(tev) study on entity build tech ltd

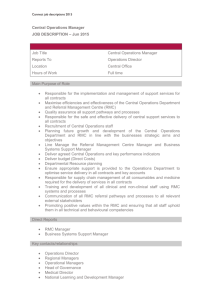

advertisement