Ropes for Towing

advertisement

Ropes for Towing

Part one

by David Bowyer

In this chapter David Bowyer explains what ropes are available and how to use them.

Every Land Rover, Discovery or Range Rover owner will at some time or other need

to either recover someone else, or be recovered themselves. For some it's a

necessity to haul and recover stuck loads and vehicles as part of their profession.

Then there are some of us who simply enjoy the opportunity of getting one or other

stuck firmly in the mire creating recovery situations. Great fun.

All recoveries by rope in any situation could be potentially dangerous, especially if the

stuck vehicle is bogged well down. Not only is it essential to use the correct type of

rope for the job in hand, but also it is extremely important to attach the said rope to

proper strong towing points that should always be fitted to both the front and rear of

the vehicles.

Before getting tied up with knotty explanations of what type of rope to hang around

with, let's consider where and what we intend to hook onto. This is a serious subject,

so don't read between the lines if I spin a yarn or two! I'm sure I can think of several

puns.

Every 4 x 4 should have a proper rear towing point. All Land Rover products are very

capable towing machines, probably more so than what some of you may think.

Before now, I've towed a fully laden 38 tonner off a bend on the A30 where the

broken down lorry was a danger to other road users. I'll come back to emergency

heavy towing techniques later.

Without doubt the standard Land Rover supplied fixed height rear towing unit with

either a towing ball or universal jaw and ball is the best for the majority of on and off

road recoveries.

If you have an adjustable towing unit made by either Dixon Bate or Witter, be sure to

only recover heavy loads with the adjustable slider unit raised to it's highest point.

This is to ensure you pull in line with the chassis and not at some point way below.

Never contemplate carrying out a heavy recovery with a tow ball mounted at the

bottom of an 'extended' drop plate. Doing so could cause serious damage to the rear

cross member.

Whilst on the subject of rear cross members, make sure you know how good yours

is, or that of your mate's Land Rover if he's about to zap you out of a mud hole. Rust

is the biggest killer of strength in the rear end of a chassis. And the front end come to

that!

It is also vitally important that any towing unit and it's tow ball or jaw is installed

correctly to the vehicle in accordance with both the vehicle's and the towing unit

manufacturer's instructions using only the correct grade of high tensile bolts

It would not be a good idea to carry out a

heavy recovery with a rope placed over this

very low tow ball

The towing eye on this Discovery is

designed to take a steady pull and not for

heavy recoveries

An alternative for the serious 'off roader' is having a heavy duty Nato towing hook

fitted to the standard drop plate on either a Discovery or Range Rover or direct to the

rear cross member on a Land Rover.

One securing point that should NOT be used for recovery purposes is the lashing

eyes that are fitted to both front and rear of coil sprung Land Rovers and Range

Rovers. These lashing eyes are only designed for chaining the vehicle down on a

transporter. They are only secured to the chassis with a single bolt and therefore

cannot take the stress of a heavy recovery.

However in an emergency, providing they are installed as original on the outside of

the chassis with the bolt head against the side of the lashing eye, one could use a

bridle across the pair, either on the front or rear. Your mediocre recovery point would

be the centre of this bridle thereby halving the load on each side. These lashing eyes

should not be relied upon as they could bend easily if you carried out a heavy

recovery using only one of them.

Worse still, if they have been re-fitted incorrectly with the bolts the wrong way round

so that the nuts are up against the lashing eyes, then woe betide. Under high

tension, the nut can spring off the bolt never to be seen again, leaving the lashing

eye to catapult along the axis of the rope with alarming results. I'm not making this

up, in years gone past I've proved it!

One of the best and strongest is a 'Nato' tow

hook as fitted to the front of this 101

This lashing eye is fine for towing, but not

heavy recoveries if used singularly

A far superior recovery point to use in place of the lashing eyes is a pair of 'Chassis

Shackles', also known as Jate Rings. These towing rings are specially forged and

installed using new longer high tensile bolts and appropriate shims so they fit snugly

around the chassis. They are ideal for use as major recovery points with a bridle in

between. These 'Chassis Shackles' will fit either the front or rear of all coil sprung

Land Rovers, Discoverys and Range Rovers. They are stocked in our Off Road Shop

coming complete with high tensile bolts, nuts and washers to suit.

