SAMET GENERIC SITE SAFETY PLAN JAN 2014

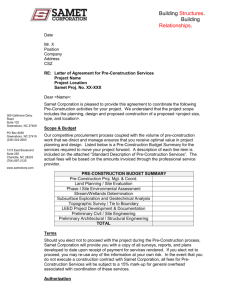

advertisement