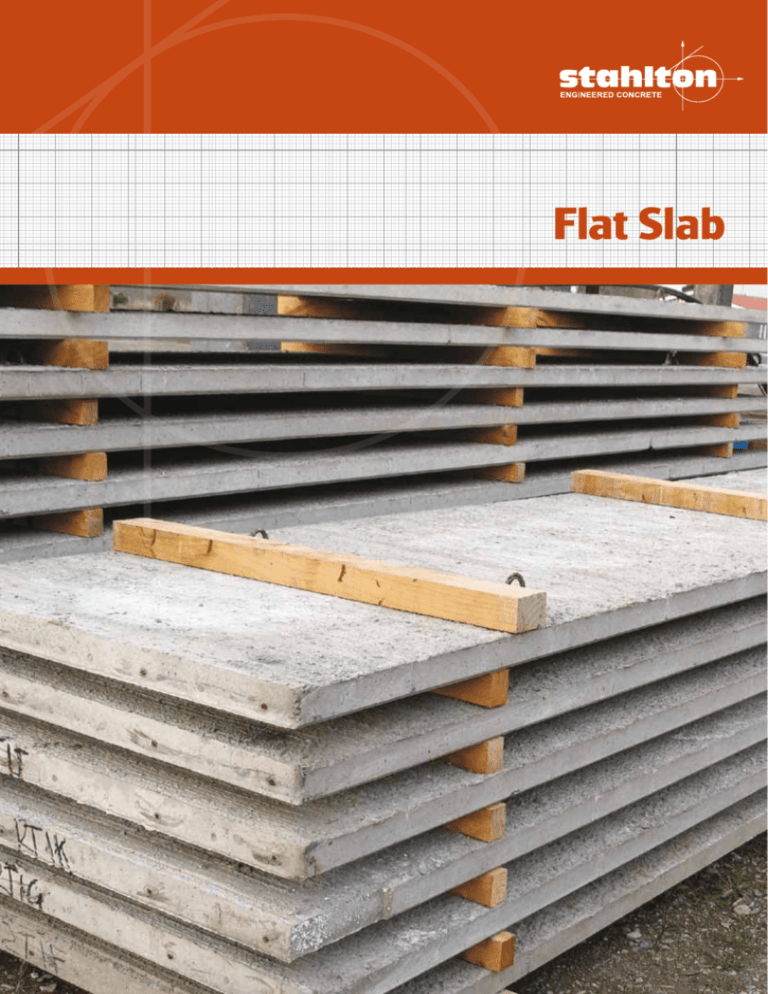

Flat Slab - Stahlton Engineered Concrete

advertisement

Flat Slab Contents Flat Slab is ideal for short span floors which are subjected to uniformly distributed loads, and is used extensively in residential buildings as well as in certain areas of commercial buildings. Flat Slab can also be used for cantilever balconies as permanent formwork. Flat Slab is manufactured using a wet pour process, poured onto a long heated steel bed. This manufacturing process allows the product to be poured to any achievable design length and shape, making Flat Slab versatile and flexible to use on building sites. 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 Introduction & Contents Architects General 1.0 Acoustic Rating 1.1 Durability 1.2 Thermal Rating 1.3 Fire Rating Consulting Engineers 2.0Loadings 2.1 End Seating 2.2Topping 2.3Design Weight Including Topping Concrete Contractors 3.0 Temporary Propping 3.1 Camber 3.2 Handling & Storage 3.3 Penetrations & Fixings Specifications 4.0Drawing Call-up 4.1 Written Specification Clauses Specifications 4.1 Written Specification Clauses Key Plan Flat Slab Sections 1 & 2 Flat Slab Sections 3 & 4 Flat Slab Sections 5 & 6 Flat Slab Sections 7 & 8 Flat Slab Section 9 Fixings to Flat Slab Camber Allowances, Support & Handling 75 & 100 Flat Slab 125 & 150 Flat Slab Load Span Graph 75 Flat Slab Load Span Graph 100 Flat Slab Load Span Graph 125 Flat Slab Load Span Graph 150 Flat Slab www.stahlton.co.nz 2 Architects General 1.2 Thermal Rating Stahlton Engineered Concrete supplies Flat Slab to any location in New Zealand. Four standard depths of Flat Slab are available including 75mm, 100mm, 125mm and 150mm deep by 1200mm wide in dimension. In some areas we can supply 2400mm wide units, please check with your local plant to see if this option is available in your region. Estimated thermal ratings (R) for Stahlton Flat Slab with 75mm deep topping are: 1.0 Acoustic Rating The Stahlton Engineered Concrete Flat Slab, with a minimum 75mm depth of topping, will provide a Standard Transmission Class (STC) rating of 55dB. 1.1 Durability Stahlton Flat Slab slabs meet exposure classifications A1, A2, B1 & B2 as per table 3.6 in NZS 3101:Part 1:2006 for a 50 year life. 3 www.stahlton.co.nz 75mm 0.10m2 oC/W 100mm 0.12m2 oC/W 125mm 0.14m2 oC/W 150mm 0.16m2 oC/W These values are a guide only; if further information is required please contact the Stahlton Engineered Concrete Technical Department. 1.3 Fire Rating All Stahlton Flat Slab floors with a minimum of 75mm of on site topping have a 60 minute Fire Resistance Rating (FRR). Refer NZS 3101:Part1:2006 table 4.3 & 4.4 for one-way slabs. Increased FRR can be achieved in some circumstances; please contact the Stahlton Technical Department if you wish to discuss further. Any penetrations through the Stahlton Flat Slab floors must also be fire rated, see page 13. Advice should be sought from the fire protection suppliers regarding suitability of their tested products with the Flat Slab floor systems. Consulting Engineers 2.0 Loadings 2.2 Topping Generally common loadings used on residential, office and apartment buildings are suitable for Stahlton Engineered Concrete Flat Slab flooring systems. The Load Span graphs (pages 18-21) assume that there is maximum strand, the flooring may be temporarily propped, the floor is simply supported and that loads are uniformly distributed. Load factors of 1.2G and 1.5Q as per AS/NZS 1170.1 have been allowed for in the design analysis. Simply compare your factored superimposed dead and live loads with the allowable shown on the graph i.e. if your project has G=0.5kPa & Q=3.0kPa, factor accordingly 1.2x0.5 + 1.5x3.0 = 5.1kPa. Compare this figure with that shown on the y-axis of the load span graph. Please note high dead loads may induce higher creep values than expected and advice should be sought from the Stahlton Engineered Concrete Technical Team for unusual cases. The topping concrete strength should be specified as a minimum of 25MPa as per NZS 3101:2006 cl 5.2.1. The minimum topping depth for Stahlton Flat Slab at midspan is 75mm. Additional topping depth will usually be required feathered out to the ends of the units to allow for an even finished floor level. Floor reinforcement and saddle bars should be designed and shown on the Consulting Engineers drawings. Steps in the topping can be formed using suitable density polystyrene, however the extra topping thickness needs to be accounted for as a gravity load and allowed for in the design. Flat Slab floors can sustain point loads and line loads. However significant loadings should be checked by one of the Stahlton Engineers at the preliminary design stage. 