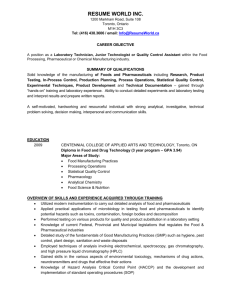

resume - Cemcorp

advertisement

cemcorp RESUME PETER F. BLAZIER, P.ENG. ACADEMIC: 1971 B.A.Sc. Chemical Engineering, University of Toronto Post Graduate Studies: Managing Safety: E.I. du Pont de Nemours & Co. Evaporation Technology: The Center for Professional Advancement Food and Fermentation Engineering: Canadian Society for Chemical Engineering Quality System Internal Auditing (QS-9000): KPMG Quality Registrar Production/Operations Management Course: School of Business Administration, University of Western Ontario, London Financial & Managerial Accounting for the Non-financial Manager, York University PROFESSIONAL AFFILIATIONS: Professional Engineers of Ontario Canadian Society of Chemical Engineers Institute of Packaging Professionals Associates of Erindale College, University of Toronto Association of Canadian Distillers - Industrial Relations Committee - Vice Chairman - Energy Task Force - Fire Code Subcommittee PROFESSIONAL EXPERIENCE: 1998-present cemcorp LTD., Mississauga, Ontario Distillery Engineering Associate Partial List of Distillery Clients and Projects Advance Property Synergies, PLC, Prachinburi, Thailand cemcorp Team member for review, evaluation Vendor interviews and recommendation to Purchase for turnkey 300,000 lpd Cassava-based Bioethanol Plant Quaking Aspen Distillery, Park City, Utah Conceptual Design & Cost Estimate Study for new Microdistillery Bourbon and Vodka plant: responsible for Barreling Warehouse layout and capital cost estimating for major distillery equipment. VIN.S Industries, Sofia Bulgaria Conceptual Design & Cost Estimate Study for conversion and addition of new 26 million lpy Bioethanol; originally with Gluten Separation and Drying to final design using whole wheat. Plant: Responsible for Process Design, mass balance, equipment selection and project cost estimating for all Hydrolysis, VHG Fermentation and Dryhouse systems Conducted Commissioning and Start-up of Grain Handling and Hydrolysis systems UCM EFI, Barrie , Ontario Conceptual Design & Cost Estimate Study for new 300 million lpy Fuel Alcohol Plant: Responsible for Process Design, mass balance, equipment selection and project cost estimating for all Dryhouse systems including Centrifuges, Evaporators, Dryers. 106758800 File Updated: 01/08/2009 Page 1 of 2 cemcorp 1996-1997 U.S.E. HICKSON PRODUCTS LTD., Toronto, Ontario Operations Manager 1972-1996 GILBEY CANADA, INC., Toronto, Ontario Plant Manager & Director, Process Engineering (1991-1996) Managed and organized relocation of distillation system from Toronto to Lethbridge in conjunction with automating the total distillery process, Managed plant demolition and environmental rehabilitation program by coordinating and directing demolition contractors, local government officials, Ministry of Environment, and company's financial group, resulting in successful sale of site, Reorganized, rewrote and renegotiated 3 collective agreements. Plant Manager (1987-1991) Managed all aspects of plant's operations with 18 staff and 95 plant employees, Prepared and administered $22 M overhead and $3 M capital budgets, Implemented a new Joint Health and Safety policy and procedure, resolving a major union confrontation involving the Ministry of Labour. Manager - Process Engineering (1979 - 1987) Created the position of Manager - Process Engineering and the Corporate Engineering department for the Canadian manufacturing operation. Developed and managed approved capital projects in the plant. 106758800 File Updated: 01/08/2009 Page 2 of 2