ME251 Fall 2005 Instructo

advertisement

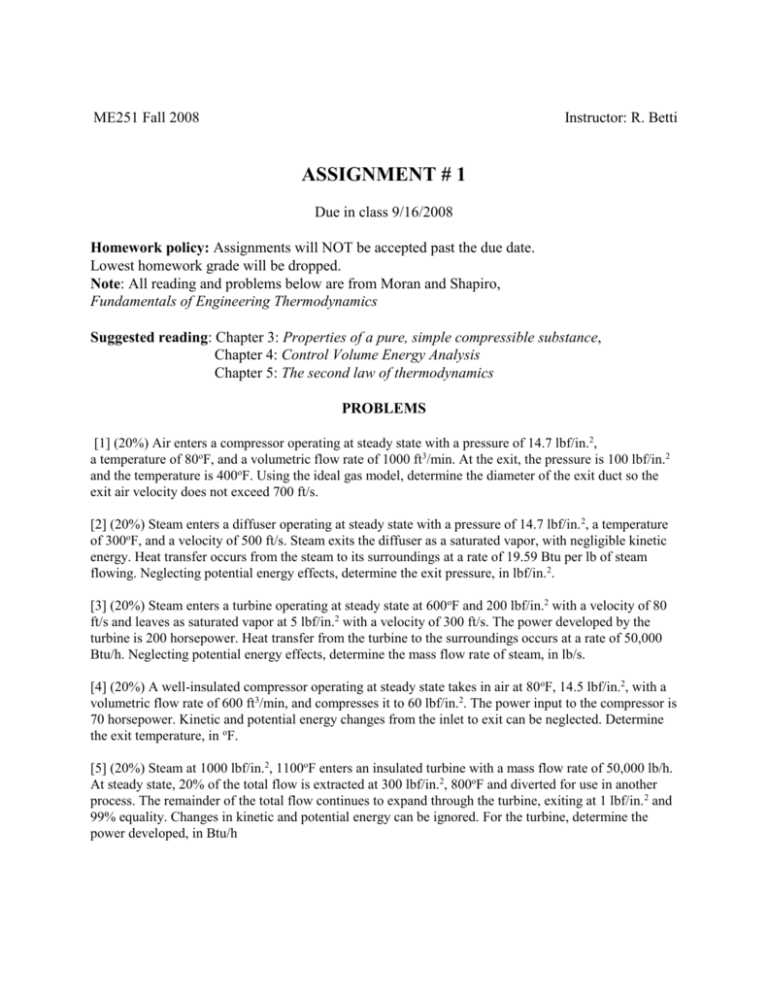

ME251 Fall 2008 Instructor: R. Betti ASSIGNMENT # 1 Due in class 9/16/2008 Homework policy: Assignments will NOT be accepted past the due date. Lowest homework grade will be dropped. Note: All reading and problems below are from Moran and Shapiro, Fundamentals of Engineering Thermodynamics Suggested reading: Chapter 3: Properties of a pure, simple compressible substance, Chapter 4: Control Volume Energy Analysis Chapter 5: The second law of thermodynamics PROBLEMS [1] (20%) Air enters a compressor operating at steady state with a pressure of 14.7 lbf/in.2, a temperature of 80oF, and a volumetric flow rate of 1000 ft3/min. At the exit, the pressure is 100 lbf/in.2 and the temperature is 400oF. Using the ideal gas model, determine the diameter of the exit duct so the exit air velocity does not exceed 700 ft/s. [2] (20%) Steam enters a diffuser operating at steady state with a pressure of 14.7 lbf/in.2, a temperature of 300oF, and a velocity of 500 ft/s. Steam exits the diffuser as a saturated vapor, with negligible kinetic energy. Heat transfer occurs from the steam to its surroundings at a rate of 19.59 Btu per lb of steam flowing. Neglecting potential energy effects, determine the exit pressure, in lbf/in. 2. [3] (20%) Steam enters a turbine operating at steady state at 600oF and 200 lbf/in.2 with a velocity of 80 ft/s and leaves as saturated vapor at 5 lbf/in.2 with a velocity of 300 ft/s. The power developed by the turbine is 200 horsepower. Heat transfer from the turbine to the surroundings occurs at a rate of 50,000 Btu/h. Neglecting potential energy effects, determine the mass flow rate of steam, in lb/s. [4] (20%) A well-insulated compressor operating at steady state takes in air at 80oF, 14.5 lbf/in.2, with a volumetric flow rate of 600 ft3/min, and compresses it to 60 lbf/in.2. The power input to the compressor is 70 horsepower. Kinetic and potential energy changes from the inlet to exit can be neglected. Determine the exit temperature, in oF. [5] (20%) Steam at 1000 lbf/in.2, 1100oF enters an insulated turbine with a mass flow rate of 50,000 lb/h. At steady state, 20% of the total flow is extracted at 300 lbf/in.2, 800oF and diverted for use in another process. The remainder of the total flow continues to expand through the turbine, exiting at 1 lbf/in. 2 and 99% equality. Changes in kinetic and potential energy can be ignored. For the turbine, determine the power developed, in Btu/h