2.1 End Seating All Stahlton Flat Slab flooring requires a minimum of 75mm or span/180, whichever is greater, seating onto walls or beams. 15mm of construction tolerance needs to be added to both of these figures if sitting on an unarmoured concrete beam. If seating onto a steel beam or armoured edge concrete beam, 60mm of seating plus 15mm of tolerance is required. Stahlton Engineered Concrete recommends the use of low friction bearing strips for Flat Slab. Please refer to NZS 3101 cl 18.7.4B. Note ‘solid slabs’ refers to Flat Slab units used in residential applications and less seating is acceptable if only residential loadings are used. Care should be taken when pouring topping not to mound up the concrete in one place as this can produce large point loads. The mounding of in situ concrete should not exceed the construction loadings the units are designed to sustain. 2.3 Design Weight Including Topping Concrete The following figures are based on the average cross-section for each product. Topping Depth of 75mm (1.8kPa) has been allowed Depth (mm) Design Weight (kPa) 75 3.7 100 4.3 125 5.0 150 5.6 www.stahlton.co.nz 4 Contractors 3.0 Temporary Propping Temporary propping may be required for Stahlton Flat Slab to increase bottom fibre stress capacity or to even out camber variations in the flooring soffit. The natural variations in precamber expected in prestressed members can be minimized by the use of propping. Under standard uniformly distributed loadings temporary propping would be expected for spans exceeding 2.5m, 4m, 5m and 6m for 75mm 100mm, 125mm, and 150mm deep Stahlton Flat Slab units respectively. A suitably qualified Engineer will need to be consulted for the design of the propping system. 3.1 Camber Stahlton Flat Slab units will arrive at site with some positive camber (hog). This is unavoidable due to the nature of prestressing. The amount of hog will depend on a number of factors including, amount of prestress, how long the units have been exposed to the sun and length of unit to name but a few variables. As a rule of thumb allow 2-3mm of hog for every 1m of span. Generally half of the hog of the Flat Slab unit will come down after the topping concrete is poured and any propping is removed. Half of the remaining hog will eventually come out over time due to creep and shrinkage. 3.2 Handling & Storage Stahlton Flat Slab is designed to be lifted at the ends. Specifically designed lifting chains and hooks or lifting clutches can be used to lift the units. The Flat Slab unit will arrive on site with provision for hooks or lifting clutches. These anchoring points should be used without substitution. All lifting gear should be checked for any wear or damage regularly as concrete elements can be abrasive. Stahlton Flat Slab units if stored on site need to be dunnaged near the lifting points. The dunnage blocks need to be aligned on top of each other so as not to induce large point loads on the units below. 5 www.stahlton.co.nz If props are indicated on the shop drawings, the Flat Slab units will need dunnaging at these propping locations as well. Care needs to be taken as to the suitability of the ground the units are stored on and should be checked by a suitably qualified Engineer. Handling weights for Stahlton Flat Slab are: 1.2m wide 2.4m wide Depth (mm) kg/m kg/m 75 232 464 100 309 618 125 386 772 150 463 926 3.3 Penetrations & Fixings Stahlton Flat Slab units can have penetrations core drilled through the unit in specific locations (see sheet 14). No more than one penetration per 750mm of span or width of the unit is