Operations Plan - University of Saskatchewan

advertisement

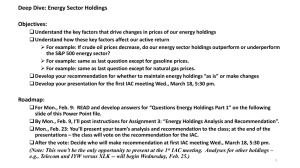

Dykal Holdings 1.0 Introduction 1.1 Industry Overview Currently a poultry farm has been raising chickens and selling them to Lilydale processing plant. Lilydale limits the weight of chickens they purchase to 1.75kg in order to supply KFC throughout the province. However, by using the terms set out by Lilydale the farm is unable to maximize the potential of its chicken barns and therefore is currently exploring ways to increase production. Essentially the idea has been to extend the chickens growing period from the current 37 day cycle to a 56 day cycle. This would eliminate the period in which the barns are vacant. In turn this would increase the chicken’s weight and therefore make them unsaleable to Lilydale. Therefore the idea is for the farm to expand into a market of both Halal (Islamic) and non-Halal chicken by opening its own processing facility. The concept of opening a live kill poultry processing plant which uses procedures approved by the Islamic community will allow for the proper promotion of the chicken into a niche market. The plant will be constructed at VIS-A-VIS; an old bottling building located in Wynyard in close proximity to poultry suppliers. Presently the existing structure has been gutted and has the potential to be renovated into the proper processing facility. Over the past few years chicken has become a health alternative to red meats. This creates a large expanding potential market within the Prairie Provinces (Muslim Population Statistics website, 2003). The Halal market is also expanding as immigration increases and the population of Islamic people increase in the Western Provinces. This creates the potential for the development of a new chicken processing plant to service the needs of the consumers and the highly expanding niche market. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 1 Dykal Holdings 1.2 Mission Statement “Dykal Holdings, a Saskatchewan based company, will strive to meet the needs of all customers by providing competitive prices and a premium, value-added product while providing a pleasant working environment for all employees.” 1.3 Business Goals The business goals of Dykal Holdings are to: Form a ten year financial analysis as to the projected outlook of the processing plant. Convert an existing building into a high revenue business by generating high amounts of sales capital Develop a production plant which uses processing techniques that satisfies the Islamic ethnic groups. Establish a successful marketing plan in order to penetrate the Halal chicken market and the existing poultry market. To achieve a 20% profit, before income taxes on gross sales of $4.54 million in the first year of operation Grow sales less allowances for returns of Halal poultry, to $9.39 million within the first 10 years of operation. 1.4 Policy Current legislation puts chicken production under a quota system. This means that for a producer to produce and sell chicken they must have a quota from the government. This quota assigns the number of kilograms of chicken the producer will grow per 56 day cycle. However this quota does not affect where the chicken is sold to, therefore Dykal Holdings is able to sell the processed chicken outside of Saskatchewan, with the only requirement being that the plant is federally inspected (Ted Baas, 2003). Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 2 Dykal Holdings In order to ensure that poultry processed at the facility will be classified as Halal a number of special criteria must be followed; the animal must be slaughtered by a Muslim, a Jew or a Christian. The animal should be held and its throat should be slit with a very sharp knife to make sure that the three main blood vessels are cut. In addition to this the animal must be facing east. While cutting the throat of the animal (without severing the spinal cord), the person must pronounce the name of Allah or recite a blessing which contains the name of Allah, such as "Bismillah Allah-u-Akbar" (The Most Kind, The Most Merciful). Dykal Holdings plans on obtaining certification from a number of Islamic groups. This will be done in order to express the authenticity of the product to the consumer. This process is easily accomplished; representatives from the groups often travel to the processing plant in order to inspect the facility firsthand. Once they are satisfied that the requirements are being fulfilled the product is certified. Additional random checks of the plant will also be conducted throughout the year. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 3 Dykal Holdings 2.0 Operations Plan 2.1 Organizational Structure Dykal Holdings will be established as a corporation. Refer to Figure 1 for a visual representation of the organizational structure. CEO Plant Office Secretary Kill Receiver (2) Eviscer- Hanger Packaging Cutter Killing Gutters (3) Cropper (3) Custodian Sanitizer (2) Cutter Accountant Other Packer Maintenance Shipper CFIA Inspector (1.5) Offal Preparers HACCP Figure 1. Organizational Structure of Dykal Holdings 2.2 Site Plan The plant is located in Wynyard on Highway 16. There is a service road along this highway to allow easy access to the plant. The offices and front entrance to the plant are on the north side of the building, facing the highway. There is sufficient parking located on the northwest and Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 4 Dykal Holdings southeast corners of the property. The receiving and shipping docks are located on the south side of the building. (See Appendix A) In the next ten years Dykal Holdings does not expect any additions to the site as the expansion is already incorporated into the site design. 2.3 Building and Floor Plans The building is 42,388 square feet, this includes 34,334 square feet for manufacturing and office space totals 8,054 square feet which includes space for offices, locker rooms, showers, an atrium and a board room. (See Appendix B) The processing line will accommodate a 50% planned increase in production therefore the plant layout will not change in the next five years. 2.4 Work Plan and Flow of Work 2.4.1 Process Flow a. Birds will be received by truck in crates. Two shipments of birds will be received over the day; the first shipment in the morning and the second just before noon. Each shipment will contain half of the day’s birds. Birds will be removed from crates and hung on shackles facing east. Figure 2 shows letters a – n in a flow chart. b. The hand slaughter line will run on the same line as the stunning line, the stunner will not be implemented when the Halal chickens are being slaughtered. Birds must be hand killed; being sure that the spinal cord is kept intact when the neck is silt, which can be done at the killing point on the line, in the same location the non-Halal bird’s throats would be slit. Each bird must be blessed by a Muslim, Jew or Christian before it is killed to grant Halal certification. This person will assist in the slaughter of the chickens, whether processing Halal or non-Halal chicken. After the birds have been hand killed they will be bled the same as non-Halal birds and continue on to be further processed. c. To keep birds separate (Halal and non-Halal) a gap will be left between the Halal chickens and non-Halal chickens, if both methods are utilized on the same day. This is the same Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 5 Dykal Holdings criteria followed by other processing facilities such as Maple Leaf Pork in Brandon to keep vegetable fed hogs and non-vegetable fed hogs separate. When not killing for the Halal a. Receive Live Birds c. Stunning and Slaughter b. Hand Slaughter d. Scalding and Defeathering e. Head Puller/ Hock Cutter f. Evisceration g. Giblets h. Cooling i. Cutting i. Cutting k. Packing and Grading l. Refrigeration n. Distribution j. Blast Tunnel k. Packing and Grading m. Freezer n. Distribution Figure 2. Process Flow Diagram market, the birds will go through the stunner. The bird’s throat is then cut and is allowed to bleed for 1.5 to 2 minutes before dressing begins. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 6 Dykal Holdings d. Both Halal and non-Halal birds will be treated the same from here on. The birds are lowered into a scalding tank, which is at 52°C. The speed of the line ensures that the birds are in the water for the correct amount of time. The scald tank is set up so the birds go through the same tank twice; the purpose of this is to minimize that area required for scalding in the plant. The scald water must be agitated to ensure uniform temperature throughout. After the birds are through the scald tank they go into the plucker. This machine is equipped with rubber fingers and brushes the feathers off the bird. e. The defeathered bird then goes through a Head Puller that pulls the neck out straight, and cuts it off leaving the neck intact. This method of head removal will be beneficial when it comes to eviscerating the bird. Next on the line the birds go to the Hock Cutter. Here the bird’s feet are cut off and the bird drops down onto a conveyor that will lead to the evisceration tables. The feet stay on the shackles until they reach the Foot Unloader where the feet are taken off and the shackles move through a washer and then back to be reloaded with live birds. There is a viable Asian market for the feet, but for the purposes of this study they will not be considered. f. The birds now on the conveyor will be rehung onto the evisceration line. Next, a series of workers will manually eviscerate the birds. A cut is made around the vent, being careful not to cut intestines; this cut must be large enough to fit a hand into. Next a drawing tool is inserted into the cut and the offal is pulled out. The heart, liver and gizzards are removed and go to the giblet room. Next an incision is made on the crop which is removed by hand. The lungs are removed by a vacuum operated lung pistol. With the use of a pneumatic neck shear, the necks with skin are harvested. The bird then goes through an outside bird washer. The wash cabinet has a series of water spray heads that line the conveyor. The water is chlorinated when it comes out of these nozzles. The nozzles rotate as they clean the carcass. The cleaning process takes about one minute. g. The heart, liver and gizzards move into the giblet room where they are hand cleaned and packaged in plastic bags. The gizzards must be sliced open, washed out, and then skinned. