Experiment - Louisiana Space Consortium

advertisement

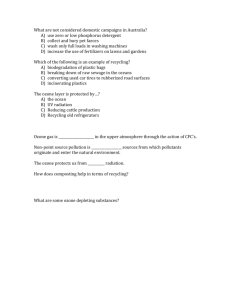

LA ACES Program Preliminary Design Review Document for the Operation Ozone Experiment by Team UNO Prepared by: Christopher Barber Date Donald Swart Date Gregg Ridlon Date Robert Schefferstein Date Michael O’Leary Date Larry Blanchard Date Institution Signoff (replace with name) Date LA SPACE Signoff Date Submitted: Reviewed: Revised: Approved: Team UNO i PDR v2.0 Change Information Page Title: PDR Document for Operation Ozone Date: 02/22/2005 List of Affected Pages Page Number Team UNO Issue Add Section 3.2, 4.6 Change 3.2 to 3.3 (Technical Goals) Change 2.0, 3.0, 3.3, 4.0 – 4.2, 4.4, 4.5 Change 5.0, 6.0, 7.1, 8.1, 9.0, 9.2, 10.0 ii Date 19 Mar 05 19 Mar 05 21 Mar 05 23 Mar 05 PDR v2.0 Status of TBDs TBD Section Number 4.4 6.1 7.3 Team UNO Description Thermal System performance Sampling rate and packet size Data Analysis Algorithm iii Date Date Created Resolved 1 Apr 05 5 Apr 05 25 Mar 05 PDR v2.0 TABLE OF CONTENTS Cover ............................................................................................................................................. i Change Information Page ............................................................................................................ ii Status of TBDs ............................................................................................................................ iii Table of Contents ........................................................................................................................ iv List of Figures and Tables.............................................................................................................v 1.0 Document Purpose ..................................................................................................................1 1.1 Document Scope ...............................................................................................................1 1.2 Change Control and Update Procedures ...........................................................................1 2.0 Reference Documents .............................................................................................................1 3.0 Mission Objectives..................................................................................................................1 3.1 Science Goals ....................................................................................................................2 3.2 Science Background..........................................................................................................2 3.3 Technical Goals ................................................................................................................3 4.0 Payload Design .......................................................................................................................4 4.1 Principle of Operation .......................................................................................................4 4.2 System Design ..................................................................................................................4 4.3 Electrical Design ...............................................................................................................6 4.4 Thermal Design .................................................................................................................7 4.5 Mechanical Design............................................................................................................8 4.6 Power Budget ....................................................................................................................8 5.0 Payload Development Plan ...................................................................................................10 6.0 Hardware Fabrication and Testing ........................................................................................10 6.1 Integration Plan ...............................................................................................................11 6.2 Software Implementation and Verification .....................................................................11 6.3 Flight Certification Testing .............................................................................................12 7.0 Launch Requirements ...........................................................................................................12 7.1 Flight Requirements and Operations ..............................................................................12 7.2 Data Acquisition and Analysis Plan ...............................................................................12 8.0 Project Management .............................................................................................................11 8.1 Interface Control .............................................................................................................13 9.0 Master Schedule ....................................................................................................................14 9.1 Staffing