permitted, as too many holes will reduce the load capacity of the Flat Slab unit. The area of concrete around the strand must be avoided altogether. If a strand is cut onsite, temporary prop either side of the penetration immediately, then contact Stahlton Engineered Concrete as a design check will need to be done to ascertain whether the unit is still structurally sound. Advice should be sort from the fixing manufacturer as to the suitability and load carrying capacity of their products in Stahlton Engineered Concrete Flat Slab. Units can be designed with additional prestressing tendons to allow for cutting of occasional tendons, however this needs to be thought about at the start of the project and built into the design before the units are cast, bearing in mind that extra strand could induce more hog in the slab. Specifications 4.0 Drawing Call-Up: To specify the Stahlton Flat Slab system on your drawings we suggest you use the following designation; Stahlton depth Flat Slab with 75mm topping For example if the project is to be made from 100mm deep Stahlton Flat Slab with a 75mm deep topping; then the specification would read: Stahlton 100 Flat Slab with 75mm topping If Stahlton 75mm deep Flat Slab with 90mm topping is desired then; (v) Stahlton Flat Slab shall be designed to have a maximum crack width of 0.3mm under full live load conditions. (vi) The acoustic STC (Sound Transmission Class) and IIC rating of the floor system shall meet or exceed 55dB as tested at a registered institution or a field test of 50dB measured in ‘on-site’ conditions. These ratings apply to the finished floor system, including any carpeting and suspended ceiling systems. (vii) The Stahlton Flat Slab units shall have a minimum of 75mm end seating or L/180, whichever is greater, as per clause 18.7.4 in NZS 3101:2006 plus tolerance of 15mm if seated on an unarmoured concrete beam. Stahlton 75 Flat Slab with 90mm topping Materials 4.1 Written Specification Clauses: Stahlton Flat Slab products in general comply with the following standards: NZS 3101:2006 ‘Concrete Structures Standard Part 1 & 2’ NZS 3109:1997 ‘Concrete Construction’ AS/NZS 4671:2001 ‘Steel Reinforcing Materials’ BS 5896:1980 ‘Specification for High Tensile Steel Wire and Standard for the Prestressing of Concrete’ (i) Concrete shall be specifically mixed depending on environmental conditions and should have a 28 day cylinder strength of 45MPa as a minimum. (ii) All concrete shall show signs of thorough compaction otherwise rejected if repair cannot be undertaken to bring the unit back to the original specification. (iii) An air entraining agent complying with BS EN 934-2-2001 may be included in the concrete mix to improve workability. Design (iv)The strand reinforcement used in Stahlton Flat Slab shall be 9.6mm, 11.3mm, 12.7mm or 12.9mm diameter complying with the requirements of AS/NZS 4671:2001 (i) The design of Stahlton Flat Slab shall be in accordance with the requirements and recommendations of NZS 3101:2006 ‘Concrete Structures Standard Part 1 & 2’ and or any recognized international Standard or part thereof, for example BS 8110:2007 ‘The Structural Use of Concrete’. (v) Prestressing strand shall be clean and free from deleterious substances. Superficial rust is acceptable, however strand with corrosion that has caused surface pitting shall be rejected for the main longitudinal reinforcement of the unit. (ii) The prestress strand pattern in the Stahlton Flat Slab shall be designed to sustain the loadings shown on the Consulting Engineer’s drawings and allowance will be made for self weight of the unit and topping concrete. Manufacture (iii) The Stahlton Flat Slab shall be designed for exposure classification A1/A2/B1/B2 as per table 3.6 in NZS 3101:2006. (i) Materials, execution of stressing prestress strand and workmanship of the Stahlton Flat Slab units shall conform with Stahlton Engineered Concrete ISO 9001 Quality Assurance Operating Procedures (iv)The Stahlton Flat Slab unit shall have a FRR (Fire Resisting Rating) of 60/60/60. Penetrations through the flooring system shall be reinstated to the required FRR by an approved fire protection