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 7 Dykal Holdings Again there is a lucrative market for these products which will not be considered for this study. h. After the birds have been cleaned they are cooled. An air chiller will be used, which will decrease the temperature of the carcass from 35°C to 5°C. The birds are being cooled in this manner as a premium air cooled product. A water chilled system is more economical, however does not create as high of quality product as water is added to the chicken, which is unfavoured by consumers. Some birds will be left whole and others will be further processed. The birds also pass through a carousel weigher and grader. After the birds are chilled they leave the line by an unloader. The shackles pass through a washer and return to the hanging line. i. A portioning machine will be used to cut the birds into pieces. The machine is equipped with an arm that is pointed towards the operator. The carcass is placed in the groove of the machine and the arm pushed down to cut the bird into two pieces. Other pieces of chicken can easily be made by cleavers and knives. Most of the product sold will be cut into pieces and sold as chilled fresh product. Note that this product will not be deboned as this is a very labour intensive process and requires highly trained personnel to decrease wastes. j. The whole birds will go through a blast chiller to freeze them extremely fast before entering a freezer room. Only a small portion of the whole birds will be sold frozen, the ones to be sold in the Halal market. The non-Halal market will be sold fresh, chilled whole chickens. The whole birds must be frozen as there is not a large enough market for fresh whole birds. k. The Halal whole chickens will be vacuum package and weighed. Vacuum packaging has been chosen as it will increase shelf life by eliminating the amount of oxygen in the package. The Halal pieces will be boxed into 5 kg lots and sold as legs, thighs, breasts, and wings. Any of the Halal processed chicken will have a Halal certified sticker added to the package to keep it distinguished from non-Halal chicken. The non-Halal product will be sold in large crates to individual stores. There will be separation of breast, thighs, wings, drumsticks, and Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 8 Dykal Holdings whole chickens, all of which are sold chilled and fresh. All the products (Halal and nonHalal) will have the vegetable grain fed label on, as well as the air chilled label. l. The cut product will then be placed into coolers and shipped out within two days to our wholesale buyers (IGA). m. The Halal chicken will be shipped every other week to different locations through the same distributor as the non-Halal. n. The product will be delivered to the wholesale buyers by truck (CoolX). The truck must be refrigerated for transport so products do not spoil. Non-edible waste such as the feathers, heads, and intestines are transported by water through the floor gutters to the pits. The solid wastes are separated from the water wastes. From here the offal will be stored and disposed of at the Wynyard Waste Facility. Other disposal options, such as rendering may be looked at in the future. Water from the feather separator will be recycled to the feather gutter by a recirculation pump. The remainder of water will be disposed of through the sewers. Refer to Appendix C for a visual representation of the above process. 2.5 Average Day and Week In an average day at Dykal Holdings employees will come to work and change into work clothes (supplied by Dykal Holdings). Each employee is required to go through a boot wash and hand station. All employees will be required to wear latex gloves and hairnets. All jewellery must be removed prior to the start of the shift. The line will run continuously, with the slaughter line, and processing lines, coffee and lunch breaks spread over a period of time so that the operation does not have to completely shut down. This means the kill will stop for the breaks, but the next position goes on break only after the birds have been past their work station. After 10 hours of work the plant will shut down for the day. Employees then will proceed to change out of their work clothes and shower if they choose. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 9 Dykal Holdings Once the kill and processing line is shut down the plant must be sanitized. Different employees than those working on the slaughter and processing lines will sanitize the building at the end of each shift. These employees do the same as the line workers in regards to changing clothing and washing their boots and hands. Once changed all equipment is washed down and then soaked with an organic acid. This organic acid has to sit for 2 hours and then is rinsed. Once all cleaning is complete the employees change out of their work clothes. This is the end of one full day for the processing and cleaning staff. The average day for office staff is coming to work and leaving after an eight-hour day. During this day tasks such as book keeping, pay roll, taking orders and other office work will be done. In an average week the following hours will be required for each position. Line staff will be required to work four ten hour shifts. The sanitation staff will be required to work five eight hour shifts a week. The receptionists and plant manager will all be required to work five eight hour shifts per week. The maintenance persons will be required to five eight hour shift per week. Finally the HACCP (Hazard Analysis Critical Control Points) employee will be required to work four ten hour shifts per week. There will be two CFIA inspectors, one CFIA Inspector will work four ten hour shifts per week, and the other will only be required to work approximately 20 hours a week. This will be the only part-time employee; all other employees will work a 40 hour week. The only seasonal effect there may be on the plant is the Ramadan holy month. However, this will not affect the plant as the same amount of chicken will be processed from week to week and month to month. This season may affect the marketer of the product, but not Dykal Holdings directly. This is not foreseen as a problem as the majority of chicken sold by Dykal Holdings will be non-Halal. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 10 Dykal Holdings 2.6 Quality Control Program There will be a HACCP employee responsible for doing random microbiological tests, looking for bacteria, and for bio-film build up on the equipment. This person will also be responsible for making sure that all employees wash correctly and will ensure that any meat that gets dropped onto the floor is disposed of in a correct manner. On top of these duties the HAACP co-ordinator will conduct random tests looking for drugs in birds which are used in production, but can not be present at the time of processing. Finally this person will be responsible for documenting checks in the event that a government inspector does an audit of the plant. One full time CFIA (Canadian Food Inspection Agency) inspector will be employed along with one part time inspector. These employees are required by the provincial government and report directly to them. One will be working on the slaughter line checking and inspecting every bird that comes off the trucks and into the processing plant to be slaughtered. This person is required to be present during all hours of operation in the live kill area. The second CFIA inspector will work only half time and be located on the processing side of the operation and will be responsible for doing 20 hours worth of random checks. 2.7 Supply/Service Analysis One poultry farm, which wishes to remain anonymous at this time, will supply all live chickens. All packaging supplies will come from Rayton Packing located in Calgary. All water supplies will come from the Town of Wynyard (Sheila Hitchings, 2003). 2.8 Limitations There are some limitations that Dykal Holdings may encounter. One foreseen limitation was water; however after consulting with the Town of Wynyard, Shelia Hitchings assured Dykal Holdings that there would be sufficient water supply for the plant. The town of Wynyard also assured Dykal Holdings that the sewer system would be able to handle the excess waste water. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 11 Dykal Holdings Different alternatives to dealing with waste products exist. The easiest and cheapest method appears to be disposing of wastes in the Wynyard Waste Facility, and as such this is the method that will be utilized; the cost is $0.01/kg, see Schedule 3. 2.9 Capital Budget 2004 Costs: Land and Building Equipment: Arrival department Defeathering department Evisceration department Chilling department Weighing department Offal department Miscellaneous Spare parts Office Supplies Electrical Installation Piping Air Conditioning Total Capital Costs 2006 2008 2010 2012 1,100,000 Input Input Input Input Input Input Input Input Input Input Input Input Input Working Capital Cash Input Accounts Receivable Inventories Accounts Payable Total Net Working Capital 20,691 284,130 182,805 290,000 141,224 67,933 136,030 82,432 50,000 20,000 250,000 22,000 30,000 2,677,245 87,113 21,120 92,059 22,240 97,287 23,360 102,811 24,480 108,233 114,299 120,647 127,291 400,000 340,461 16,143 275,032 481,571 593,593 23,136 464,775 151,955 625,072 24,162 491,033 158,200 656,550 25,236 518,759 163,027 688,028 26,361 548,036 166,354 Table 1. Capital Budget 2.10 Working Capital Planning and Management 2.10.1 Cost of Goods Sold The total cost of goods sold is equal to cost of goods available for sales less the ending inventory. Cost of goods available for sale is the beginning inventory plus the cost of goods Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 12 Dykal Holdings manufactured. The total cost of goods sold is therefore $4,607,298 in the first year, see Table 2. The direct labour costs include all line worker wages totalling $628,210 in the first year including benefits. Manufacturing overhead consists of, maintenance staff wages, inspector wages, HACCP wages, taxes, insurance, capital cost allowance, gas costs, and electricity costs. The total manufacturing overhead costs are $656,457 in the first year . 2004 Beginning Inventory Cost of Goods Manufactured Cost of Goods Available for Sale Ending Inventory Cost of Goods Sold 0 4,623,441 4,623,441 16,143 4,607,298 2006 2008 2010 2012 19,763 23,643 24,693 25,792 7,176,718 7,489,528 7,844,989 8,235,236 7,196,481 7,513,171 7,869,682 8,261,028 23,136 24,162 25,236 26,361 7,173,345 7,489,009 7,844,446 8,234,667 Table 2. Cost of Goods Sold 2.10.2 Inventories There will not be any raw material inventory as live birds will come in at increments through out the day. Finished goods stored will be 20,000 birds at peak times. The ideal inventory is 10,000 birds. Total inventory costs will be $16,143 in the first year of operation. (See Appendix E.1) Essentially Dykal Holdings will be utilizing a just-in-time inventory control system. 2.10.3 Accounts Receivable Assuming that Dykal Holdings will allow 30 days for accounts to be paid and no discount will be provided if an early payment is received the accounts receivable will be $340,461 in the first year of operations. (See Appendix E.2) 2.10.4 Accounts Payable Assuming that poultry supplier is not giving Dykal Holdings a discount, and is allowing Dykal Holdings to have 30 days to pay without interest, also the packing supplier allows 30 days to Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 13 Dykal Holdings pay, and the delivery charges are paid every two weeks the accounts payable will be $275,032 in the first year of operations. (See Appendix E.3) 2.11 Cash Conversion Cycle No raw material inventories exist as birds arrive on an ongoing basis throughout the day; packaging supplies are delivered every two weeks. Finished goods inventory will consist of 2 days of fully processed birds. WPF is allowing 30 days to pay for the raw materials, with no discount for early payment. As such the accounts payable will be for 30 days. Likewise Dykal Holdings wholesalers will provide payment within 30 days of receiving the product. With no discount for early payment, Dykal Holdings will assume a 30 day accounts payable. Therefore the Cash Conversion Cycle of Dykal Holdings is 2 days. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 14 Dykal Holdings 3.0 Human Resources Plan 3.1 Employee Plan As a large production plant there will be a number of individuals required for Dykal Holdings to operate in a continuous manner. Originally 26.5 employees ranging from management to floor workers will be hired. Meaning 26 full time employees and one part time employee will be hired. No additional people are believed to be needed upon increasing the slaughter of chicken. This is because at the beginning employees will be under worked, but each position is required for the line to flow. All employees will be required to go through a training program which will outline the companies’ expectations and give full details pertaining to Halal processing. This is important so that during Halal processing proper methods are used and the company complies with certification requirements. There will also be training sessions available to new staff. These sessions will focus on processing practices that are used in day to day operations including regular processing techniques, not just those for Halal. During the training programs employees will be given a chance to get hands on experience specifically outlining their individual duties according to what division of the operations cycle they fall in. Safety training is also mandatory for new employees. A one week orientation course will outline proper procedures in order to reduce the risk of industrial accidents also including First Aid and CPR. 3.2 Labour, Hiring and Training Policy Within the processing plant there are jobs that require specific knowledge and training and therefore will require someone with qualifications that meet the guidelines of that particular position. These positions include foremen, supervisors, plant manager, maintenance and several production line workers. All salaries are outlined in Table 3. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 15 Dykal Holdings Although an individual has already been selected for the position of Plant Manager, criteria for other positions of authority involved with plant manufacturing and operations will be as follows: Plant Manager Description Manage cost effective and efficient production of quality products. Develop and maintain capable and effective employees in all areas of production. Maintain a positive employee-relations environment in support of cost effective production of quality products by all plant workers. Ensure open and effective communications with all other departments within Wynyard Poultry Processing Plant. Continuously improve our manufacturing resources, process, and efficiencies. Criteria Bachelor’s degree, preferably in Chemical, Mechanical or Food engineering. Experience with or assisting in the management of a food manufacturing plant... Excellent interpersonal and team building skills. Expertise in process and cost management. Excellent communication skills Strong leadership skills with the proven ability to take the initiative. Maintenance Supervisor Description Ensure that capital equipment is properly maintained to ensure smooth and constant production. Responsible for the care and up keep of site grounds. Maintain building and site Criteria Working knowledge of relevant equipment Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 16 Dykal Holdings Ability to perform quick and efficient tasks in order to minimize down time. Production Line Worker Description Ability to work within a team setting Complete on the job training and safety courses Develop skills necessary to operate proper equipment Proven ability to work in a fast paced environment Criteria Basic knowledge of equipment Ability to work in a fast-paced food product environment Ability to follow instructions Demonstrates independent work habits Preference will be given to individuals of Islamic decent Receptionist Description Communicating with suppliers and customers via person and phone Dealing with small public relations Perform general office duties Criteria Ability to multi-task Familiar with various word processing programs including but not exclusively: Microsoft Word, Corel, WordPerfect Possess excellent keyboarding skills Excellent managerial, organizational, and verbal/written communication skills. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 17 Dykal Holdings Accountant Description Responsible for recording financial records of day to day activities Demonstrate an understanding of tax concepts and apply them appropriately Complete employee payroll Criteria Bachelor’s degree in one of the following disciplines; Accounting, Finance or Business administration. Ability to work in a team environment CFIA Inspector Description Inspects incoming birds and final product. Responsible for ensuring all government regulations are followed. Ensures that safety protocol is followed. Works closely with HACCP Coordinator. Criteria Bachelor’s degree in one of the following: Food Science, Applied Microbiology, Animal Science or a related field Preferably experience in processing as there is only one full time inspector. Ability to enforce guidelines and rules. HACCP Coordinator Description Responsible for random microbial tests and monitoring of product. Ensures food quality and food safety. Works closely with CFIA Inspectors Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 18 Dykal Holdings Criteria Bachelor’s degree in one of the following disciplines; Food Science, Applied Microbiology or a related field Good laboratory skill and knowledge Ability to enforce guidelines and rules. 