Plan....................................................................................................................14 9.2 Timeline and Milestones .................................................................................................15 10.0 Master Budget .....................................................................................................................16 10.1 Material Acquisition Plan .............................................................................................16 11.0 Risk Management and Contingency ...................................................................................16 12.0 Glossary .............................................................................................................................19 Team UNO iv PDR v2.0 LIST OF FIGURES 1. Absorption Cross Sections in the Atmosphere .........................................................................2 2. Ozone Density as a function of Altitude ...................................................................................3 3. Summing Circuit Diagram ........................................................................................................6 4. Discharge Curve under constant resistance ..............................................................................7 5. Heater Circuit Diagram .............................................................................................................7 6. Discharge Curve under constant current ...................................................................................9 7. Rate Sensitivity under continuous current at different temperatures ........................................9 LIST OF TABLES 1. List of Systems ..........................................................................................................................4 2. Table of Interfaces ....................................................................................................................6 3. Weight Budget ..........................................................................................................................8 4. Power Budget ............................................................................................................................8 5. Work breakdown structure ......................................................................................................14 6. Project Timeline ......................................................................................................................15 7. Project budget .........................................................................................................................16 8. Risk Matrix .............................................................................................................................18 Team UNO v PDR v2.0 1.0 Document Purpose This document describes the preliminary design for the Operation Ozone experiment by Team UNO for the ACES Program. It fulfills part of the LA ACES Project requirements for the Preliminary Design Review (PDR) to be held April 9, 2005. 1.1 Document Scope This PDR document specifies the scientific purpose and requirements for the Operation Ozone experiment and provides a guideline for the development, operation, and cost of this payload under the La ACES Project. The document includes details of the payload design, fabrication, integration, testing, flight operation, and data analysis. In addition, project management, timelines, work breakdown, expenditures, and risk management is discussed. Finally, the designs and plans presented here are preliminary and will be finalized at the time of the Critical Design Review (CDR). 1.2 Change Control and Update Procedures Changes to this PDR document shall only be made after approval by designated representatives from Team UNO and the La ACES Institution Representative. Document change requests should be sent to Team members and the La ACES Institution Representative and the La ACES Project. 2.0 Reference Documents Jacobson, Mark Z; Atmospheric Pollution; Copyright 2002; Cambridge University Press http://en.wikipedia.org/wiki/Ultraviolet Solar Radiation Research Laboratory http://www.nrel.gov/midc/srrl_bms/ Equations http://scienceworld.wolfram.com/physics/ Absorptional Cross Sections http://www.heliosat3.de/e-learning/radiative-transfer/rt1/AT622_section10.pdf 3.0 Mission Objectives Our objective is to measure ozone thickness as a function of altitude. Measurements will be derived from the measurable quantities of UV intensity and temperature. Team UNO 1 PDR v2.0 3.1 Science Goals Our main goal is to measure UVB and UVC irradiance as it is transmitted through the ozone layer, in order to determine the relative thickness of the ozone layer as a function of height above the surface. Then we will correlating this data to Fig. 2, as an approximation for what we have measured. We predict that our data of the relative thickness of ozone will be within ±10 DU as a function of height above the ground. 