system. (ii) Stahlton Flat Slab units shall be nominally 1200mm wide (or 24000mm depending on manufacturing plant) and made from the nominal depth; 75mm, 100mm, 125mm or 150mm www.stahlton.co.nz 6 Specifications (iii) The top surface of the Stahlton Flat Slab unit shall have a nominal roughness of 5mm or more as stipulated in NZS3101:2006 clause 18.5.4.1(a) any additional requirements shown on the Stahlton Engineered Concrete drawings. (iv) The tolerance for length of the Stahlton Flat Slab units shall be in accordance with NZS 3109 (usually +/- 10mm). (iv) All proposed systems with supporting calculations shall be submitted to the Specifying Engineer prior to erection on site for approval. Handling, Protection & Placing Units Topping Concrete (i) The Stahlton Flat Slab units shall to be designed to sustain all lifting stresses. (i) The top surface of the Stahlton Flat Slab units shall be clean and free of all dust, oil or any deleterious substances which may adversely affect the wet topping bond to the Stahlton Flat Slab units. (ii) The Stahlton Flat Slab shall be lifted only at the lifting position as nominated by the manufacturer. (iii) Stahlton Flat Slab units shall be handled using certified lifting hooks or clutches. Chain angles must not exceed 30 degrees to the vertical and must be checked regularly for wear and tear. (iv) Dunnage used for storing the Stahlton Flat Slab units needs to be of suitable quality and placed on ‘good’ ground at the correct points in from the end of the units. (v) Where units are stacked one above the other, bearing dunnage shall be positioned in vertical lines. (vi) The Stahlton Flat Slab shall be handled and placed according to references contained in the Occupational Safety & Health approved code of practice entitled ‘Safe Handling, Transportation and Erection of Precast Concrete’ (vii) The units shall not be damaged in any way including chips and cracks during the erection and placing phase. Any damage should be bought to the attention of the supervising Engineer immediately. Temporary Propping (i) Design of temporary propping, back propping, bracing systems and ground conditions to support prop loads shall be carried out by a suitably qualified Engineer. (ii) Propping shall not be removed until the topping concrete has reached at least 75% of the 28 day strength. (iii) It is the Contractors responsibility to ensure the propping system used on site meets the criteria as detailed in the aforementioned design and 7 www.stahlton.co.nz (ii) Prewet precast concrete surfaces prior to placing the topping concrete. (iii) Free water shall be broomed away before the topping is applied. (iv) Topping reinforcement shall be laid and supported to the Specifying Engineers requirements and shall be supported to prevent displacement during concreting. (v) Topping concrete shall have a minimum aggregate size of ____ (normally 13mm) and a 28 day strength of ____ (minimum of 25MPa) and be well compacted with mechanical vibrators. (vi) Topping concrete shall be poured to a true surface so that the specified thickness of ____ (minimum of 75mm) is achieved at the centre of the span. (vii) In-situ concrete shall be cured by the application of an approved curing membrane or by being kept continuously wet for not less than seven days. Fixings & Penetrations (i) Fixing to the Stahlton Flat Slab units shall be in accordance with the approved details only and shall not impair or reduce the strength of the unit in any way. (ii) Documentation of tested fixings proposed for the project shall be submitted to the Specifying Engineer prior to installation. (iii) Penetrations, setdowns or chases to the Stahlton Flat Slab unit or topping concrete shall be in accordance with the details agreed by the Specifying Engineer and Stahlton Engineered Concrete prior to any work being undertaken on site. Key Plan Scale: NTS www.stahlton.co.nz 8 9 Section 1 Scale: NTS Section 2 Scale: NTS www.stahlton.co.nz Section 3 Scale: NTS Section 4 Scale: NTS www.stahlton.co.nz 10 11 Section 5 Scale: NTS Section 6 Scale: NTS www.stahlton.co.nz Section 7 Scale: NTS Section 8 Scale: NTS www.stahlton.co.nz 12 Section 