Steelcor Industries - the Acadia Institute of Case Studies

Steelcor Industries

In October 1989, Steelcor Industries Limited opened for business in the former machine shop of the abandoned Buchans' mine. When the American Smelting and Refining

Company (ASARCO) dosed down the mine in 1984, the single industry community in the interior of Newfoundland seemed doomed to become a ghost town. The mineworkers' union, the Regional Development Association in the area and the Buchans Town Council joined forces to form the Buchans Development Corporation (BDC), which succeeded in gaining control of the mine assets, including its well-equipped machine shop.

Steelcor was formed by a prominent Newfoundland businessperson to bid on national defense contracts, with the BDC machine shop as the production facility Former Buchans mayor and BDC Marketing Director, Sean Power, was hued as President of the new company, and in January 1991 Steelcor was awarded a five-year contract with General

Electric Aerospace (GE) of Syracuse, New York, to produce radar components in

Buchans. Power praised the Canada-US Free Trade Agreement for making the deal possible. Using the latest computerized machining equipment, provided to Steelcor by

GE, the Steelcor components would be integrated into the final product in the US.

This can was prepared by Professor Robert Greenwood of Memorial University of Newfoundland for the Atlantic

Entrepreneurial "A Institute as a basis for classroom discussion, and is not meant to Illustrate either effective or ineffective management.

Copyright © 1993, the Atlantic Entrepreneurial Institute. Reproduction of this case is allowed without permission for educational purposes, but all such reproductions must acknowledge the copyright. This permission does not include publication.

For GE, the contract provided low-cost components – because labour and overhead costs were so much lower in a peripheral region - and improved their chances of winning

Canadian government tenders because of pi procurement conditions. With the machining equipment provided under the agreement, Steelcor not only gained a potentially lucrative international sub-contracting arrangement, but could use its improved productive capability to bid on other contracts.

When the Canadian government announced dramatic cuts in the Canadian Armed Forces in April 1991, however, the vulnerability of niche markets in the defense industry was revealed. Could Steelcor continue to rely on international sub-contracting arrangements, or could it adapt its new manufacturing equipment to develop domestic markets? The future profitability of the new company was at stake - along with the hopes of Buchans' residents for a renewed local economy.

Mine Closure and Community Action

Buchans was one of several single-industry towns established in Newfoundland during the first decades of the twentieth century. The Newfoundland government, then an independent Dominion within the British Empire, was eager to diversify away from the stagnating fishery. The American-controlled mine opened in 1928, attracting workers from coastal communities throughout the island.

As a company town, Buchans boasted housing and recreational facilities second to none at the time, although this meant extensive dependence on the company, an all-pervasive presence in the isolated community The miner's union emerged as the primary voice for the town's residents, and in the early 1970S violent strikes took place over pay levels and the introduction of a severance package, as ASARCO reported diminishing reserves and increased pressure on profitability. Not until 1976 was an elected Town Council established, on the recommendation of a Provincial Task Force formed to resolve the labour strife and make recommendations for the town's future.

In 1984, the mine closed permanently, and Buchans' residents rallied to find alternative economic activities to ensure the town's survival. The worker's union and the Town

Council had formed the Buchans Action Committee in 1977, in co-operation with the

Red Indian Lake Development Association (RILDA). Regional Development

Associations were formed throughout the province beginning in the late 1960s. They represented a regional effort by resource-dependent communities to work together on common economic and social initiatives. With administrative and project funding provided by the national and provincial governments, they filled the organizational void in many rural areas where local government was virtually nonexistent.

