Calendar - word file - APICS North Shore Chapter

advertisement

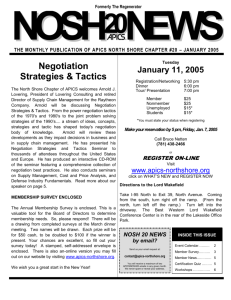

Formerly The Regenerator 2 0 NOSH NEWS THE MONTHLY PUBLICATION OF APICS NORTH SHORE CHAPTER #20 – NOVEMBER 2004 Smith & Nephew Plant Tour The North Shore Chapter of APICS is proud to announce that it will be holding a plant tour at Smith & Nephew, at the plant located at 160 Dascomb Road in Andover, Massachusetts, on Tuesday, November 9, 2004. It should be a great tour—but you must register by November 1st—don’t miss it! Smith & Nephew develops and markets advanced medical devices that help healthcare professional treat patients more effectively - and patients get back to their normal lives faster. Orthapaedics, Endoscopy and Advance Wound Management - specialise in innovative, cost-effective products that meet pressing healthcare needs. Tuesday November 9, 2004 Registration/Networking 5:30 pm Dinner 6:00 pm Tour/ Presentation 7:00 pm Member Nonmember Unemployed Students $25 $25 $15* $15* *You must state your status when registering Make your reservation by 5 pm, Tuesday, Nov. 1, 2004 Call Bruce Netten (781) 438-2466 or REGISTER ON-LINE Visit www.apics-northshore.org Smith & Nephew Endoscopy is committed to reducing click on WHAT’S NEW and REGISTER NOW trauma and pain to the patient, reducing cost to healthcare systems, and providing better outcomes for surgeons with its broad range of techniques and Directions to the Plant Tour instruments for minimally invasive surgery. Take Smith & Nephew is located off exit 42 on Rte 93. This business unit is the world leader in arthroscopy, For Directions see the bottom of page 2. minimally invasive surgery for articulating joints. This is a dynamic and growing market, driven by the desire for an improved quality of life among patients, and the increase in sports-related injuries. In addition, the business unit is broadening its scope beyond NOSH 20 NEWS INSIDE THIS ISSUE arthroscopy to include all areas of endoscopy. by email? The Endoscopy corporate business is located at Minuteman Park in Andover, MA with manufacturing sites in Andover ( Dascomb Road), Mansfield MA and OKC, OK. Endoscopy employs 1000 people in MA, and 1400 worldwide. Send us your email request at: contact@apics-northshore.org You will receive a maximum of two APICSNOSH20 emails in any given month. We never spam or reveal your address. Event Calendar ……... 2 President’s Message… 3 Member News…………. 3 Certification Quiz ……… 4 Workshops …………… 5 North Shore Chapter 2 APICS North Shore Chapter 2002-2004 Board of Directors PRESIDENT Kevin Burnell E-mail: contact@apics-northshore.org H: 978-373-3762 North Shore Chapter #20 2004 - 2005 CALENDAR VP & AWARDS open SECRETARY Joyce Vecchiarelli E-mail: joyce.vecchiarelli@smith-nephew.com W: 978-749-1075 TREASURER Doug Wilson, CFPIM H: 603-382-5368 EDUCATION & RESEARCH Marc Ratte E-mail: rattem@tycoelectronics.com W: 978-442-5066 Ken Duratti, CPIM E-mail: ken_duratti@hotmail.com H: 781-245-1773 NEWSLETTER Adrienne Galbraith, CPIM E-mail: aagalbraith@hotmail.com H: 978-440-8019 FACILITIES Bruce Netten, CPIM E-mail: netten@peoplepc.com H: 781-438-2466 PROGRAMS & AWARDS Susan Sulesky E-mail: sulesky@gtequipment.com MARKETING open Date Day Activity Agenda 11/9/04 Tue PDM Plant Tour at Smith & Nephew 12/7/04 Tue BOD Chapter Business 01/1105 Tue PDM SIG Night 02/08/05 Tue PDM Student Night, Member Survey Contest Robert Adelson, Esq., “Contract Negotiation” 03/08/05 Tue PDM Joint meeting 04/12/05 Tue PDM Dr. Michael O’Connor, "Six Sigma – Business Improvement Processes" Nominations 05/10/05 Tue PDM Election of Officers 06/14/05 Tue PDM Annual Bash, Installation of Officers WEBSITE Frank Clapp E-mail: clapp5@comcast.net W: 978-703-2677 WEBMASTER Michael Burkett E-mail: webmaster@apics-northshore.org ACTIVITIES LIAISON Kenneth B.Glasser, CPIM, C.P.M. E-mail: kenneth.glasser@axcelis.com W: 978-787-9273 MEMBERSHIP Rich Hopkins, CFPIM,CIRM E-mail: richard.hopkins@vsea.com W: 978-282-2339 EMPLOYMENT Patrick Stack E-Mail: pstack@newalliance.com W: 978-681-0677 x212 ACADEMIC LIAISON Billie Gettel H: 978-897-5284 E-mail: billie.gettel@comcast.net PAST PRESIDENT Paul Blanchet, CPIM E-mail: paul.blanchet3@averydennison.com W: 978-345-8119 DIRECTOR AT LARGE Preston Holleman, CPIM E-mail: presolder@aol.com H: 978-369-8727 COMPANY CO-ORDINATOR Brenda DeCoff E-mail: Brenda.Decoff@itt.com Directions to the Plant Tour Smith & Nephew is located off exit 42 on Rte 93. From the North: Rte 93 to exit 42 Dascomb Road. Take a left at the end of the ramp. At the traffic lights take a right and take the next quick left (Smith & Nephew will be on the right of the drive and Brockway