9 13 www.stahlton.co.nz Scale: NTS Fixings to Flat Slab Scale: NTS Fixings to Flat Slab Scale: NTS www.stahlton.co.nz 14 15 Camber (hog) Allowances Scale: NTS Support Scale: NTS Handling Scale: NTS www.stahlton.co.nz 75 Flat Slab Scale: NTS 100 Flat Slab Scale: NTS www.stahlton.co.nz 16 17 125 Flat Slab Scale: NTS 150 Flat Slab Scale: NTS www.stahlton.co.nz 18 Level/Grid: Project Name: 0 6 12 18 24 30 36 Compare factored design load with this axis Factored Design Load, kPa 3 Date: Project Number: 3.5 4 5 0800 STAHLTON | www.stahlton.co.nz Span, m 4.5 5.5 1 Prop 5. S pecified loads on engineers drawings need to be shown unfactored. 4. S elf weight and 75mm topping have been allowed for. 3. If G>1/2Q, or if G>0.5kPa for maximum span and near maximum loads, please contact Stahlton to discuss further. 2. If your design is close to the line, please contact Stahlton to discuss options. 1. Refer to section 2.0 for more information. Notes: Factored Design Load = _______ kPa Q: 1.5 x ________________ = _______ kPa G: 1.2 x ________________ = _______ kPa Superimposed Loads Load Span Graph 75 Stahlton Flat Slab 19 Level/Grid: Project Name: 0 5 10 15 20 25 30 Compare factored design load with this axis Factored Design Load, kPa 3.5 4.5 Date: Project Number: 4 5 5.5 6 6.5 7 0800 STAHLTON | www.stahlton.co.nz Span, m No Prop 1 Prop 5. S pecified loads on engineers drawings need to be shown unfactored. 4. S elf weight and 75mm topping have been allowed for. 3. If G>1/2Q, or if G>0.5kPa for maximum span and near maximum loads, please contact Stahlton to discuss further. 2. If your design is close to the line, please contact Stahlton to discuss options. 1. Refer to section 2.0 for more information. Notes: Factored Design Load = _______ kPa Q: 1.5 x ________________ = _______ kPa G: 1.2 x ________________ = _______ kPa Superimposed Loads Load Span Graph 100 Stahlton Flat Slab 20 Level/Grid: Project Name: 0 5 10 15 20 25 30 Compare factored design load with this axis Factored Design Load, kPa 4 5 Date: Project Number: 4.5 5.5 6 6.5 7 7.5 0800 STAHLTON | www.stahlton.co.nz Span, m No Prop 1 Prop 5. S pecified loads on engineers drawings need to be shown unfactored. 4. S elf weight and 75mm topping have been allowed for. 3. If G>1/2Q, or if G>0.5kPa for maximum span and near maximum loads, please contact Stahlton to discuss further. 2. If your design is close to the line, please contact Stahlton to discuss options. 1. Refer to section 2.0 for more information. Notes: Factored Design Load = _______ kPa Q: 1.5 x ________________ = _______ kPa G: 1.2 x ________________ = _______ kPa Superimposed Loads Load Span Graph 125 Stahlton Flat Slab 21 Level/Grid: Project Name: 0 5 10 15 20 25 30 Compare factored design load with this axis Factored Design Load, kPa 5 6 Date: Project Number: 5.5 6.5 7.5 8 0800 STAHLTON | www.stahlton.co.nz Span, m 7 No Prop 1 Prop 5. S pecified loads on engineers drawings need to be shown unfactored. 4. S elf weight and 75mm topping have been allowed for. 3. If G>1/2Q, or if G>0.5kPa for maximum span and near maximum loads, please contact Stahlton to discuss further. 2. If your design is close to the line, please contact Stahlton to discuss options. 1. Refer to section 2.0 for more information. Notes: Factored Design Load = _______ kPa Q: 1.5 x ________________ = _______ kPa G: 1.2 x ________________ = _______ kPa Superimposed Loads Load Span Graph 150 Stahlton Flat Slab A Division of Fulton Hogan Limited 0800 STAHLTON | www.stahlton.co.nz The recommendations in this literature are based on good engineering judgement and building practice, but are not an exhaustive statement of all relevant information that needs to be considered to comply with the NZBC. Further, as the successful performance of the relevant system depends on numerous factors outside the control of Stahlton Engineered Concrete (eg quality of workmanship on site) Stahlton Engineered Concrete shall not be liable for the recommendations in this literature and the performance of the relevant system, including its suitability for any purpose or ability to satisfy the relevant provisions of the NZBC, regulations and Standards.