Pulley System Design Brief: Rube Goldberg Machine

advertisement

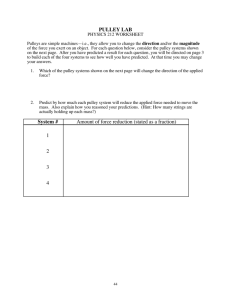

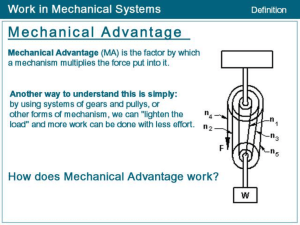

For illustration purposes only! You may use this document as a template for your Design Brief, but all content must be your own. Delete all the content within each section before you begin writing. ENGR 101: Design Brief I Section 999, Group 99 Group members Brandon Terranova, bbt25@drexel.edu Katie Jo, kjs364@drexel.edu Archimedes, a@drexel.edu Abstract The device presented in this design brief represents the first simple machine of a two-dimensional Rube Goldberg apparatus. Using a drafted design, through conceptual analysis the device was conceived to perform as a simple machine, and once the device was constructed, it was shown to perform as anticipated from the conceptual phase of the design process. Introduction In this design brief, a pulley system is evaluated to serve as the first simple machine (SM1) in the first event in our twodimensional Rube Goldberg (2DRG) apparatus. Theory The pulley system created to serve as SM1 is shown in Figure 1a. The pulley system consists of a movable pulley (pulley 1) and a fixed pulley (pulley 2) attached to masses 1 and 2 respectively. This system can be evaluated theoretically by performing a force balance using the free-body diagrams shown in Figure 1b. To perform this analysis, certain assumptions must be made about the pulley system, and the assumptions are as follows: 1.) The string used in the pulley system does not stretch, and thus the length of string remains constant. 2.) The tension in the string is constant throughout the pulley system. 3.) The mass of the pulleys and the string is neglected. 4.) Friction is neglected. 5.) The mechanical advantage is equal to the number of strings supporting the load. Both masses are free to move, and as all the forces are in the vertical ( ĵ ) direction, the sum of the forces on each mass yields the following equations of motion: 2T - m1g = m1a1 T - m2 g = m2a2 (1) (2) Where T is the tension in the string, m1 is the mass of “mass 1”, m2 is the mass of “mass 2”, a1 is the acceleration of mass 1, a2 is the acceleration of mass 2, and g is the acceleration due to gravity. These equations reveal there are three unknowns (T, a1, a2), and since there are only two equations, this is an underdetermined system. Another equation is thus needed to solve the equations of motion. For illustration purposes only! You may use this document as a template for your Design Brief, but all content must be your own. Delete all the content within each section before you begin writing. Noting that the length of string is constant, we can write down an expression for the total length as L = 2d1 + d2 + 2 æç 2p r ö÷ , è 2 ø where the æç 2p r ö÷ term represents each half-circle length (circumference/2) traversed by the string as it passes over each è 2 ø pulley. Noting that the radius of each pulley is constant, and taking the first derivative of this expression, we arrive at an d d expression for the rate at which d1 and d2 change: 0 = 2 d1 + d2 . As the lengths of the strings increase, the mass dt dt d lowers, such that d = -v where v is the velocity of the mass. We now have an expression for the velocities of the dt masses: -2v1 - v2 = 0 . The time derivative of this velocity relationship gives us an expression for the accelerations of each block: -2a1 - a2 = 0 . Assuming m1 = m2, plugging this acceleration relationship into Equations 1 and 2 reveals that mass 2 will fall with acceleration a2 = - 2 g . 5 (a) (b) Figure 1: a) Pulley system. b) Free-body diagrams for mass 1 and mass 2. Experimental The pulley system was built from various materials and assembled on a pegboard designated for use with the 2DRG. Table 1 lists the materials used to construct SM1. In Figure 1a, the upper left end of the string is connected to the pegboard using a thumbscrew-wingnut combination, and is fixed to the pegboard in that position. The red pulley is free to move, and a 1” K’nex rod is inserted into the red pulley to support mass 1, and is held in place using two standard tan clip connectors. The blue pulley is fixed to the pegboard using a thumbscrew-wingnut-washer combination. Mass 2 rests on the 5” foam board which is supported by six 2.4” K’nex rods, secured standard tan clip connectors on both sides of the pegboard. For illustration purposes only! You may use this document as a template for your Design Brief, but all content must be your own. Delete all the content within each section before you begin writing. Table 1: Materials list. Quantity Description 6 12 2 2 2.4” K’nex rod (K’nex part #509532) K’nex standard tan clip connector (K’nex part #90900) K’nex 2” grey pulley/tire insert (K’nex part #90979) 2” thumbscrews with ¼”-20 thread (McMaster part #90179A550) 2 ¼”-20 thread wingnuts (McMaster part #92001A321) 1 1” OD, 0.281 ID washer (McMaster part #90313A107) 1 1 2 5” long ¼” foam board 2’ long section of string 50 g hanging masses Results Once the apparatus is set up, pulling the 5” section foam board allows mass 2 to fall, and then mass 1 will rise, initiating the next event. The distance mass 1 must rise, d3, must not be so large that the red pulley falls off. Therefore, d3 < d1 – r sets a constraint on the distance between the upper surface of mass 1, and the next event. This first simple machine was created and the action was initiated via pulling the foam board to free mass 2, and mass 1 was observed to raise as expected. Using a timer on a smartphone, our group conducted a series of 10 trials to measure the time it took mass 1 to reach the desired height d3. Using the average time it took to fall (considering the limits on d3), and assuming a constant acceleration, the linear kinematic equations of motion were used to determine that mass 2 accelerated in accordance with the acceleration predicted in the theory section ( a2 = - 2 g ) within 6% of the expected theoretical value. The sources of 5 error include timer measurement human error, friction with the pulleys, stretch of the string, possible flexure of the foam board, and the mass of the string. Discussion Overall, the pulley system used for the first simple machine of our 2DRG operated as expected, and our theoretical analysis agreed well with the experimentally determined results. This first simple machine is the first of four total simple machines to be introduced into our 2DRG, and this particular machine has an ideal mechanical advantage of 2, as there were 2 strings supporting mass 1.