These 'Chassis Shackles' are ideal for

attaching ropes to a coil sprung vehicle

When attaching ropes to towing eyes,

always use decent 3/4 inch shackle

My personal favourite securing points for all Land Rover series 1,11,111, Ninety and

One Tens is the 'Bumper D Ring'. This galvanised towing ring is attached to a heavy

base plate with four holes in it. The rearmost holes accept the original (or new

replacement) high tensile bumper bolts. After fitting the 'Bumper D Ring' to these

bolts, insert a drill bit down through the front two holes and drill into the bumper to

take two shorter bolts. When fitting these D Rings to a Ninety or One Ten it is easier

to remove the louvred grille first so as to remove the bumper bolts. When refitting the

grille, cut or file away a small part of the bottom louvre to miss the back of the 'D'.

Lightweight Land Rovers are often fitted with lifting eyes both front and rear. As these

forged eyes only have two securing points at a right angle to a strain exerted when

carrying out a heavy recovery, I would prefer them not to be used. They are only

intended for steady helicopter or dockside lifting operations and furthermore will not

accept a 3/4" shackle pin (unless reamed out). Best to use 'Bumper D Rings' instead.

A pair of 'Bumper D Rings' is a must on all

models of Land Rover should you have a

standard bumper ...

... and very useful too on other models

All BRB Roo Bars have two recovery points installed, one on each side in line with the chassis

I do not like the American style chassis/bumper forged hook as ropes can fall off very

easily with embarrassing results.

Large dynamo lifting eyes, providing they are well plated behind the bumper do have

a place, but should never be used for a 'Kinetic Recovery'.

Finally on the subject of recovery points, our BRB Roo Bars and Winch Bumpers

have recovery points fitted as standard, one each side in line with the chassis.

The lifting ring fitted on a lightweight should

not be used for heavy recoveries

... the same here applies to the lifting ring

on this 101

Fibres used in rope making

When I first started driving Land Rovers in 1960, all that was available to me were

natural fibre ropes for recovery. For steady pulls and on-road towing they were fine,

but there were disadvantages.

The most common natural fibres that were available in years gone past were manila

and sisal.

Manila consists of the sheath fibres from the leaves of a type of banana tree, Musa

textilis, indigenous to the Philippines. The leaves are picked when the plant is three

years old and the stems are cut into narrow strips 20 - 30 mm wide and about 5mm

thick. These are scraped against blunt knives. In this way the soft juicy parts are

removed, leaving the fibres clean. They are then dried and made ready for packing

and export. This treatment was first done in Manila, which gave this type of hemp it's

world famous name. Manila is also grown in the Sunda Islands (Sumatra manila),

India and the West Indies.

The fibres are very hydroscopic and swell considerably in water, where the rope will

shrink, stretching again when it dries. A manila rope is identifiable by it's slightly

speckled appearance, due to the fact that both darker and lighter coloured fibres are

used in its manufacture. A new manila rope is smooth in appearance and slightly

shiny, unlike sisal.

Sisal hemp consists of the fibres in the fleshy leaves of the various aloe and agave

plants, in particular Agava rigida var. Sisalana, indigenous to the the dry, high, stony

plateaus of Central America and first shipped from the small port of Sisal on the north

coast of the Yucatan peninsula.

The sisal plant has a long stem and the large, sword like leaves grow in a big rosette

near the ground. The leaves are first picked when the plant is three to four years old

and are put through a machine which washes and separates the fibres from the

fleshy parts. The clean fibres are then dried on racks before being baled for export.

Sisal hemp has long even fibres. New sisal is distinguishable from manila by it's

uniform pale yellow colour being duller in appearance to manila. Around the turn of

the century sisal growing was introduced into East Africa and later into Sumatra and

Java. Nowadays it is grown in many tropical areas, particularly Tanzania and Kenya.

There are other natural fibres as well used in rope making, but none of them are as

strong as manila and sisal.

