Blue-Tip SCREW-BOLT

advertisement

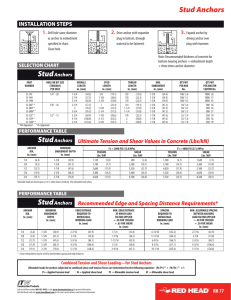

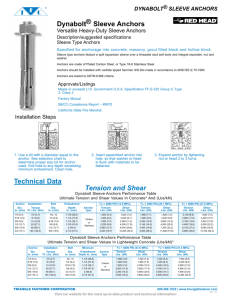

® FAS T E N E R S Blue-Tip SCREW-BOLT™ zero expansion one piece completely removable Edition: Jan 2005 ® FA S T E N E R S Powers offers the widest range of mechanical and adhesive fasteners in the market place. Powers products cover the full traditional anchoring range while specialising in innovative products that provide the architect, engineer and end user with aesthetic, high performance, labour saving fastening solutions. Fast technical advice, free samples and free on site demonstrations. Call toll free 1800 677 872 or visit our web site www.powers.com.au Other Powers fastening systemss 2 Support AC100® PRO High performance. Fast cure Styrene free vinylester In House Product Power-Bolt® Heavy duty Self-undercut design Vibration resistant In-house Product & Application Testing Service Melbourne Vertigo™ One piece Various styles National on Site Anchor Testing Service PBI Structural® anchor High performance Economical Versatile National On Site Service Powers Training Vehicles (PTV) Training Facility Melbourne ® FA S T E N E R S Contents Description 4 Material specification 5 Installation procedures 5 Anchor sizes and styles 6 Performance data 8 Design criteria – concrete 10 Design criteria – masonry 12 TRADAC SCREW-BOLT® 14 Suggested specification 15 3 ® Blue-Tip SCREW-BOLT™ FA S T E N E R S Blue-Tip SCREW-BOLT™ Introduction Blue -Tip SCREW-BOLT™ anchors have many unique features and benefits that make this innovative anchor well suited for almost every application. Optimum performance is obtained using a combination of patented design concepts. The benefit to the designer is higher load capacities while the benefit to the user is easy and fast installation.steel. Description Blue-Tip SCREW-BOLT™ anchor Blue -Tip SCREW-BOLT™ anchors are one-piece units featuring a finished hex head formed with an integral washer, a patented dual lead thread, and a chamfered tip. Blue -Tip SCREW-BOLT™ anchors cut a thread into the base material. Since there are no expansion forces, the Blue -Tip SCREW-BOLT™ anchor can be installed closer to the edge than traditional mechanical anchors without damaging the base material. Finished hex head with easy to read size identification Ratchet teeth locks head against fixture Reverse parabolic threads privide high load capacity Double lead thread for easystraight centering, fast advancing and higher load capacity Chamfered tip for easy centering High helix angle for fast installation Relief grooves for low installation torque, also privides dust relief Blue -Tip SCREW-BOLT™ anchors are designed to match standard fixture holes that are 2mm over nominal to provide a secure fit. Since the Blue -Tip SCREWBOLT™ is specifically matched to the clearance hole, the need for hole layout is eliminated and can be used in a variety of base materials. Blue -Tip SCREW-BOLT™ anchors can be installed at a shallower embedment than traditional wedge or sleeve anchors reducing the chance of striking reinforcing bars or embedded cables. Blue -Tip SCREW-BOLT™ anchors are designed with a patented double lead, elliptical profile thread to facilitate easy centering, faster installation and higher load capacities Blue -Tip SCREW-BOLT™ anchors are vibration resistant. Unlike traditional anchors that have a small expansion mechanism, the double lead threads grip the base material over the full embedment length and there are no expansion forces to pulverise the concrete. For additional vibration resistance, the ratchet teeth on the underside of the hex washer head lock against the fixture.effort in all base materials. 