Smith on the left of the drive.) Take your first right and right again into a parking lot. Proceed to the main entrance for admittance into the building. From the South: Rte 93 to exit 42 Dascomb Road. Take a left at the end of the ramp. At the traffic lights go straight but stay on the left side of the road. Take a left at the first opening (Smith and Nephew will be on the right of the drive and Brockway Smith on the left of the drive). Take your first right and right again into the parking lot. Proceed to the main entrance for admittance into the building. North Shore Chapter President’s Message 3 Certification Corner Dear Fellow APICS Members, Each month in this section, we will feature five sample questions from one of the five modules in the CPIM Certification Program. For more information on the CPIM Certification process, call Rich Hopkins at 978282-2339. We encourage you to plan ahead for your education. Visit www.apics-northshore.org for more information on these upcoming classes: This month's questions are taken from the Detailed Scheduling and Planning module: 1. WINTER 2005 (A) The individual operation due dates on open shop orders are not being met. (B) The current date of need is different from the order due date. (C) The material is not available when a shop order is due to be released. (D) The quantity of an open order is not sufficient to cover requirements. Basics of Supply Chain Mgt. Elements of the Supply Chain Just in Time (JIT) Total Quality Management (TQM) Manufacturing Resources Planning (MRP II) Demand Planning Capacity Management Master Planning of Resources 2. 3. Prioritizing and Sequencing Work Executing Plans & Implementing Controls Authorizing work and Reporting for Push & Pull Systems Evaluating Performance and Providing Feedback Quality Management Processes We also encourage you to take advantage of all the educational opportunities APICS has to offer—at the chapter, region and society levels. For Society webinars, seminars visit http://www.apics.org . New Members The North Shore Chapter welcomes the following new members: Billy Monroy Caleb Page Answers to Quiz: 1. A, 2. D, 3. C, 4. B, 5. C N O P E E K I N G ! The term “full pegging,” as contrasted with “single-level pegging,” implies which of the following? (A) Requirements for all items in the system are pegged. (B) Open orders, as well as gross requirements, are pegged to planned and open orders at the parent level. (C) Item requirements are pegged directly to customer order or end-item lots in the master production schedule. (D) Item requirements are pegged to planned orders, to net requirements, and to gross requirements at the parent level. 4. Allowances for scrap/yield estimates in the manufacture of a component require overplanning of (A) (B) (C) (D) Sincerely, Kevin Burnell, President APICS North Shore Chapter #20 One of the key built-in abilities of an MRP system is to (A) compute open order priorities using a dynamic priority ratio (B) control the sequence of work being performed on the shop floor (C) compute operation priorities using a standard backwardscheduling technique (D) help keep the due dates valid for all open orders Business Planning Process Forecasting Demand Distribution Planning Process Sales and Operations Planning Master Scheduling Process Execution & Control of Operations An MRP system has the ability to advise the planner of all of the following situations EXCEPT 5. parent safety stock component planned releases parent planned releases component planned receipts Firm planned orders are useful for doing which of the following? I. II. III. IV. Preventing the system from automatically rescheduling Creating a planned order that does not agree with lot sizing rule for that item Preventing the explosion of requirements at lower levels Freezing the timing of a planned order release (A) I only (B) III and IV only (C) I, II and IV only (D) I, II, III, and IV APICS North Shore Chapter #20 PO Box 108 Beverly, MA 01915 Return Service Requested Plan Ahead for Workshops! http://www.apics-northshore.org/education.htm Computer Based Testing (CBT) Sites ASI Assessment Ctr. 500 W. Cummings Park Suite # 1950, Woburn, MA 01810 Dartmouth ASI Ctr. Smith Mills Shops, 331 State Road, Suite C, North Dartmouth, MA 02747 HOST SITES NEEDED! ASI Cosmetology Ctr. Gateway Apartment Bldg. 14 Summer St. Malden MA 02148 One registration fee will be waived if your site hosts a workshop! ASI Ctr. 181 Park Avenue, Suite 5, West Springfield MA 01089 Call Ken Duratti 781-245-1773 or e-mail ken_duratti@hotmail.com for more info Seating is limited. Early registration is strongly recommended. Call ASI at (800) 274-8399.