Stronger man-made synthetic fibres

Nylon rope was first used only about fifty - sixty years ago and it didn't take long to

cotton onto (excuse the pun). The fishing industry took to it very quickly as nylon fibre

rope is unaffected by water, and size for size against manila and sisal it is at least

50% stronger allowing smaller diameter ropes to be used for rigging, fishing and

towing.

Synthetic fibres are man-made fibres which are produced entirely by chemical

synthesis from simple basic substances. As compared with natural fibres they are of

better uniformity and continuity. Fibres made of Polyvinyl alcohol and of Polyvinyl

chloride are now almost exclusively made only in Japan.

Nylon fibred rope is very elastic. It can stretch up to about 30% returning to it's

original length when the tension is released. This elasticity is particularly useful in

certain applications, but also carries with it a certain amount of risk: if a nylon rope

breaks under stress it may act like a rubber band in contracting and catapult say, a

heavy shackle or part of a towing point back towards the other point of attachment

which could be highly dangerous. However, in our off-road field we use this 'Kinetic

Energy' to our advantage - with an awful lot of care.

In more recent years there has been growth in other man-made synthetic fibres such

as polypropylene, polyethylene and polyester. All these fibres have far less stretch

than that of nylon though are slightly less strong.

Nylon, polypropylene, polyethylene and polyester fibres are manufactured in long

threads - the length of the rope. This produces ropes that generally have a smooth,

slippery surface.

Weaker ropes are made from carded waste. This spun fibre has a vaguely fluffy

surface, not unlike cotton. This type of rope is called staple spun and is not used for

our type of work.

A 4.5 meter 'Dead' staple polyprop tow rope

which carries an 8 tonne breaking strain

All nylon tow ropes have a shiny surface. It is

amply strong enough for all towing

applications, as it is rated at 12 tonne

Manufacture

From our point of view, nearly all the rope that we are likely to use with the exception

of braided capstan rope and 8 strand Kinetic Energy Recovery Rope (KERR), will be

3 strand rope.

If you look at a piece of lets say 3 strand tow rope it will most probably have a right

hand lay - that is, the three strands go up and around the rope clockwise just like a

screw thread. This is 'hawser laid' rope that has been twisted three times in the

course of the manufacture: the fibres are initially twisted to make the rope yarn, the

yarn is then twisted into strands, and the strands twisted into the final rope.

Three strand ropes can either be tightly or loosely laid (twisted). The specification I

ask for when having our ropes made up is between the two, giving good strength and

wear characteristics.

Eight strand nylon rope is made by using four strands of left hand lay and four

strands of right hand lay, which in turn is plaited in pairs to form the rope. It is this

rope that we use for our 'Kinetic Energy Recovery Rope' (KERR).

In years gone by, one only referred to the ropes' size by it's circumference in inches.

Nowadays, certainly in the case of synthetic rope, we quote their size in mm for their

diameter.

As regards to the strength of the rope, we quote Minimum Breaking Load. We are not

talking of lifting, but if we were, we would divide the above figure by six to give Safe

Working Load (SWL).

Choice of Rope

In my earlier days of Land Rover recovery there was not much choice, you used what

you had! My rope was sisal, purchased from a nearby ex WD dealer by the coil. I

found a piece of it the other day when clearing out the garage. Having measured it's

size, I've just worked out that it's Minimum Breaking Load is only 4 tonne. No wonder

ropes never lasted long in those days!

When choosing a rope you must decide what you are going to use it for, i.e. there's a

big difference between swinging the children, tying loads on the roof rack and pulling

a stuck One Ten out of a bog.

Manila and sisal ropes are fairly cheap and for the first two uses above it will be fine,

but for towing or recovering vehicles between two and three tonnes, think again.

Another sound reason for discounting manila or sisal is that they don't like being

stored wet as this leads to deterioration of the natural fibres of the rope. It will also

smell horrible.

The second best rope is a polypropylene rope made from fibrillated film tape. This

man-made raffia type fibre is in fact a twisted 'tape' as you get in baler twine.

Normally light blue in colour, has a slippery surface and is quite cheap. I don't like it

for on-road towing as it has no 'give' in it. In other words, it is a 'Dead' rope.

Polypropylene ropes also come in 'Monofilament', which is made up of single

filaments enlikened to fishing line. This is more expensive, very slippery and difficult

to handle.

