nikhil bhardwaj

advertisement

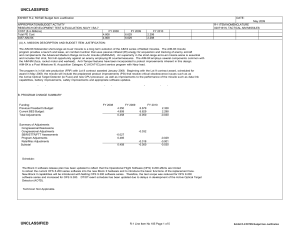

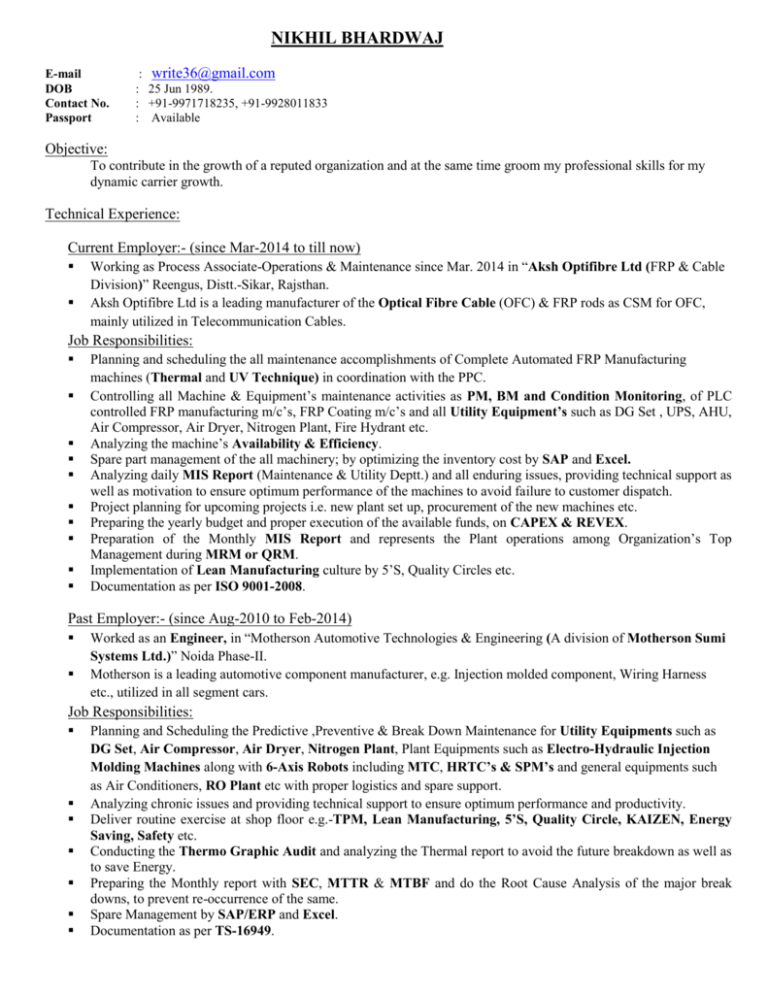

NIKHIL BHARDWAJ E-mail DOB Contact No. Passport : write36@gmail.com : 25 Jun 1989. : +91-9971718235, +91-9928011833 : Available Objective: To contribute in the growth of a reputed organization and at the same time groom my professional skills for my dynamic carrier growth. Technical Experience: Current Employer:- (since Mar-2014 to till now) Working as Process Associate-Operations & Maintenance since Mar. 2014 in “Aksh Optifibre Ltd (FRP & Cable Division)” Reengus, Distt.-Sikar, Rajsthan. Aksh Optifibre Ltd is a leading manufacturer of the Optical Fibre Cable (OFC) & FRP rods as CSM for OFC, mainly utilized in Telecommunication Cables. Job Responsibilities: Planning and scheduling the all maintenance accomplishments of Complete Automated FRP Manufacturing machines (Thermal and UV Technique) in coordination with the PPC. Controlling all Machine & Equipment’s maintenance activities as PM, BM and Condition Monitoring, of PLC controlled FRP manufacturing m/c’s, FRP Coating m/c’s and all Utility Equipment’s such as DG Set , UPS, AHU, Air Compressor, Air Dryer, Nitrogen Plant, Fire Hydrant etc. Analyzing the machine’s Availability & Efficiency. Spare part management of the all machinery; by optimizing the inventory cost by SAP and Excel. Analyzing daily MIS Report (Maintenance & Utility Deptt.) and all enduring issues, providing technical support as well as motivation to ensure optimum performance of the machines to avoid failure to customer dispatch. Project planning for upcoming projects i.e. new plant set up, procurement of the new machines etc. Preparing the yearly budget and proper execution of the available funds, on CAPEX & REVEX. Preparation of the Monthly MIS Report and represents the Plant operations among Organization’s Top Management during MRM or QRM. Implementation of Lean Manufacturing culture by 5’S, Quality Circles etc. Documentation as per ISO 9001-2008. Past Employer:- (since Aug-2010 to Feb-2014) Worked as an Engineer, in “Motherson Automotive Technologies & Engineering (A division of Motherson Sumi Systems Ltd.)” Noida Phase-II. Motherson is a leading automotive component manufacturer, e.g. Injection molded component, Wiring Harness etc., utilized in all segment cars. Job Responsibilities: Planning and Scheduling the Predictive ,Preventive & Break Down Maintenance for Utility Equipments such as DG Set, Air Compressor, Air Dryer, Nitrogen Plant, Plant Equipments such as Electro-Hydraulic Injection Molding Machines along with 6-Axis Robots including MTC, HRTC’s & SPM’s and general equipments such as Air Conditioners, RO Plant etc with proper logistics and spare support. Analyzing chronic issues and providing technical support to ensure optimum performance and productivity. Deliver routine exercise at shop floor e.g.-TPM, Lean Manufacturing, 5’S, Quality Circle, KAIZEN, Energy Saving, Safety etc. Conducting the Thermo Graphic Audit and analyzing the Thermal report to avoid the future breakdown as well as to save Energy. Preparing the Monthly report with SEC, MTTR & MTBF and do the Root Cause Analysis of the major break downs, to prevent re-occurrence of the same. Spare Management by SAP/ERP and Excel. Documentation as per TS-16949. Training & Project: Basic Pneumatic Training at m/s SMC Noida. B.Tech Final year project “Automatic Power Jack”, which is a lifting device for Passenger Cars. Practical training of 45 days in PE Deptt. Of “MINDA CORPORATION LTD.” at Noida. Successfully completed summer training project on “Lean Manufacturing” . Technical Qualification: Passed B.Tech in Mechanical Engineering with 67.48% from U.P. Technical University Lucknow, in 2010. Academic Qualification: Passed Class 10+2(PCM) from CBSE Board with 70% in 2006. Passed Class 10th from CBSE Board with 85.4% in 2004. Area of Interest: Zeal to know about New Technologies. Enthusiastic of Automobiles. Doing experiments for Automation. Keen Interests in Engines & Machines. Achievement: Reconditioning of the burned out Cable sheathing machine before prescribed timeline. Designed & Established best quality UV FRP manufacturing machine locally. Developed “Automatic Power Jack”, (First time in India) to lift the small segment cars. It was published in the state level news paper. Computer Skills: SAP-SE CATIA V5, AUTO CAD. MS Word, PPT, Excel. Hobbies: Date: Place: Net surfing. Listening Songs & Reading Books. Playing Guitar. (NIKHIL BHARDWAJ)