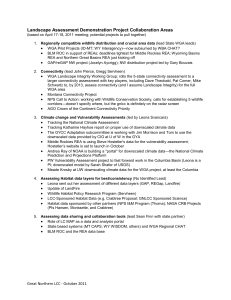

request for proposal - Western Regional Air Partnership

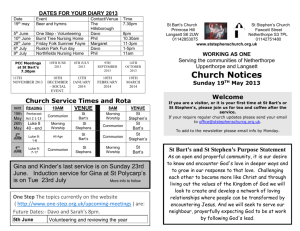

advertisement