Splicing at its best, five 'tucks' with loose ends 'dogged'

If requiring a cheaper rope for whatever reason, I suggest a Staple polypropylene tow

rope. It has a 'hairy' surface similar to sisal, easy to grip, not too expensive, but still

has no 'give' in it. The colour is always white. If you prefer a 'Dead' rope, then this is

the one to have.

Polyethylene rope is similar to monofilement polypropylene and is normally orange in

colour. It is no good whatsoever in large diameters for towing as it is very slippery

and awkward to handle. However, in much smaller sizes, in an 8 strand versions, we

supplied thousands of tow ropes for the 'car field'. This was in fact our 'Easytie' tow

rope - the simple to splice rope that we had on Tomorrows' World.

That was in the late seventies. As you can tell, I've been tied up for years in the rope

field!

The third best tow rope is without doubt a three strand nylon one. It's the strongest of

all the normal man-made fibre ropes, but what's more important it's got some give in

it. So when you are towing someone on-road you won't get all that nasty jolting that

you get with a polypropylene 'dead' rope. Nylon rope is always white in colour and

has a smooth surface.

Towing

Perhaps this is a good time to explain how to tow another vehicle on-road, or off-road

come to that.

Firstly, the maximum distance between vehicles when being towed on road is 4.5

Metres, so it's appropriate to have a 4.5 M tow rope. Ideally, all tow rope should have

a soft eye spliced loop in each end with no less than five 'tucks' to create the best

possible splice. As a matter of interest all the ropes that our shop supplies has their

loose ends 'dogged'. This prevents the splicing coming apart however badly the rope

is misused.

Obviously adequate towing points are essential - tow hook on the recovery vehicle,

shackleable point on the vehicle being towed.

Talking of shackles, if towing or recovering another heavy 4x4, always use no smaller

than a 3/4" shackle, with a 3/4" pin. This size shackle has an approx Safe Working

Load (SWL) of approx 3 tonnes, which equates to a Minimum Breaking Load of about

18 tonnes. Put it this way, I've never bent a 3/4" pin yet!

Always carry with your tow rope a 3/4" D shackle, a 3/4" large Bow shackle and for

hooking up smaller ordinary cars, a 1/2" D shackle. With this combination you can

tow anything.

Good communication between the two vehicles is extremely important whether by

sight, hand signals and the driver behind anticipating ahead, as well as closely

following his mates brake and indicator lamps in front. If you have CB communication

in both vehicles - use it!

Towing vehicle should have headlights on. Towed vehicle, side lights. By rights the

towing vehicle should have a reflective sign up front say 'TOWING' and the towed

vehicle having a reflective sign on the rear saying 'ON TOW'. Make the 'dead vehicle'

safe, gearbox in neutral, steering lock free and driver aware that the brake servo will

not be working.

Towing vehicle takes up the slack and proceeds when clear to go and aims to to

maintain a steady speed of probably no more than 25-30 miles per hour.

It is very important for the person being towed to keep the rope in front taught at all

times. If the rope starts to go slack, then gently apply the foot brake to hold back. The

aim is never to let the rope fall to the ground until the journey is concluded. If you can

do this you will avoid any vicious snatching and reduce the risk of breaking a weaker

rope. This usually happens when the towing vehicle reaches slower moving traffic,

comes up to a road junction or proceeds down a hill. As the recovery vehicle starts to

pull away from you, come off the footbrake. This way you will have a reasonably

pleasant journey without too many frighteners.

A nice large white nylon rope is obviously a good choice, a bonus being, it shows up

well between the vehicles. Be very careful when you pull out of a junction turning

right across the traffic. Try and plan your journey ahead so you don't have nasty blind

junctions, as you could risk some idiot driving too fast around a corner to your right

and possibly driving between you. Oh, it can happen!

Land Rover to the rescue, using a blue Polyprop 'Dead' rope

Pulling someone out of a ditch is another use for a tow rope. When you, as a 'knight

in shining armour' offer to help some poor unfortunate person, be certain what you

are hooking your nice strong tow rope onto. I will never forget the day, many years

ago one Winter, when I came around this bend in thickish snow and found a sports

car gone off the road and into a small ditch. Naturally I pulled up, got my tow rope out

to offer my help.

