Case study - Asia Food

advertisement

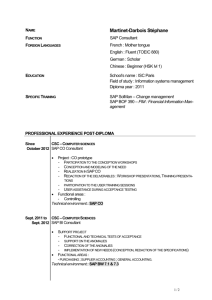

BUSINESS SOLUTIONS TECHNOLOGY OUTSOURCING SAP SOLUTION FOR INSTANT FOOD MANUFACTURER OBJECTIVES • Automate operation and management processes in a multi-site company. SOLUTION • Standardize business processes and integrate into a single ERP system. CUSTOMER A leading company in Vietnam specialized in producing instant food. CLIENT PROFILE Our client is a leading company in Viet Nam specialized in producing instant noodle and other instant foods. With over 1700 employees and 11 production lines, the company is providing billions of packs of products for domestic and many foreign markets. TECHNOLOGY Sales & Distribution (SD) module in SAP R/3 Product Planning (PP) module in SAP R/3 Materials Management (MM) module in SAP R/3 Financial Accounting (FI) module in SAP R/3 Quality management (QM) module in SAP R/3 Controlling (CO) module in SAP R/3 Basis configuration SERVICE REQUEST Even though our client has been presented on the market for more than 20 years and is a leader in both domestic and many foreign markets, they was still facing a lot of problems with managing and operating due to the lack of automatic management processes, loose connection between divisions, and lack of data transparency between business and operation units. An ERP solution to provide standardized processes to improve productivity, manageability and operation was an urgent need. CHALLENGE Green field implementation to a company that had never used an ERP solution. To provide a solution for 100 SKUs with different pack sizes and flavors. Warehouse control procedures were not in place. There were almost no tools to support information integration, most of the logistics operations were manually logged. Information was not transparent among business and operation units which led to inefficient planning and operation. Simplify processes and consolidate activities where possible. Preparedness for future expansion plans. Standardization of business processes and integration in a single ERP system. KEY SUCCESS FACTORS People • 12 resources on average, delivered solution in 12 weeks. Results • Efficiency in end-to-end business processes by streamlining the internal and external operations. SOLUTION Provide an SAP-based solution including the following modules: SD, MM, PP, QM, FI, and CO. Efficient development of customer specific solutions while, at the same time, pursuing standardization. Transparently mapping the logistical procedures with traceable lot-related production. Control up-front profit segment and cost. Clearly identify cost drivers through transparent accounting procedures and cost management. RESULTS Efficiency in end-to-end business processes by streamlining the internal and external operations. Improved decision making through achievement of data integrity and real-time reporting. Better inventory control by eliminating manual processes and by improving inventory accuracy. Improved monitoring, managing, and controlling of primary sales data. Optimized production control by facilitating efficient planning, execution and reducing costs. Efficient quality management by handling traditional quality tasks: planning, inspection, certification, notification and control. Better accounting practices, fully compliant with Vietnam Accounting Standard. Improved financial control, gained visibility into the organization with financial and management accounting functionality. The project has been received “The Fastest Implement SAP Project Award” selected by SAP. CSC Vietnam 366 Nguyen Trai, District 5, Ho Chi Minh City, Vietnam Email: CSCV-Info@csc.com www.csc.com/vn_en Copyright © 2011 CSC Vietnam

![IS 788 [Process] Change Management](http://s3.studylib.net/store/data/009436316_1-f757e8917dd2355696a4b5ae7aa5d9ab-300x300.png)