Ganong case study FINAL.ai

advertisement

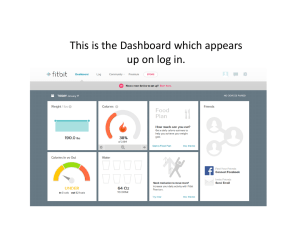

Virtual Energy Management CASE STUDY Based in St. Stephen, N.B. Canada, Ganong Bros. Limited is Canada’s oldest independent candy maker. It’s a family-owned manufacturer of premium chocolates, sugar confectionary and fruit snacks, including well-known brands such as Ganong, Delecto, Chicken Bones, Fruitfull and Sunkist. The facility is 180,000 ft² in size and employs approximately 400 people. The Case The main facility of Ganong was constructed in 1999. Since that time, energy efficiency or environmental considerations have changed for a plant’s design. Even though the facility has gone through many upgrades and retrofits since then, there were still opportunities for improvement. Like many small-to-medium manufactures, for Ganong to stay competitive and cost effective , continuous improvement has become an essential ingredient to profitablity. At the same time, consumers are also becoming more aware about their vendors’ environmental record and policies. To meet their goals of energy efficiency & cost savings, Ganong decided to innovate by integrating an energy management solution into its operations. CUSTOMER COMMENTS This is a progressive energy soluon. It is an ongoing connuous improvement program. Analyzing energy usage has become a science and having access to SHIFT’s experse and our data will allow us to make decisions based on facts. We consider them our partner in energy reducon. Jeff Prucell Vice President of Operaons While talking to the journalists in a press conference introducing SHIFT’s VEM soluon at Ganong Bros. SHIFT Energy and MCW Maricor worked together to conduct a site audit identifying energy saving opportunities and to develop the foundation for the development of an energy monitoring strategy. Subsequently,Ganong entered into an agreement with SHIFT Energy to use its EnergyMentor™ solution. Virtual Energy Manager Engagement Ganong realized that for any energy performance improvement project to be successful in regards to energy utilization, plant managers must be able to measure what they were managing. EnergyMentor™, SHIFT’s real time energy analytics dashboard, proved to be the best available solution for their need. The dashboard would give plant managers a way to monitor and gain energy insights about their production lines. It would also provide information to the Executives and indeed all of the facitility employees so that everybody could contribute – opening up efficiency possibilities not just the plant floor but to the entire facility including non-production areas like office rooms, cafeteria even outside the building (i.e. outdoor lighting). Access to information is good. But it was clear from the beginning that Ganong needed more than an energy information system. They needed to spot the opportunities and act on them. For example, looking at the dashboard, their employees could know they had a marginal electricity demand cost of $13.1138/kW. But is it normal for their facility? If not, why is it high/low? What can they do to change that? Given that it’s a complex factory that runs almost 24/7, figuring out such questions would be daunting for even a regular person from looking at an energy monitoring dashboard. Figure: SHIFT VEM Model VEM Energy Balance Energy ng Modeling Data to Information Ongoing Audit Benchmark & Evaluation Best Practices s To translate such information and to actively help Ganong in their search for efficiency and sustainability, SHIFT suggested our VEM (Virtual Energy Manager) offering. Our VEM package is designed for customers who do not have the engineering capability or resources to analyze the real-time information provided by an EMIS dashboard. SHIFT would assign a certified energy manager to such customers who would work with them over the period of the contract and help them on energy, process and sustainability improvement initiatives. This included: Consulting and analysis by our certified energy engineers; On site engagement as and when needed; Performance target setting and notification; Help with energy sourcing and energy efficient equipment procurement; Monthly and quarterly reports on the progress; Workshops and training for employees. Saving Opportunities The table below shows what energy measures were focused and the impacting areas: Table: Areas of Opportunity Source of Energy Use Energy Efficiency Measures Lighting Total 20+ areas were observed for CFL/LED upgrades, occupancy sensors, separate circuit controls etc. Air Damper By turning off unused/redundant air flow to the Compressor Room. Air Handler Unit Building control system adjustment for set-points, schedule optimization, filter changes etc. for total 12 AHUs in various areas of the facility. Heating Adjusting the thermostat for Shipping Warehouse during weekends and nights. Power Factor PF correction for Line 5 in Electrical Room Substation Funding Assistance SHIFT’s energy management program that would help Ganong identifying opportunities to save energy through energy monitoring and ongoing energy management was approved by Efficiency New Brunswick and Department of Energy for a 50% funding assistance. Their aim was to learn how an energy management program could be appropriately scaled from a large industrial model to a medium size plant using an Energy Management Information System (EMIS). Conclusion The work SHIFT has done with Ganong in collaboration with other partners solidified our understanding of successful energy management programs in the mid-size manufacturing market. It proves that, energy management program can be designed to be cost effective and deliver desired outcomes in even mid-sized manufacturing environments. For more information please visit us at: www.shiftenergy.com To contact us: Address Call/Fax SHIFT Energy Inc. 75 Prince William Street Saint John, New Brunswick Canada, E2L 2B2 Email Toll-free: 1-800-SHIFT-60 Phone: (506) 642 9422 Fax: (506) 642 6138 info@shiftenergy.com Linkup with us on social media: SHIFT Energy Blog www.twitter.com/ shiftenergyca www.linkedin.com/company/ shift-energy-inc. www.youtube.com/user/ shiftenergy http://blog.shiftenergy.com