I asked the owner, 'what should I attach to', he replied 'that tube under the front'. So I

did. As I pulled forward with the Range Rover, I pulled the tube clean off the car. It

wasn't after all a solid part. Much embarrassment, a lesson learnt, look twice at what

you are hooking on to.

Want a 'bump start', no problem, my 4 x 4 can pull anything! Well of course it can.

But do check all the obvious first, ignition, fuel etc.

Again good communication is required. Make sure that the person you are towing

knows what to do. Get a thumb up from the driver behind when he or she has the

ignition on, in gear usually third, foot on the clutch and handbrake off. Make sure that

the person knows when to let the clutch out (about 5-10 MPH) and that they must

blow their horn as soon as their engine is running or want you to stop.

Here's another tip to remember. Your friend's Land Rover has just stalled when off

road and it won't re- start. You back up, hook on, without thinking he selects first

gear. Normally not a big problem, but he is still in low ratio! Ping-pong and the rope

breaks as he lets the clutch out. Remember to go back into high ratio if you want a

non-dramatic bump start.

Perhaps you are called upon to move a very heavy lorry a short distance. You will by

now have got the message that a good strong nylon tow rope is essential for all

towing with a 4 x 4 such as yours.

I recommend a 3 strand nylon tow rope, 4.5 Metres long, soft eye spliced loops each

end and 24 mm in diameter. This size of nylon rope has a Minimum Breaking Load of

12 tonnes and therefore sufficiently strong enough to get even the largest load

moving providing you have a rolling load.

Attach your rope to a strong point on the front of the lorry (most lorries have a centre

pintle for emergency bar towing) and the strongest point on the back of your 4 x 4. If

you have a universal combination jaw and tow ball, use only the pin through the jaw

to attach to. These units are stronger here than the neck of the tow ball above.

Engage low ratio, as well as the centre diff lock if fitted, select first gear, take up the

slack as the lorry driver releases his brakes. By very carefully slipping the clutch (no

problem with an automatic) the tremendous power that you have available will firstly

be absorbed by the nylon rope and slowly your juggernaut will follow you. As your

load comes with you, remove your left foot well clear of the clutch. If possible don't

slip the clutch at all, but that's easier said than done! Remember, slipping the clutch

for too long or too often will soon burn it out.

You really only ought to be doing this in a straight line. If you steer out too much to

either side you risk damage to your transmission through 'axle wind up'. A Range

Rover with a centre viscous coupling unit (VCU) does not have this problem. With an

exceptionally heavy load you have to use the centre diff lock if fitted, because as the

high load pulls the back of the vehicle downwards the front can lift allowing the front

wheels to spin.

Come to a halt very slowly to ensure the lorry stops behind you. Remember his

brakes will be very inefficient as he has a dead engine.

When towing is completed, disengage your centre diff lock immediately. If it won't

clear, drive forward in a straight line a few metres, then reverse back also in a

straight line. If is still won't clear, try 'flopping' the vehicle on the throttle and as a last

resort drive ahead again putting the nearside front wheel just onto the grassy verge

and 'flop' the transmission again to spin that wheel out.

So there you are. 'Have a 4x4 and recover more!'

Do bear in mind though, if you go to recover somebody, there may not be insurance

cover should you pull something off their vehicle. I am not a 'legal beagle', but I would

suggest when offering your services you should say in front of a witness:- "I accept

no responsibility for this recovery and any damage that may be caused". After all, in

recovering someone's vehicle from a ditch, their vehicle could slide sideways getting

trapped on a hidden rock causing damage. However, as in any recovery situation,

stop, observe, and discuss the plan with the other driver before doing it.

Remember, except in an emergency and I mean an emergency situation, you are

NOT allowed to tow anyone on a motorway. Recoveries on this class of road may

only be carried out by an official recovery contractor.

Care of Ropes

I've already mentioned that it's important not to store wet and muddy natural fibre

ropes as they can rot and go smelly quite quickly. If your new, or Ex WD manila or

sisal rope gets wet and muddy, hose it down when you get back to base and hang it

out to dry thoroughly before putting it away.