3.2.1 Total Salary Costs 2004 Direct Labour Costs Permanent Labourers 20 Wage 12.00 Hours 2,080 Total 499,200 Overhead Salary Workers HACCP Inspector 1 Salary 40,000 CFIA Inspector 1.5 Salary 60,000 Maintenance Supervisor 1 Salary 47,877 Total Fixed Salaries 177,877 Admin Salary Workers Plant Manager 1 Salary 100,000 Receptionist/Accounting Clerk I 2 Salary 25,676 Total Admin Salaries 151,352 Total Salaries 828,429 2006 2008 2010 2012 20 12.67 2,080 527,155 20 13.34 2,080 555,110 20 14.02 2,080 583,066 20 14.69 2,080 611,021 1 42,240 1.5 63,360 1 50,558 187,838 1 44,480 1.5 66,720 1 53,239 197,799 1 46,720 1.5 70,080 1 55,920 207,760 1 48,960 1.5 73,440 1 58,601 217,721 1 105,600 2 27,114 159,828 874,821 1 111,200 2 28,552 168,303 921,213 1 1 116,800 122,400 2 2 29,990 31,427 176,779 185,255 967,605 1,013,997 Table 3. Salary Costs 3.3 Employee Benefits All employees will be eligible for a benefit package, set out by the company. All employees will go through a six month probationary period before becoming eligible for benefits. The cost of health and dental insurance, along with the accidental death or injury is $145.13 per employee. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 19 Dykal Holdings 2004 Benefits for Direct Labour Employees Employment Insurance 10,483 Canada Pension Plan 23,136 Holiday Pay 28,954 Workers Compensation 36,541 Blife 628 ADD 166 LTD 4,238 Dent 7,463 EHC 4,921 Pension Plan 12,480 Total 129,010 Benefits for Overhead Salaried Employees Employment Insurance 3,735 Canada Pension Plan 6,078 Holiday Pay 10,317 Workers Compensation 6,433 Blife 63 ADD 17 LTD 71 Dent 299 EHC 492 Pension Plan 2,197 Total 29,700 Benefits for Salaried Employees Employment Insurance 3,178 Canada Pension Plan 5,172 Holiday Pay 8,778 Workers Compensation 3,784 Blife 94 ADD 25 LTD 636 Dent 1,119 EHC 738 Pension Plan 3,784 Total 27,308 Total Benefits 186,018 2006 2008 2010 2012 11,070 24,431 30,575 38,588 663 175 4,479 7,887 5,201 13,179 136,248 11,657 25,727 32,196 40,634 701 185 4,733 8,334 5,496 13,878 143,542 12,244 27,023 33,818 42,680 741 195 5,002 8,808 5,808 14,577 150,896 12,831 28,318 35,439 44,727 783 207 5,286 9,308 6,138 15,276 158,312 3,945 6,418 10,895 6,793 66 18 75 315 520 2,320 31,364 4,154 6,759 11,472 7,153 70 18 79 333 550 2,443 33,031 4,363 7,099 12,050 7,513 74 20 83 352 581 2,566 34,702 4,572 7,440 12,628 7,873 78 21 88 372 614 2,689 36,375 3,356 5,461 9,270 3,996 99 26 672 1,183 780 3,996 28,840 196,452 3,534 5,751 9,762 4,208 105 28 710 1,250 824 4,208 30,380 206,953 3,712 6,041 10,253 4,419 111 29 750 1,321 871 4,419 31,928 217,526 3,890 6,330 10,745 4,631 117 31 793 1,396 921 4,631 33,486 228,174 Table 4. Benefits Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 20 Dykal Holdings All employees will be subjected to monthly deductions from their pay cheques as seen in Table 4. These deductions will also be an expense incurred by the employer as they are required to contribute to these. Assuming that the rates will remain constant over the next five years the employer will pay equal amounts of CPP (Canada Pension Plan) as the employee with a rate of 3.417%. EI (Employment Insurance) is set at a rate of 2.10%. Other deductions are pension plan 2.50% of gross wage and worker’s compensation is 7.32% of gross wage. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 21 Dykal Holdings 4.0 Marketing Plan 4.1 Sales and Profit Objectives The objective of Dykal Holdings is to achieve a 20% profit before taxes on gross sales of $4.54 million in the first year of operations, growing to $9.39 million within 10 years of operation. This will be accomplished by selling 90% of the product under store label through a partnership agreement with the Saskatchewan IGAs and 10% of the product as a branded product to individual Islamic associations located in the major cities of Alberta, Saskatchewan and Manitoba. Lists of all IGAs in Saskatchewan, and Islamic Centres in Manitoba, Saskatchewan and Alberta, can be found in Appendix F and G, respectively. 4.2 Product Dykal Holdings will be selling two separate product lines. There will be a Halal product and a non-Halal product. Both will be marketed under the Prairie Pride Poultry (PPP) name. Both products are a vegetable fed, air chilled product, and each characteristic will be represented by a label on all packages. All chicken will be federally inspected to ensure a high quality, certified product, which Dykal Holdings will be able to sell across the country. All whole, broiler chickens will be sold at an average weight of 1.54 kgs. Halal products will be sold frozen, as pieces and whole products. The pieces will be packaged in 5kg boxes and the whole birds will be packaged in a vacuum sealed bag. The Halal products will have an additional sticker on it stating that the product is Halal certified. Non-Halal products will be sent as a fresh bulk product in crates. These crates are ice packed to maintain temperature. There will be individual crates for wings, thighs, breasts, drumsticks, and whole chickens. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 22 Dykal Holdings 4.3 Price Dykal Holdings’ product will be priced based on the market rates + $0.08 per kilogram because the chickens that are being processed will be 100% vegetable fed. In the first year of operation the expected selling price of non-Halal product will be $2.798/kg. This means that Dykal Holdings will be pricing at a premium. The price for the Halal chicken that Dykal Holdings will be selling will be priced in accordance to other chicken sold as Halal. In the first year of operation the expected selling price will be $2.8496/kg. Dykal Holdings will largely be a price taker in the market, as it will have to competitively price the product to ensure continued contracts. To minimize these effects Dykal Holdings will seek to establish long-term contracts. The terms and conditions for the non-Halal product will be different from that of the Halal product. The non-Halal product will have prices set monthly and allow 30 days for payment with no discount for early payment. The Halal product will require payment upon delivery, with a return policy stating that all products not sold will be given a credit towards future purchases worth 50% of the value of the purchase. Although this will cost approximately $6,490 in the first year it will reduce the risk for the Islamic associations therefore encouraging them to purchase products from Dykal Holdings. 4.4 Market Analysis 4.4.1 The Chicken Market Over the past few years the chicken market has been growing in Canada. In January of 2003 grocery sales of chicken increased by 8.9% compared to the past five year increase of 2.8% per year (Canadian Chicken Market Review website, 2003). Consumers are beginning to see the health benefits of chicken and purchase this as an alternative to red meats. The demand for chicken varies seasonally throughout the year, shown in Figure 3, with an overall increase in chicken demand over the last 3 years. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 23 Dykal Holdings Figure 3. The Consumer Demand of Chicken - June 2001-January 2003 (Canadian Chicken Market Review) Consumers appear to be replacing their pork consumption with chicken as this ratio of chicken to pork continues to increase, while the ratio of chicken to beef remains at an all time low and is on a decreasing trend, as see in Figure 4. Figure 4. The Wholesale Ratio of Chicken to Beef and Pork (Canadian Chicken Market Review website, 2003) Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 24 Dykal Holdings Chicken production across Canada has decreased over the past few months. This may be due to low prices of the wholesaler, and constant grain prices, making the industry less profitable. Another factor is the implication of quotas, which has decreased the amount of chickens to be raised in each province, setting a maximum amount each producer can grow and sell. This decline in overall chicken production, as seen in Figure 5, shows a decrease in provincial storage stock of chicken in Saskatchewan since 2002. There have also been decreases in Alberta, and Manitoba, which are major targets of Dykal Holdings. Increases in stored chicken are present in other Canadian provinces, but will not affect Dykal Holdings’ market, as these areas are not being marketed by Dykal Holdings. Figure 5. The Storage of Chicken in various Canadian Provinces 2002-03 (Canadian Chicken Market Review website, 2003) 4.4.2 Non-Halal Market The Canadian population has increased over the last few years with a 4.0% increase in population from 1996 to 2001, while the Saskatchewan population decreased by 1.1% in the same time period, shown in Table 5. There has been substantial growth in Alberta, which is a close location for Dykal Holdings to target in the future. Manitoba has remained constant over these years with a slight increase of 0.5% (Stats Canada 93F0053XIE). These numbers overall show an increasing market in the Prairie Provinces. It can also be seen that Saskatoon has Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 25 Dykal Holdings experienced the greatest growth of the major cities in Saskatchewan and several of the other cities have reduced in size. With Alberta’s significant growth new markets are being created, Dykal Holdings can use this area as an expansion option in the future once the IGA market in Saskatchewan is fully developed and prospering. Tables 6, 7, and 8 illustrate the population change in the cities being targeted. Name Canada Manitoba Saskatchewan Alberta Population 2001 30,007,094 1,119,583 978,933 2,974,807 1996 28,846,761 1,113,898 990,237 2,696,826 % change 4.0 0.5 -1.1 10.3 Table 5. Canadian Population and Growth (Stats Canada 93F0053XIE) Saskatchewan Saskatoon Regina Moose Jaw Swift Current 978,933 Population in 2001 Population in 1996 990,237 Population Change (%) -1.1 Table 6. 