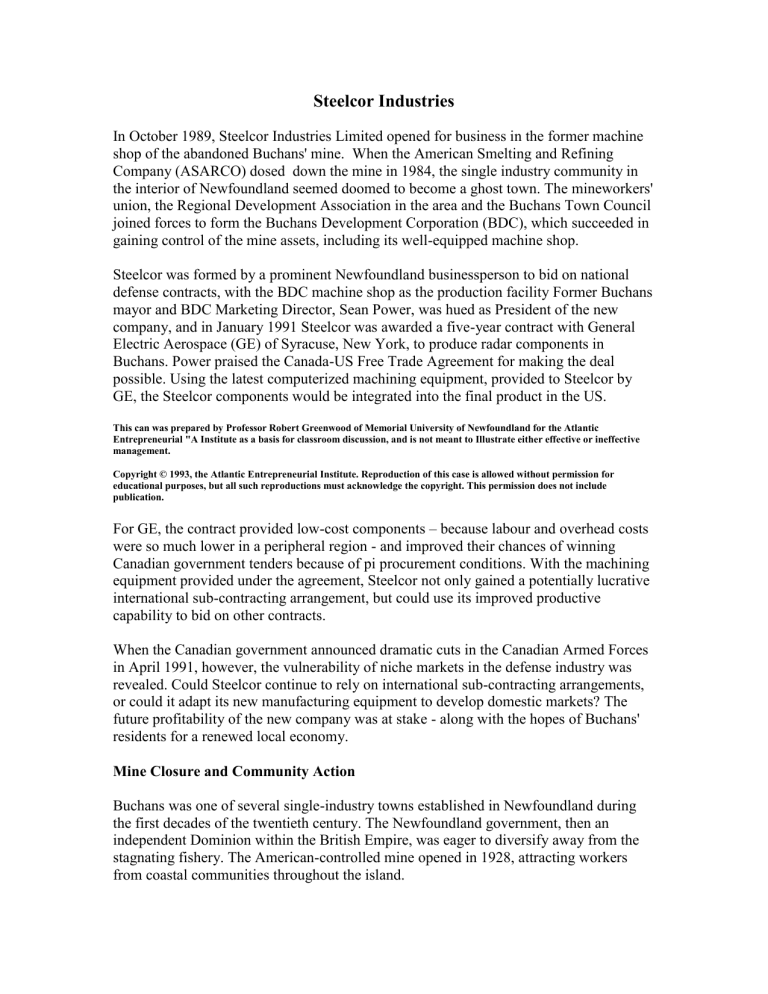

RILDA was established in 1972 by residents of Buchans and the two smaller communities situated on the shores of Red Indian Lake - Millertown, a logging community with declining employment, and Buchans Junction, which depended on forestry and mining. Together, the three communities formed a regional cul-de-sac, 73 kilometers from the Trans Canada Highway and 170 kilometers from the nearest airport

(see Exhibit 1). Between 1981 and 1988, the region's population declined by 25 percent, with an official unemployment rate in June 1987 of 73.6 percent.

The Development Association received its first administrative grant in 1976, and like most such Associations in the province served as a mechanism for the federal and provincial governments to administer short-term 'make-work-, projects, designed to enable under-employed workers to qualify for unemployment insurance MY). The federal unemployment insurance system was designed for industrial workforces where unemployment was generally temporary. In rural Newfoundland, unemployment was seasonal or long-term, and the federal and provincial governments provided funds to community groups to employ people long enough to qualify for UI, diminishing the number of applicants for social assistance.

Many Rural Development Associations took on longer-term development initiatives, however, and in 1984 RILDA was provided with federal funding to conduct a study of development possibilities for the region. A private consultant was hired, and the subsequent Buchans Area Development Strategy called for a range of tourism and resource-related activities, and suggested the possibility for Buchans to establish a new

'core industry,, such as a federal prison. It also called for a Buchans Development

Corporation to be formed to take over and manage the mine assets, which included substantial office and warehouse space, as well as an automotive and heavy equipment garage, a carpenter shop, a paint shop, an electrical shop and a machine shop.

The Development Association, mine workers union and the Buchans Town Council worked together to lobby the federal and provincial governments for support to implement the Strategy. In 1986, funding was received under a federal government program designed to meet the needs of unemployed mine workers in Sudbury, Ontario.

This provided the financial wherewithal for the coalition, now called the MILAP

Committee (after the name of the federal program) to conduct various studies to support their cause and pay for travel to lobby federal and provincial politicians.

The effort to attract a federal prison absorbed much of the committee's time, but construction of such government institutions is very political and Buchans' declining population (1,200 in 1987) did not carry much voting power. Buchans did benefit from tenacious and politically astute leadership, however, especially in the person of Sean

Power. In 1986, Power served as Buchans Mayor, Chairman of the MILAP Committee and was employed as the Co-ordinator of the Development Association. Such overlapping positions, including a few other key local leaders as well as Power, enabled the resources of local organizations to be effectively pooled and co-ordinated.

