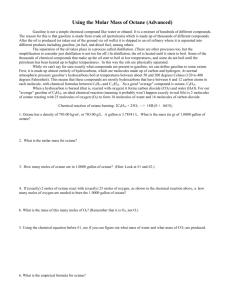

Fuelish Facts

advertisement

Fuelish Facts By Ken Mosher Midlands Chapter Member Back to Basics Before we get down and start stirring the witch's brew of petroleum distillates needed to make a good racing fuel, let's take a few moments to define and explore a few basic terms and definitions. When talking about racing fuel, there seems to be many myths and half-truths that are delivered to the novice as absolutes. The following article tries to clarify some of the jargon associated with racing fuels and the manufacturer's literature. How big is an Octane? First, let's take the term "Octane". Octane is a measure of a fuel's anti-detonation resistance. Octane is a unit for detonation resistance, just as grams are a unit of mass and inches are a unit of measure. Having more octane does not necessarily indicate the fuel has "more power" or is a magic elixir, it just means that the engine can run more compression, boost, timing, etc. (and that makes power). Octane is measured using three methods: motor octane (MON), research octane (RON), and "pump" octane. With the motor octane method, a specially calibrated single cylinder test motor runs on test sample at 900 RPM with intake charge heated and a spark advance engaged until knock is detected. The test sample is rated on an octane scale that has two reference fuels. NHeptane is at the bottom end of the scale with almost no antidetonation qualities and Isooctane (Octane rating 100) is on the high end of the scale with the maximum resistance to detonation. The research octane method involves running a single cylinder motor running at 600 RPM and results in a higher number, since it a less stressful test. Generally, the motor octane is the number to pay the most attention to in the Turbo Regals. This number is much more indicative of detonation resistance under the high boost situations favored by the little blown V6s. The research octane number applies more to low load, low RPM situations. The common octane rating found posted at your local filling station is the "pump" method, which averages the two ratings (R + M/2, where M = Motor Octane and R = Research Octane). This is a standard way to compare different gasolines, but isn't quite as informative as the individual ratings. When Things Go Boom! What is "Detonation"? Detonation is basically the uncontrolled ignition of the fuel/air mixture that results in a sharp explosion in the combustion chamber. A typical combustion cycle consists of four parts in the conventional four stroke automotive engine. The first cycle is the intake 1 stroke, where the piston goes from Top Dead Center (TDC) to Bottom Dead Center (BDC) with the intake valve open to allow the mixture of fuel and air to fill the cylinder. The next cycle is the compression stroke, in which the piston goes from BDC to TDC with the valves closed, compressing the fuel/air mixture. The third cycle is the power stroke resulting from the ignition of the fuel/air mixture in the compression stroke. The piston again goes from TDC to BDC and power is transmitted to the crankshaft. The final cycle is the exhaust stroke where the piston goes from BDC to TDC and forces the spent combustion gases out throught the open exhaust valve. Detonation is a phenomenon that occurs during the compression stroke. As the piston approaches TDC, a spark is fired prior to TDC (BTDC), such that the peak of the cylinder pressure will occur at or slightly after TDC. Normal combustion produces a nice controlled propagated wave front that propogates smoothly from the spark plug to the edges of the combustion chamber. As it does so, it compresses the unburned gases ahead of it, which increases their temperature and pressure. If the spark plug fires late, burning continues to occur after TDC and the exhaust gas temperature rises dramatically. This waste heat represents lost power and fuel economy. If the spark fires early during the compression stroke, the pressure peak happens before the piston has finished its upward stroke and this,. in combination with a wide open throttle condition, can lead to extremely high cylinder pressures and temperatures. The extreme conditions cause small pockets of the fuel/air mixture not yet reached by the flame front to detonate and begin burning outward from the ignition point. It is different than normal combustion, because it happens at a point in front of the advancing flame front as it propagates away from the spark plug. At these high temperatures, chemical reactions in the unburned gas can lead to extremely rapid uncontrolled combustion before the flame front arrives. This fast combustion can produce very high (even damaging) pressures and temperatures and results in "knock" or "ping". This sound is the audible pressure oscillation caused by this abnormal combustion. This condition results in extreme turbulence in the burned mixture, which greatly increases the rate of heat transfer into the cylinder walls and piston crown. This hot, pressurized, turbulent mixture is what causes engine damage, because it exceeds the combustion chamber's capacity to remove waste heat. Burned and pitted pistons, burned valves, and ring damage will result from severe pinging or knocking. The mechanical shock of the detonation can also damage connecting rod bearings. The power output of the engine drops dramatically when detonation occurs because the pressure peak occurs while the piston is still on an upward stroke. In the Turbo Regals, the ECM detects the detonation via the knock sensor and immediately cranks the timing back several degrees to try to stop the condition. Black smoke is often seen when preignition occurs because the turbulent conditions in the chamber result in incomplete combustion of the mixture, and the unburned gases create black smoke. In the Turbo Regal, it is important to use enough octane to prevent and/or limit detonation when operating the car in a given condition. Detonation is caused by too much cylinder pressure for the octane (boost), too much ignition advance, an air/fuel ratio that is too lean, or hot spots in the combustion chamber (sharp edges, carbon build up, insufficient cooling). Fuels with higher octane are more resistant to detonation. It's always nice to have a little "cushion" of detonation resistance to adjust for changing conditions (i.e., the air gets very cold and dense and more octane 2 is required). However, using a fuel with more octane than is required doesn't have any benefits other than the ability to "turn the wick up" another notch without having to refill the tank with more expensive gas. This can be done with more boost or a more aggressive chip. A word of caution here, ALWAYS USE ENOUGH OCTANE to account for the conditions. If you are driving around on the street with the boost turned down to 16 pounds, a mild chip and a 160 degree thermostat you may only need 92-93 octane gas. However, you turn the boost up to 18-20 pounds and I'll guarantee that you'll need more octane to prevent harmful detonation. In fact, if you push these limits hard enough, all the pretty shiny metal parts on the INSIDE of the motor may end up on the OUTSIDE of the motor! Detonation is extremely hard on rings, piston tops, connecting rod bearings, and even valves. Why do I need "Curves" in Drag Racing? Racing gasoline contains many different petroleum ingredients, all of which add to a distinctive signature that is called the distillation curve. The distillation curve is compiled using a test that heats a sample of gasoline and then measures the temperature at which the fuel vaporizes in 10 percent increments until it is completely vaporized. These curves can tell you a lot about the performance of a racing gasoline. Flat spots in the curves can indicate large amounts of oxygenates or additives. A very steep curve may indicate poor starting characteristics and poor throttle response. A very shallow curve may indicate a gasoline with to many "light" components (also referred to as "front-ends"), which may effect its ability to be stored and may induce vapor lock. What you are looking for is a gasoline that has a high enough initial temperature to prevent vapor lock on a hot day or under high heat conditions, yet have a low enough upper temperature to ensure that all the fuel is converted to energy in the combustion chamber. Some example distillation curves are shown in Figure 1. The data for these curves was extracted from data obtained by an independent test conducted by Texaco for Circle Track magazine. 3 310 300 290 280 270 260 250 240 230 220 210 200 190 180 170 160 150 140 130 120 110 100 90 80 Turbo Blue VP C-12 Unocal CAM 2 Phillips Trick 66 Initial T10% T20% T30% T40% T50% T60% T70% T80% T90% T95% T100% Figure 1 Distillation Curves of Several Popular Racing Gasolines The Pressure's On Reid Vapor Pressure (RVP) is another helpful indicator as to the contents and performance characteristics of a racing gasoline. This measure is affected by chemicals that are blended with the gasoline, such as butane and isopentane. These components are the "front-ends" or volitiles. This measurement refers to how easily a gasoline will vaporize, with a higher RVP indicating more front ends and a motor that is easier to start when cold. A lower RVP indicates less frontends, which sometimes indicates that it is a "heavier" fuel