3.2 Science Background Radiation at wavelengths less than 4000 Å correspond to ultraviolet radiation which accounts for about 7% of total solar radiation. When discussing ozone, we are concerned with radiation in the ultraviolet region of the electromagnetic spectrum. Ultraviolet radiation is divided in to three spectral types: UVA, UVB, and UVC. UVA falls right below visible light; with wavelengths that vary from 3200 to 4000 Å. Ozone is totally transparent to UVA radiation and due to its low energy will not be absorbed. UVB radiation, which ranges in wavelength from 2800 to 3200 Å, is partially absorbed by ozone concentrations and is more energetic than UVA thought it is harmful to the biosphere. Fortunately, it exists in lesser amounts and is largely absorbed by ozone. UVC, at 2000 to 2800 Å, which is the most energetic and most damaging but least prevalent of the UV radiation types, is totally absorbed by ozone and normal diatomic oxygen high in the atmosphere. Figure 1 - Absorption properties of various compounds in the atmosphere Team UNO 2 PDR v2.0 Ozone is most effective at absorbing radiation at the 2500Å wavelength. In fact, it is 100 times more efficient at 2500Å than it is at 3500Å. After ozone absorbs radiation at this wavelength it reradiates it at longer wavelengths as an isotropic source into the atmosphere. When considering UV radiation at the altitudes that we will be flying one of our concerns is how much UV is absorbed at altitudes greater than the balloons burst altitude. With burst altitude being approximately 33km and knowing that the ozone layer extents above 50km we will have to make approximations for thickness levels and transmissions properties from. The density of the ozone varies with altitude and at about 30km our payload will be well over ½ to ⅔ of the ozone layer. That will mean that the only sources of UV reduction will be the small portion of ozone still above our payload. Research shows that molecular oxygen (O2) absorbs much of the lower wavelengths of UV, wavelengths between 1000Å and 2400Å. This is one of the major reasons that ozone exists primarily at upper altitudes. Molecular oxygen absorbs the high energy radiation, which causes it to dissociate into atomic oxygen, and upon emitting the light again its energy is reduced as a result and has a longer wavelength. Atomic oxygen is highly reactive and therefore it spends very little time in this state before recombining with another molecule of oxygen to form ozone. As a whole, the atmosphere contains a myriad of gases that absorb an equally wide variety of light wavelengths; however, the only molecule that absorbs a significant amount of UV light (>.01%) through our wavelength range is O3. Figure 2 – Ozone Density Measuring the amount of UV irradiance, especially within the range of ozone where it is most absorbent, we will have a crude method of measuring the relative thickness of the ozone layer. The unit used in measuring the thickness of the ozone layer is the Dobson Unit (DU), which is equal to a one column of ozone .01mm thick at STP. 3.3 Technical Goals In order to meet the science goals we have outlined we will need to be able to put together an effective method to measure UV radiation that can easily be correlated into flux levels. We will be exposing an array of photodiodes to the incident flux at our payload’s given altitude. The high altitude will require a thermal source in order to keep the payload components from dropping below operating temperatures. The low pressure will mean that the payload will need to be able to vent and that our thermal control is effective using only radiation and conduction. Team UNO 3 PDR v2.0 4.0 Payload Design The sensory unit is an array of 4 photodiodes that are sensitive to a very specific wavelength band of UV light. The output of these diodes will be conditioned through a summing circuit to a single channel on the BalloonSAT. This output will then interface with the analog-to-digital converter on the BalloonSAT which will also record the information in EEPROM. To compliment our UV readings we will include an external and an internal temperature measurement, as well as a pressure sensor. External temperature and pressure will be measured and recorded by the HOBO data collection unit, and the internal temperature will be measured and recorded by the BalloonSAT in order to facilitate activation of the heating unit at low internal temperatures. 4.1 Principle of Operation UV detection system: This system’s goal is to collect digital data of UV intensity in a specific wavelength range which will then be correlated to effective ozone coverage. The sensors’ wavelength range is 2250 Å to 3200 Å with peak sensitivity at 2800 Å. Data acquisition system: UV acquisition: Four photodiodes will provide a signal to a summing circuit which will collect and condition the analog signal sent to an ADC, which will then be sent to the BASIC stamp for processing and storage. Temperature acquisition: HOBO unit will measure the external temperature; BalloonSAT will measure internal temperature. Pressure acquisition: HOBO will record and measure pressure. Temperature regulation system: A lightweight industrial battery will power a small resistor array to provide heat throughout the flight. Its activation will be regulated by the BalloonSAT based on internal temperature measurements. 