Ensure too that mud and grit isn't caught up within the 'lay' or it will weaken the rope

the next time you use it in anger. Inspect as well for cuts in the surface and watch out

for loose ends pulling back out through the splices.

Sunlight does not affect natural fibre ropes too much, but I still do not recommend

that you leave it wrapped around the front bumper or draped over the spare wheel or

the bonnet. Best to store it inside the vehicle.

Man-made synthetic ropes on the other hand are impervious to water and does not

get mouldy. These ropes can be scrubbed if they get muddied and don't necessarily

have to be dried before being stowed away.

They can however be damaged by high temperatures and melting can occur about

200 degrees centigrade.

Therefore ensure they never come close to a hot exhaust system. Talking of heat

and light, never leave a man-made synthetic rope hanging outside, wrapped or

draped over the vehicle or stored inside directly inside the windows. These ropes

deteriorate with the effect of ultra-violet (UV) light on them. Best to stow them inside a

sack or plastic chest as I do in my vehicle. Some made made ropes can be affected

by acids, oils and in particular solvents. Best to ensure your ropes are kept away

from such fluids.

Again, after nylon and polyproplene ropes have been used in muddy conditions,

inspect for wear and tear and give them a good wash. One of my off-road friends

places his ropes in their washing machine when his wife is out. He assures me that

he uses a warm wash only and rinse cycle. I don't think many mums and wives would

appreciate it though!

So there you have it, always look after you ropes...and they will look after you...for

many years to come.

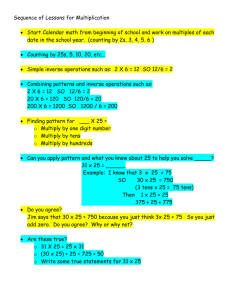

Comparison in order of strength

These are the normal types of 3 strand ropes used for towing Land Rover sized

vehicles both on & off road. Based on the recommended diameter of 24mm (3"

circumference) and 4.5 Metres (15') between soft eye spliced looped ends.

Type

Colour

Finish

Minimum

breaking

load

Sisal

Pale Yellow

Hairy

4000kg (4

tonne)

Manilla

Yellow/Brown Smooth

4500kg (4.5

tonne)

Fibrillated Polypropylene ('Polyprop'

for short) 'Dead Rope'

Yellow/Brown Slippery

8000kg (8

tonne)

Staple Polyprop 'Dead Rope'

White

Hairy

8000kg (8

tonne)

Nylon 'Stretchy'- The best for towing

White

Smooth

12000kg (12

tonne)

Ropes for Towing

Part two - Heavy Pulling

by David Bowyer

Having bought or owned for some time,one of the world's best 4x4's why not start

using it occasionally for some mild off-roading! Maybe you have already got the bug

and sampled the vehicle's true off-road prowess.

Either way, my series is to show you what other ropes, jacks, and winches later on,

are available and how to use them, both effectively and safely.

A KERR rope kit - including a bridle

Professional splicing is essential

For most, a gentle green laning day is a perfect start in becoming acquainted with

what could be, or what maybe already, a life long wonderful hobby and pastime driving your Land Rover product 'off-road'.

For others, joining one of our school sessions, will be your first introduction.

Either way, always go prepared. I consider that the first piece of off-road kit to

purchase is a good long and strong nylon tow rope and a bridle to attach it to your

vehicle. The second item would be a high lift jack, but more about that in another

chapter.

The Recoverline KERR rope

'KERR' stands for 'Kinetic Energy Recovery Rope'. This is the rope to carry in your

kit. Sooner or later either you or someone else will need a recovery ranging from a

mild pull out to a more serious yank out of deep mud! I designed and developed the

Recoverline KERR rope in the mid eighties in conjunction with Marlow Ropes when

they were looking for a recovery rope system for 'light skin' military Land Rovers. The

British Army had been using KERR ropes for de-bogging 60 tonne Challenger tanks

made from multiplait 90mm dia (3.5 inch) nylon rope. That's some rope

A bridle halves the load across the chassis of

the vehicle being recovered

Over the course of time we evaluated many different lengths and diameters of

multiplait 8 strand nylon rope and eventually settled on the 'ideal' specification. This

was 8 metres between bearing points and 24mm diameter, giving a minimum

breaking capacity of 12 tonnes with an elongation of approximately 30% at full load.