225,927 192,800 33,519 16,527 219,056 193,652 34,829 16,437 3.1 -0.4 -3.8 0.5 Population Growth of Saskatchewan and Major Saskatchewan Cities (Stats Canada 93F0053XIE) The target market for the non-Halal market will be IGA store managers. IGA will in turn, market the product to the end consumer, who are middle to upper class, health conscious individuals. These people have excess discretionary money to purchase a premium product. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 26 Dykal Holdings Alberta Population in 2001 2,974,807 Population in 1996 2,696,826 Population Change (%) 10.3 Table 7. Calgary Edmonton Red Deer Lethbridge 951,395 927,845 67,707 67,374 821,628 862,597 60,080 63,053 15.8 8.7 12.7 6.9 Population Growth of Alberta and Major Alberta Cities (Stats Canada 93F0053XIE) Manitoba Winnipeg Population in 2001 1,119,583 671,274 Population in 1996 11,131,898 667,093 Population Change (%) Table 8. 0.5 0.6 Population Growth of Manitoba and Major Manitoba Cities (Stats Canada 93F0053XIE) 4.4.3 The Halal Market The Islamic population is growing in Canada, especially in the western provinces due to increasing immigration from Pakistan. As seen in Figure 6, the Islamic population has doubled in the last ten years. In 1991 the population was 253,260 making up 0.9% of the Canadian demographics. By 2001 this level has increased to 579,640 making up 2% of the Canadian population (Muslim Population Statistics website, 2003). Figure 7 shows the Islamic population as it is distributed across Canada. Alberta has a fairly significant Islamic population ranging between 25,000 and 50,000. This is a close market for Dykal Holdings to capture and penetrate and will be easy to develop early on. The Saskatchewan and Manitoba Islamic populations, although lower than Alberta, show potential Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 27 Dykal Holdings for Dykal Holdings to become a sole provider for these markets. Other parts of Canada are seen Muslim Population to have large Islamic populations, which may be areas for future expansion. 800,000 600,000 400,000 200,000 0 1991 2001 Year Figure 6. Islamic Population of Canada (Canadian Muslim Population Stats website, 2003) Figure 7. Distribution of Canadian Islamic Population in 1991 (Halal Food Product Market Report website, 2003) Table 9 shows the Islamic population in Saskatchewan, Alberta, Manitoba, Quebec, Ontario and British Columbia. Dykal Holdings will target cities, which have Islamic Centres. The majority Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 28 Dykal Holdings of the Halal market will be in Alberta. Table 10 shows the Islamic population in each city being targeted. In Saskatchewan, Saskatoon has the greatest Islamic population therefore will be Dykal Holdings’ major focus; however this is only a small market. The majority of the Halal chicken will be marketed to Alberta, with the two major cities being Edmonton and Calgary, both with much larger Islamic populations. Finally, Dykal Holdings will target Manitoba, essentially Winnipeg, as this city is the closest major Manitoban city with an Islamic Centre to Wynyard. Province Islamic Population Quebec 108,620 Ontario 352,525 Manitoba 5,095 Saskatchewan 2,230 Alberta 49,045 Table 9. British Columbia 56,220 2001 (Stats Canada 93F0053XIE) City Islamic Population Saskatoon Regina Swift Current Calgary Edmonton Red Deer Lethbridge Winnipeg 1,140 770 40 25,920 19,575 420 145 4,805 Canadian Islamic Population in Table 10. Islamic Population in SK, AB, and MB cities in 2001 (Stats Canada 93F0053XIE) Other Halal meat products available for Islamic populations are lamb/mutton/goat, chicken, and beef/veal. A major goal of Dykal Holdings marketing will be to bring a health aspect of chicken across to the Islamic consumer demonstrating the benefits of chicken as a better alternative than Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 29 Dykal Holdings other meat choices. Table 11 shows chicken as a healthy alternative to other meats such as beef, lamb and pork, as it is lower in calories and fat and similar in protein content. Turkey has better nutritional value, but does not lend itself to being an “everyday” meat, thus is not foreseen as a major problem. In Canada the population is aging, meaning the ratio of young to old is low. The Islamic population is the opposite, with half their population below the age of 20 (Halal Food Product Market Report). In the future, immigration and movement of the Islamic population could potentially affect the marketing strategy of Dykal Holdings. By looking at past trends it can be assumed that the Islamic population will continue to increase in Canada and expand further into the Prairie Provinces. Product* Calories (kcal) Protein Fat Lean Beef 123 20.3 4.6 Lamb 162 20.8 8.8 Pork 147 20.7 7.1 Turkey 107 21.9 2.2 Chicken 121 20.5 4.3 * All values are based on raw, meat only basis. Table 11. The Nutritional Value of Different Meats (per 100 grams) (McCanca & Widdowson, 1991) Green Peace and animal rights groups may also cause problems for the Halal market. In the Halal method of slaughter the birds will not be stunned before they are killed. This may cause an up rise to occur with animal rights groups. Hopefully educating activists can avoid this and show that this method of slaughter is for religious purposes only, and is a humane method of slaughter. Dykal Holdings will be targeting all Islamic people who practice their faith and are involved with Islamic Centres, more specifically females. This is because females generally are responsible for the household cooking. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 30 Dykal Holdings 4.5 SWOT analysis 4.5.1 Strengths Dykal Holdings will have access to a constant supply of raw materials, in this case live chickens. The processing plant will have the ability to accommodate a 50% increase in production at any time, and the processing lines will be able to process both Halal chicken and nonHalal chicken. Ability to reach two markets using one processing line. All chicken will be air chilled, vegetable fed and federally inspected, capturing a premium market. Management experience and expertise in the industry based on plant location. 4.5.2 Weaknesses The cost of setting up a new plant is expensive with the machinery being the largest cost of approximately one million dollars. Dykal Holdings will not own a fleet of trucks, therefore shipping will have to be contracted out which will cause fluctuations in price. 4.5.3 Opportunities Growing Halal market. Only one other major chicken processing plant in Saskatchewan; Lilydale. Large pool of trained workers in Wynyard, giving a large easily accessible trained workforce for Dykal Holdings. Chicken is becoming a healthier alternative for meals; in addition Halal products are starting to become more common. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 31 Dykal Holdings 4.5.4 Threats Within the town of Wynyard there is currently a processing plant; Lilydale Cooperative. Lilydale Cooperative lost approximately $16 million last year. This may indicate weakness in the market. There are strict requirements for processing Halal chicken which will add costs to production. 