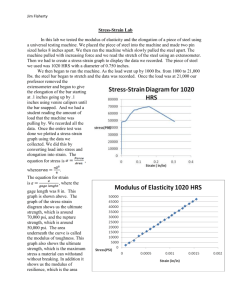

Stress-strain curve

advertisement

Stress-strain curve A stress-strain curve is a graph derived from measuring load (stress - σ) versus extension (strain - ε) for a sample of a material. The nature of the curve varies from material to material. The following diagrams illustrate the stress-strain behaviour of typical materials in terms of the engineering stress and engineering strain where the stress and strain are calculated based on the original dimensions of the sample and not the instantaneous values. In each case the samples are loaded in tension although in many cases similar behaviour is observed in compression. Ductile materials Fig 1. A stress-strain curve typical of structural steel 1. Ultimate Strength 2. Yield Strength 3. Rupture 4. Strain hardening region 5. Necking region. Steel generally exhibits a very linear stress-strain relationship up to a well defined yield point (figure 1). The linear portion of the curve is the elastic region and the slope is the modulus of elasticity or Young's Modulus. After the yield point the curve typically decreases slightly due to dislocations escaping from Cottrell atmospheres. As deformation continues the stress increases due to strain hardening until it reaches the ultimate strength. Until this point the cross-sectional area decreases uniformly due to Poisson contractions. However, beyond this point a neck forms where the local cross-sectional area decreases more quickly than the rest of the sample resulting in an increase in the true stress. On an engineering stress-strain curve this is seen as a decrease in the stress. Conversely, if the curve is plotted in terms of true stress and true strain the stress will continue to rise until failure. Eventually the neck becomes unstable and the specimen ruptures (fractures). Most ductile metals other than steel do not have a well-defined yield point (figure 2). For these materials the yield strength is typically determined by the "offset yield method", by which a line is drawn parallel to the linear elastic portion of the curve and intersecting the abscissa at some arbitrary value (most commonly .2%). The intersection of this line and the stress-strain curve is reported as the yield point. Brittle materials Brittle materials such as concrete or ceramics do not have a yield point. For these materials the rupture strength and the ultimate strength are the same. Properties The area underneath the stress-strain curve is the toughness of the material- i.e. the energy the material can absorb prior to rupture......... The resilience of the material is the triangular area underneath the elastic region of the curve. Yield (engineering) Yield strength, or the yield point, is defined in engineering and materials science as the stress at which a material begins to plastically deform. Prior to the yield point the material will deform elastically and will return to its original shape when the applied stress is removed. Once the yield point is passed some fraction of the deformation will be permanent and non-reversible. Knowledge of the yield point is vital when designing a component since it generally represents an upper limit to the load that can be applied. It is also important for the control of many materials production techniques such as forging, rolling, or pressing In structural engineering, yield is the permanent plastic deformation of a structural member under stress. This is a soft failure mode which does not normally cause catastrophic failure unless it accelerates buckling. In 3D space of principal stresses (σ1,σ2,σ3), an infinite number of yield points form together a yield surface. Definition It is often difficult to precisely define yield due to the wide variety of stress-strain behaviours exhibited by real materials. In addition there are several possible ways to define the yield point in a given material: The point at which dislocations first begin to move. Given that dislocations begin to move at very low stresses, and the difficulty in detecting such movement, this definition is rarely used. Elastic Limit - The lowest stress at which permanent deformation can be measured. This requires a complex iteractive load-unload procedure and is critically dependent on the accuracy of the equipment and the skill of the operator. Proportional Limit - The point at which the stress-strain curve becomes nonlinear. In most metallic materials the elastic limit and proportional limit are essentially the same. Offset Yield Point (proof stress) - Due to the lack of a clear border between the elastic and plastic regions in many materials, the yield point is often defined as the stress at some arbitrary plastic strain (typically 0.2% [1]). This is determined by the intersection of a line offset from the linear region by the required strain. In some materials there is essentially no linear region and so a certain value of plastic strain is defined instead. Although somewhat arbitrary this method does allow for a consistent comparison of materials and is the most common. Yield criterion A yield criterion, often expressed as yield surface, is an hypothesis concerning the limit of elasticity under any combination of stresses. There are two interpretations of yield criterion: one is purely mathematical in taking a statistical approach while other models attempt to provide a justification based on established physical principles. Since stress and strain are tensor qualities they can be described on the basis of three principal directions, in the case of stress these are denoted by , and . The following represent the most common yield criterion as applied to an isotropic material (uniform properties in all directions). Other equations have been proposed or are used in specialist situations. Maximum Principal Stress Theory - Yield occurs when the largest principal stress exceeds the uniaxial tensile yield