4.2 System Design List of Systems UV Detection Controller Pressure Detection Temperature Detection Temperature Regulation Power Mechanical Table 1 – Systems Team UNO 4 PDR v2.0 Description of Major Systems: UV Detection System – This system will detect ultraviolet radiation throughout our flight from 0 to 30 km. It is composed of two subsystems Subsystems: Photodiodes – Four photodiodes filtered to detect ultraviolet light in the wavelength range of 2250 to 3200 Å. The peak sensitivity is at 2800 Å which is close to the peak absorption wavelength of 2500 Å for ozone. This will yield more accurate results in determining the amount of ozone present between the sun and the payload. The photodiodes will be arrayed evenly around the payload exterior, one per side. DCU – The BalloonSAT will be the controller for the UV detection system. It will process and store all data received by the photodiodes in memory on board. Controller System – The BASIC stamp will be the controlling unit of the BalloonSAT, and therefore of the entire payload. It will store programming and execute its commands when conditions for each are met. Its programming will be uploaded prior to flight. Power System – One 9V battery will be used to power the BalloonSAT and its major components. The battery’s capacity is 1200 mAh, reduced to approximately 600 mAh at 273K. A second battery of the same model will be used to separately power the thermal system. Pressure Detection System – A pressure transducer with a measurement range of 0 to 15 PSIA will be included so that pressure measurements can be included with every time stamp. The transducer will be controlled, processed and stored by the BASIC stamp. Temperature Detection System – In order to regulate core temperature as well as monitor exterior temperature two different subsystems will be utilized. Subsystems External Temperature: The external temperature reading will be taken by a thermocouple that is fed directly into the HOBO for processing and storage. It will be exposed to the external environment through the base of the payload, slightly depressed so that it remains out of the direct radiation of the sun. This will make sure our temperature reading is that of the atmosphere and not that of the solar heated thermocouple. Internal: The BalloonSAT has an onboard temperature sensor that will take readings of the internal temperature of the payload. This will be useful in two ways. It allows the BalloonSAT to regulate to the thermal system by controlling power to the heater at the designated temperatures via a relay in order to conserve the heating system’s battery life. It will also allow us to know if our payload experienced any extreme temperatures that could possibly cause erratic readings or other malfunctions. Temperature Regulation System: A 9V battery of the same model used to power the BalloonSAT will be used to provide power to a 12Ω resistor array in order to produce heat. The heat will be distributed to the other internal components primarily through conduction Team UNO 5 PDR v2.0 Mechanical System – A foam board box will be constructed to house an inner construct that will hold all components in place during flight. This inner construct serves to both protect the payload from damage and to hold all inner components securely in place so that they can be placed in very close proximity and minimize the distance heat must radiate to maximize heating efficiency. The outer shell will be insulated with polystyrene to better retain heat and will be covered by reflective tape to prevent overheating due to radiation absorption. System Interfaces: UV Detection System: all photodiodes interface to the BASIC Stamp through a summing amplifier circuit. Power System: 1 9V battery provides power to the circuit systems; physical interface with thermal system keeps temperature at optimum. Thermal System: BalloonSAT will detect temperature and activate heater at 273K All Systems: Physical interfacing will keep boards and components within operating ranges. No other systems physically interface. Table 2 – Interfaces 4.3 Electrical Design The photodiode signal conditioning circuit is intended to amplify the output of the photodiode to a readable analog voltage signal which is then algebraically summed and can be measured by the ADC included on the BalloonSAT board. Capacitor values for C1 through C4 of 5660 pF shown in the schematic were provided by the Op Amp manufacturer’s circuit calculator, the capacitors serve the purpose of compensating the reverse junction capacitance of the photodiode and the input capacitance of the Op Amp(s). Similarly, the resistors R1, R3, R5, and R7 in the circuit control the Op amplifiers (U1 – U4) output gain. The 100 K Ohm resistors (R2, R4, R6, R8, and R9) bias the summing Op Amp (U5) to produce a gain factor of 1:1. The actual values Figure 3 – Summing Circuit of both resistance and capacitance are subject to modification to adjust output to ideal gain with our actual circuit. The combined summing-amplifier Team UNO 6 PDR v2.0 circuit is intended to operate from the regulated five volt power bus of the BalloonSAT, thereby simplifying construction as well as avoiding additional mass of a discrete power supply and regulation system. 