4 ® Blue-Tip SCREW-BOLT™ FA S T E N E R S Material specifications Blue -Tip SCREW-BOLT™ anchors are manufactured from heat treated carbon steel that is plated with commercial bright zinc, and a supplementary yellow chromate treatment in accordance with AS1789 and AS1791 Coating Designation C. Anchor Specification: Anchor body AISI 1020 /1040 carbon steel (heat treated) Zinc plating 5 microns (minimum) Mechanical plating* 15 microns (minimum) * Mechanical plating provides equivalent corrosion resistance to Hot Dipped galvanising with 42 micron coating thickness in accordance with AS1214 Installation procedures Using the proper diameter bit, drill a hole into the base material to a depth of at least 13mm or one anchor diameter deeper than the embedment required. Blow the hole clean of dust and other material. Installation tips: 1. 2. 3. Use quality hexagonal socket with a ratchet spanner. Where substrate allows, a torque controlled impact wrench can be used. During installation debris or dust created by the thread cutting action may cause some resistance to be experienced. This is easily overcome by unscrewing the Blue -Tip SCREW-BOLT™ for one turn, or more and then continue to fix to the full embedment. Insert the anchor through the fixture into the anchor hole. Begin tightening the anchor by applying forward pressure when engaging the first thread. Additional initial forward pressure may be required for installation in high strength, dense base materials. Continue tightening the anchor until the head is firmly seated against the fixture. In extremely dense materials, use of an impact wrench is recommended. · Be sure the anchor is at the required embedment depth. · Don’t exceed the maximum clamping torque. · The installation is now complete. 5 ® Blue-Tip SCREW-BOLT™ FA S T E N E R S Anchor sizes and styles The following table lists the sizes of hex head Blue -Tip SCREW-BOLT™ anchors. To select the proper length; (1), determine the embedment depth required to obtain the desired load capacity (2), add the thickness of the fixture, (including any spacers or shims), to the embedment depth. Zinc plated carbon steel, hex head Blue-Tip SCREW-BOLT™ Carbon steel Blue-Tip SCREW-BOLT™ anchors are manufactured from carbon steel which is plated with commercial bright zinc and a supplementary chromate treatment. Part No BT550 BT6530 BT6550 BT6575 BT65100 BT850 BT875 BT8100 BT1060 BT1075 BT10100 BT10120 BT1275 BT12100 BT12150 BT16100 BT16150 Drill Ø Length mm 5 6.5 8 10 12 16 Minimum embedment mm Maximum fixture thickness mm Clearance hole Ø mm Box Carton mm Thread length mm qty qty 50 30 50 75 100 50 75 100 60 75 100 120 75 100 150 100 150 44.5 28.5 44.5 70 95 44.5 70 95 54 70 95 95 70 95 95 95 95 25 25 5 25 50 75 15 40 65 20 35 60 80 25 50 100 35 85 7 100 100 100 50 50 50 50 50 50 50 50 50 50 50 25 15 15 500 500 500 250 250 250 250 250 250 250 250 250 150 150 75 60 60 25 35 40 50 65 8 10 12 15 19 Carbon steel, mechanically galvanised Blue-Tip SCREW-BOLT™ Mechanically plated Blue-Tip SCREW-BOLT™ anchors are manufactured from steel which has a mechanically galvanised coating. Part No BTG550 BTG6530 BTG6550 BTG6575 BTG65100 BTG850 BTG875 BTG8100 BTG1060 BTG1075 BTG10100 BTG10120 BTG1275 BTG12100 BTG12150 BTG16100 BTG16150 6 Minimum embedment mm Maximum fixture thickness