File - Audrey Markovich's Page!

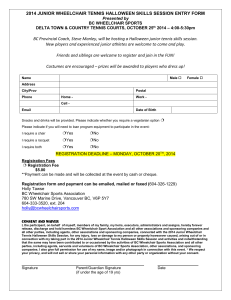

advertisement

DESIGN PROPOSAL STEPPING STOOL Meiluo Li Audrey Markovich Andy Meyer 25 February 2009 Team F ME 340 Project #2 2/25/09 Page 1 of 12 Executive Summary The focus of this project is to implement the design process in attempt to reach a unanimous decision regarding a solution to the given problem. This is exactly what has been completed for the problem at hand. The process consisted of creating multiple concepts and analyzing each one based on their simplicity, cost, ease to use and ability to be stored easily. The problem statement called for the design and development of a device that could assist individuals back to their wheelchairs after a non-fatal fall had occurred. This task was attempted and successfully, a single best solution remained at the completion of the design process. The solution is similar to a common stepping stool meaning that the design is not very original. In essence, it is easier, cheaper and less time consuming to implement an existing design than to create a new one. This is why the solution is based off a previously developed stepping stool. The stool will be collapsible and storable within the wheelchair itself, thus allowing for quick access when needed. The solution was designed around this important detail. By keeping the design as simple as possible, overall cost could be minimized. Additionally, the desire for this device to be stored within a standard wheelchair could be honored; this feature ensures that the user has the necessary equipment to get back into the wheelchair with relative ease. Although other solutions were considered, the stepping stool design remains as the single best solution to the given problem. Details and the breakdown of the completed process are described within the following paragraphs. Table of Contents Executive Summary 1. Introduction 1.1 Background 1.2 Task Description 2. Problem Definition 3. Customer Needs Assessment 3.1 Gathering Customer Input 3.2 Weighting of Customer Needs 4. Engineering Specifications 4.1 Establishing Target Specifications 4.2 Relating Specifications to Customer Needs 5. Concept Generation 5.1 External Search 5.2 Design Concepts 6. Concept Selection 7. Final Design 8. Conclusions and Recommendations 9. References Appendices ME 340 Project #2 2/25/09 Page 3 3 4 4 4 5 5 6 8 9 Page 2 of 12 1. Introduction 1.1 Background For years, problems existed for those who are permanently wheel chair bound. Without working legs, it is extremely challenging to engage in activities of daily life. In these situations, individuals rely heavily upon wheelchairs and may experience some fears of falling. Paraplegic individuals have made this a concern, especially since it limits their independence. This problem deserves some attention; our design team’s task is to explore possible solutions. A final, logical, solution to the problem is desired and if achieved, the product will be marketed towards paraplegic individuals. 1.2 Task Description The overall task of this project is to follow the steps of the design process in order to determine a single best solution to the problem at hand. The objective is to brainstorm and work as a team while collecting and combining thoughts and ideas in a casual setting. This allows for open discussion of details that will contribute to the development of the finalized product. The design team will then undergo a process of elimination based on the given criteria and constraints. A single solution should result from this process and at this point, the concept prototyping would begin. This specific project does not require a physical prototype to be created; however, the design team needs to prepare and present their solution as if the complete design process has been carried out. 2. Problem Definition According to the patient safety authority, “Wheelchairs falling and tipping cause more deaths in persons over 65 years of age. Falls are more likely to occur when using a wheelchair if footrests, wheel locks or other parts do not work well or are loose.” This document was used as justification of the problem statement. It is important to attempt to reduce fatalities due to falling from a wheelchair and this is what needs to be addressed. Solving the overall problem was one task; however, it was decided to attempt to meet an additional need that has been recognized. Based on the selection criteria chart, it was determined that the ability to store the device within the wheel chair itself was crucial. In the event of an incident, it is necessary to have the step device within an arm’s reach. Therefore, our team needed to design a wheel chair assistance device that could be stored underneath a standard model wheel chair. While keeping all this in mind, the task of designing a logical solution to the problem was then given attention. The device needed to