4.6 Competition The major competitors in the Western non-Halal poultry market are Lilydale Cooperative and Maple Leaf. There are many other poultry brand names being sold in stores but they are subsidiaries of Lilydale Cooperative. In the Halal market Lilydale and small chicken processors are the main competition. After conducting a market analysis, it has been observed that Lilydale and Maple Leaf together hold approximately 80% share of the market, and other store brands hold approximately 20% of the market. Lilydale Cooperative and Maple Leaf have many strengths and weaknesses. The most important strength that they both hold is that they have efficient economies of scale. At Maple Leaf and Lilydale plants chicken is produced in extremely large quantities, and their cost of producing one bird is substantially less than Dykal Holdings will be. Maple Leaf’s main advantage over Lilydale is that its product is branded as a prime natural product, whereas Lilydale sells both branded and non-branded products. Consumers see both companies’ products as high quality in comparison to other chicken on the market. A major weakness of Lilydale is that last year it lost approximately $16 million dollars. This was the result of a combination of two factors, the first being a planned five million dollar expansion of the Lilydale Plant in Wynyard. The second factor was the 9-11 crisis which caused the demand for KFC, Lilydale’s major buyer, therefore, frozen stocks of products increased and prices were adjusted downwards to reduce inventory. This factor is a one time event and will not affect the future of the industry. Consumers view Lilydale’s products to be of high quality in the Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 32 Dykal Holdings frozen market, and in many cases in the fresh market consumers are unaware that they are eating Lilydale’s fresh chicken when they purchase some of the unbranded chicken at the store. Other competitors include Schneiders, who sell chicken as pieces in boxes and as a frozen product rather than fresh. Schneiders will be an indirect competitor, since Dykal Holdings will not be selling non-Halal product in this form. Dykal Holdings will have to meet all of the needs of the consumers in order to get a comparable product to its competitors. Dykal Holdings’ product is vegetable fed, therefore can be labelled as a natural product as well is air chilled making it comparable to Maple Leaf’s Prime Chicken. Trends in the industry show that the pieces market will be of greater importance, as people tend not to purchase whole chicken products as often. 4.7 Distribution Warehousing of PPP will be minimal and will be prepared for a “just in time” distribution system. Dykal Holding will use CoolX, a division of TransX (a logistics firm with operations throughout Canada) to deliver the product, on a daily basis, in bulk crates to individual IGA stores located in Saskatchewan. CoolX will also deliver the Halal product to the Islamic Association’s centers in Manitoba, Saskatchewan and Alberta, on a bi-weekly basis. A contract will be established with CoolX defining operating terms. Initial estimates are $0.04/kg for nonHalal poultry and $0.06/kg for Halal poultry (Craig Strilchuk, 2003). This type of contract, will allow Dykal Holdings to ensure a lower cost, although this option will require that Dykal Holdings use CoolX for a defined time frame. This distribution method is different from Lilydale’s method, which utilizes a fleet of company owned and operated trucks to deliver the product. The use of CoolX is a good fit for the product because it allows timely, low cost delivery to a widely distributed geographic area. This will also reduce Dykal Holdings initial capital investment, as a fleet of trucks will not be required. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 33 Dykal Holdings 4.8 Promotion Dykal Holdings will have to persuade the IGA head office to certify PPP as a registered supplier for the chain. This will allow Dykal Holdings to supply the product to individual IGA stores. Upon receiving certification Dykal Holdings will give sales pitches to IGA managers to gain them as a purchaser of PPP. Advertising for the non-Halal market will be minimal because the product will not be branded as PPP, it will be an IGA branded product. 4.9 Selling and Advertising The main focus of the marketing will be with regards to developing the Halal product. To do this, Dykal Holdings will advertise in print media such as magazines and newsletters. Although no western magazines are currently available with a direct focus on the Islamic community a number of national magazines are available, with larger readership in Western Canada. These include: Azizah, a magazine directed towards Islamic women, who will be the primary target group as they do most of the cooking in the family. Message, is a magazine which focuses on cultural and religious issues. This will provide a broad base of readership of customers who are concerned about upholding their faith, and therefore consuming Halal products. The American Muslim magazine, presents the comprehensive and balanced understanding of Islam, addresses Islamic issues, and covers Islamic events. Again this will provide Dykal with the opportunity to reach a wide targeted audience. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 34 Dykal Holdings Dykal will purchase advertising space in the three magazines mentioned above which each have monthly issues. This will have a cost of $36,000 per year (12 issues X 3 magazines X $1000). Newsletters and articles distributed to patrons by the Islamic associations are also an excellent means of reaching a target audience. This will provide Dykal Holdings with concentrated local penetration, at a lower cost than magazine advertising. The cost for purchasing advertising space in the 17 Islamic Associations’ newsletters listed in Appendix B is $20,400 per year (17 newsletters X 12 issues per year X $100). 2004 Advertising Magazine ads Newsletters Total Advertising Promotion & Development Web page Maintance Travel expenses Trade shows Total Promotion Total Marketing Expenses 2006 2007 2008 36,000 20,400 56,400 37,008 20,971 57,979 38,016 21,542 59,558 39,024 22,114 61,138 40,032 22,685 62,717 18,000 2,000 28,000 2,000 50,000 106,400 2,056 28,784 2,056 32,896 90,875 2,112 29,568 2,112 33,792 93,350 2,168 30,352 2,168 34,688 95,826 2,224 31,136 2,224 35,584 98,301 2009 Advertising Magazine ads Newsletters Total Advertising Promotion & Development Web page Maintance Travel expenses Trade shows Total Promotion Total Marketing Expenses 2005 2010 2011 2012 2013 41,040 23,256 64,296 42,048 23,827 65,875 43,056 24,398 67,454 44,064 24,970 69,034 45,072 25,541 70,613 2,280 31,920 2,280 36,480 100,776 2,336 32,704 2,336 37,376 103,251 2,392 33,488 2,392 38,272 105,726 2,448 34,272 2,448 39,168 108,202 2,504 35,056 2,504 40,064 110,677 Table 12. Dykal Holdings: Marketing Budget It is important to note that word of mouth advertising is the best means of increasing sales in the Halal market as the community is very closely “knit,” therefore actively controlling product quality and adhering to Halal requirements is essential to the products success. The Halal and Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 35 Dykal Holdings non-Halal products will also require additional marketing to ensure success. This will include the development of a website for the two products, so that interested parties can research the company and its products. The website will allow both IGA stores and Halal customers to place and pay for orders online. The total cost for development and maintenance the website for the first year is $18,000 and $2,000 respectfully. In the remaining years only the $2,000 maintenance charge will be incurred. Dykal Holdings will also need to travel to trade shows and conventions to actively promote the products. The total traveling expenses are estimated to be $28,000 (4 trade shows X $2,000 per trip + $20,000 travel to individual Halal buyers and IGA store managers). The cost of the trade show itself is minimal, requiring only the purchase of booth space, for a total cost of $2,000 per year (4 trade shows X $500/booth). The total cost for marketing will be $106,400 in the first year and $90,875 in year two with inflation calculated at 2.8%. For a complete look at the marketing budget see Table 12. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 36 Dykal Holdings 5.0 Financial Plan 5.1 Sources of Funding In order for Dykal Holdings to meet initial capital expenditures, and maintain a positive cash flow, a total of $3,158,815 of long-term debt and owner’s equity will be required, see Table 13. The long-term debt will be financed with a loan from the Royal Bank of Canada (RBC) and the client will supply the owner’s equity. The total loan amount is $2,369,111 or 75% of the total funding required (Schedule 8). Normally, a bank would be unwilling to lend such a large percentage of the total investment; however, the client is willing to pledge additional land and buildings as collateral to secure the loan. Long Term Debt Owner's Equity Total 75% 25% 2004 2,369,111 789,704 3,158,815 Table 13. Financing Budget The amount of the loan $2,369,111 will be amortized over 25 years with an interest rate of 7.2%. The loan will have fixed payments of $206,971 per year with the option of contributing additional money in any year towards the principle of the loan (Schedule 9). It is important to note that the entire loan could be paid in full in the base case by 2010 using cash on hand. 5.2 Opening Balance Sheet Land will be purchased for a nominal fee of $1, this will allow for the legal transfer of ownership and is common in small communities. The cost of the building is $1,099,999, this includes an allowance of $300,000 for renovations to the existing building as it has been vacate for a number of years. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 37 Dykal Holdings All processing equipment prices are quoted from Meyn Food Technologies. For a breakdown of the equipment required and individual specifications please refer to Appendix D. Of note are spare parts which must be purchased every other year (Schedule 7). Office equipment was estimated after an assessment of the current facility and was valued at $50,000. This would include the purchase of office chairs desks and computers and general supplies. As well, $20,000/year will be allotted for replacement and new office supplies. An air conditioning unit must also be purchased in order to cool the manufacturing area. The cost is estimated to be $30,000 and includes installation. A summary of the capital budget is seen in Table 14. 