mm Clearance hole Ø mm Box Carton mm Thread length mm qty qty 50 30 50 75 100 50 75 100 60 75 100 120 75 100 150 100 150 44.5 28.5 44.5 70 95 44.5 70 95 54 70 95 95 70 95 95 95 95 25 25 5 25 50 75 15 40 65 20 35 60 80 25 50 100 35 85 7 100 100 100 50 50 50 50 50 50 50 50 50 50 50 25 15 15 500 500 500 250 250 250 250 250 250 250 250 250 150 150 75 60 60 Drill Ø Length mm 5 6.5 8 10 12 16 25 35 40 50 65 8 10 12 15 19 ® Blue-Tip SCREW-BOLT™ FA S T E N E R S Carbon steel, Countersunk Blue-Tip SCREW-BOLT™ Carbon steel Blue-Tip SCREW-BOLT™ anchors are manufactured from carbon steel which is plated with commercial bright zinc and a supplementary chromate treatment. The following table lists the sizes of Countersunk Blue -Tip SCREW-BOLT™ anchors. To select the proper length; (1), determine the embedment depth required to obtain the desired load capacity (2), add the thickness of the fixture, to the embedment depth. Part No BTCSK06550 BTCSK06575 BTCSK0850 BTCSK0875 BTCSK08100 BTCSK1060 BTCSK1075 BTCSK10100 BTCSK1275 BTCSK12100 BTCSK12150 Drill Ø Length mm 6.5 8 10 12 Thread length Head Ø Head height mm mm mm mm 50 75 50 75 100 60 75 120 75 100 150 44.5 70 44.5 70 95 54 70 95 70 95 95 Hex drive Min. embed. mm 16 6.5 A/F5mm 25 20 8.0 A/F6mm 35 24.5 9.5 A/F8mm 40 27.5 10.5 A/F10mm 50 Maximum fixture thickness mm 25 50 15 40 65 20 35 60 25 50 100 Clearance hole Ø Box mm qty qty 100 50 50 50 50 50 50 50 50 50 25 500 250 250 250 250 250 250 250 150 150 75 7 10 12 15 Carton Carbon steel, Blue-Tip SCREW-BOLT™, Eyebolt Carbon steel Blue-Tip SCREW-BOLT™ Eyebolt anchors are manufactured from carbon steel which is plated with commercial bright zinc and a supplementary chromate treatment. The following table lists the sizes of Blue -Tip SCREW-BOLT™ Eyebolt anchors. To select the proper length, determine the embedment depth required to obtain the desired load capacity. Part No BTEYE06550 BTEYE08055 BTEYE10065 BTEYE12075 Drill Ø Length Thread length Internal Ø Box Carton mm 6.5 8 10 12 mm mm mm qty qty 50 55 65 75 44.5 44.5 54 70 12.7 15.2 17 21.6 100 50 50 50 500 250 250 150 7 ® Blue-Tip SCREW-BOLT™ FA S T E N E R S Performance data Mechanical properties Blue-Tip SCREW-BOLT™ is manufactured using carbon steel that is heat treated to form a surface hardened high performance concrete anchor. The heat treatment process ensures: � a high strength and wear resistant surface providing easy, consistent and safe installation even in high compressive strength base materials � increased core strength and toughness for impact and cyclic loading applications Mechanical Properties Units 5 6.5 8 10 12 16 Nominal tensile strength fu Yield strength f y Stress cross sectional area As Section modulus Z Nominal moment capacity Mf N/mm2 N/mm2 mm2 mm3 N/m 1000 900 11.1 5.2 4.7 1000 900 21.1 13.7 12.3 1000 900 38.5 33.5 30.2 1000 900 60.7 66.6 59.9 1000 900 82.7 106.1 95.5 1000 900 153.8 269.1 242.2 Installation specification B E A 16/150 mm D C A Anchor Ø C Flanged head height mm D Washer Ø E Wrench size mm B Clearance hole Ø mm mm mm 5 6.5 8 10 12 16 7 8 10 12 15 19 5 6 8 9.5 11.5 13.2 12 13 17 22 25 30 7 10 13 17 19 24 Maximum clamping force (Nm) Blue -Tip SCREW-BOLT™ anchors achieve their load capacity by threads undercutting the base material. It is not necessary to tighten the anchor to any special torque value. The table shows the maximum permissible torque value to be used to clamp the fixture to the base material. Base material 15 MPa Concrete 30 MPa Concrete 40 MPa Concrete