strength. Although this criterion allows for a quick and easy comparison with experimental data it is rarely suitable for design purposes. Maximum Principal Strain Theory - Yield occurs when the maximum principal strain reaches the strain corresponding to the yield point during a simple tensile test. In terms of the principal stresses this is determined by the equation: Maximum Shear Stress Theory - Also known as the Tresca criterion, after the French scientist Henri Tresca. This assumes that yield occurs when the shear stress exceeds the shear yield strength : Total Strain Energy Theory - This theory assumes that the stored energy associated with elastic deformation at the point of yield is independent of the specific stress tensor. Thus yield occurs when the strain energy per unit volume is greater than the strain energy at the elastic limit in simple tension. For a 3-dimensional stress state this is given by: Distortion Energy Theory - This theory proposes that the total strain energy can be separated into two components: the volumetric (hydrostatic) strain energy and the shape (distortion or shear) strain energy. It is proposed that yield occurs when the distortion component exceeds that at the yield point for a simple tensile test. This is generally referred to as the Von Mises criterion and is expressed as: Based on a different theoretical underpinning this expression is also referred to as octahedral shear stress theory. Factors influencing yield stress The stress at which yield occurs is dependent on both the rate of deformation (strain rate) and, more significantly, the temperature at which the deformation occurs. Early work by Alder and Philips in 1954 found that the relationship between yield stress and strain rate (at constant temperature) was best described by a power law relationship of the form where C is a constant and m is the strain rate sensitivity. The latter generally increases with temperature, and materials where m reaches a value greater than ~0.5 tend to exhibit super plastic behaviour. Later, more complex equations were proposed that simultaneously dealt with both temperature and strain rate: where α and A are constants and Z is the temperature-compensated strain-rate - often described by the Zener-Hollomon parameter: where QHW is the activation energy for hot deformation and T is the absolute temperature. Implications for structural engineering Yielded structures have a lower and less constant modulus of elasticity, so deflections increase and buckling strength decreases, and both become more difficult to predict. When load is removed, the structure will remain permanently bent, and may have residual pre-stress. If buckling is avoided, structures have a tendency to adapt a more efficient shape that will be better able to sustain (or avoid) the loads that bent it. Because of this, highly engineered structures rely on yielding as a graceful failure mode which allows fail-safe operation. In aerospace engineering, for example, no safety factor is needed when comparing limit loads (the highest loads expected during normal operation) to yield criteria. Safety factors are only required when comparing limit loads to ultimate failure criteria, (buckling or rupture.) In other words, a plane which undergoes extraordinary loading beyond its operational envelope may bend a wing slightly, but this is considered to be a fail-safe failure mode which will not prevent it from making an emergency landing. Elastic modulus An elastic modulus, or modulus of elasticity, is the mathematical description of an object or substance's tendency to be deformed elastically (i.e. non-permanently) when a force is applied to it. The elastic modulus of an object is defined as the slope of its stress-strain curve in the elastic deformation region: where λ is the elastic modulus; stress is the force causing the deformation divided by the area to which the force is applied; and strain is the ratio of the change caused by the stress to the original state of the object. Because stress is measured in pascals and strain is a unitless ratio, the units of λ are therefore pascals as well. An alternative definition is that the elastic modulus is the stress required to cause a sample of the material to double in length. This is not literally true for most materials because the value is far greater than the yield stress of the material or the point where elongation becomes nonlinear but some may find this definition more intuitive. Specifying how stress and strain are to be measured, including directions, allows for many types of elastic moduli to be defined. The three primary ones are Young's modulus (E) describes tensile elasticity, or the tendency of an object to deform along an axis when opposing forces are applied along that axis; it is defined as the ratio of tensile stress to tensile strain. It is often referred to simply as the elastic modulus. The shear modulus or modulus of rigidity (G or μ) describes an object's tendency to shear (the deformation of shape at constant volume) when acted upon by opposing forces; it is defined as shear stress over shear strain. The shear modulus is part of the derivation of viscosity. The bulk modulus (K) describes volumetric elasticity, or the tendency of an object's volume to deform when under pressure; it is defined as volumetric stress over volumetric strain, and is the inverse of compressibility. The bulk modulus is an extension of Young's modulus to three dimensions. Three other elastic moduli are Poisson's ratio, Lamé's first parameter, and P-wave modulus. Homogeneous and isotropic (similar in all directions) materials (solids) have their (linear) elastic properties fully described by two elastic moduli, and one may choose any pair. Given a pair of elastic moduli, all other elastic moduli can be calculated according to formulas in the table below. Inviscid fluids are special in that they can not support shear stress, meaning that the shear modulus is always zero. This also implies that Young's modulus is always zero. Young's modulus In solid mechanics, Young's modulus (E) is a measure of the stiffness of a given material. It is also known as the Young modulus, modulus of elasticity, elastic modulus or tensile modulus (the bulk modulus and shear modulus are different types of elastic modulus). It is defined as the ratio, for small strains, of the rate of change of stress with strain.