Lever Lab

advertisement

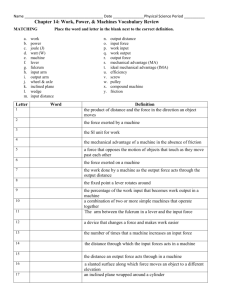

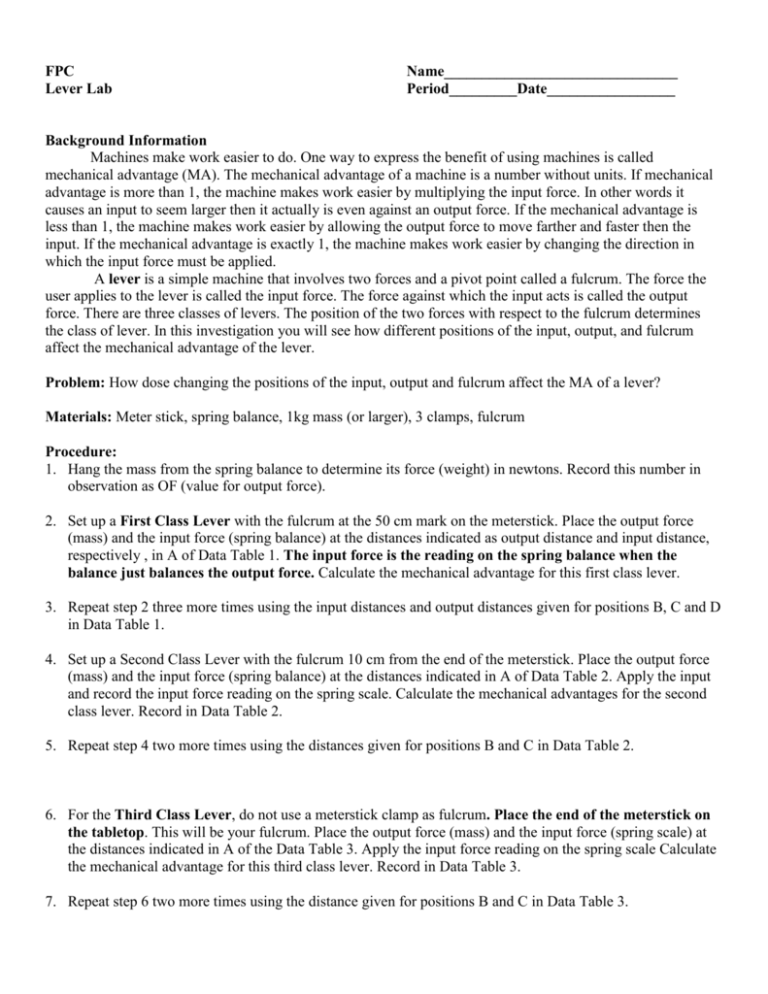

FPC Lever Lab Name_______________________________ Period_________Date_________________ Background Information Machines make work easier to do. One way to express the benefit of using machines is called mechanical advantage (MA). The mechanical advantage of a machine is a number without units. If mechanical advantage is more than 1, the machine makes work easier by multiplying the input force. In other words it causes an input to seem larger then it actually is even against an output force. If the mechanical advantage is less than 1, the machine makes work easier by allowing the output force to move farther and faster then the input. If the mechanical advantage is exactly 1, the machine makes work easier by changing the direction in which the input force must be applied. A lever is a simple machine that involves two forces and a pivot point called a fulcrum. The force the user applies to the lever is called the input force. The force against which the input acts is called the output force. There are three classes of levers. The position of the two forces with respect to the fulcrum determines the class of lever. In this investigation you will see how different positions of the input, output, and fulcrum affect the mechanical advantage of the lever. Problem: How dose changing the positions of the input, output and fulcrum affect the MA of a lever? Materials: Meter stick, spring balance, 1kg mass (or larger), 3 clamps, fulcrum Procedure: 1. Hang the mass from the spring balance to determine its force (weight) in newtons. Record this number in observation as OF (value for output force). 2. Set up a First Class Lever with the fulcrum at the 50 cm mark on the meterstick. Place the output force (mass) and the input force (spring balance) at the distances indicated as output distance and input distance, respectively , in A of Data Table 1. The input force is the reading on the spring balance when the balance just balances the output force. Calculate the mechanical advantage for this first class lever. 3. Repeat step 2 three more times using the input distances and output distances given for positions B, C and D in Data Table 1. 4. Set up a Second Class Lever with the fulcrum 10 cm from the end of the meterstick. Place the output force (mass) and the input force (spring balance) at the distances indicated in A of Data Table 2. Apply the input and record the input force reading on the spring scale. Calculate the mechanical advantages for the second class lever. Record in Data Table 2. 5. Repeat step 4 two more times using the distances given for positions B and C in Data Table 2. 6. For the Third Class Lever, do not use a meterstick clamp as fulcrum. Place the end of the meterstick on the tabletop. This will be your fulcrum. Place the output force (mass) and the input force (spring scale) at the distances indicated in A of the Data Table 3. Apply the input force reading on the spring scale Calculate the mechanical advantage for this third class lever. Record in Data Table 3. 7. Repeat step 6 two more times using the distance given for positions B and C in Data Table 3. Observations Output Force:_____________N MA = OF IF DATA TABLE 1: First Class Lever. Fulcrum at 50 cm Position A Input Distance (cm) 40 Output Distance (cm) 40 B 40 20 C 40 10 D 20 40 Input Force (N) Mechanical Advantage DATA TABLE: 2 Second Class Lever: Fulcrum at 10 cm from end of meterstick Position Input Distance (cm) Output Distance (cm) A 50 40 B 50 25 C 50 10 Input Force (N) Mechanical Advantage Input Force (N) Mechanical Advantage DATA TABLE 3: Third Class Lever Position A Input Distance (cm) 20 Output Distance (cm) 80 B 40 80 C 60 80 Analysis and Conclusions: 1. In the first class lever, how did the input force compare with the output force when the input distance was equal to the output distance? 2. What was the mechanical advantage of the first class lever in which the input distance was equal to the output distance? 3. In the second class lever, how does the input force compare with the output force? 4. In the second class lever, was the mechanical advantage the lowest when the output was close to the fulcrum or close to the input? 5. In the second class lever, was the mechanical advantage the greatest when the output was close to the fulcrum or close to the input? 6. Which third class lever had the greatest mechanical advantage? 7. Which third class lever had the least mechanical advantage? Critical Thinking and Application 1. In the first class lever, where would you place the input and output forces to have the greatest possible mechanical advantage? 2. In the second class lever, how did moving the fulcrum closer to the output affect the amount of input needed to balance the output? How did it affect the mechanical advantage? 3. If you wanted to have the greatest possible mechanical advantage for a third-class lever, would you move the input closer to the fulcrum or closer to the output? 4. If the mechanical advantage of a third class lever is always less then one, what is the benefit? (Read the introduction!) Extra Credit: Make a list of at least 10 items in your home that are levers. Indicate the class of lever to which each item belongs, sketch each, and label the input force, output force, and fulcrum.