Grout filled block Solid red brick 8 Anchor Ø 5 6.5 8 10 12 16 5 8 8 8 8 7 15 15 15 15 15 45 45 15 15 55 55 55 20 40 80 80 80 55 80 100 100 100 80 100 ® Blue-Tip SCREW-BOLT™ FA S T E N E R S Performance data – concrete Working stress design – concrete Allowable working load capacities for carbon steel Blue-Tip SCREW-BOLT™ ANCHOR Ø mm 5 6.5 8 10 12 16 EMBED. DEPTH mm 25 25 30 45 35 40 60 40 50 75 90 50 60 90 110 65 75 100 125 15 MPa concrete Tension kN 0.6 1.5 2.4 3.3 3.0 3.5 5.9 3.9 4.8 7.4 9.3 6.7 7.1 10.6 10.7 6.8 8.2 13.0 17.5 Shear kN 0.8 1.4 3.4 3.7 3.5 4.5 6.4 4.9 6.6 8.3 9.8 8.8 10.0 11.6 11.6 10.5 13.5 18.3 22.0 32 MPa concrete 40 MPa concrete Tension kN Shear kN Tension kN Shear kN 0.9 2.5 3.0 5.0 4.0 4.7 7.4 4.9 6.0 9.5 12.3 7.3 9.2 17.4 19.5 9.3 11.0 17.4 23.5 1.7 2.8 3.8 4.0 4.8 6.1 6.4 6.6 8.5 8.7 10.0 9.9 11.4 12.6 12.9 15.2 17.1 20.5 23.7 1.0 2.6 3.2 5.9 4.3 5.2 9.7 5.6 7.0 11.8 14.7 8.8 10.6 18.7 20.5 11.3 13.0 20.2 27.1 2.0 3.3 3.8 4.5 6.3 6.7 6.7 9.9 9.9 9.9 10.2 12.0 12.3 12.6 12.9 18.3 19.2 21.2 23.7 Note: Performance data is based on tests conducted in un-reinforced concrete of specified cylinder compressive strength. NOTE: Incorporated safety factor (Tension and shear) Fsc =3 (concrete). Limit state design – concrete Limit state design capacities for carbon steel Blue-Tip SCREW-BOLT™ ANCHOR Ø mm 5 6.5 8 10 12 16 EMBED. DEPTH mm 25 25 30 45 35 40 60 40 50 75 90 50 60 90 110 65 75 100 125 15 MPa concrete Tension kN 1.1 2.6 4.3 5.9 5.3 6.3 10.7 7.1 8.6 13.3 16.8 12.1 12.8 19.1 19.3 12.2 14.8 23.5 31.4 Shear kN 1.5 2.5 6.2 6.7 6.4 8.2 11.5 8.8 11.9 14.9 17.6 15.8 17.9 20.8 20.8 18.9 24.4 32.9 39.6 32 MPa concrete Tension kN 1.6 4.4 5.4 9.0 7.3 8.5 13.3 8.8 10.9 17.1 22.1 13.1 16.6 31.4 35.0 16.8 19.7 31.3 42.2 Shear kN 3.0 5.1 6.9 7.1 8.6 11.0 11.5 11.8 15.4 15.7 17.9 17.8 20.6 22.7 23.2 27.4 30.8 37.0 42.7 40 MPa concrete Tension kN 1.9 4.7 5.7 10.6 7.8 9.4 17.5 10.0 12.5 21.2 26.5 15.9 19.1 33.6 37.0 20.3 23.5 36.4 48.8 Shear kN 3.5 5.9 6.9 8.1 11.3 12.1 12.1 17.8 17.8 17.8 18.4 21.6 22.1 22.7 23.2 32.9 34.6 38.2 42.7 Note: Performance data is based on tests conducted in un-reinforced concrete of specified cylinder compressive strength. NOTE: Incorporated strength reduction factor (Tension and shear) φ = 0.6. 9 ® Blue-Tip SCREW-BOLT™ FA S T E N E R S Design criteria – Concrete Base material thickness The minimum recommended thickness of solid base material, BMT, is 125% of the embedment to be used. For example, when installing an anchor to a depth of 100mm, the base material thickness should be 125mm. Spacing between anchors To obtain the maximum load in tension or shear, a spacing, S, of 10 anchor diameters (10d) should be used. The minimum recommended anchor spacing, S, is 5 anchor diameters (5d) at which point the load should be reduced by 50%. The following table lists the load reduction factor, Rs, for each anchor diameter, d, based on the center to center anchor spacing. ANCHOR HOLE SIZE Ø mm 10d 50 65 80 100 120 160 1.00 5 6.5 8 10 12 16 Rs Spacing distance, S (mm) Tension and Shear 9d 8d 7d 6d 45 40 35 30 58.5 52 45.5 39 72 64 56 48 90 80 70 60 108 96 84 72 144 128 112 96 0.90 0.80 0.70 0.60 5d 25 32.5 40 50 60 80 0.50 Edge distance – Tension An edge distance, E, of 10 anchor diameters (10d) should be used to obtain the maximum tension load. The minimum recommended edge distance, E, is 3 anchor diameters (3d) at which point the tension load should be reduced by 28%. The following table lists the load reduction