The dehydrohalogenation of 2-bromobutane: A simple illustration of

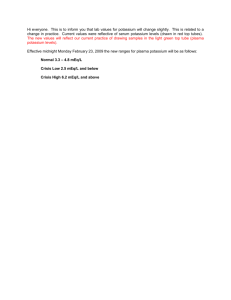

advertisement

The Dehydrohalogenationof 2-Brombutane: A Simple Illustration of Anti-Saytzeff Elimination as a Laboratory Experiment for Organic Chemistry Stephen A. Leone and J. David Davis Merrimack College North Andover, MA 01845 The dehydrohalogenation (E2) reaction of 2-bromobutane with alcoholic potassium hydroxide has been studied kinetically at the microscale level, and the results have been reported previously in this Journal (1).In the present paper we illustrate a quantitative microscale experiment ofthis reaction, and we use it to explore how increasing the base size affects the distribution of products. CH3CH2CHBrCH3+ base + cisltrans-CH3CH=CHCH3+ CH3CH2CH=CH2 Both the hydroxide-promoted dehydmhalogenation reaction cited here and the acid-catalyzed (El) reaction of 2-butanol demonstrate the Saytzeff rule, in which the more highly substituted and stable alkene usually predominates (2,3). In this case, the trans-2-butene will predominate. However, in the E2 reaction, as the base becomes bulkier according to the following sequence sodium methoxide potassium isopropmide potassium t-butoxide potassium 3ethyl-3-pentoxide the percentages of the three butanes change, showing a pmgressive increase in the l-butene a t the expense of the trans-2-butene. This trend, which represents a clear devican be observed readily ation from the Saytzeff trend (4,5), by gas chromatography. It is apparent in the chromatograms in the figure and in the data of the table. As a n additional experiment, it would also be informative to perform the E2 reaction of l-bmmobutane using either of the two larger alkoxide bases as a comparative study with the dehydration of l-butanol. This sequence not only demonstrates the poorer nucleophilicity of the larger Gas cnromatograms oJlene product 0 strcDLtlon from the E2 Reac!#onof 2-brornooutanew r h o~nercnta <oxoe bases (a, NaOCH,, rb) XOCh(Ch,),. ,c, XOC(Crl,),. (01 XOC(Ch,Ch,j, Butene Product Distribution from the E2 Reaction of 2-Bromobutane with Different Alkoxide Bases Base 'C l-butene trans-2. cis-2- butene butene bases but also reveals that, unlike the E l reaction, the E2 reactions proceed without rearrangement. Experimental Caution. Care should be used in handling potassium metal. It is very actiue, and it reacts vigorously with oxygen. Keep it under liquid that contains no oxygen. Caution: Care should be used in handline sodium metal. It 1~1olon11)decornposcc uater, formmg sodlurn hydrox~drand htdragen, whwh may rgmre spontaneou4y Sodlum rrans wgnmusly wth oxygen, hurnrng w t h a yellow llnrnc Keep it under liquid that contains no oxygen. - The estimated time to complete the experiment is two and one-half hours for any student performing two reactions. A 3-4-mL portion of the anhydrous alcohol was placed in a 5.0-mL conical vial containing a magnetic spin vane. An air condenser was attached to the vial. Then a 60-mg piece of freshly cut potassium or sodium was added. A drying tube was placed atop the condenser. The reaction vial was placed in a sand bath on a magnetic stirrer and then heated gently. (For the sodium and methanol, heat was not necessary. A water-cooled condenser is recommended.) When all the metal was reacted, the assembly was removed from the sand bath and cooled to nearly room temperature. With an Eppendorf pipet, 100 pl; of 2-bromobutane was introduced to the alcohol-alkoxide mixture. Then the assembled reaction setup was placed in the preheated sand bath. The drying tube was removed, and the gas delivery tube was attached to the condenser, with the open end of the tube beneath the water level of the reservoir. ARer several air bubbles emerged, the delivery tube was inserted under the open end of the water-filled gas-collection tube. The gas-collection apparatus was constructed as reported by Mayo, Pike, and Butcher (3)and by Pavia, Lampman, Kriz, and Engel (6). After 3-4 mL of gas was collected, the gas-delivery tube was disconnected only from the condenser to keep water from backing into the reaction vial. A2-mL gas sample was withdrawn using a hypodermic syringe. The gas sample was analyzed a t mom temperature by direct injection into the gas chromatograph. A Gow-Mac Series 150 Thermal Conductivity Detector GC was used with a flow rate of 50mLlmin of helium gas and with a column (114 in. x 8 R) packed with 20% silicone DC200 on Chromasorb P 801100 mesh. The butenes eluted from the column in the following sequence: l-butene, trans-2-butene, and cis-2-butene. The percentage ratio of the three components was calculated by triangulation. (Continuedon page A176) Volume 69 Number 6 June 1992 A175