and may contain more energy (measured in BTUs) per gallon than a lighter gasoline. This difference is normally so small in this respect that it doesn't have any practical effect in real world situations. The exception to this would be if you are injector limited, which means you need to put more BTU value into the 4 combustion chambers per volume of fuel delivered. This compensates a small degree for the lack of ability to deliver the total volume actually needed to produce a given power level. A winter blended street gas will typically show an RVP of between 11 and 13, a summer blended street gas will typically show an RVP of 7-9, and racing gas usually shows an RVP of between 5-8. Are You Dense? One last number you often see in the manufacturer's literature is Specific Gravity. Specific Gravity is basically a measure of how dense the fuel is at a given temperature and pressure and is related to the RVP. It can give you a basic feel how much BTU content is in the fuel, but is again really only critical in limited volume situations. So Now What? Below are listed some gasolines that you can practice some of what you learned. The data displayed came from the manufacturers' literature: SUNOCO "Standard" Color.....................Purple Research Octane...........115 Motor Octane..............107 R+M/2 ....................111 Specific Gravity........0.725 Reid Vapor Pressure........ 8# -- Distallation temp, degrees F -Initial............90 10%...............160 50%...............220 Final.............360 5 360 350 340 330 320 310 300 290 280 270 260 250 240 230 220 210 200 190 180 170 160 150 140 130 120 110 100 90 Initial T10% T50% T100% VP C-10 Research Octane...........105 Motor Octane...............96 R+M/2 ....................100 Specific Gravity........0.760 Reid Vapor Pressure....... 1.9# -- Distallation temp, degrees F -Initial...........198 10%...............212 50%...............224 Final.............281 6 290 280 270 260 250 240 230 220 210 200 190 Initial T10% T50% T100% VP Performance Unleaded Research Octane...........104 Motor Octane...............93 R+M/2 .....................99 Specific Gravity........0.760 Reid Vapor Pressure....... 6# -- Distallation temp, degrees F -Initial...........105 10%...............160 50%...............225 Final.............390 7 390 380 370 360 350 340 330 320 310 300 290 280 270 260 250 240 230 220 210 200 190 180 170 160 150 140 130 120 110 100 Initial T10% T50% T100% SUNOCO "GT Unleaded" Color....................Natural Research Octane...........105 Motor Octane...............95 R+M/2 ....................100 Specific Gravity........0.760 Reid Vapor Pressure....... 8# -- Distallation temp, degrees F -Initial............90 10%...............150 50%...............210 Final.............230 8 260 250 240 230 220 210 200 190 180 170 160 150 140 130 120 110 100 90 Initial T10% T50% T100% SUNOCO "Supreme" Color......................Blue Research Octane............116 Motor Octane...............109 R+M/2 .....................112 Specific Gravity.........0.715 Reid Vapor Pressure..... 8# -- Distallation temp, degrees F -Initial............90 10%...............155 50%...............215 Final.............260 9 260 250 240 230 220 210 200 190 180 170 160 150 140 130 120 110 100 90 Initial T10% T50% T100% SUNOCO "Maximal" Color......................Red Research Octane...........118 Motor Octane..............115 R+M/2 ....................117 Specific Gravity........0.700 Reid Vapor Pressure....... 6# -- Distallation temp, degrees F -Initial............100 10%................150 50%................220 Final..............240 10 260 250 240 230 220 210 200 190 180 170 160 150 140 130 120 110 100 90 Initial T10% T50% T100% Comparing these different offerings from the these two companies reveals that they are very similar to one another, which is not unexpected. However, there are some important differences here. Notice that the Initial Boiling Point (IBP) is about 10 degrees higher with the CAM 2 Maximal from Sunoco and it is a whopping 100 degrees higher with the VP C-10. This could be important in trying to start the motor when it''s cold. Another thing to notice is the T100% or the Final Boiling Point. There is a significant difference between the "Standard" fuel and the others. The much higher FBP could indicate a tendancy to have heavier distallates and might be better in in volume limited circumstances. In summary, racing fuel is a complex issue that is fraught with old wive's tales and magic claims. However, hopefully I have provided you with some data that will help you do some research to locate the fuel that is right for your combination. -- Midlands Chapter GSCA -- 11