factor, Re, for each anchor diameter, d, based on the anchor centre to edge distance. ANCHOR HOLE SIZE Ø mm 5 6.5 8 10 12 16 Re(t) 10d 50 65 80 100 120 160 1.00 9d 45 58.5 72 90 108 144 0.96 Edge distance, E (mm) Tension only 8d 7d 6d 5d 40 35 30 25 52 45.5 39 32.5 64 56 48 40 80 70 60 50 96 84 72 60 128 112 96 80 0.92 0.88 0.84 0.80 4d 20 26 32 40 48 64 0.76 3d 15 19.5 24 30 36 48 0.72 Edge distance – Shear For shear loads, an edge distance, E, of 10 anchor diameters (10d) should be used to obtain the maximum load. The minimum recommended edge distance, E, is 3 anchor diameters (3d) at which point the shear load should be reduced by 84%. The following table lists the load reduction factor, Re, for each anchor diameter, d, based on the anchor centre to edge distance. ANCHOR HOLE SIZE Ø mm 5 6.5 8 10 12 16 Re(s) 10 10d 50 65 80 100 120 160 1.00 9d 45 58.5 72 90 108 144 0.88 Edge distance, E (mm) Shear only 8d 7d 6d 5d 40 35 30 25 52 45.5 39 32.5 64 56 48 40 80 70 60 50 96 84 72 60 128 112 96 80 0.76 0.64 0.52 0.40 4d 20 26 32 40 48 64 0.28 3d 15 19.5 24 30 36 48 0.16 ® Blue-Tip SCREW-BOLT™ FA S T E N E R S Performance data – masonry Working load capacities for grout filled block (kN) Anchor Ø mm Embedment depth mm Tension Shear 5 6.5 8 10 12 16 30 65 80 90 100 100 0.5 2.9 3.2 4.3 6.1 7.7 0.8 1.9 3.1 4.8 8.9 14.2 400 x 200 x 200mm block Manufacturer: NUBRIK Block compressive strength: 12MPa Grout compressive strength: 20MPa NOTE: Incorporated safety factor (Tension and shear) Fsc =3 (concrete). Limit state design capacities for grout filled block (kN) Anchor Ø mm Embedment depth mm Tension Shear 5 6.5 8 10 12 16 30 65 80 90 100 100 0.9 5.2 5.8 7.7 10.9 13.9 1.4 3.4 5.5 8.7 16. 25.5 NOTE: Incorporated strength reduction factor (Tension and shear) «= 0.6. Working load capacities for solid pressed red brick (kN) Anchor Ø mm Embedment depth mm Tension Shear 5 6.5 8 10 12 16 35 40 50 60 75 80 3.1 4.6 6.5 7.7 11.2 13.3 1.7 2.2 4.2 5.7 10.5 16.1 230 x 110 x 76mm Manufacturer; NUBRIK Brick compressive strength: 40MPa NOTE: Incorporated safety factor (Tension and shear) Fsc =3 (concrete). Limit state design capacities for solid pressed red brick (kN) Anchor Ø mm Embedment depth mm Tension Shear 5 6.5 8 10 12 16 35 40 50 60 75 80 5.5 8.2 11.8 13.9 20.2 24.0 3.1 4.0 7.5 10.3 19.0 29.0 NOTE: Incorporated strength reduction factor (Tension and shear) «= 0.6. Working load capacities for 10 hole extruded wire cut brick (kN) Anchor Ø mm Embedment depth mm Tension Shear 5 6.5 8 10 25 65 65 65 0.3 0.7 1.0 1.0 0.6 1.3 2.1 3.3 230 x 110 x 76mm Manufacturer; BORAL Brick compressive strength: 15MPa NOTE: Incorporated safety factor (Tension and shear) Fsc =3 (concrete). 11 ® Blue-Tip SCREW-BOLT™ FA S T E N E R S Limit state design capacities for 10 hole extruded wire cut brick (kN) Anchor Ø mm Embedment depth mm Tension Shear 5 6.5 8 10 25 65 65 65 0.5 1.3 1.8 1.9 1.0 2.3 3.8 5.9 NOTE: Incorporated strength reduction factor (Tension and shear) «= 0.6. Working load capacities for 3 hole extruded wire cut brick (kN) Anchor Ø mm Embedment depth mm 5 6.5 8 10 12 230 x 110 x 76mm Manufacturer; BORAL Brick compressive strength: 55MPa Tension Shear 2.5 5.7 6.5 7.8 8.7 1.8 2.2 3.8 5.6 9.2 40 NOTE: Incorporated safety factor (Tension and shear) Fsc =3 (concrete). Limit state design capacities for 3 hole extruded wire cut brick (kN) Anchor Ø mm Embedment depth mm 5 6.5 8 10 12 Tension Shear 4.4 10.3 11.8 14.0 15.7 3.2 4.0 6.8 10.0 16.5 40 NOTE: Incorporated strength reduction factor (Tension and shear) «= 0.6. Note: The consistency of brick and block walls varies greatly. Load capacities listed above are based on actual tests conducted in brick and block walls with M3 specification mortar (1 : 1 : 6, AS3700) Capacities should be used as guidance only. Design criteria – Masonry (Brick and Blockwork) • When fixing into brickwork or blockwork, position anchors a minimum of 300mm from an edge or opening. • Anchors should be positioned four brick & 2 block courses down from the top of an unrestrained wall • Minimum recommended spacing between anchors is 200mm • Embedment should be limited to within 30mm of the remote face of the block / brick • Avoid fixing into mortar joints Combined loading Anchors loaded in both tension and shear must satisfy the following equations: Working stress design TS TA 12 5/3 S + S SA 5/3 ≤1 Limit state design N* φNA 5/3 V* + φVA 5/3 ≤1 Where: Where: TS= Applied Tension Load TA= Allowable Tension Load SS= Applied Shear Load SA= Allowable Shear Load N* = Design Tension Force φNA= Design Tension Anchor Capacity V* = Design Shear Force φVA= Design Shear Anchor Capacity ® Blue-Tip SCREW-BOLT™ FA S T E N E R S Anchors for use in Seismic/Cyclic applications Chart 1 The selection and suitability of anchoring systems for seismic applications should be determined by a design professional in accordance with relevant building codes and standards. To assist in selecting the correct anchoring system, Powers Fasteners have conducted independent seismic tests on the Blue -Tip SCREWBOLT™ anchor highlighting its suitability. Chart 2 Earthquakes can induce loads in anchoring systems well in excess of their allowable working load levels. Evaluating the suitability of the Blue -Tip SCREW-BOLT™ involved subjecting the anchor to a simulated seismic test program in accordance with ICBO Evaluation Services Inc. (USA Standard). Load cycles are shown in Chart1 and 2 (Frequency 1Hz). Load was applied sinusoidally between a load no greater than 5% of the ultimate load and the required cyclic load level. Chart 3 Tension 100% 94% Cyclic ultimate load 96% Static ultimate load Static ultimate load � Anchor must be able to attain at least 80% of the static ultimate tension or shear capacity Load � Anchor must withstand the loading cycles without failure 100% Cyclic ultimate load Acceptance criteria in accordance with ICBO Evaluation Services Inc. AC01 (USA Standard) is as follows: Shear Blue -Tip SCREW-BOLT™ � Blue -Tip SCREW-BOLT™passed both criteria, refer chart 3. 13 ® Blue-Tip SCREW-BOLT™ FA S T E N E R S TRADAC SCREW-BOLT® Description The TRDAC SCREW-BOLT® is a quick and simple system,which provides timber frame top plate tie-down to slabs for residential timber frame construction without the costly time consuming requirements of chemical anchoring systems. Its unique thread design provides an undercutting effect in the concrete ensuring optimum performance in residential slabs at minimal edge distance (e.g.35mm). Material Specification Blue -Tip SCREW-BOLT™ anchors are manufactured from heat treated carbon steel that is plated with commercial bright zinc, and a supplementary yellow chromate treatment in accordance with AS1789 and AS1791 Coating Designation C. Anchor Specification: Anchor body AISI 1020 /1040 carbon steel (heat treated) Zinc plating 5 microns (minimum) Mechanical plating* 15 microns (minimum) * Mechanical plating provides equivalent corrosion resistance to Hot Dipped galvanising with 42 micron coating thickness