EL272 - SharePoint - Erie Community College

advertisement

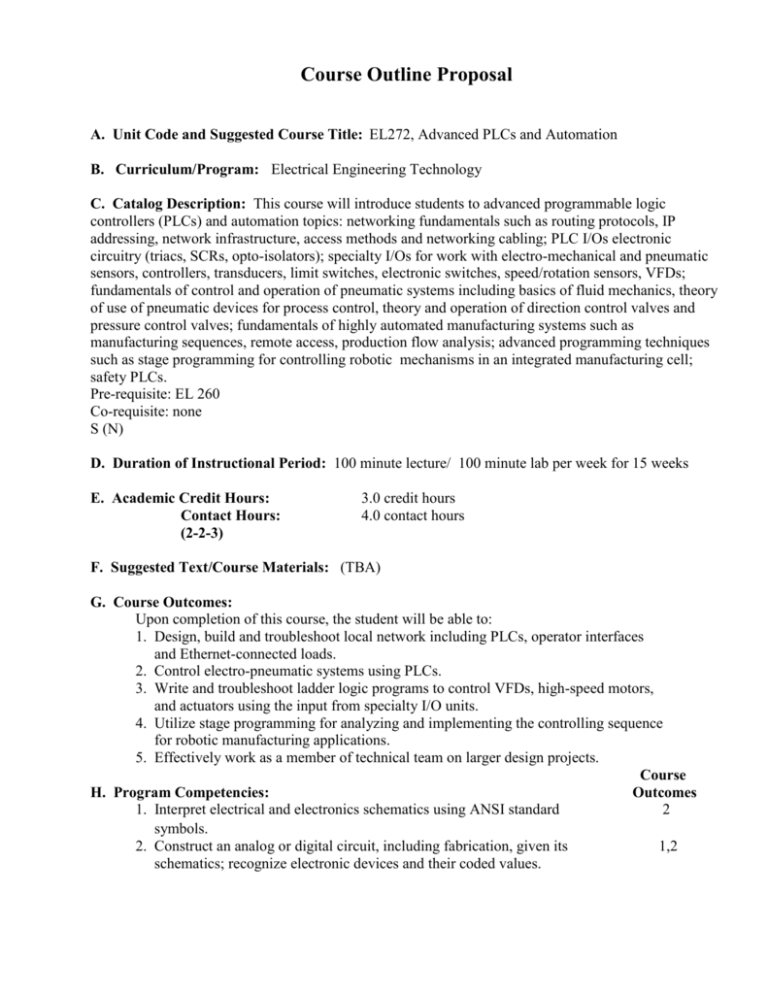

Course Outline Proposal A. Unit Code and Suggested Course Title: EL272, Advanced PLCs and Automation B. Curriculum/Program: Electrical Engineering Technology C. Catalog Description: This course will introduce students to advanced programmable logic controllers (PLCs) and automation topics: networking fundamentals such as routing protocols, IP addressing, network infrastructure, access methods and networking cabling; PLC I/Os electronic circuitry (triacs, SCRs, opto-isolators); specialty I/Os for work with electro-mechanical and pneumatic sensors, controllers, transducers, limit switches, electronic switches, speed/rotation sensors, VFDs; fundamentals of control and operation of pneumatic systems including basics of fluid mechanics, theory of use of pneumatic devices for process control, theory and operation of direction control valves and pressure control valves; fundamentals of highly automated manufacturing systems such as manufacturing sequences, remote access, production flow analysis; advanced programming techniques such as stage programming for controlling robotic mechanisms in an integrated manufacturing cell; safety PLCs. Pre-requisite: EL 260 Co-requisite: none S (N) D. Duration of Instructional Period: 100 minute lecture/ 100 minute lab per week for 15 weeks E. Academic Credit Hours: Contact Hours: (2-2-3) 3.0 credit hours 4.0 contact hours F. Suggested Text/Course Materials: (TBA) G. Course Outcomes: Upon completion of this course, the student will be able to: 1. Design, build and troubleshoot local network including PLCs, operator interfaces and Ethernet-connected loads. 2. Control electro-pneumatic systems using PLCs. 3. Write and troubleshoot ladder logic programs to control VFDs, high-speed motors, and actuators using the input from specialty I/O units. 4. Utilize stage programming for analyzing and implementing the controlling sequence for robotic manufacturing applications. 5. Effectively work as a member of technical team on larger design projects. Course H. Program Competencies: Outcomes 1. Interpret electrical and electronics schematics using ANSI standard 2 symbols. 2. Construct an analog or digital circuit, including fabrication, given its 1,2 schematics; recognize electronic devices and their coded values. 5. Use industry-standard computer applications such as Multisim, PLC software, AutoCAD, microcontroller, IDE, spreadsheet). 8. Function effectively as a member of a technical team. 3,4 5 I. SUNY General Education Knowledge and Skills Areas: N/A J. ECC Learning Outcomes (LO): 1. Technological Competency. 