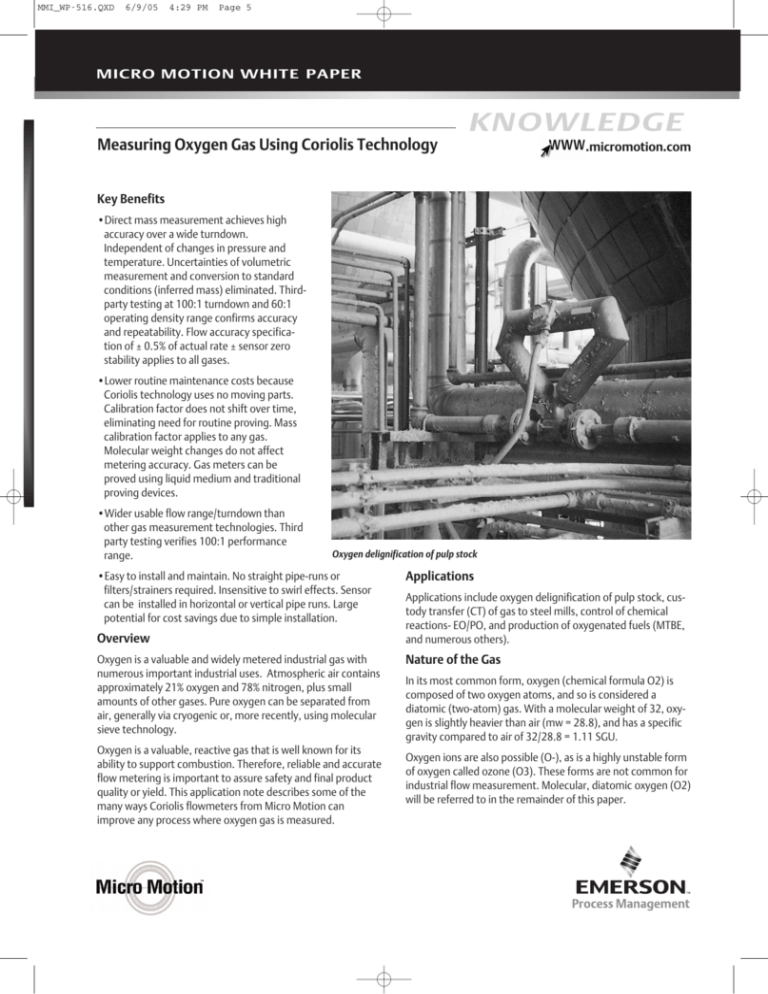

Oxygen delignification of pulp stock

•Easy to install and maintain. No straight pipe-runs or

filters/strainers required. Insensitive to swirl effects. Sensor

can be installed in horizontal or vertical pipe runs. Large

potential for cost savings due to simple installation.

Overview

Oxygen is a valuable and widely metered industrial gas with

numerous important industrial uses. Atmospheric air contains

approximately 21% oxygen and 78% nitrogen, plus small

amounts of other gases. Pure oxygen can be separated from

air, generally via cryogenic or, more recently, using molecular

sieve technology.

Oxygen is a valuable, reactive gas that is well known for its

ability to support combustion. Therefore, reliable and accurate

flow metering is important to assure safety and final product

quality or yield. This application note describes some of the

many ways Coriolis flowmeters from Micro Motion can

improve any process where oxygen gas is measured.

Applications

Applications include oxygen delignification of pulp stock, custody transfer (CT) of gas to steel mills, control of chemical

reactions- EO/PO, and production of oxygenated fuels (MTBE,

and numerous others).

Nature of the Gas

In its most common form, oxygen (chemical formula O2) is

composed of two oxygen atoms, and so is considered a

diatomic (two-atom) gas. With a molecular weight of 32, oxygen is slightly heavier than air (mw = 28.8), and has a specific

gravity compared to air of 32/28.8 = 1.11 SGU.

Oxygen ions are also possible (O-), as is a highly unstable form

of oxygen called ozone (O3). These forms are not common for

industrial flow measurement. Molecular, diatomic oxygen (O2)

will be referred to in the remainder of this paper.

