Spring 2006 Exam II Solution - University of San Diego Home Pages

advertisement

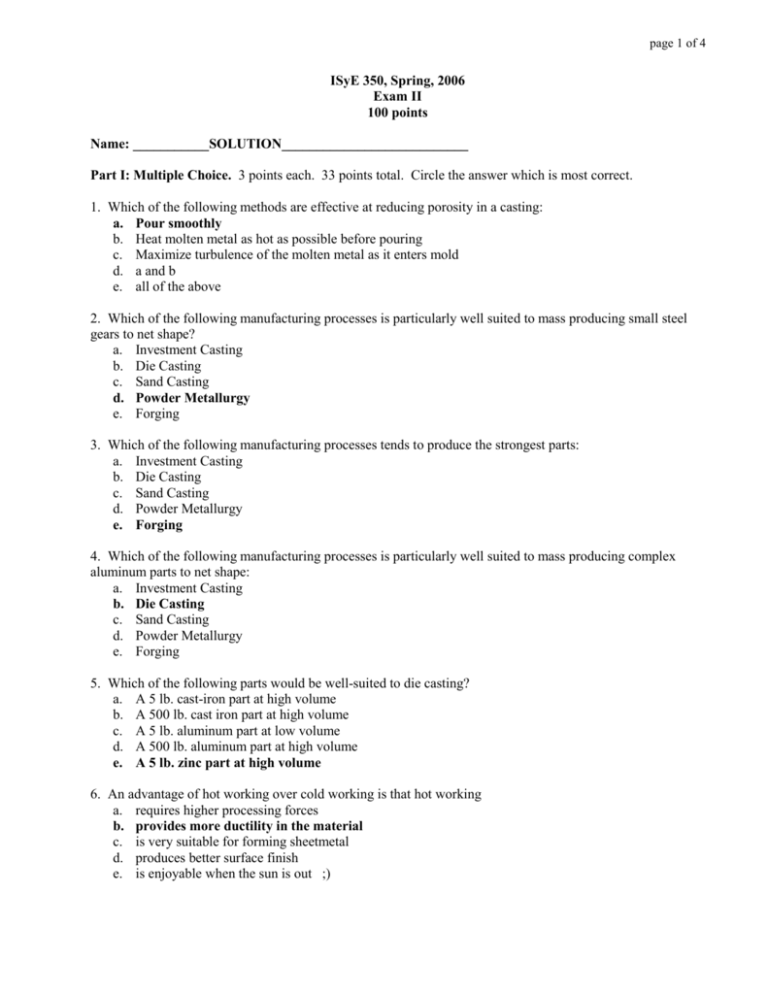

page 1 of 4 ISyE 350, Spring, 2006 Exam II 100 points Name: ___________SOLUTION___________________________ Part I: Multiple Choice. 3 points each. 33 points total. Circle the answer which is most correct. 1. Which of the following methods are effective at reducing porosity in a casting: a. Pour smoothly b. Heat molten metal as hot as possible before pouring c. Maximize turbulence of the molten metal as it enters mold d. a and b e. all of the above 2. Which of the following manufacturing processes is particularly well suited to mass producing small steel gears to net shape? a. Investment Casting b. Die Casting c. Sand Casting d. Powder Metallurgy e. Forging 3. Which of the following manufacturing processes tends to produce the strongest parts: a. Investment Casting b. Die Casting c. Sand Casting d. Powder Metallurgy e. Forging 4. Which of the following manufacturing processes is particularly well suited to mass producing complex aluminum parts to net shape: a. Investment Casting b. Die Casting c. Sand Casting d. Powder Metallurgy e. Forging 5. Which of the following parts would be well-suited to die casting? a. A 5 lb. cast-iron part at high volume b. A 500 lb. cast iron part at high volume c. A 5 lb. aluminum part at low volume d. A 500 lb. aluminum part at high volume e. A 5 lb. zinc part at high volume 6. An advantage of hot working over cold working is that hot working a. requires higher processing forces b. provides more ductility in the material c. is very suitable for forming sheetmetal d. produces better surface finish e. is enjoyable when the sun is out ;) page 2 of 4 7. Which of these forming processes is best-suited to making long parts with a complex cross-section such as this: a. b. c. d. e. Hot rolling Cold rolling Deep drawing Roll forming Extrusion 8. Which of the following processes is the most economical for mass producing cup-shaped parts. a. Hot rolling b. Cold rolling c. Deep drawing d. Roll forming e. Extrusion 9. The We-Roll-It company wants to turn 1” thick steel slabs into 1/16” sheets with good surface finish. What manufacturing process(es) would be best? a. hot rolling b. cold rolling c. hot rolling followed by cold rolling d. cold rolling followed by hot rolling e. the Pillsbury process 10. Why are Powder Metallurgy parts limited in size to a few square inches in cross-section? a. The compaction press tonnage capacity is limited b. The injection cylinder can only inject a certain amount of molten metal c. Large P/M parts do not sinter properly d. Large P/M parts are too expensive 11. Which of the following manufacturing processes is the most common and versatile casting method: a. Permanent Mold Casting b. Die Casting c. Investment Casting d. Sand Casting e. Fly casting Part II: Short Answer. 4 points each. 44 points total. Succinctly answer these questions. (A few words in some cases, a few sentences in others, sketches as needed/desired). 1. Casting and Powder Metallurgy are said to be “net shape” or “near-net shape” processes. What does “net shape” mean? The part is complete and of the correct shape right after the casting or P/M process, and requires no secondary machining operations. 