[1] This can be experimentally determined from the slope of a stressstrain curve created during tensile tests conducted on a sample of the material. Young's modulus is named after Thomas Young, the 18th Century British scientist. Units The SI unit of modulus of elasticity (E, or less commonly Y) is the pascal. Given the large values typical of many common materials, figures are usually quoted in megapascals or gigapascals. Some use an alternative unit form, kN/mm², which gives the same numeric value as gigapascals. The modulus of elasticity can also be measured in other units of pressure, for example pounds per square inch. Usage The Young's modulus allows the behavior of a material under load to be calculated. For instance, it can be used to predict the amount a wire will extend under tension, or to predict the load at which a thin column will buckle under compression. Some calculations also require the use of other material properties, such as the shear modulus, density, or Poisson's ratio. Linear vs non-linear For many materials, Young's modulus is a constant over a range of strains. Such materials are called linear, and are said to obey Hooke's law. Examples of linear materials include steel, carbon fiber, and glass. Rubber and soil (except at very low strains) are non-linear materials. Directional materials Most metals and ceramics, along with many other materials, are isotropic - their mechanical properties are the same in all directions, but metals and ceramics can be treated to create different grain sizes and orientations. This treatment makes them anisotropic, meaning that Young's modulus will change depending on which direction the force is applied from. However, some materials, particularly those which are composites of two or more ingredients have a "grain" or similar mechanical structure. As a result, these anisotropic materials have different mechanical properties when load is applied in different directions. For example, carbon fiber is much stiffer (higher Young's modulus) when loaded parallel to the fibers (along the grain). Other such materials include wood and reinforced concrete. Engineers can use this directional phenomonon to their advantage in creating various structures in our environment. Concrete is commonly used to construct support columns in buildings, supporting huge loads under compression. However, when concrete is used in the construction of bridges and is in tension, it needs to be reinforced with steel which has a far higher value of Young's modulus in tension and compensates for concrete's low value in tension. Copper is an excellent conductor of electricity and is used to transmit electricity over long distance cables, however copper has a relatively low value for Young's modulus at 130GPa and it tends to stretch in tension. When the copper cable is bound completely in steel wire around its outside this stretching can be prevented as the steel (with a higher value of Young's modulus in tension) takes up the tension that the copper would otherwise experience. Calculation Young's modulus, E, can be calculated by dividing the tensile stress by the tensile strain: where E is the Young's modulus (modulus of elasticity) measured in pascals; F is the force applied to the object; A0 is the original cross-sectional area through which the force is applied; ΔL is the amount by which the length of the object changes; L0 is the original length of the object. Force exerted by stretched or compressed material The Young's modulus of a material can be used to calculate the force it exerts under a specific strain. where F is the force exerted by the material when compressed or stretched by ΔL. From this formula can be derived Hooke's law, which describes the stiffness of an ideal spring: where Elastic potential energy The elastic potential energy stored is given by the integral of this expression with respect to L: where Ue is the elastic potential energy. The elastic potential energy per unit volume is given by: , where is the strain in the material. This formula can also be expressed as the integral of Hooke's law: Approximate values Young's modulus can vary considerably depending on the exact composition of the material. For example, the value for most metals can vary by 5% or more, depending on the precise composition of the alloy and any heat treatment applied during manufacture. As such, many of the values here are approximate. Approximate Young's moduli of various solids Young's modulus Young's modulus (E) in Material (E) in GPa lbf/in² (psi) Rubber (small strain) 0.01-0.1 1,500-15,000 Low density polyethylene 0.2 30,000 Polypropylene 1.5-2 217,000-290,000 Bacteriophage capsids 1-3 150,000-435,000 Polyethylene terephthalate 2-2.5 290,000-360,000 Polystyrene 3-3.5 435,000-505,000 Nylon 3-7 290,000-580,000 Oak wood (along grain) 11 1,600,000 30 4,350,000 Magnesium metal (Mg) 45 6,500,000 Aluminium alloy 69 10,000,000 High-strength concrete compression) (under Glass (all types) 72 10,400,000 Brass and bronze 103-124 17,000,000 Titanium (Ti) 105-120 15,000,000-17,500,000 10 - 20 1,500,000 - 3,200,000 Wrought iron and steel 190-210 30,000,000 Tungsten (W) 400-410 58,000,000-59,500,000 Silicon carbide (SiC) 450 65,000,000 Tungsten carbide (WC) 450-650 65,000,000-94,000,000 Single carbon nanotube [1] 1,000+ 145,000,000 Diamond (C) 1,050-1,200 Carbon fiber reinforced (unidirectional, along grain) plastic 150,000,000175,000,000