This co-ordination was institutionalized in 1986 with the formation of the Buchans

Development Corporation (BDC). As recommended in the Area Development Strategy, the BDC was structured independently from the Town Council and the Development

Association. Shares were sold to residents or former residents of Buchans- for twentyfive dollars each, more to encourage participation than to raise capital. The BDC was registered under the provincial Companies Act and each shareholder received one vote at general meetings, regardless of the number of shares held. No shareholder could hold more than 10 percent of the total shares, and some 70 percent of households in Buchans purchased one or more shares.

After extended negotiations with ASARCO, the BDC succeeded in gaining control of the mine assets, valued at two million dollars, in August 1986. The combination of community and political resources was then successfully employed to gain designation of the region as a federal Community Futures Area. Community Futures was a federal government program administered by Employment and Immigration Canada. it Provided funds to groups of communities which could demonstrate economic need and could show a willingness to engage in economic development initiatives. The federal department selected membership of a load board and approved various program funds to be used by that board, such as development and implementation of a strategic plan, administered local training funds and worked with private sector firms to generate local economic development.

Politics was a crucial aspect of Buchans' success in gaining designation of the region as a

Community Futures Area. In addition to his various other roles, Sean Power had also run as a candidate for the provincial Progressive Conservative Party. While this was insufficient to win the federal prison for Buchans, Power's efforts no doubt contributed to co-operative relations with the federal and provincial governments - both of which were

Progressive Conservative.

The Community Futures designation, announced in 1987, was seen as consolation for losing the prison. Taking in the same three communities as RILDA, the Buchans Area

Community Futures Committee added yet another local organization to the mix. Like the others, it was well integrated through over-lapping leadership. Sean Power emerged as

Chairperson of the Committee, and Sandy Ivany, a former union official, became

Measurer. This was in addition to Ivany's positions as a Town Councillor and Executive

Director of the BDC. Formal links may have been missing - and with them, formal lines of communication and accountability - but the people of Buchans had succeeded in garnering a substantial level of financial, human and physical resources to pursue their community development strategy.

Steelcor Industries Limited

The Buchans Area Community Futures Committee enabled the BDC to draw on a range of technical, training and project assistance available under the program. When the BDC received a three-year allocation under the Community Futures Innovations Program to employ staff and manage the mine assets in 1989, Power resigned his various positions and was hued on as Marketing Director for the Corporation. The Community Futures

Committee office was located in one of the BDC buildings, and the two organizations continued to work closely The Development Association office, meanwhile, was in the

Town Council building, and both organizations lost touch with the BDC activities.

Without the overlapping leadership which had fused the organizations so successfully,

RILDA reverted to its 'make-work' role and the Town Council concentrated on service provision and municipal administration.

Led by Ivany and Power, the BDC searched for viable operations Which could be operated within the mine offices and work spaces. A former Buchans resident was the first industrial tenant in the facilities. He relocated his decorative rock souvenir manufacturing operation to the site, benefitting from the provision of heavy equipment and office services by the BDC. Several resource companies also rented warehouse and office space from the Corporation, contributing to its goal of economic self-sufficiency.

Long-term viability would require additional employers, however, and the BDC promoted itself on the basis of its available work spaces and reserve of unemployed industrial workers. Because the Buchans mine had been so remote, it had generated a substantial core of skilled workers to make necessary repairs on demand - shipping in new equipment was a time-consuming final alternative. ASARCO had initially hired skilled Swedish machinists to run the mine's metal shop, but gradually local workers learned the trade. Indeed, several local families of skilled metal workers emerged, passing the trade from father to son. Although many had moved when the mine dosed, there was a core of skilled metal workers and machinists to build on if the right opportunity could be generated.

Working as Marketing Director in St. John's, the government and business centre of

Newfoundland, Sean Power was contacted by a prominent Newfoundland businessperson

who saw possibilities in defense contracting - an area where Newfoundland had long complained it did not receive its share of national procurement . Calvin Powell controlled a group of companies, led by a large grocery wholesaling business. He saw the BDC's combination of facilities, workforce and development organizations as a promising launching pad for a firm specializing in high-precision machining and metal fabrication.

