doc

advertisement

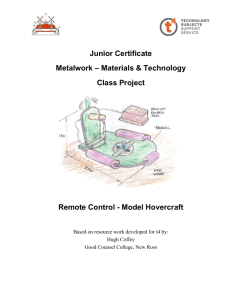

Final Report Web Controlled Hovercraft ECE4007 Senior Design Project Section L03, Team Hovercraft Mitchell Lentini, Team Leader Justin Earnest Brandon Dyer Submitted 30 April 2009 TABLE OF CONTENTS Executive Summary ......................................................................................................... iii 1. Introduction ..................................................................................................................1 1.1 1.2 1.3 Objective .............................................................................................................1 Motivation ...........................................................................................................1 Background .........................................................................................................2 2. Project Description and Goals ....................................................................................3 3. Technical Specification ................................................................................................3 4. Design Approach and Details ......................................................................................5 4.1 Design Approach ..................................................................................................5 4.2 Codes and Standards .............................................................................................8 4.3 Constraints, Alternatives, and Tradeoffs ..............................................................9 5. Schedule, Tasks, and Milestones.................................................................................9 6. Project Demonstration...............................................................................................10 7. Marketing and Cost Analysis ....................................................................................11 7.1 Marketing Analysis .............................................................................................11 7.2 Cost Analysis ......................................................................................................12 8. Summary .....................................................................................................................15 9. References ...................................................................................................................16 Appendix A .......................................................................................................................17 Team Hovercraft (ECE4007L03) ii EXECUTIVE SUMMARY The unmanned web controlled hovercraft is a useful prototype device designed for military use in potentially dangerous situations. The craft is relatively small, measuring 12” wide by 24” long. The hovercraft connects via Wi-Fi to a “command station”. From the remote “command station” the user pilots the craft with a forward, right, left, and stop button. Through the graphical user interface (GUI) the pilot sees receives a real time video sent from the hovercraft. Unmanned vehicles have been in use by the military for several years. Their popularity is on the rise, especially in the most recent military actions, because of the lives they save. While the value of human life is priceless, the cost of these vehicles often makes them unaffordable. These unmanned vehicles are capable of going into dangerous territory for tasks such as surveillance. The proposed web controlled hovercraft is one possible solution. Because of the hovercrafts properties it is ideal for environments with multiple types of terrain such as sand and water. The hovercraft was constructed to be as affordable as possible. The total cost of the device, not including man hours for a mass production model, is less than $500. At this price the device is affordable to use and also more dispensable than current competition for worst case scenarios. Because of the sensitivity of the control system we are experiencing difficulty getting a useable signal from the PSoC. Therefore the control mechanism is currently non functional. We also experienced problems with motor grounding. Once these problems are resolved the system will work. Future expansions include implementing the variable pitch portion of the propeller as well as increasing the resolution and response time of the video feed. Team Hovercraft (ECE4007L03) iii Web Controlled Hovercraft 1. INTRODUCTION The need for unmanned vehicles for military applications has never been higher. The value of human life is far greater than the price of any robot. A variety of vehicle types are needed for the diverse terrain of the world. One particular type of vehicle of interest is the hovercraft. Because it is able to travel on air and land, it is diverse and potentially useful in operations with multiple types of terrain. 1.1 Objective The unmanned remote controlled hovercraft is a prototype vehicle for military and hobbyist use. The vehicle is constructed using a blower and a flexible skirt, to create an air cushion on which the vehicle is supported. The thrust is supplied by two Electrifly V-Pitch propellers motors and electric speed controllers (ESC). Each motor ESC combination is then connected to the Cpyress CY3210 PSOC and that in turn is coupled into the eBox. The hovercraft utilizes remote control and remote video internet video transmission. It is controlled remotely from another computer through a GUI that we call the “command station”. 