4.4 Thermal Design The thermal environment that Operation Ozone expects to encounter is 223K through 298K. The thermal operating ranges for the major components are as follows: Battery – 233K-348K; Photodiodes – 248K-348K; HOBO – 253K-348K. The temperature control system will consist of low mass battery/resistor array that will be activated by the Balloon SAT when internal temperatures reach 273K or lower. The advantage to the battery and resister array is its ability to be activated in flight to prevent premature power usage and its ability to rapidly heat to 338K from 293K and slowly return to 293K over a period of 2 hours. The schematic diagram for the heating system follows: Figure 4 – Discharge Curve under constant resistance Heat will be distributed though the payload primarily through conduction. The heating array will be placed in immediate contact with power supply for the BalloonSAT to keep the Figure 5 – Heater Circuit battery at an optimum operating temperature. A heat sink will be attached to the heating elements to distribute the heat to the BalloonSAT components. Team UNO 7 PDR v2.0 4.5 Mechanical Design The payload mechanical design will be a cube approximately 15 cm to a side. This size is optimum allowing sufficient space for electronics as well as the insulation. Keeping it as small as possible will reduce the surface area resulting in slower radiation of heat away from the payload. Also the padding of essential parts on the interior (mostly data storage units) will also be key. A removable construct will be used to house the internal components. A shelf of foam board 10 cm by 12.5 cm with a 6.25 cm by 5cm hole in the center will hold the BalloonSAT. A lidless box of dimensions 6.25 cm by 5 cm and 5 cm tall will house the HOBO, batteries, and heating element. The box will be sized to fit snuggly into the BalloonSAT shelf in order to keep all components close to the heat source to maximize heat distribution by conduction and radiation. Weight Considerations: The weight constraint is 500g with a 10% margin for error. At this time we are working with a 450g allowance and 50g back up in the event that original figures and estimates are incorrect. Weight Breakdown: Mass (g) Component Box Photodiodes HOBO Thermocouple Pressure Transducer Battery BalloonSAT Thermal System TOTAL 141 16 15 15 15 35 75 60 372 Table 3 – Weight Budget 4.6 Power Budget Our payload will operate on one 9V, 1200 mAh battery that is capable of operating in temperatures as low as 233K. The battery will be capable of operating for about 20 hours at a constant drain of 60mA and 293K. At our planed internal temperature of 273K it will be capable of generating 600 mAh of current which will sustain our payload for approximately 10 hours. Component BalloonSAT OpAmp x 4 Summing Circuit Total Draw (mAh) 20 20 (est) 20 (est) 4 Hour total 80 80 80 60 mAh 240 mAh Table 4 – Power Budget Team UNO 8 PDR v2.0 Figure 6 – Discharge Curve under constant current Figure 7 – Rate Sensitivity under continuous current at different temperatures Team UNO 9 PDR v2.0 5.0 Payload Development Plan The preliminary design of the payload involves a balance of UV collection and sensor sensitivity. Initially we had thought to use fiber optics to channel light to the payload interior but because of the uncertainty of the light transmission and interference we abandoned the idea in favor of simply using four photodiodes, each to a side, with peak sensitivity at 2800 Å. The wavelength range is optimum for measuring the wavelengths most absorbed by ozone which will relate more directly to ozone cover. Prior to payload fabrication we will be testing various materials for box construction in order to determine what will give us a good balance of shock absorption, thermal maintenance, and overall strength. A method to have easy access to the interior without sacrificing thermal maintenance will also be devised. 6.0 Hardware Fabrication and Testing Electronics: The BalloonSAT itself is already constructed, however there are many components left to be added to the board. The photodiode array and its op amps will be mounted directly to the board in the open area for addition circuitry. The photodiodes will be connected by adapters that allow them to be added and removed as needed so that the BalloonSAT can still be removed from the payload without needing to ruin the payload shell. Until the photodiodes are received we will conduct tests for the radiation array using ordinary off the shelf photodiodes. Once the UV photodiodes are received they will be integrated, tested, and calibrated. Additionally, a pressure transducer will be mounted and routed through the BASIC stamp. The HOBO is a completely self reliant piece of equipment that will be measuring external temperatures using an attachable thermocouple. Thermal testing: Once the electronics are completed and functional they will be placed in the outer shell and insulation and then immersed in a dry ice chest