2004 Costs: Land and Building Equipment: Arrival department Defeathering department Evisceration department Chilling department Weighing department Offal department Miscellaneous Spare parts Office Supplies Electrical Installation Piping Air Conditioning Total Capital Costs 2006 2008 2010 2012 1,100,000 Input Input Input Input Input Input Input Input Input Input Input Input Input Working Capital Cash Input Accounts Receivable Inventories Accounts Payable Total Net Working Capital 20,691 284,130 182,805 290,000 141,224 67,933 136,030 82,432 50,000 20,000 250,000 22,000 30,000 2,677,245 87,113 21,120 92,059 22,240 97,287 23,360 102,811 24,480 108,233 114,299 120,647 127,291 400,000 340,461 16,143 275,032 481,571 593,593 23,136 464,775 151,955 625,072 24,162 491,033 158,200 656,550 25,236 518,759 163,027 688,028 26,361 548,036 166,354 Table 14. Capital Budget Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 38 Dykal Holdings 5.3 Summary of Financial Results Table 15 is an overview of several key values in the financial plan over the 10 year period. Key Variables Selling Price Non-Halal Raw Materials Frieght Non-Halal Direct Labour Employees Base Case $2.798/Kg $1.289/Kg $0.04/Kg 20 Base Case Sales Revenue Cost of Goods Sold Gross Margin Expenses Income Before Taxes Income Taxes Net Income (Loss) Cash end of year 2004 4,541,357 4,607,298 -65,941 455,636 -521,577 0 -521,577 41,753 2005 6,188,455 6,046,919 141,536 442,494 -300,958 0 -300,958 6,041 2006 7,918,456 7,173,345 745,112 447,164 297,947 0 297,947 423,460 2007 8,128,699 7,326,486 802,214 451,635 350,579 0 350,579 936,426 2008 8,338,943 7,489,009 849,933 455,891 394,043 68,063 339,034 1,332,758 Sales Revenue Cost of Goods Sold Gross Margin Expenses Income Before Taxes Income Taxes Net Income (Loss) Cash end of year 2009 8,549,186 7,661,836 887,349 459,916 427,433 131,283 300,186 1,754,374 2010 8,759,429 7,844,446 914,983 463,695 451,288 140,967 314,260 2,069,854 2011 8,969,672 8,035,404 934,268 467,209 467,059 147,330 323,565 2,472,428 2012 9,179,915 8,234,667 945,249 470,439 474,809 150,397 328,138 2,760,497 2013 9,390,158 8,441,123 949,035 473,365 475,670 150,631 328,646 3,137,582 Net Present Value of Equity Investment 213,134 Internal Rate of Return on Equity Investment 26% External Rate of Return on Equity Investment 12% Table 15. Base Case Financial Results Examination of these summary results leads to the logical conclusion that under the base case scenario Dykal Holdings is an excellent investment opportunity due to a 26% IRR. This is higher then the standard required rate of return of 15%. Complete financial schedules and projections are provided in Appendix H. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 39 Dykal Holdings 5.4 Unit Cost Analysis In order to make accurate decisions regarding management of a business it is important to evaluate the distribution of the costs associated with the production, marketing and selling of the product. Understanding what represents the majority of the costs per unit allows a manager to evaluate where costs could be reduced and monitored if costs are increasing to the point where there is a need to change production methods or selling tactics. Table 16 is the breakdown of the average cost to produce and sell one kilogram of poultry. Average cost was calculated by taking the ten year financial projections and averaging them, which was completed for each variable. For chicken processing the largest single cost is the purchase of live birds which makes up approximately 75% of the total cost for non-Halal and 68% for Halal. Direct labour is the second largest single cost making up approximately 9.5% and 8.6%, for non-Halal and Halal respectfully. Average Cost Breakdown Non-Halal Live Poultry Packaging Supplies Freight and Pallet Charges Total Direct Labour + Benefits Water Total Fixed Overhead Total Overhead Salaries and Benefits Magazine ads Newsletters Website Travel expenses Trade shows Admin Expense Total Cost Non-Halal Cost % of Cost 5,023,491 75.088% 42,534 0.636% 107,991 1.614% 636,783 9.518% 54,235 0.811% 417,932 6.247% 210,367 3.144% 0 0.000% 0 0.000% 3,647 0.055% 15,764 0.236% 1,126 0.017% 176,302 2.635% 6,690,171 Halal Live Poultry Packaging Supplies Freight and Pallet Charges Total Direct Labour + Benefits Water Total Fixed Overhead Total Overhead Salaries and Benefits Magazine ads Newsletters Website Travel expenses Trade shows Admin Expense Total Cost Halal Cost % of Cost 558,166 68.12% 18,671 2.28% 15,121 1.85% 70,754 8.64% 6,026 0.74% 46,437 5.67% 23,374 2.85% 40,536 4.95% 22,970 2.80% 405 0.05% 15,764 1.92% 1,126 0.14% 19,589 2.39% 819,350 Kg's of Product Cost per Kg 2,268,191 2.95 Kg's of Product Cost per Kg 252,021 3.25 Table 16. Average Cost Breakdown of Dykal Holdings Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 40 Dykal Holdings As noted in Table 16 the average cost per kg for non-Halal is $2.95, over the next 10 years, while Halal is $3.25. This difference in price is due mainly to economies of scale with 90% of the production being distributed as non-Halal and the remaining 10% being sold as a Halal product. Advertising expenses, which include, magazines and newsletters also provide additional costs for Halal products totalling approximately 8%. 5.5 Key Variables Several variables where analyzed in order to determine which would have the largest effect on the feasibility of the project. To determine this, each variable was manipulated separately to obtain an Internal Rate of Return of zero. From the Table 17 it becomes clear that there are two extremely important variables, selling price of Non-Halal poultry and the purchase price of raw materials (live chicken). Dykal holdings will have little control over raw materials prices as these are governed by marketing boards. Dykal Holdings will also be limited in its ability to demand higher prices for its nonHalal product as it will be providing it to a single buyer, who therefore will have high bargaining power. Key Variables Base Case Selling Price Non-Halal $2.798/Kg Raw Materials $1.289/Kg Frieght Non-Halal $0.04/Kg Direct Labour Employees 20 IRR=0 $2.680/Kg $1.358/Kg $0.16/Kg 29 Allowable % Change - 4.20% + 5.10% + 75% + 31% Table 17. Breakeven points of key variables for Dykal Holdings 5.6 Best Case Results By affecting the key decision variable of selling price for both products the sensitivity of the projects bottom line can be evaluated. In the best case, seen in Table 18, the selling price would be at a 10% higher price. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 41 Dykal Holdings Best Case 2004 Selling Prices (per kg) Non-Halal Poultry Halal Poultry Average Selling Price Gross Margin Net Income (Loss) Net Cash Flow from Operations Cash end of year 2006 2007 2008 3.078 3.135 3.106 3.164 3.222 3.193 3.250 3.310 3.280 3.336 3.398 3.367 3.423 3.486 3.454 397,580 -49,095 35,012 516,147 783,426 277,621 579,817 1,058,998 1,582,811 726,373 932,823 1,865,081 1,668,870 774,502 985,311 2,807,912 1,744,648 816,685 991,062 3,661,376 2009 Selling Prices (per kg) Non-Halal Poultry Halal Poultry Average Selling Price Gross Margin Net Income (Loss) Net Cash Flow from Operations Cash end of year 2005 2010 2011 2012 2013 3.509 3.573 3.541 3.595 3.661 3.628 3.681 3.749 3.715 3.767 3.837 3.802 3.853 3.924 3.889 1,808,908 852,202 997,257 4,609,816 1,862,937 881,820 1,003,255 5,463,451 1,907,737 906,141 1,008,528 6,415,878 1,944,079 925,630 1,012,639 7,265,567 1,972,552 940,647 1,015,226 8,216,323 Net Present Value of Equity Investment 2,217,154 Internal Rate of Return on Equity Investment 74% External Rate of Return on Equity Investment 27% Table 18. Best Case Financial Results In this scenario, Dykal Holdings becomes an even better investment. The internal rate of return rises substantially to 74% and net income grows to almost $1,000,000 in 2013. In addition to this the entire long-term debt outstanding could be paid off in full by 2007 with cash on hand. 5.7 Worst Case Results By affecting the key decision variable of selling price for both products the sensitivity of the projects bottom line can be further evaluated. In the worst case, seen in Table 19, the selling price would be at a 10% lower price. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 42 Dykal Holdings Worst Case 2004 Selling Prices (per kg) Non-Halal Poultry Halal Poultry Average Selling Price Gross Margin Net Income (Loss) Net Cash Flow from Operations Cash end of year 2.518 2.565 2.541 2.589 2.636 2.613 2006 2007 2.659 2.708 2.684 2.730 2.780 2.755 2008 2.800 2.852 2.826 -511,989 -954,987 -802,788 -388,961 -455,986 -3,023 40,988 74,717 -880,719 -432,490 -393,028 -363,649 -553,831 -200,106 -179,072 -186,125 -978,916 -1,304,860 -1,525,446 -1,848,132 2009 2010 Selling Prices (per kg) Non-Halal Poultry Halal Poultry Average Selling Price Gross Margin Net Income (Loss) Net Cash Flow from Operations Cash end of year 2005 2.871 2.924 2.897 2.941 2.995 2.968 2011 2012 3.012 3.067 3.040 3.082 3.139 3.111 2013 3.153 3.211 3.182 96,928 108,909 111,659 105,953 92,377 -345,575 -337,503 -338,416 -347,524 -364,219 -197,372 -212,921 -232,882 -257,367 -286,492 -2,093,211 -2,454,561 -2,742,266 -3,161,216 -3,510,711 Net Present Value of Equity Investment -2,494,911 Internal Rate of Return on Equity Investment Negative External Rate of Return on Equity Investment Negative Table 19. Worst Case Financial Results In this scenario, Dykal Holdings becomes a very poor investment. The internal rate of return drops substantially to a negative number and net income remains negative throughout the project. In addition to this the cash on hand is negative throughout the entire project meaning that both short term and long term obligations would be unable to be fulfilled. Cash on hand drops to negative $3,510,711 by 2013. 