be easy to use, durable, and able to hold an average weight of 250 lbs. This all needed to be done without the use of motors or any electronics, costing less than $100, and weighing less than 30 lbs. These constraints restricted the concept development process; however, a final result was eventually achieved with hope that it would benefit the paraplegic population. ME 340 Project #2 2/25/09 Page 3 of 12 3. Customer Needs Assessment 3.1 Gathering Customer Input Customer input was gathered through extensive internet searches as well personal input from a wheelchair bound individual. The father of Professor Laura Pauley was the main source of information, answering questions such as: 1) How high can you lift yourself off of the ground using your own arm strength? 2) How important would it be to have the device located within the wheelchair? This is how we developed many of the details found in our final design. From these questions, it was determined that a paraplegic person could lift himself/herself roughly 4 inches off the ground. The second question helped to expose the overall importance of the device being easily accessible. The best way to achieve this is to store it in the wheelchair itself. 3.2 Weighting of Customer Needs In order to determine the specific needs that require the most attention, it is crucial to weight the individual customer needs. Due to many design constraints, it is unlikely that all customer needs will be met. Therefore, using this process shown in the table below, various customer needs receive a ranking of their importance. Weighted customer needs Need Weighting Ease of use Ease of manufacturing Portability Storing within chair Durability Figure 1 30% 5% 20% 20% 25% 4. Engineering Specifications 4.1 Establishing Target Specifications and Metrics Our team chose to use the weighted matrix method. The customer needs selection criteria is as follows: easy to use, looks good, stable, reliable, portable with wheels, self propelled, can store it in the wheelchair, inexpensive, lightweight, and durable. The metric needs selection criteria includes: total mass, unit manufacturing cost, no electronics, stress, material, ability to move freely, and ability to be compact. This shows how the customer needs relate to the engineering requirements. ME 340 Project #2 2/25/09 Page 4 of 12 7 Ability to be compact 6 Ability to Move Freely 5 4 Stress Material 3 2 Unit Manufacturing Cost No Electronics 1 Total Mass Customer Needs easy to use looks good stable reliable portable with wheels self propelled store in wheelchair inexpensive lightweight durable No. No. 1 2 3 4 5 6 7 8 9 10 Metric 4.2 Relationship of Engineering Specifications to Customer Needs X X X X X X X X X X X Figure 2 5. Concept Generation 5.1 External Search In the conduction of several patent searches and research endeavors, it was discovered that personal lifting devices similar to our design contained motors and electronics. Most of these are specifically manufactured for use in nursing homes or hospitals. These lifting devices are typically fixed to the ceiling and therefore not portable. ME 340 Project #2 2/25/09 Page 5 of 12 Benchmarking of Patent Products Selection Ease of Use Ease of Manufacturing Portable Store in Chair Durability Design 3: Patient Design 1: Design 2: Lifting and Weight Personal Lift Patient Life Transferring (%) Device Mechanism System 30 2 3 2 5 20 20 25 Total (out of 5) 1 0 0 4 2 0 0 4 2 0 0 4 1.65 2 1.7 Figure 3 5.2 Design Concepts Compressed Air Design The compressed air design is a platform with wheels that has a seat for the individual to sit on. There are two metal bars that would balance the seat. In between these bars are air bags that would fill with compressed air. The seat would slowly lift off the ground to the height of the chair. Figure 4 Car Jack Design The car jack design is basically a car jack but modified to lift an individual from the floor into his or her wheelchair. There is a seat that has an attached hand crank. This will allow the individual to rotate the crank until the desired height is reach. ME 340 Project #2 2/25/09 Page 6 of 12 Figure 5 Stair Step Design The stair step design is a very simple design. It consists of a set of stairs that the individual will be able to lift themselves up onto. Each stair will be used as a different platform allowing an individual to lift themselves up one level at a time. Figure 6 Concept Classification Tree Figure 7 ME 340 Project #2 2/25/09 Page 7 of 12 6. Concept Selection Decision Matrix: Concepts Weight Air Pressure Jack Stair-Step Ease of Use 30% 2 4 5 Ease of Manufacture 5% 1 2 4 Portable 20% 3 3 4 Storability in Wheel Chair 20% 4 4 5 Durability 25% 4 5 5 Total Points 100% 3.05 3.95 4.75 3 2 1 Final Standings Figure 8 The characteristic of this device is organized into above seven factors. Ease of Use weighs the most since the design focus is on the adaptation of using the device. Durability is the second most weighted factor that assures the device can withstand long-term use. Ease of Manufacture is the least important due to the assumption that manufacturing will be easy if the device is a simple structured, being able to be stored within the wheel chair. The result is very statistically significant since the winner has a point value of 4.75 out of a possible 5. 