RA_MW01_metalwork_centre_lathe

advertisement

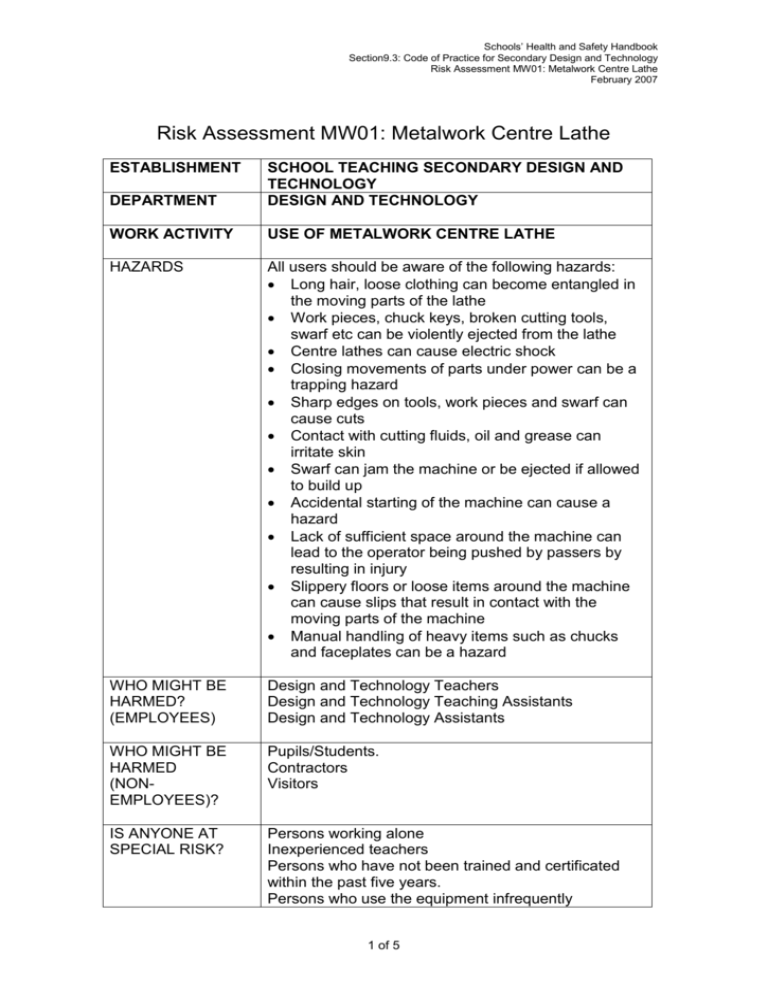

Schools’ Health and Safety Handbook Section9.3: Code of Practice for Secondary Design and Technology Risk Assessment MW01: Metalwork Centre Lathe February 2007 Risk Assessment MW01: Metalwork Centre Lathe ESTABLISHMENT DEPARTMENT SCHOOL TEACHING SECONDARY DESIGN AND TECHNOLOGY DESIGN AND TECHNOLOGY WORK ACTIVITY USE OF METALWORK CENTRE LATHE HAZARDS All users should be aware of the following hazards: Long hair, loose clothing can become entangled in the moving parts of the lathe Work pieces, chuck keys, broken cutting tools, swarf etc can be violently ejected from the lathe Centre lathes can cause electric shock Closing movements of parts under power can be a trapping hazard Sharp edges on tools, work pieces and swarf can cause cuts Contact with cutting fluids, oil and grease can irritate skin Swarf can jam the machine or be ejected if allowed to build up Accidental starting of the machine can cause a hazard Lack of sufficient space around the machine can lead to the operator being pushed by passers by resulting in injury Slippery floors or loose items around the machine can cause slips that result in contact with the moving parts of the machine Manual handling of heavy items such as chucks and faceplates can be a hazard WHO MIGHT BE HARMED? (EMPLOYEES) Design and Technology Teachers Design and Technology Teaching Assistants Design and Technology Assistants WHO MIGHT BE HARMED (NONEMPLOYEES)? Pupils/Students. Contractors Visitors IS ANYONE AT SPECIAL RISK? Persons working alone Inexperienced teachers Persons who have not been trained and certificated within the past five years. Persons who use the equipment infrequently 1 of 5 Schools’ Health and Safety Handbook Section9.3: Code of Practice for Secondary Design and Technology Risk Assessment MW01: Metalwork Centre Lathe February 2007 Unauthorised users, for example, site manager, caretakers, teaching or support staff RISK CONTROL MEASURES Switchgear The machine must be provided with a means of isolation using a fused switch disconnector on or adjacent to the machine, and that it is controlled by a starter incorporating overload protection and novolt release Emergency Switchgear The machine must be provided with a conveniently positioned mushroom headed stop button or other suitable control device that can bring the machine to rest within 10 seconds in an emergency Cabling All cabling should be armoured to protect it from damage Guarding The machine must be provided with fixed guards that are removable only with the use of a tool, or alternatively interlocked guards that enclose the drive mechanisms The machine must be fitted with a suitable chuck guard The spindle mandrel must be guarded A telescopic helical metal guard must be provided if the feed shafts and lead screws are not sufficiently protected by the overhang of the bedways and/or saddle and swarf trays, a telescopic metal guard should be provided. Flooring and Space There must be sufficient space around the machine to prevent the operator being accidentally pushed by passers-by. This zone should be marked with yellow tape or paint. The floor surface must not be slippery and must be kept free of loose items and swarf Operator Safety and Personal Protective Equipment Only one person at a time may operate the machine Eye protection must be worn by the operator when using the machine 2 of 5 Schools’ Health and Safety Handbook Section9.3: Code of Practice for Secondary Design and Technology Risk Assessment MW01: Metalwork Centre Lathe