1.2 Motivation Sometimes certain agencies and groups, such as police forces, armed forces and researchers, need to observe a location that might be potentially dangerous for a person. A good way to solve this problem is to use an unmanned vehicle to inspect the area. Wheeled vehicles cannot traverse all types of terrain; however, a hovercraft is more versatile and can move over more types of terrain Team Hovercraft (ECE4007L03) 1 such as water, mud, or marshland. Therefore a remotely controlled hovercraft with a video feed is preferable for remotely monitoring an area without putting anyone in danger. Hobbyists can also enjoy the technology. For years they have enjoyed the world of RC cars, boats, and airplanes. Hovercrafts potentially could also be popular. 1.3 Background Unmanned Vehicles Unmanned vehicles have been in development by the government for years, with unmanned systems developed for air, ground, and underwater use as well as use in space. There are two main types of unmanned vehicle depending on the control system: remotely operated and autonomous. Companies such as iRobot produce unmanned vehicles of both types to meet various needs and uses in military, home, and industrial applications. Remotely operated vehicles, such as iRobot and Boeing’s SUGV300 series, provide the operator with real-time visual feedback using fix-focused, wide angle cameras in the front of the vehicle, with optional secondary cameras and other types of sensors available as well [1]. Hovercrafts Hovercrafts are vehicles that move around on top of a cushion of air contained within an attached skirt. The diversity gives a hovercraft an advantage over other ground based vehicles in terms of the types of terrain it can cover, performing equally well on dry land, ice, and water. Griffon Hovercraft notes that its vehicles are in use by several military organizations around the world and provide key benefits such as the ability to move over mines with little trouble due to the low pressures hovercrafts produce [2]. Companies that produce hovercraft for commercial and military use focus on vehicles designed for small rescue missions (seat 1-5 people) to large vehicles designed for transporting many passengers or freight such as vehicles. Team Hovercraft (ECE4007L03) 2 2. PROJECT DESCRIPTION AND GOALS The development team created a prototype unit of an unmanned hovercraft with web based controls and video feedback for use by the military and other government agencies. A control interface was developed to operate the hovercraft from a standard PC. The final specifications of our hovercraft were: 30 minute continuous of battery life $500 price tag Video feedback with a delay less than 1 sec Web control GUI or “command center” Capable of carrying a load of 23 lbs. Close to real time response to controls The final prototype provided the basis for an inexpensive unmanned hovercraft for use by government agencies and hobbyists. 3. TECHNICAL SPECIFICATIONS Hovercraft The physical dimensions of the hovercraft are listed in Table 1. The size of the hovercraft was chosen to best fit all the equipment needed on the craft. For the purpose of stability we added weight to the craft. While this slowed the craft down it prevented the air cushion from shaking and thus deflating. With the listed specifications the hovercraft got a lift of .1 inches off the ground and reached a top speed of 3 mph. Team Hovercraft (ECE4007L03) 3 Controls The controls for the hovercraft were separated into two bodies, the on-board and the remote components. For the remote component, a GUI was developed which ran on the “command station.” The GUI allows the user to control the direction of the craft using direction buttons within it. When the direction is selected a signal is sent out through the eBox to the PSoC where the square wave is generated that controls the fans. The on-board component runs off the eBox. The eBox is the “brains” of the hovercraft. The video from the camera is sent to the eBox, which then is sent to the “command center” via the eBox’s internal Wi-Fi. The camera allows the person controlling the hovercraft to navigate the craft. All Specs for the eBox were taken directly from its website [3]. Table 1. Technical design specifications. Design Aspect Length Width Height Robot Weight Wireless Communication Range Control Response Time Video Feed Robot Battery Life Interface Operational Temperature Operational Terrain Hovering Height Top Speed Team Hovercraft (ECE4007L03) Specification 24 in 12 in 6 in 20 lb 40 m indoors, 150 m outdoors Close to real time Close to real time 30 minutes 802.11b/g wireless connection 0 °F - 100 °F Smooth surface .10 in 3 mph 4 4. DESIGN APPROACH AND DETAILS 4.1 Design Approach To simplify the design of this project, the construction of the craft was broken down into the following components: Design of the physical body of the hovercraft (body, skirt, lift mechanism) Design of the controls system (motor/prop, PSOC, web camera) Design of the command station Integration of hovercraft and controls Integration of controls with command station via Wi-Fi To visualize the breakdown see Figure 1 for a component diagram. Figure 1. Diagram of component in Hovercraft. Team Hovercraft (ECE4007L03) 5 Hovercraft Body The hovercraft body was constructed entirely from scratch. For the frame we used a 24”x12” sheet of ¼” plexi glass. In the middle of the plexi glass a hole was cut out for the lift blower to push air into the skit, which was mounted below. The skirt was constructed out of a dense plastic sheet. The skirt was constructed so that the bottom was smaller than the top to allow it to inflate into a tube like shape. The outcome can be seen in Figure 2. Figure 2. Hovercraft Body. Control System The path of the hovercraft is remotely controlled by the user in the “command station.” The user is fed live video from the web camera and uses the GUI buttons to control the hovercraft