Report Received - Regional Office, Chandigarh

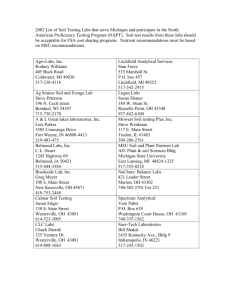

advertisement