5.8 Net-Income Break-even Analysis The results of this sensitivity analysis where calculated by varying the selling price of non-Halal poultry in order to obtain a net income of zero in each year. The results further illustrate the fact that this project is extremely sensitive to changes in selling prices. See Table 20. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 43 Dykal Holdings Net Income Break-even Analysis Year Net Income After-Tax Cash 2004 0 565,150 2005 0 862,565 2006 0 1,006,929 2007 0 1,181,765 2008 0 1,224,203 2009 0 1,325,149 2010 0 1,300,831 2011 0 1,350,226 2012 0 1,276,700 2013 0 1,288,581 Selling Price 3.1434 3.0133 2.8068 2.8601 2.9175 2.9796 3.0458 3.1158 3.1891 3.2656 Base Case Selling Price % Change 2.7980 11% 2.8763 5% 2.9547 -5% 3.0330 -6% 3.1114 -7% 3.1897 -7% 3.2681 -7% 3.3464 -7% 3.4248 -7% 3.5031 -7% Table 20. Break-even analysis of Dykal Holdings 5.9 After-tax Year End Cash Break-even Analysis The results of this sensitivity analysis where calculated by varying the selling price of non-Halal poultry in order to obtain an after-tax cash balance of zero in each year. Once again the results illustrate that this project is particularly sensitive to changes in selling prices. See Table 21. After-Tax Cash Break-Even Analysis Year Net Income After-Tax Cash 2004 -565,772 0 2005 -274,806 0 2006 -133,728 0 2007 -179,527 0 2008 -30,959 0 2009 -108,357 0 2010 35,263 0 2011 -58,282 0 2012 84,239 0 2013 -21,974 0 Selling Price 2.7588 2.8700 2.7504 2.7845 2.9035 2.9335 3.0594 3.0906 3.2231 3.2555 Base Case Selling Price % Change 2.7980 -1% 2.8763 0% 2.9547 -7% 3.0330 -9% 3.1114 -7% 3.1897 -9% 3.2681 -7% 3.3464 -8% 3.4248 -6% 3.5031 -8% Table 21. After-tax break-even analysis of Dykal Holdings Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 44 Dykal Holdings 5.10 Ratio Analysis When interpreting ratios it is important to remember the nature of Dykal Holdings industry, processing. Analysis should be compared to the ratios to those in industry. Lilydale, the main competitor of Dykal Holdings will be used to compare ratios and determine how they relate to one another. Looking at the overall ratios of the company, seen in Table 22, Dykal Holdings appears to be a good investment opportunity. Liquidity ratios are used to measure the ability of the company to meet short term obligations. The current ratio is used to measure the liquidity and is calculated by dividing current assets by current liabilities. Dykal Holdings has a higher degree of liquidity when compared to Lilydale. Liquidity is a measure of how quickly assets can be turned into cash. The current ratio for Dykal Holdings is very high as the current assets are increasing because cash is not being paid out in the form of dividends. This means that Dykal Holdings has a lower risk of insolvency, 4.1572, than Lilydale which has a current ratio 1.1647. Solvency ratios measure the risk of financing the business and making fixed debt payments. A large portion, 75%, of the processing plant will be financed through a bank loan. The debt-toequity ratio is total liabilities divided by total equities. Dykal Holdings has a negative, 4.7014, debt-to-equity ratio as a result of the companies high debt load. The debt ratio is the total liabilities divided by total assets. A debt ratio 72.62%, as seen in Dykal Holdings, would indicate a high debt payment which implies high financial risk. Lilydale is seen to have a high debt ratio, 0.8414, indicating this is normal for the industry. This anomaly can be primarily contributed to the high initial fixed cost when starting a manufacturing plant. Investment utilization ratios measure how efficiently the company is using its assets. The total asset turnover is calculated by dividing total sales by total assets. A higher assets turnover is preferred as implies that assets are being converted into sales faster. Lilydale has a more efficient asset turnover ratio, 3.7352, and can be primarily contributed to its larger economies of scale. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 45 Dykal Holdings Profitability ratios measure the financial performance of the company. These are often used to set targets for the company and compare performance to competitors in the industry. Lilydale has a negative profitability ratio as they had a $16 million loss last year. Higher ratios are also seen in Dykal Holdings as no dividends are being paid out, as the client wants to keep the money in the company for future investment. Taking these two factors into account, the profitability ratios are a bias observation of Dykal Holdings actual profits. Current Ratio Debt to Equity Total Asset Turnover Debt Ratio Gross Profit Margin Net Profit Margin Return on Assets Return on Equity Dykal Holdings Average 4.1572 -4.7014 2.1498 0.7262 0.0820 0.0136 0.0367 1.0157 Lilydale for 1998-2003 1.1647 2.0534 3.7352 0.8414 0.0779 0.0006 -0.0003 -0.0316 Table 22. Comparison of Key Ratios 5.11 Conclusion Based on the financial model completed for Dykal Holdings, the company appears to be a viable business venture as it becomes profitable after only the first two years of operation. It should noted that even a small change in the price of raw materials (live chicken price increasing 5.10%) or a small change in the selling price (only 4.20% for non-Halal chicken) will wipe out all of the profits obtained by Dykal Holdings at the present levels. This makes the project more risky and is the reason for the higher IRR and ERR. The giblets and feet market was not looked at for the purpose of this project, but is foreseen to be a potentially profitable market. As well increasing the number of birds that are processed in the plant would increase the economies of scale but was also not looked at in developing this plan. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 46 Dykal Holdings 6.0 References 6.1 Personal References Kevin Bolt Pineview All Natural Meats Phone: 306-239-4763 Bob Conklin Stork Gamco Inc. Phone: 770-532-7041 Website: http://www.stork-gamco.com Darleen Derow Lilydale Foods Food Safety Inspector Wynyard, SK Phone: 306-554-2555 Jerry Dyer AutoPlan Consultants Phone: 770-535-0135 Autoplan@aol.com Sheila Hitchings Wynyard Town Office Wynyard, SK Phone: 306-554-2123 Rick Johannason Lilydale Foods Manager Wynyard, SK Phone: 306-554-2555 Bob Kolheler Meyn Food Processing Technology B.V. Edmonton, AB Phone: 780-953-7063 Cell: 1-780-953-7063 bob@meyncanada.com http://www.meyn.nl Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 47 Dykal Holdings Clint Lacoste Rayton Packaging Calgary, Alberta Phone: 403-640-9276 Dwayne Onofriechuck Vis-à-vis Caretaker Wynyard, SK Phone : 306-554-2529 Cel : 306-554-7077 Tom Reins Cantrell Machine Company, Inc. P. O. Box 757 1400 S. Bradford Street Gainesville, GA. 30503 Phone: 1-800-922-1232 http://www.cantrell.com/contact.htm Shelly RiteWay Packaging Supplies and Services Inc. Edmonton, Alberta Phone: 780-467-7131 Van Stewart Saskatchewan Poultry Producers Phone: 306-775-1677 Craig Strilchuk TransX craig_strilchuk@transx.com 6.2 Internet References An Up-To-Date Assessment of the Muslim method of Slaughter, http://www.hmspoultry.ca.uk/AN%20UP-TO-DATE%20ASSESSMENT.htm September 21, 2003] [accessed Canadian Chicken Market Review, (Oct 10, 2003) http://www.georgemorris.org/PDF%20Files/CCMRSample0403.pdf Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 48 Dykal Holdings Canadian Muslim Population Statistics, (Oct 16, 2003) http://www.jannah.org/popstatistics/canadamuslims.html Chicken Farmers of Canada, http://www.chicken.ca/E_links.htm [Accessed September 30, 2003] Halal Food Product Market Report, (Oct 7, 2003) http://atn-riae.agr.ca/africa/e3281.pdf IGA, (October 21, 2003) www.iga.com Lilydale Foods, www.lilydale.com [accessed September 15, 2003] MapleLeafFarms, (October 20, 2003) www.zabihahalal.com Monster, www.monster.ca [accessed September 29, 2003] Muslim Population Statistics, (Oct 16, 2003) http://www.muslim-canada.org/muslimstats.html Small Poultry Processing, http://64.4.20.250/cgibin/linkrd?_lang=EN&lah=98c7eb7d299def8e70332fe9be833fd2&lat=1065243588&hm___acti on=http%3a%2f%2fwww%2efao%2eorg%2fdocrep%2f003%2ft0561e%2fT0561E00%2ehtm [accessed September 15, 2003] Statistics Canada, (October 16, 2003) http://www12.statcan.ca/english/Profil01/PlaceSearchForm1.cfm http://geodepot.statcan.ca/Diss/Highlights/Highlights_e.cfm The Canadian Poultry Meat Processing Industry, http://www.agr.gc.ca/food/profiles/poultry/poultry_e.html [Accessed September 17, 2003] Town of Wynyard, http://www.town.wynyard.sk.ca/ [accessed September 12, 2003] Trying to Help Muslims Eat Halal, http://eat-halal.com [Accessed on September 21, 2003] Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 49 Dykal Holdings 6.3 Books McCanca and Widdowson’s, The Composition of Foods, Fifth Edition. The Royal Society of Chemistry. 1991. Comm 492.3- College of Agriculture and College of Commerce, University of Saskatchewan 50