In the fall of 1990, he hired Sean Power as President of Steelcor Industries Limited, to pursue contracts which would 'ensure that at a minimum we get a proportionate share ... of federal government spending-'

Powell contended that the machining equipment and facilities leased from the BDC greatly reduced Steelcor's long-term debt, enhancing the firm's ability to compete.

Community Futures funding was also received to upgrade the skills of some of the local workforce, particularly in the use of new computerized machining equipment. Power made full use of federal and provincial government agencies and programs designed to assist manufacturing and export market development. He attended defense industry trade shows and researched which firms were bidding on Canadian government defense contracts.

In January 1991, the BDC's efforts and Powells perception of market opportunities were rewarded when Steelcor was awarded a contract by General Electric Aerospace of

Syracuse, New York to manufacture radar components. The provincial government provided a $1 million loan to Steelcor and the BDC contributed over $ 200,000 in equipment as equity to enable Steelcor to make the five-year supplier commitment required by GE. As part of the long-term sub-contracting arrangement, GE supplied

Steelcor with two computer numerically controlled (CNC) vertical machining centres worth $1 million, which the Buchans-based firm would own upon completion of the contract. These state-of-the-art machines provided computercontrolled precision coupled with flexibility in production. GE would have first call on the use of the machines to meet their order requirements, but Steelcor was free to use them to bid on other contracts.

Crucial to General Electric’s interest in Buchans was the federal government procurement policy, which awarded points to bidders according to the degree of

Canadian content in their production. GE was competing with Westinghouse for a $100 million contract to update the Canada-US early warning coastal radar system. Under the federal Industrial Regional Benefits Program, additional points went to companies with production in depressed regions of the country.

At the official contract signing in Buchans, attended by the Newfoundland Premier as well as company officials, Sean Power claimed that the deal would not have been possible without the 1988 Free Trade Agreement between Canada and the US. Under the trade pact, components entering the US in 1991 were subject to a 4 percent tariff, down from the previous 12 percent. ‘This agreement is one example of how a smaller industrial centre like Buchans can contribute its resources and skills to specialized manufacturing for international markets,' Power stated.

Representatives of GE maintained that the Buchans contract was signed for purely economic reasons. Apart from federal procurement policies, the American manufacturer was eager to take advantage of Steelcor's competitive charge-out costs. Consisting of both overhead and labour costs, the Buchans firms chargeout cost of $35 per hour was half that of GE's New York factory Power explained that GE was contracting more and more of its work out to small firms to avoid the expensive unionized workforce and low productivity of centralized operations. With CNC machining equipment, decentralized operations could perform equally demanding work with strict quality control.

Power noted that the rent Steelcor paid the BDC in Buchans was no more than property taxes paid on similar facilities in St. jokes, not to mention rates in urban centers on the mainland. Transportation costs did not present a problem either. Because so few goods are processed or manufactured in Newfoundland, Power explained, countless transport trucks returned to the mainland empty. Consequently, transport firms offered low rates on goods shipped out of the province, making shipping costs one of the lowest components of the company's budgeting.

For the Buchans residents employed by Steelcor, sub-contracting arrangements designed, in part, to access low-cost labour, did not appear to signify exploitation. The Production

Control Manager, a Buchans native, confirmed that they were paid equal to or above the rates in union shops in Newfoundland, and enjoyed substantial benefits, such as a company health plan. He added that in Buchans, where housing was so inexpensive (like most rural Newfoundland communities), this afforded a much higher standard of living than equivalent jobs on the mainland. With a core of six full-time employees and up to twenty-one hued as needed, Steelcor provided substantial employment creation in an area desperate for jobs.

As a mining town which endured several violent strikes in its history, though, Buchans was not a likely location to take advantage of a docile workforce. Indeed, the BDC maintained a condition on all leaseholders of its assets that, not only were they to employ

Buchans residents (or former residents) wherever they possessed the necessary skills, but that they were to be paid the equivalent of union rates for each trade in Newfoundland.