The soft eye splices are protected with polyester lay flat tubing with the splices being

made with 5 tucks with the 'ends' split, dogged (bound with twine) and heat sealed.

The non-rotating 8 plait construction is used to avoid the inherent problems such as

kinking and hocking associated with conventional 3 strand ropes. The use of

multiplait construction is also ideal as the rope is more supple and is therefore easier

to handle.

This is quite a high specification, but remember, in a serious recovery situation the

load is phenomenal. Before I explain how the Recoverline KERR rope works, lets

consider general 'getting stuck' and getting the vehicle out.

Recovery situations can be potentially dangerous, especially when attempting to

'pluck' a well stuck vehicle out of the mire, or if wedged in deep ruts.

Personally, I prefer to use either an electric winch to recover either myself or another

4x4, as the recovery is fully under control at the 'touch of a button'. Or equally safe is

using a Brano or Tirfor hand winch. But by employing a rope recovery it is generally

much quicker to de - bog a stuck vehicle.

When carrying out a recovery, by whatever method, do check first that the stuck

vehicle isn't stuck fast on an enormous rock or log hidden under the vehicle. The last

thing you want is to damage the steering gear, axles, exhaust system or what-haveyou.

Maybe just three or four people could push the vehicle out of it's predicament, but be

careful not to get trapped between the side of the vehicle and a tree or a bank as the

vehicle gains traction, and definitely watch out for flying mud from those spinning

road wheels!

Mild Recovery

The Recoverline KERR rope can of course be used for a gentle pull out. It's long

length of 8 metres (27 feet) will enable the recovery vehicle to find good ground to

pull from.

When using ropes just as in any recovery situation make sure that there is good

communication between the parties concerned, that the stuck vehicle's driver knows

when he or she is about to be recovered, and that his or her handbrake is off - you

may laugh! Also remember to have the engine running to both run the power

steering, and assist with the road wheels if necessary. This also ensures the steering

lock unit isn't locked - you may laugh again! The driver of the stuck vehicle must

communicate with the recovery driver in front, either directly with hand signals,

headlight flashing, CB radio or via an assistant standing to one side between the

vehicles to say that he or she is ready.

By all means assist the rope recovery with road wheels turning slowly in first or

second gear in low ratio to try and gain traction. But be careful not to overrun the

rope and definitely don't get a front wheel over the rope as it could get taken around

the tyre with disastrous results, if the recovery vehicle goes off again at warp 9 and

he or she thinks you are catching them up. At best, the rope will tighten around the

front swivel housing and squash the flexible brake pipe. At worst, you could get your

axle ripped off as the recovery vehicle goes charging off.

Heavy KERR Recoveries

When a Recoverline KERR rope is used to recover a fairly stuck load, this is where

the 'kinetic energy' that is stored up in the nylon rope does it's job.

The energy is created by the speed times the weight of the recovery vehicle. As the

rope is literally stretched to its maximum being pulled towards the recovery vehicle,

much like a powerful elastic band!

Imagine a well stuck vehicle. Always use a bridle made from 3 strand 24mm diameter

nylon rope about 2 metres long with soft eye splices at each end. Attach this bridle to

the stuck vehicle after rigging it through the protected eye splice of the KERR rope.

NEVER EVER rig a shackle directly on to the end of a KERR rope.

If that shackle should break through blowing apart you would have a flying

missile which would travel back along the length of rope towards the recovery

vehicle and embed itself through its tailgate or rear window which would be

exceedingly dangerous.

The same goes if a towing or recovery point fails, please refer to my last chapter on

safety issues. I digress, back to attaching the bridle to the front of the stuck vehicle to

those strong Jate Rings, 'Bumper D Rings' or Jackmates. Here you can use

shackles, as by using one at each end of the bridle you are halving the load and

protecting the chassis rather than yanking the stuck vehicle from one side only.

