Chapter 9 Supply Chain Strategy

advertisement

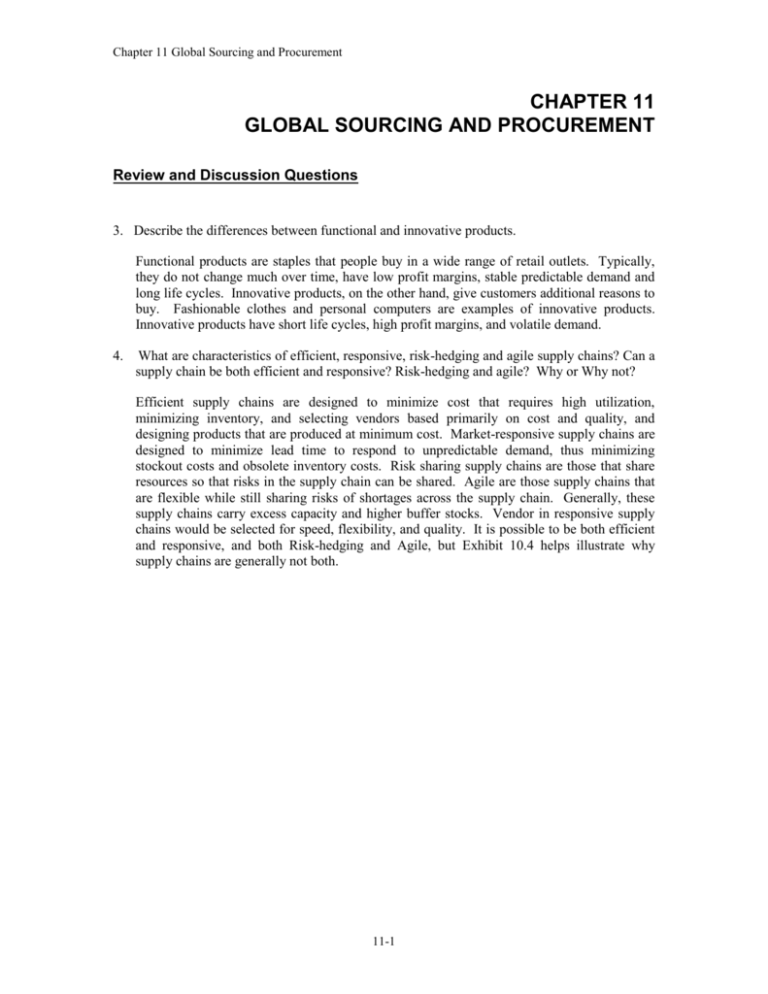

Chapter 11 Global Sourcing and Procurement CHAPTER 11 GLOBAL SOURCING AND PROCUREMENT Review and Discussion Questions 3. Describe the differences between functional and innovative products. Functional products are staples that people buy in a wide range of retail outlets. Typically, they do not change much over time, have low profit margins, stable predictable demand and long life cycles. Innovative products, on the other hand, give customers additional reasons to buy. Fashionable clothes and personal computers are examples of innovative products. Innovative products have short life cycles, high profit margins, and volatile demand. 4. What are characteristics of efficient, responsive, risk-hedging and agile supply chains? Can a supply chain be both efficient and responsive? Risk-hedging and agile? Why or Why not? Efficient supply chains are designed to minimize cost that requires high utilization, minimizing inventory, and selecting vendors based primarily on cost and quality, and designing products that are produced at minimum cost. Market-responsive supply chains are designed to minimize lead time to respond to unpredictable demand, thus minimizing stockout costs and obsolete inventory costs. Risk sharing supply chains are those that share resources so that risks in the supply chain can be shared. Agile are those supply chains that are flexible while still sharing risks of shortages across the supply chain. Generally, these supply chains carry excess capacity and higher buffer stocks. Vendor in responsive supply chains would be selected for speed, flexibility, and quality. It is possible to be both efficient and responsive, and both Risk-hedging and Agile, but Exhibit 10.4 helps illustrate why supply chains are generally not both. 11-1 Chapter 11 Global Sourcing and Procurement 3. The problem tells us that we sell 4,000 QUARTER pound burgers a week, therefore we sell 1,000 pounds a week, and each pound of hamburger costs $1.00. The problem also tells us that on average, the store has 350 pounds of inventory on hand. By dividing the Cost of Goods Sold by Average aggregate Inventory Value, We can figure the Inventory Turns. This means that their inventory turns 148.6 times a year. * 52 = .35 4. Sales (Total Quarter): United States Canada Europe Cost of Goods Sold (Total Quarter) Raw Materials at Louisville Plant (End-of-Quarter) Work-in-Process and Finished Goods at the Louisville Plant (End-of-Quarter) Quarter 1 (January Through March) Quarter 2 (April Through June) Quarter 3 (July Through September) Quarter 4 (October Through December) 300 75 30 350 60 33 405 75 20 375 70 15 280 295 340 350 50 40 55 60 100 105 120 150 11-2 Chapter 11 Global Sourcing and Procurement Distribution Center Inventory (End-of-Quarter): United States Canada Europe 25 10 5 27 11 4 23 15 5 30 16 5 Total Inventory 190 187 218 261 1.5 1.6 1.6 1.3 Inventory Turnover Q1 Q2 Q3 Q4 If you were given the assignment to increase inventory turnover, what would you focus on? Why? To increase the inventory turns, a firm needs to reduce the amount of inventory or increase sales or both. To increase turns, the item most readily within our control is the amount of inventory that the firm has on hand. The Work-in-Process is the most obvious target for reduction. The company reported that it used 500M worth of raw material during the year. On average, how many weeks supply of the raw material are on hand at the factory? The 500M does not come into play in this problem. 11-3