February 2007 Long hair and loose clothing must be secured and dangling jewellery must not be worn when operating the machine Gloves must not be worn when using the machine Substantial, non-slip, footwear which covers the whole foot, should be worn when using the equipment. Trainers do not give adequate protection. Manual Handling of Chucks and Faceplates A risk assessment must be made of the manual handling tasks associated with changing heavy chucks and faceplates etc which can be beyond the physical ability of some people. Measures must be implemented to minimise the risks associated with lifting heavy items by the use of lifting aids, team lifts and correct lifting techniques Adjustment and Setting Up of Machine The machine must be electrically isolated before any internal mechanisms are adjusted. The drive to the feed shafts and lead screws must be disconnected until required. The chuck key, which should be spring loaded, must always be removed from the chuck immediately after use and before starting the machine Work mounted to a faceplate, a chuck or between centres must be properly secured and balanced to prevent excessive vibration The rotational clearance must be checked by hand before starting the machine The cutting tool must be checked for security before the machine is started The stock bar must not project beyond the head stock or where this is unavoidable, the portion of the stock bar projecting beyond the headstock must be guarded to prevent entanglement Coolant nozzles must not be adjusted whilst the machine is in operation The machine must always be stopped when measuring or gauging and positioning the cutting tool so as to minimise possible contact. Files and abrasive tape must not be used on the centre lathe Tools post grinders must only be used if they have been specifically designed for the lathe 3 of 5 Schools’ Health and Safety Handbook Section9.3: Code of Practice for Secondary Design and Technology Risk Assessment MW01: Metalwork Centre Lathe February 2007 Removal of Swarf Swarf must not be allowed to accumulate as it can become entangled or ejected by the chuck or work piece. Swarf must never be removed whilst the machine is in operation A suitable implement must be used to remove swarf so as to avoid hands coming into contact with swarf. Metalworking Fluids If metalwork fluids are used they must be mixed and changed in accordance with the manufacturer’s instructions Supplier’s hazard data sheets and COSHH risk assessments for metalworking fluids must be available and their instructions followed. Contact of metal work fluids with the skin must be minimised. Hands must always be washed thoroughly after the use of metalworking fluids. Safety Rules Safety rules for the use of this machine should be displayed near the machine where they can readily be referred to. Maintenance of Machine The machine must be included in a planned programme of servicing and maintenance which should include electrical safety checks. Records of servicing and maintenance must be available for inspection by health and safety advisers, subject advisers/consultants and other authorised persons. Manufacturer’s Instructions A copy of the manufacturer’s instruction book should be kept by the machine and a spare copy in the departmental office. FURTHER ACTION REQUIRED TO CONTROL RISK ACTION BY 4 of 5 Schools’ Health and Safety Handbook Section9.3: Code of Practice for Secondary Design and Technology Risk Assessment MW01: Metalwork Centre Lathe February 2007 PERSON ACTION BY DATE DATE REVISION OF ASSESSMENT DUE ASSESSED BY DATE 5 of 5