1-4 K. Student Learning K1. Evaluation of Student Learning: (A combined grade from both lecture and lab will be given) ▪ Lecture (exams, quizzes, homework) ▪ Lab reports and pre-lab assignments, design projects and practical tests in lab ▪ TOTAL grade 40% 60% 100% K2. Assessment of Student Learning: Assessment of student learning will be done based on the final project as per CWAC-approved department assessment plan. L. Library Resources: Appropriate library resources are outlined in the Electrical Engineering Technology lib-guide. M. Topical Outline: WEEKS I. PLC FUNDAMENTALS REVIEW 1. PLC architecture, I/O configuration, scan routine. 2. PLC Memory Organization for DL06 PLCs. 1 II. INTRODUCTION TO Direct Logic PLCs 1. Introduce DirectSoft5 software suite and computer interface. 2. Introduce various NO and NC contacts, coils, timers, counters, and comparative instructions for DL06 PLCs. 3. LAB 1: Introductory laboratory with timers and counters using computer interface. 1 III. I/O ELECTRONICS 1. Discussion of PLC I/O circuits: use of triacs, SCRs, opto-isolators, etc. 2. Introduction to specialty I/Os: sensors, controllers, transducers, and electronic controls. 3. LAB 2: Use analog input unit to utilize analog information from the PV irradiance sensor to control green house electrical loads. 4. LAB 3: Use high-speed rotation sensors and specialty I/O unit to process input from and control fast-rotating motor. 3 1st HOURLY TEST 1/4 IV. ELECTRO-PNEUMATIC SYSTEMS CONTROL 1. Introduce fundamentals and applications of fluid mechanics (fluid properties, fluid statics, conservation of energy and mass, pipe and duct flow, pumps, and measurement of fluid properties and states). 2. Use electro-pneumatic and electrical devices to activate and regulate the displacement and position of machine components in motor/actuator circuits. 3. LAB 4: Operating simple electro-pneumatic system using inputs from electrical and electro-pneumatic sensors to control pneumatic valves and motor/actuators. 4. LAB 5: Operating complex electro-pneumatic system. V. NETWORKING PLCs 1. Introduce Ethernet fundamentals, networking protocols, IP addressing, network infrastructure concentrating on switch/router configuration. 2. Discuss network media, access methods, network cabling. 3. LAB 6: Build simple network to access remote I/O racks. 4. LAB 7: Remotely access VFD from C-More panel to control network-connected AC motor. 2nd HOURLY TEST VI. 3-3/4 2 1/4 FUNDAMENTALS OF HIGHLY AUTOMATED MANUFACTURING SYSTEMS 3 – 3/4 1. Introduce manufacturing sequences, production flow analysis. 2. Introduce stage programming. 3. Introduce different types of robots and their application, control of robot mechanisms, robot programming, use of robots in an integrated manufacturing cell. 4. Safety PLCs. 5. LAB 8: Use stage programming to analyze, implement and troubleshoot the operation of the manufacturing welding cell. 6. FINAL DESIGN PROJECT: Design, implement and troubleshoot the remote control system for the pneumatic factory. N. Proposal Prepared by: Dr. E. Brewer Date Prepared: December 2013 Date Last Updated: March 2014