Significantly, the BDC did not actually require unionization. While still working as

Marketing Director for the BDC, Power emphasized that they had to 'overcome the view that the [BDC] was some type of socialist enterprise and the view that a mining town lacked entrepreneurial spirit.' Clearly, they were successful in projecting the right image to Calvin Powell and to GE

International Sub-contracting and Local Linkages: Reducing Vulnerability

Steelcor hired a skilled CNC operator from Ontario on a oneyear contract to carry out the initial prototype work for GE, and to train Steelcor's permanent employees from Buchans how to operate the equipment. Once the prototypes received approval from GE, it was expected that twenty people would be employed in production. This was for the initial contract alone, as Steelcor was bidding on further component-supply contracts with the

Aerospace and other divisions of GE, which would generate further employment.

Possession of the state-of-the-art production equipment also enabled Steelcor to bid on supply contracts with other defense contractors. Powell maintained that the GE contract increased Steelcor's legitimacy in bidding on others, as they were now an established defense industry sub-contractor Bids were being prepared for companies in California and Northern Ireland. Employment of Buchans residents would continue to increase if such additional contracts could be won.

Within Newfoundland, the metal fabrication business was considered close to saturated when Steelcor started up, a fact Which had little impact on an international niche marketing strategy. However, the CNC equipment gave Steelcor a competitive advantage not enjoyed by other Newfoundland firms, and the Buchans plant was soon attracting possibilities because of its specialized capabilities. A small firm in Bishops Falls, some

120 kilometers from Buchans, developed a high-pressure hose for fighting forest fires.

The hose required a coupling unavailable on the market, so the firm contracted Steelcor to develop a prototype. If this proved successful, there would be yet more employment as this component went into production.

In the meantime, the BDC continued to work on additional development projects to utilize the remaining office space and work shops in Buchans. When the operator of the rock souvenir facility indicated interest in moving into the production of dimension stone

- large marble or granite tiles used in construction - the BDC offered to take over his business and assist him in establishing the new facility.

The BDC also saw potential in developing fresh water aquaculture in the region. A labour force skilled in salmon hatchery operations had been developed near Millertown because of a long-standing federal government salmon enhancement program on the Exploits

River The BDC was working with a Norwegian fish farmer who had set up a fish hatchery and farm in Prince Edward Island. Sandy Ivany explained that these advantages could be combined with Steelcor's expertise in metal fabrication, by launching R&D and production for export of the steel cages and tanks used in aquaculture operations. If realized, such linkages could generate the emergence of a mutually reinforcing local production system in Buchans, generating spin-offs and innovations which could truly revitalize the economy of the region.

For Steelcor, such possibilities offered hope for the future; but for the present the GE contract remained the only game in town. Specialized production for a niche market created the firm in the first place, but it also made it vulnerable, at least until additional contracts could be won. In April 1991, the Canadian government announced dramatic cuts in the armed forces. National governments throughout the Western world seized on the thawing of the Cold War as an opportunity to cut defense spending. This was just one of many ways in which financially-strapped governments were attempting to reduce fiscal deficits in the early 1990s.

A production strategy targeted on increasing Newfoundland's share of government procurement was aiming for a larger share of a shrinking pie. Power maintained that

Steelcor's emphasis on radar components would be less vulnerable, as countries placed greater weight on surveillance and defensive measures. Indeed, the early warning coastal radar system was not threatened by the April cuts. But decreased expenditure in other areas of defense procurement would only increase competition in such areas as radar components, as established producers and sub-contractors focused on remaining areas of demand.

Could Steelcor continue to rely on defence sub-contracting to form the core of its operations? Without the GE contract they would not even have the CNC equipment, which could generate new opportunities in other sectors. Winning contracts with companies other than GE, particularly those outside North America, would surely indicate that the Buchans facility and workforce could compete globally, even without free trade and procurement advantages. But those contracts had yet to be won.

Was increased integration with the BDC development strategies a feasible alternative?

Steelcor's expertise would contribute greatly to successful inter-firm linkages and would create a regional competitive advantage in any industry requiring metal fabrication or machining. But the aquaculture project was still in its formative stage. Buchan's residents had demonstrated tremendous community spirit and substantial and political skills in getting as far as they had. Was this enough in the intensifying competitive environment of the 1990s?

Exhibit 1

Area Map