2. Briefly explain why casting tends to produce grains perpendicular to the mold wall. Grains begin to grow in random directions away from the mold wall, but those perpendicular to the wall shutoff the growth of other grains, leaving the perpendicular grain structure towards the center. page 3 of 4 3. In a casting, why is it desirable for solidification to start at the extremities of the mold and end at a riser? The riser must be able to continuously feed molten metal to the part sections that have just solidified and shrunk. This can only be achieved by starting solidification at extremities and progressing to riser. If not, cavities and/or porosity will occur. 4. Name 3 key disadvantages of hot working. Poor surface finish, lower strength, high heat input, warped parts, looser tolerances. 5. Why are permanent mold castings generally removed from the mold immediately after solidification has been completed? The casting can crack because the rigid mold does not allow the casting to contract as it cools. 6. Both Investment Casting and Die Casting produce accurate parts with excellent surface appearance. Name two key factors that would determine whether one method is preferred over the other. If part is ferrous (steel, cast iron), Investment casting is preferred. If volume is high, die casting is preferred. 7. In Powder Metallurgy, what additional challenge is there to making “tall” parts of high quality? (for example, a hollow cylinder with a length of 2”, an outer diameter of 1”, and an inner diameter of 0.5”) Compaction tends to produce variable density from top to bottom, so a tall part has more variation in density from top to bottom. 8. Which manufacturing process would be best suited to making complexly shaped ferrous (iron, steel) parts, to a rough level of accuracy, at low volume? Sand casting. 9. Benny’s Bending Company is bending 12” squares of cold-rolled sheetmetal. They find that when they bend it along the x-x axis, it bends normally. But when they bend it along the y-y axis, it cracks. Why? y x x y The grains are oriented along the y-y axis due to cold rolling. Grain boundaries are relatively weak. 10. In casting, what are the benefits of not having to remove the pattern from the mold (e.g., investment casting)? Less or no concern for draft angle Higher part complexity is possible. No risk of damaging mold (or pattern) by pattern removal. Eliminates a step. Parting line may be eliminated. page 4 of 4 11. In Powder Metallurgy, why is a protective atmosphere (no oxygen) needed in the sintering operation? To prevent the porous metal from oxidizing at high temperature. Part III: Identification: 13 points 1. (10pts) For the mold shown below, label the components that have letters pointing to them: Ostwald A = sprue B = cope C = drag D = riser E = core F = gate G = runner H = parting line 2. (3 pts) What is the specific name for this manufacturing process? Kalpakjian Closed-die forging Part IV: Problem Solving: 10 points Calculate the dimensions of an effective riser for a casting that is a 1” x 3” x 6” rectangular plate. Assume that the casting and riser are not connected except by a gate and runner, and that the riser is a cylinder of height/diameter ratio H/D = 2.0. Triser = 1.25*Tcasting Chvorinov’s rule and solving gives D=1.86”, H=3.73”