MMI_WP-516.QXD

6/9/05

4:29 PM

Page 2

Page 2 of 4

MICRO MOTION WHITE PAPER

Oxygen has no group classification, per the National Electric

Code (NEC). However, since oxygen supports combustion of

other substances, certain precautions are typically used in oxygen piping systems to increase safety. These precautions

include special cleaning of all piping components and velocity

guidelines. Brochure G-4.4 from the USA Compressed Gas

Association is frequently used in the design, installation, and

startup of oxygen gas piping systems. CGA brochures are voluntary guidelines reflecting current industrial practices in the

chemical, steel, petroleum, and other industries, and as such,

are designed to benefit users in the areas of safety and economic transmission and distribution of gaseous oxygen.

Selected excerpts from pamphlet G-4.4 will be referenced in

this paper, specifically as applied to Coriolis measurement of

oxygen gas. It is suggested that pamphlet G-4.4 be consulted

in its entirety for additional guidelines beyond the scope of this

paper. Micro Motion wishes to express its appreciation to the

CGA for the excerpts contained herein.

The Applications

O2 delignification of pulp stock

Exposing wood pulp to oxygen gas removes additional lignins

after the Kraft digester—without attacking the wood fibers

themselves. Since lignins adversely affect pulp brightness,

delignification effectively whitens the pulp stock. In many

processes, the pulp stock is bleached using chlorine after the

O2 delignification stage. A typical process schematic is shown

below:

Fiscal transfer of oxygen gas; air separation plant to steel mill

were cited by users as valuable attributes:

“It is a great benefit to have an in-line meter capable of measuring

mass flow of O2 directly and accurately without the need to pressure and temperature compensate.”

“We forgot where the meter was because it has worked so reliably

in the 2+ years in service.”

Custody transfer of oxygen gas

Oxygen gas is commonly used in the production of steel

throughout the world. Metering the amount of gas consumed

is a custody transfer (CT) application. Payment is based on the

totalized flowmeter reading. Pricing is usually on a mass or

standard volume (inferred mass) basis, making the Coriolis

meter ideal for this application. Oxygen is usually generated

“on-demand” by an air separation plant located on site. Flow

rate can vary widely, depending on the demand from the oxygen blast furnace and the rate of steel production. High accuracy over a wide range of flow rate, pressure, and temperature

is required for accurate CT. Coriolis meters have been

approved by national governing bodies for this fiscal transfer.

Chemical reaction control

Critical chemical reactions can be controlled using Coriolis

meters to measure the mass flow rate (standard or normal volume) of oxygen feed gas. Good examples include ethylene

oxide (EO), propylene oxide (PO), and acetaldehyde.

PFD: Oxygen delignification of pulp stock

Sizing and Selection

The objective of the overall process is to use less chlorine.

Bleaching lignins requires substantial amounts of chlorine, and

removing more of the lignins earlier in the process using oxygen is more effective and reduces the amount of chorine

required. The oxygen reactor is essentially a finely tuned secondary digester.

Sizing and selection of flowmeters for oxygen service is virtually identical to sizing other Coriolis gas meters. The two primary

criteria are acceptable pressure drop and desired accuracy

over the flow range of interest. Maximum recommended

velocity per CGA Pamphlet G-4.4 can modify the flowmeter

size selected, and cleaning is frequently considered by the end

user.

Accurate control of the oxygen feed gas using a Coriolis meter

from Micro Motion enables good process control. Direct mass

measurement as well as elimination of routine maintenance

The use of the WindowsTM-based MMI WIN sizing program

greatly facilitates sizing and selection of the oxygen gas

MMI_WP-516.QXD

6/9/05

4:29 PM

Page 3

Measuring Oxygen Gas Using Coriolis Technology

Page 3 of 4

PFD: Acetaldehyde production using oxygen process

flowmeter. User-entered variables include flow rate, operating

pressure, and temperature. Several possible flowmeter models are selected by the program. The final selection is based on

allowable pressure drop, desired accuracy, and velocity.

Micro Motion’s ELITE® flowmeter is preferred for gas service

(although numerous D-model flowmeters have been used in

the past), and are preferentially selected by the sizing program. With sizes ranging from the 1/4" (6 mm) model CMF025

to the 3" (80 mm) model CMF300, oxygen flow rates from virtually zero to approximately 7000 scfm (600 lb/min) or 12 x

106 NM3/h (16,000 kg/h) can be measured using a single

flowmeter (following the CGA velocity guidelines). For higher

flow rates, two or more CMF300 sensors can be installed in

parallel.

CGA velocity guidelines are shown in Figure 1. Per CGA, pipe

size should be selected to adhere to the maximum recommended velocity as a function of gas pressure. This is based on

typical stainless steel piping. CGA guidelines also include information on system components such as flowmeters, where

due to practical sizing concerns, the piping velocity guidelines

may be exceeded.