The shackles need to be not less than 20mm (3/4 inch). Some will say that you must

only use 'tested' shackles, but in general terms a 20 x 20 mm (pin & body) is good for

about 3.25 tonnes SWL (Safe Working Load) times the recognised safety factor of 6

gives you a capacity of nearly 20 tonnes. I've never broken a shackle yet and I have

got to admit I've done one or two pretty daft things!

Snake the KERR rope on the ground as shown in the pictures and attach the other

end to a good central recovery point. Yes, you could use a bridle that end too, or use

a safety rope as shown as well. But in my experience, a good well fitted towing unit

on a sound chassis is fine.

My advice is to only have one helper as an assistant plus the two drivers in rigging

the KERR rope and bridle. All the bystanders to stand clear during the operation and

all the passengers must vacate the two vehicles.

Once the two drivers and the assistant have discussed the recovery techniques the

assistant stands well clear on the driver's side to confirm they are both ready and

signals to the recovery driver to GO. The towing vehicle accelerates to its maximum

permitted speed (see table) and snatches the rope at that speed. If the stuck vehicle

is only mildly stuck there is no need to assist recovery by having its wheels turning.

If however the stuck vehicle is really well and truly stuck then that driver should be in

gear with the clutch depressed just prior to the recovery commencing. Just as the

rope becomes taut, let the clutch out with just a little acceleration. Make sure that you

don't stall the engine and definitely don't overrun the rope.

The towing vehicle may be slowed or even halted as the Recoverline approaches

maximum elongation. It's at this point that the kinetic energy is converted into the

potential energy of the stretched rope. This build up of energy is transferred by the

rope to the stuck vehicle.

After a very slight pause the stuck vehicle should be free. If the vehicle is not

recovered by the first attempt, simply repeat the process by reversing back and relaying the Recoverline. But make sure first that there isn't a large rock or stump

wedging the vehicle solid.

In fact, gain lots of experience is safely learning the correct 'take up' speed by

slowly building up to it. It is better and far safer to shift the stuck vehicle just a

metre at a time than catapult it into the back of your recovery vehicle!

As you can see from the table, the heavier the load, the less you should charge away

from it. The reasons are of course is you will exert far greater strains on the towing

attachment points.

Hazards

All recovery procedures are potentially dangerous. Two possible reasons for

the failure are either:

1. A rope failure. Unlikely to happen unless you totally go over the top by flying

off at too great a speed with the stuck vehicle planted over a tree stump. Unlike

a steel wire rope, if the rope breaks it will travel back along its axis. The stored

energy is potentially lethal if something breaks for any reason. For instance a

worn or damaged rope.

2. A towing or recovery point failure. This is far more dangerous and more

likely to occur than a rope failure. The possibility is that part of the towing unit

might be catapulted by the recoiling rope at an enormous speed. This can be

very serious.

Safety Precautions

1. Use only good, sound and strong

recovery points and use a bridle on the

front of the stuck vehicle. Maybe also

use a safety rope on the back of the

recovery vehicle (see right).

2. Passengers should not be carried

during recovery operations.

3. Do not exceed the maximum speeds

as set out in the table.

4. Spectators should stand well clear of

the recovery for obvious reasons.

Maintenance and Inspection

All nylon ropes must be kept clear of heat and acid. Consequently, Recoverline

should be kept clear of exhaust systems and battery acids. It is also important to

avoid chafing. A simple method of checking the condition of the rope, and one which

ensures that it has not been severely overloaded, can be carried out by lifting one

pair of the strands clear of another pair passing underneath.

Should these two pairs of strands be fused together, this would indicate that the rope

has been severely overloaded and should be rejected. This check, combined with

visual inspection along the rope's length to ensure that there are no cuts to any of the

rope strands, acts as a satisfactory assessment.

Warning

The greatest care has been taken to ensure that Recoverline when new has more

than adequate safety factor for the envisaged vehicle recovery. It should be

understood, however, that the attachment points are also adequate for the recovery.

Loads of up to 7.5 tonnes could be induced on each vehicle in the most extreme

circumstances as discussed.

David Bowyer's Off Road Centre, Goodwinch, or any of our agents disclaims all

responsibility for any injury or damage however caused, during recovery operations.