that will simulate conditions at 30km altitude. To ensure no unnecessary damage to electronics immersion will be for short durations and then successively lengthened until we are sure it will last for approximately 2 hours below 273K. Simultaneously we will be testing the HOBO thermocouple so we will know the temperature within the dry ice chest. Impact testing: The payload will be dropped from progressively greater heights and checked for proper functioning after each fall until it is dropped from about 12 feet and still functions. If any indication of needing improvement is evident the test will be halted and the shock absorption will be improved before continuing. Calibration: In order to calibrate and scale the photodiodes mercury lamps will be placed a specified distance away to emit a known wavelength and test the voltage output by the photodiodes within its range of sensitivity. This will require only that the photodiode circuit is assembled and that the data storage program is completed. Vacuum: The pressure transducer will be subjected to a near vacuum in a chamber in order to scale the voltage outputs correctly. Team UNO 10 PDR v2.0 Heater: The heater will be constructed using a series of resistors that will radiate heat as current passes through them. Thermal testing: The first phase of testing was to assess the ability of the array to rapidly rise in temperature. This test was done at room temperature (approx 298K) in order to have an idea of the unit’s necessary response time when temperature begins to fall. Based on our initial test and data we will program the BalloonSAT to activate the heater when internal temperatures are 283K and continue to heat the unit until it reaches 293K at which point the heater will be turned off to conserve battery power. Outer shell/Insulation: The outer shell is constructed using foam board cut to have an interior cavity with dimensions of 15 cm to a side. Polystyrene will be used to insulate the shell interior. Thermal testing: The shell and insulation will be immersed in dry ice along with the heater to test the ability of the system to generate and retain heat in a cold environment. The goal is a successful submersion of 2 hours or more with out dropping below 273K. In order to facilitate keeping the thermal unit battery alive long enough to make a long length submersion the spare BalloonSAT with the heater activation program will be integrated to the test Impact testing: This test will follow the same guidelines for the drop test with the electronics. 6.1 Integration Plan Subsystems will be entirely contained within the mechanical system, directly connected to allow good thermal conduction. The UV detection subsystem will be routed through the BalloonSAT by physically being a part of the circuit board and directly routed to the BASIC stamp. The HOBO will be self contained and will control the pressure transducer and the external thermocouple. The HOBO will be removed from its casing, for mass regulation, and then it will be placed in contact with the thermal system in order to keep it within operating temperatures A separate circuit board will be constructed for the thermal system but it will also be routed to the BalloonSAT circuitry so that it may be controlled by the BASIC stamp. It will be in physical contact will all components either through direct contact or through indirect contact, such as aluminum (or other similar heat conducting metal) strips. The external thermocouple will protrude from the base of the payload so that it can detect external temperature with as little interference from the sun’s radiation as possible. Similarly, each photodiode will be exposed from each size so that it may receive as much of the sun’s radiation as it can. 6.2 Software Implementation and Verification Flight software will be divided into collection and retrieval stages. Only the collection portion will be included in-flight, and this will allow us to use one switch to signal when collection or retrieval should be started. Team UNO 11 PDR v2.0 Before flight stored memory will be zero and the collection program will be stored on the BalloonSat. When ready a switch will be turned on signaling the BalloonSat to begin storing data. During flight an infinite run loop will collect data and store it in packet form, then a system pause defined by packet size and available space. The packet’s data will be defined as a timestamp followed output from each sensor. At the end, the last packet will be designated as an End Of File marker (EOF) that will be moved with each new packet. In case of an unexpected shutdown during flight the BalloonSat will have instructions to operate a start up process that will reset the current file marker to the EOF and make a check that the last packet was complete. If the last packet was incomplete a marker will be placed to an interruption and the collection will continue. After flight the switch will be moved to the off position and a new run program will be stored instructing the BalloonSat to output all data to an external file, which will be formatted according to the same packet structure we defined for collection. 