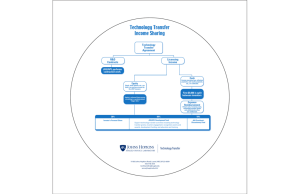

Current Problem - The Johns Hopkins University Applied Physics

advertisement

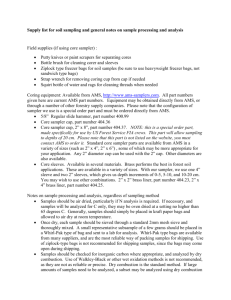

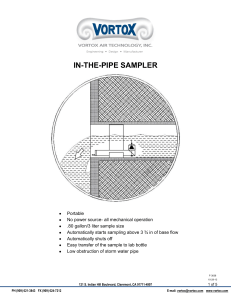

Fluid Sampling Interface For Vehicles (JHU/APL Ref 1818) Industry Challenge It is unsafe and often impossible for humans to directly assess potentially hazardous environments. Today, unmanned vehicles and robots are often used to perform activities that are difficult, dangerous, or impossible for humans. Unmanned vehicles are very successful obtaining materials that need to be chemically analyzed. For example, it is desirable to obtain chemical analysis of water samples at different locations and different depths. However, if there are high radiation or toxin levels, the water may be hazardous for humans to obtain the samples directly. Similarly, it may be impossible for humans to descend below certain water depths, while different machines and vehicles can easily exceed human limits. As collection devices become more proficient, there has been a push to integrate instantaneous sample preparation. Instead of first collecting, then transporting volumes of material to a separate location where they are prepared and analyzed, a better system would perform the necessary preparation immediately, stabilize the sample, and discard the extra, possibly hazardous matter. This remote sampling capability would eliminate other variables often introduced by the conventional methods, which often do not detect the true chemical nature of the area being studied. Conventional methods require the collection be transported to a separate location where they can be properly sampled, prepared and analyzed. During transport the materials can undergo changes. In addition, once the collections are brought to the testing facility, somewhat elaborate procedures are needed to perform the chemical analysis. Not only is this process time consuming, there is also a greater opportunity for samples to be contaminated – leading to inaccurate results. JHU/APL Solution Scientists at The Johns Hopkins University Applied Physics Laboratory, in conjunction with their support of Navy operations, have devised an efficient way to quickly and accurately perform remote sampling and analysis. In addition, the invention can be used in any environment where matter can be pumped into the sampling interface, including gas, liquid, and particle environments. A pumping system has been designed to precisely direct any material that can flow to and from different reservoirs under the direction of remote or pre-programmed signals. After remote processing of the sample, the unit is transported to a safe location where chemical analyses can be performed immediately. Because of the immediate interaction of the collection material with the sampler or analyzer unit, the sampler can better absorb chemicals from the sample while it is still fresh and in its naturally occurring state. This increases the likelihood that highly volatile chemicals or chemicals that may easily combine with the bulk material (the water) will be detected to give a more accurate assessment of the area. Chemical Sampler Assembly (32) Chemical Sampler 1.0” dia., 1.5” ht. Sample Inlet Area 16 Chemical Sampler Assembly 17 31 1 7 6 5 4 3 2 1 8 9 Rotary Valve 10 7 11 12 13 14 6 5 4 3 15 8 9 10 Rotary Valve 11 32 12 13 14 15 16 2 1 16 Gauge 2 Particle Sampler Assembly Plumbing Schematic M 7 6 5 4 3 2 1 8 9 Rotary Valve 10 11 12 13 14 Pumps M 15 16 Gauge 1 Particle Sampler 2.6” dia., 1.9” ht. Strainer Gauge 3 Particle Sampler Assembly (14) Particl Chemi Plumbi Chemi Particl calcal e ng e Sampl Schem Sampl eratic er 1.0” 2.6” Assem dia., bly 1.5” 1.9” (14)ht. (32) Goal: JHU/APL is currently seeking an exclusive licensee to further develop and commercialize this prototype. Patent: Issued # 6,837,121 Date 1/4/05 Inventors: Allmon, Carlson, Dence, Goemmer, Reach, Schein, Sternberger Keywords: remote sampling and analysis, sampling interface, instantaneous sample preparation, fluid sampling interface Contact Information: Randall Slagle Technology Transfer Manager Office of Technology Transfer www.jhuapl.edu/ott Office: 443-778-8680 Fax: 443-778-5882 E-mail: Randall.Slagle@jhuapl.edu