7. Final Design Dimensioned Drawings 1) Frame (See Appendix) 2) Board 1 (See Appendix) 3) Board 2 (See Appendix) Material Description The boards are made of Acrylic Plastic and the frame is made of A513 Steel. Material properties and stock prices are listed below. The materials are chosen based on cheap and strong characteristics. ME 340 Project #2 2/25/09 Page 8 of 12 Plastic Acrylic Shear Tensile Compressive Tensile Strength, Elongation Strength Strength, ksi ksi at break (Yield), ksi 10 17 Material ASTM A513 (low-carbon) Steel Sut, ksi 87 Rockwell Stock Size, in Price Color M93 12 x 12 x 0.5 $14.28 Clear Sy, ksi Elongation Rockwell Brinell 72 10% B89 Stock Size 1" OD x 0.12" WALL x 0.76" ID Price $5.25 Description 1 ft long Figure 9 Manufacturing Cost According to the dimension, overall material price is approximately $50; the manufacturing cost including welding, milling and surface finishing will not exceed $20. Since the overall cost is about $70 and if the retail price is set to $90, the design confidently meets the $100 limit. The device is designed for easy use. The simple, stair-step structure will not confuse the users; it is easy to adapt into the device. The simple structure is also designed for collapsibility and portability, so that the device can be easily stored in the wheelchair. Since the device consists of three plastic boards and metal tubes, it is very light weight. The device requires minimal maintenance; therefore, the user will not have to constantly spend money on necessary upkeep. Its’ long term durability provides the user with a reliable, long lasting tool for assistance when needed. The previously described advantages of the device combined with a relatively low retail price will ensure success in the market. Overall, the design is very feasible, both economically and technically. Board 2 Bolts Frame Board 1 Figure 10 ME 340 Project #2 2/25/09 Page 9 of 12 8. Conclusions and Recommendations The stair step design is a simple device designed to aid paraplegic individuals who have fallen to the floor. These individuals will no longer need any assistance since this device is self-propelled. By using the stair step design, the individual will use each step to guide him or herself back into their wheelchair seat one step at a time. There are grip bars on each side of the device for the individual to lift him/herself back up to the seat level. As an added feature, the device will slide out from under the wheelchair when needed. This is extremely beneficial since the individual will not be able to move very far from his or her position on the floor. After use, the stair step can be folded and returned to its' original position quickly and easily. There is a possibility for a design patent to prevent other companies from repeating our design. Our team will deliver on this promise. We have performed much research and have finalized our ideas while developing this final design. We also have many references cited in our research. The stair step design is guaranteed to work and guaranteed to meet the needs of our target demographic. There is no room for error. The paraplegic individual will appreciate this design because of its' easy to use features and overall usefulness. There is high economic potential for the stair step design and it is expected to do well in the market. This design will be easy to manufacture and will definitely satisfy the customers' needs. This means that the design process has been successful, resulting in a plausible and logical solution to the initial problem. Hopefully with this new product on the market, the initial problem will become non-existent. If this would occur, our design team could comfortably see that we have accomplished our overall goal. 9. References: Capaldi, Guido; Sinreich, Mark G. “Patient lift mechanism” US Patent 5,809,591. September 22, 1998 Chepurny, Mark; Molnar, Gordon J.; Wilson, Michael F. “Personal lift device” US Patent 7,240,621. July 10, 2007 Doering, Mike. "How to Reduce Your Risk of Falling." Patient Safety Authority. 17 Mar. 2008. Patient Safety Authority. 24 Feb. 2009 <http://www.psa.state.pa.us/psa/lib/psa/tips_for_consumers/falls_consumer_article_1108.pdf/>. Onlinemetals.com. 1998. 24 Feb. 2009 <http://www.onlinemetals.com/>. Roy, Duane L. “Patient Lifting and Transfer System.” US Patent 5,694,654. December 9, 1997. ME 340 Project #2 2/25/09 Page 10 of 12 Appendices: ME 340 Project #2 2/25/09 Page 11 of 12 ME 340 Project #2 2/25/09 Page 12 of 12