in accordance with AS1214 Sizes Anchor size mm Drill Ø mm Rod size mm Length mm TRDAC 12100 12x100 TRDAC 12150 12x150 12 12 M12 M12 100 150 Load capacities Limit state design – Timber frame construction (35mm timber frame) Uplift capacity of wall frame tie-down connections using Powers connectors Position of tie-down connection Uplift capacity (kN) Top or Bottom plates to slab Anchor size 12x100mm 12x150mm Unseasoned timber Seasoned timber Min.Edge Dist. mm J2 J3 J4 JD4 JD5 JD6 35 ≥45 35 ≥45 10 11 17 18 10 11 17 18 10 11 17 18 10 11 17 18 10 11 16 16 10 11 12 12 50 x 50 x 3.0 (min) washer to be used with the 12 mm TRDAC SCREW-BOLT® NOTE: For bottom plates greater than 35mm but 50mm or less in thickness, Limit State Design uplift capacities listed above shall be multiplied by 0.85. TRDAC SCREW-BOLT® uplift capacities have been derived in accordance with AS 1684-1999 requirements for top or bottom plates to slab tie down connections. Limit state design – Steel frame construction Position of tie-down connection Uplift capacity (kN) Top or Bottom plates to slab Anchor size 12x100mm Min.Edge Dist. mm 35 ≥45 17.0 18.0 50 x 50 x 3.0 (min) washer to be used with the 12 mm TRDAC SCREW-BOLT® Uplift capacities are based on installation in accordance with Powers Fasteners installation instructions in 20MPa concrete and at 95mm embedment. The designer responsible for the tie-down application also should consider the steel frame strength in their calculation. 14 ® Blue-Tip SCREW-BOLT™ FA S T E N E R S Suitable base materials Concrete Block Brick Stone Installation procedures Using the proper diameter bit, drill a hole into the base material to a depth of at least one to two anchor diameters deeper than the embedment required. Blow the hole clean of dust and other material. Insert the anchor through the fixture into the anchor hole Begin tightening the anchor by applying forward pressure when engaging the first thread. Additional initial forward pressure may be required for installation in high strength, dense base material. Continue tightening the anchor until the head is seated against the fixture. In extremely dense materials, use of an impact wrench is recommended. The installation is now complete. Installation tips: Use quality hexagonal socket with a ratchet spanner Where substrate allows, a torque controlled impact wrench can be used. During installation debris or dust created by the thread cutting action may cause some resistance to be experienced. This is easily overcome by unscrewing the TRDAC 12100 SCREWBOLT™ for one turn, or more and then continue to fix to the full embedment Suggested specification Example Product name Head style Part number Size Embedment depth Minimum spacing and edge distance Blue-tip Screw-Bolt Hex head BT12150 12 x 150 50mm Spacing: 120mm, Edge distance: 120mm Product to be installed in accordance with published installation procedure 15 ® FA S T E N E R S Distributor: VIC HQ: TELEPHONE: FACSIMILE: 03-8795 4600 03-8787 5899 NSW: TELEPHONE: FACSIMILE: 02-4634 7600 02-4648 3139 SA: TELEPHONE: FACSIMILE: 08-8346 5611 08-8346 5711 QLD: TELEPHONE: FACSIMILE: 07-3712 2600 07-3216 7216 FAR NORTH QLD: TELEPHONE: FACSIMILE: 07-4031 8387 07-4031 8386 WA : TELEPHONE: FACSIMILE: 08-9209 1211 08-9209 1055 NZ: TELEPHONE: FACSIMILE: +64-9415 2425 +64-9415 2627 THAILAND: TELEPHONE: FACSIMILE: +66 2801 2242 +66 2801 0620 EUROPE: TELEPHONE: FACSIMILE: +31-888 769 399 +31-888 769 399 USA: TELEPHONE: FACSIMILE: +1-914 235 6300 +1-914 576 6483