6.3 Flight Certification Testing During the flight temperatures are expected to reach approximately 223 K and pressure will drop to about 5 mb. We will test the payload for these expected conditions by super cooling the test payload in an vacuum chamber surrounded by dry ice. The vacuum chamber will simulate the low pressures while the dry ice will help simulate the low temperature at altitude. The importance of doing both tests together is primarily to assure that the only methods of heat distribution are conduction and radiation, not convection. A 4 meter drop test will simulate the impulse the payload will experience during landing. 7.0 Launch Requirements Clock synchronization with GPS system will be required in order to have a concrete base of time to plot readings against. Power switch will also need to be activated prior to launch. 7.1 Flight Requirements and Operations The flight is expected to be approximately 2 to 2 ½ hours, with a relatively constant ascension rate to an altitude of 30km. We will need to know altitude as a function of time from launch until landing. 7.2 Data Acquisition and Analysis Plan Operation Ozone will be acquiring UV radiation data as a function of altitude. All data will be collected and stored in the payload’s EEPROM, no data will be collected through telemetry. GPS data will be collected post flight from the LA ACES panel. Once data is collected group members using software such as Excel will analyze it. Data to be collected in flight: External Temperature UV Flux Atmospheric pressure Team UNO 12 PDR v2.0 8.0 Project Management To ensure the schedule is met on time all members have been given specific assignments and timelines to accomplish their tasks within. Periodic checks and weekly meetings help ensure that all tasks are being accomplished in a timely manner. These meetings also bring potential problems to the attention of the entire group so that the issue can be resolved as quickly as possible. 8.1 Interface Control Operation Ozone has a primary system consisting of the BalloonSAT that controls the UV sensor and the data logging of its output, as well as internal temperature monitoring and thermal regulation control. Its secondary systems are the HOBO data logger, the thermal system, and the power system. The HOBO data logger will be independent of the BalloonSAT and is responsible for logging the output from the external temperature thermocouple and the pressure transducer. The power system will be physically attached to the thermal system to ensure optimal temperature maintenance throughout flight. It will be routed to the BalloonSAT in order to provide power throughout flight. The thermal system will be powered independently of the rest of the payload’s systems; however, its activation will be controlled by the BalloonSAT and set to be activated when internal temperatures drop to 273K or less. This will conserve the power source of the thermal system until it is needed. The thermal system will be placed in direct contact with as many of the payload components as possible; those components that can not be placed in physical contact will be placed as close as possible and attached with a heat conductive metal to maximize heat transfer by radiation as well as conduction. The payload itself will not interface with any other payload or the spacecraft. Guiding cables through the payload and securing them will accomplish physical attachment. Team UNO 13 PDR v2.0 9.0 Master Schedule Milestone 1 2 3 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 C Task Proceeding Task Responsibility √ Order Photodiodes 0 Gregg Ridlon √ Research UV flux/atmospheric science 0 Donald Swart PDR 2 Team UNO √ Construct test box 0 Robert, Gregg, Donald √ Construct thermal system 0 Donald Swart Write thermal control software 5 Michael O’Leary Test thermal control 4, 6 Donald Swart √ Design UV summing circuit 0 Gregg Ridlon Acquire op amps 0 Michael O’Leary Construct summing circuits 8, 9 Donald Swart Construct radiation test array 10 Gregg Ridlon Software development 11 Michael O’Leary Test radiation test array 12 O’Leary, Ridlon Impact testing 4, 11 Schefferstein, Ridlon Thermal testing 7, 11 Schefferstein, Swart CDR 13, 14, 15 Team UNO Construct mechanical system 16 Robert Schefferstein Construct radiation detection array 16 Ridlon, O’Leary Calibrate radiation detection array 18 Christopher Barber Construct thermal control system 16 Donald Swart Integrate all system components 17, 19, 20 Ridlon, Swart, O’Leary Write algorithms for data recovery 21 Michael O’Leary Finalize presentation 16 Swart, Barber FRR 22, 23 Team UNO Table 5 – Work Breakdown Structure 9.1 Staffing Plan Donald Swart Christopher Barber Gregg Ridlon Robert Schefferstein Michael O’Leary Team UNO Team Leader/Data Analysis Research/Data Analysis Electronics/Construction Construction Programming/Construction 14 PDR v2.0 9.2 Projected Timeline Task Payload Design Order Parts PDR Test Box Fabrication Thermal Design UV summing circuit design Fabricate summing circuit Write thermal control software Test thermal control Radiation test array fabrication Complete software Test radiation array Impact