The CGA suggests that upstream filters be considered to

remove particulate material. This prevents impingement and

possible sparking.

Impingement of particulates (weld slag, bits of corrosion, or

rust particles) at high velocity is thought to create sparking,

and is therefore a source of ignition energy. In the presence of

combustible particulate material, this can initiate fires inside

the piping.

Oxygen service cleaning is frequently specified by the end-user

and is intended to eliminate sources of combustible material

inside the piping. When internal organic, inorganic, and particulate matter are removed, a system is generally considered

clean for oxygen service. The following excerpt from paragraph 3.5 Oxygen Service Cleaning of CGA Pamphlet G-4.4

explains further:

3.5.1 General requirements

A system is considered clean for oxygen service when internal

organic, inorganic, and particulate matter are removed. Removal

of contaminants such as greases, oils, thread lubricants, dirt,

water, filings, scale, weld spatter, paints, or other foreign material

is considered critical. This can be accomplished by precleaning all

parts and maintaining this condition during construction, by completely cleaning the system after construction, or by a combination of the two. CGA Pamphlet G-4.1 thoroughly describes this

procedure.

Oxygen service cleaning of the sensor is available from Micro

Motion for a nominal charge.

Performed by qualified outside vendors, the cleaned sensor is

then “bagged, tagged, and sealed.” Please contact the factory

or your local sales representative for more information on oxygen service cleaning.

References

User reference lists are available to help verify manufacturer

claims. Customer copies of third-party test data is also availFigure 1. CGA velocity guidelines

MMI_WP-516.QXD

6/9/05

4:29 PM

Page 4

Page 4 of 4

MICRO MOTION WHITE PAPER

Measuring Oxygen Gas Using Coriolis Technology

able. Please contact your local sales representative for more

information.

Summary

Oxygen is a commonly measured, valuable industrial gas and

is used in a wide variety of processes. Reliable, accurate flow

measurement is critical to insuring the safety of plant personnel, product quality, and maximum yield. Existing volumetric

technologies such as dP, turbine, and vortex are limited by

turndown, accuracy, and reliability. Thermal mass meters have

often been used, but are somewhat maintenance-intensive

and have the tendency to drift with ambient temperature

changes.

More recently, Coriolis meters from Micro Motion have been

used in oxygen service with excellent results. With useable

turndown of 100:1 and excellent accuracy over a 60:1 operating density range, Coriolis meters from Micro Motion also

eliminate straight-run requirements and routine maintenance.

Direct mass measurement, synonymous with standard or normal volumetric units, is fundamentally more accurate, and

eliminates the need for flow correction factors based on pressure and temperature. Installation is simple and straightforward, with no requirements for flow conditioning.

With an installed base of over 150,000 flow and density sensors worldwide, Micro Motion can provide the measurement

expertise and support you desire. Extensive third-party testing, and more than 7500 gas-phase applications around the

world, have increasingly shown the numerous benefits of

using Micro Motion Coriolis technology to measure oxygen

gas.

.micromotion.com

The contents of this publication are presented for informational purposes only and,

while every effort has been made to ensure their accuracy, they are not to be construed

as warranties or guarantees, expressed or implied, regarding the products or services

Micro Motion supports PlantWeb field-based architecture,

a scalable way to use open and interoperable devices and

systems to build process solutions of the future.

Micro Motion, Inc. USA

Worldwide Headquarters

7070 Winchester Circle

Boulder, Colorado 80301

T (303) 527-5200

(800) 522-6277

F (303) 530-8459

www.micromotion.com

WP-00516

Micro Motion Europe

Emerson Process Management

Wiltonstraat 30

3905 KW Veenendaal

The Netherlands

T +31 (0) 318 549 549

F +31 (0) 318 549 559

described herein or their use or applicability. We reserve the right to modify or improve

the designs or specifications of our products at any time without notice.

Micro Motion Japan

Emerson Process Management

Shinagawa NF Bldg. 5F

1-2-5, Higashi Shinagawa

Shinagawa-ku

Tokyo 140-0002 Japan

T (81) 3 5769-6803

F (81) 3 5769-6843

Micro Motion Asia

Emerson Process Management

1 Pandan Crescent

Singapore 128461

Republic of Singapore

T (65) 6 777-8211

F (65) 6 770-8003

©2004. Micro Motion, Inc. All rights reserved.