overhead absorption - Meadowgate Training

advertisement

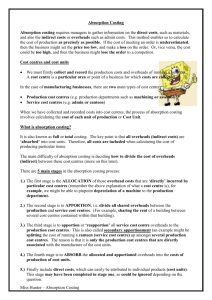

OVERHEAD ABSORPTION Encyclopaedia of Accounting OVERHEAD ABSORPTION Some costs (Direct Costs) can be directly identified with a specific product or service (Cost Unit). Other costs (Indirect Costs or Overheads) are related to a range of products or services. Therefore the total cost of a cost unit is calculated as follows: Total Cost per unit = Direct Costs of unit + a proportion of Overheads Total costs, calculated using this approach, are used for valuing stocks, calculating profit and pricing but are not usually suitable for short-term decision-making. In most organisations, only production overheads are absorbed into product costs (ie.: not sales or general administration overheads). The relevant proportion of overheads costs is calculated using the process known as Absorption Costing. This process is also known as Full Costing. There are two stages to the process of sharing out the indirect costs: 1. Allocate and apportion overhead costs to cost centres 2. Absorb overheads into the products processed in a cost centre Allocation and Apportionment Some overheads clearly belong to one cost centre (eg. The department manager’s salary) and are allocated to it. For others (e.g.: rent) a single cost may need to be divided (apportioned) between several departments. The basis for such apportionment depends on the nature of the cost. For example, rent may be divided in proportion to the floor area of the cost centres, insurance may be based on equipment value, etc. Example A factory has two departments, X (4,000 sq. metres) and Y (6,000 sq. metres). Total rental cost is £1,200,000 a year. The rental cost is therefore £1,200,000 = £120 per square metre per year 4,000 sqm + 6,000 sqm © Copyright 2012 Meadowgate Training Ltd The rental cost is apportioned as follows: Department A £480,000 £120 x 4,000 Department B £720,000 £120 x 6,000 Total £1,200,000 Absorption If a department produces only one product, the total overheads are simply divided amongst the units produced. Example Total overheads in Department X in May = £150,000 Total number of units produced in May = 300,000 Overhead per product = £150000 = £0.50 300000 This is known as the overhead absorption rate (OAR), or overhead recovery rate. When products are not identical, OAR needs to be calculated in a different way: Estimated overhead costs for period Estimated activity for the period The level of activity may be measured in various ways, including: Direct Labour Hours: OAR = £x per labour hr Machine Hours: OAR = £x per machine hr Direct Labour Cost: OAR = £x per £1 of labour or y% of labour cost Direct Material Cost: OAR = y% of material Selling price: OAR = y% of selling price An OAR of, say, £10 per labour hour implies that, whilst the production operative is working on a product for one hour, the department as a whole has spent £10 on various services to support that production. The appropriate measure to use depends on which one seems to divide the overheads amongst products in the most sensible manner. Different measures may be appropriate for different cost centres. Absorption rates are usually determined at the beginning of a period, using budget figures for overhead expenditure and cost centre volume. These are known as predetermined overhead absorption rates. Once the OAR has been established, the overhead per cost unit is calculated as: OAR x amount of activity per cost unit © Copyright 2012 Meadowgate Training Ltd Example OAR = £10 per labour hour Manufacture of Product A takes 2 hours Overhead per unit = £10/hr x 2 hrs = £20 The total cost per unit can then be calculated, given that £5 of material is required and that production staff cost £20/hour £ Material 5 Labour (2hrs x £20/hr) 40 Overhead 20 Total cost 65 Non-Production (Service) Departments For this to work, all overheads need to be charged to departments which generate goods or services. If overhead costs are allocated or apportioned to nonproduction departments, then they need to be re-apportioned to production departments in much the same way as other overheads are apportioned. For example, the overheads of the maintenance department may be charged to other departments based on the number of jobs they do for each department. Sometimes, these service departments do work for other service departments. If the re-apportionment is repeated several times (the reciprocal, or repeated distribution method), the overhead costs attributed to service departments become negligible. © Copyright 2012 Meadowgate Training Ltd OVERHEADS ALLOCATE directly to cost centres APPORTION on an equitable basis SERVICE COST CENTRES REAPPORTION to production cost centres PRODUCTION COST CENTRES ABSORB into product cost PRODUCT PRODUCT PRODUCT © Copyright 2012 Meadowgate Training Ltd Under/over Absorption If actual overhead expenditure exceeds budget, then the predetermined amount of overhead absorbed into the product cost is less than it needs to be. Any calculations using the predetermined rate will under-absorb (under-recover) the overhead (ie. Overstate profit). The same effect will arise if the actual level of activity is smaller than budget. Similarly, low actual expenditure or high actual activity lead to over-absorption of overhead. Example Department M has an OAR of £1.72 per machine hour. Actual overhead expenditure was £1,800,000 and actual machine hours were 800,000: £ Actual overhead 1,800,000 Overhead costs based on predetermined rate 1,376,000 (800,000hrs x £1.72) Under-absorption 424,000 © Copyright 2012 Meadowgate Training Ltd