testing CDR Document CDR Fabrication of payload shell Fabrication of UV array UV array calibration Final thermal control fabrication Integrate systems and final testing Data processing algorithms Presentation finalize Payload is launch ready FRR and Flight Date Started 21 Mar 2005 31 Mar 2005 31 Mar 2005 5 Apr 2005 5 Apr 2005 5 Apr 2005 7 Apr 2005 7 Apr 2005 13 Apr 2005 12 Apr 2005 14 Apr 2005 19 Apr 2005 25 Apr 2005 19 Apr 2005 28 Apr 2005 1 May 2005 1 May 2005 3 May 2005 3 May 2005 11 May 2005 13 May 2005 18 May 2005 20 May 2005 22 May 2005 Deadline 28 Mar 2005 5 Apr 2005 9 Apr 2005 9 Apr 2005 9 Apr 2005 9 Apr 2005 12 Apr 2005 12 Apr 2005 14 Apr 2005 14 Apr 2005 17 Apr 2005 21 Apr 2005 26 Apr 2005 26 Apr 2005 1 Mar 2005 3 May 2005 3 May 2005 10 May 2005 4 May 2005 16 May 2005 18 May 2005 19 May 2005 22 May 2005 26 May 2005 Completed 25 Mar 2005 5 Apr 2005 5 Apr 2005 5 Apr 2005 5 Apr 2005 Table 6 – Project Timeline Team UNO 15 PDR v2.0 10.0 Master Budget Ozone measurement Bill of Materials Name Vendor Source Delivery Time Qty Part No. Price per quantity Price UVBC Photodiodes Electro Optical Components www.eoc-inc.com 3 weeks 4 JEC 0.3 BC2 $110.00 $ 440.00 EEPROM Memory Chip 256 K Digi Key $ 2.75 $ 2.75 1 Relay switch 1 Op Amp Digi Key 5 AD8067ART-R2CT-ND $ 6.46 5660 pF capacitors Digi Key 10 P4170-ND $ .33 $ 32.30 $ 3.30 100k ohm resistor UNO store room In stock 5 2.8k ohm resistor Digi Key In Stock 5 2.80KXBK-ND $ .11 $ .55 4 ohm resistors UNO store room In Stock 3 N/A N/A N/A 1 480-1915-ND $ 30.11 $ 30.11 .5 m2 N/A N/A N/A 1 Thermocouple Pressure Transducer Digi Key Foam Board UNO store room Polystyrene Lowe’s Hardware In Stock 2.25 m $ 3.11 $ 7.00T Aluminum Tape Lowe’s Hardware In Stock 46m $ .31 $ 14.00T 9V Industrial Batteries Energizer In Stock 10 In Stock Batteries Plus 2 $7.50 $ 75.00T Contingency (Materials not Included) 1 L522 $ 50.00 $ 50.00 Shipping Costs 1 $ 50.00 $ 50.00 Taxes (where app.) Total 9.00 % $ 453.56 Table 7 – Project budget 10.1 Material Acquisition Plan Some components will be ordered from online sources. All purchases will be reviewed thoroughly by the team leader and other group members, and as many sources will be found as practical for all high dollar items. The long-lead items of immediate concern are the photodiodes. All other items can be obtained locally or quickly through the postal services. 11.0 Risk Management and Contingency Major risks to the payload include severe temperature changes, low power at extreme temperatures, impact damage to sensitive components, bursting pressure at extreme altitudes if not vented. Administrative concerns of note are the successful completion of all assigned tasks by projected completion date or, at latest, the deadline date. Mitigating factors include a heating system that works in conjunction with a sturdy mechanical system to keep all components at operational temperatures. All sensitive components will have extra padding to ensure safe landing at impact. Team UNO 16 PDR v2.0 A 30 to 45 minute administrative meeting will be held at the conclusion of every day’s work to go over all system progress and identify problems to the group. The group leader will make sure that all available manpower is used to its fullest ability and will reassign personnel or postpone projects until such times that problems can be successfully handled and overcome within reasonable deviation to planned schedule. Team UNO 17 PDR v2.0 Risk Matrix Event Prob. Effect Sub-risk Control Final Risk Temp Damage 4 3 12 H Heater 6M Low Power at alt. 3 4 12 H High Cap Batt/heat 6M Impact Damage 5 3 15 E Insulation/Padding 5M Work Lag 3 3 9H Meetings/Delegation 6M Low Pressure burst 2 4 8M Venting 4L Total Risk 5M Probability Effect 5 - Def 4 - Likely 3 - Occ. 2 - Remote 1 - Unlikely 20 16 12 8 4 1 – 4 Low 3 - Critical 15 12 9 6 3 5 - 8 Moderate 2 - Marginal 10 8 6 4 2 9 – 14 High 5 4 3 2 1 15+ Extreme 4 - Catastrophic 1 - Negligible Control Measures reduce either the probability or the effect, but usually not both Definite - Will happen continuously over course of flight Catastrophic - Total loss of payload, total loss of data Likely - Will happen for short durations frequently or once for a prolonged period Critical - Major damage that could compromise a large portion of our data Occasional - Will happen for short durations Marginal - Minor damage that could result in a loss of a small portion of data Remote - Will happen once or twice times for short durations Negligible - Mostly superficial, won't harm data collection or retrieval Unlikely - Will happen once during entire flight for a short time Table 8 – Risk Matrix Team UNO 18 PDR v2.0 12.0 Glossary La ACES ADC CDR DCU EOF EEPROM FRR GPS PDR STP TBD TBS UV WBS Team UNO Louisiana Aerospace Catalyst Experiences for Students Analog to Digital Converter Critical Design Review Data Collection Unit End of File Electronically Erasable Programmable Read Only Memory Flight Readiness Review Global Positioning Satellite Preliminary Design Review Standard Temperature and Pressure (P = 1 atm (approx 1013mb) and T = 273K) To be determined To be supplied Ultra Violet Work breakdown structure 19 PDR v2.0