according to their desire. The mechanism for motion is two Electrifly variable pitch propellers. Each propeller is controlled via an Electrifly BL-12 electronic speed controller (Figure 3). The fans are mounted on “L” brackets at the rear of the craft. Each ESC is then connected to the PSoC which is Team Hovercraft (ECE4007L03) 6 then connected to the eBox. The eBox will act as the “brain” of the hovercraft. It will communicate between the controls and the “command station” via Wi-Fi. The signal needed to drive the fans is a 10 volt peak to peak square wave with a period of 1.0 msec for initialization then ramped up to 1.9 msec for thrust. Figure 3. Control GUI. Command Station All driving is done from the “command station.” First the user boots the eBox and runs the “Server” console application. This spits out the eBox’s IP address and port number. Then those are entered into the control application running on “command station.” From there the driver views the stream of video and controls the craft using the direction buttons (Figure 4). Team Hovercraft (ECE4007L03) 7 Figure 4. Control GUI. 4.2 Codes and Standards Numerous codes were used. We first had to program the operating system (OS) for the eBox. The OS was built in Microsoft Visual Studio 2005. In addition the applications that ran from both the eBox and the “command station” were built in Visual Studio through C#. The Cypress PSoC was designed in Cypress PSoC Designer in conjunction with Assembly and C code. It was programmed onto the chip using the Cypress PSoC Programmer. Several standards were used as well. Most notably is the 802.11b wi-fi standard. This protocol is used to communicate from the “command station” to the eBox over the GTwireless network. Another common standard used is the RS-232 serial connection this connection is used to connect the eBox to the PSoC for transmission of controls to the fans. Team Hovercraft (ECE4007L03) 8 4.3 Constraints, Alternatives, and Tradeoffs Initially the first concern was weight. However when testing the 18 volt blower motor in conjunction with the skirt, it became apparent additional weight would be needed. While the addition of weight slows the craft down, the additional weight stabilizes the skirt and prevents it from deflating. At first the craft was going to be steered with a fan rudder system, however due to time and complexity issues we went with two variable pitch propellers to steer the craft. Again because of time, the varying of the variable pitch propellers had to be scrapped and instead we would control the system with an on/off between the two propellers. The addition of the variable part of the propeller would make for an excellent follow-up project. The constraint that hindered the development of the craft the most was the error occurring with the thrust fans. We were only able to get the thrust fans to run properly with the function generator. We concluded it is a grounding issue. We were able to match the output of the PSoC to the correct signal but the motors failed to initialize. Another problematic constraint was the hovercrafts battery consumption. The lift fan required an 18 volt motor. Each fan required a 10 volt power supply and an additional 10 volt peak to peak control signal. The eBox needed a battery as well and so does the PSoC then 4 more batteries were need to amplify the signal from it. In the end there were approximately 6 different battery sources on the craft as to not drain a single source too quickly. 5. SCHEDULE, TASKS, AND MILESTONES The Gantt chart in Appendix A shows the division of tasks and the time allotted to each one. The group as whole worked on each major task with minor duties given to one or two members as noted. Meetings were held every Tuesday after our Project Advisor lectures in order to determine Team Hovercraft (ECE4007L03) 9 what is needed to accomplish tasks and if any modifications should have be made to the Gantt chart as planned. Additional meeting were held as required. Three major goals listed in the Gantt chart are the development of the individual components, the integration of these components, and the final testing needed to properly demo the project. The most important date was the demo. We demoed Wednesday April 30, 2009. 6. PROJECT DEMONSTRATION The project demonstration was held in the Van Leer building in room C256. We began our demo by setting up the eBox. After connecting the eBox to the voltage regulator and a battery as well as a monitor, webcam, and keyboard and mouse, we turned it on. We then connected the PSoC. Once on we connected the Ebox to the GTwireless network via its internal 802.11b wi-fi modem. We then ran the server application that pushes out its IP address (Figure 5). Figure 5. Server App. Team Hovercraft (ECE4007L03) 10 Next we ran the host or “command station” application and input the received host IP and port number and connected the two devices (Figure 6). Figure 6. Hovercraft Connection. After this setup was complete we connected the thrust fans to their battery and PSoC. We then connected the PSoC to the eBox via a RS-232 serial cable and powered it on. Potentially hear we should have heard the beep from the thrust fans indicating they were initialized. However due to grounding issues as well as a communication issue between the PSoC and the eBox this did not happen. Parts that worked properly included the lift mechanism, the skirt, the eBox to “command station” communication. 7. MARKETING AND COST ANALYSIS 7.1 Marketing Analysis Team Hovercraft (ECE4007L03) 11 There are many different types of remote inspection vehicles of various designs. Many of these vehicles use either wheels or continuous tracks for movement and support. While these wheeled vehicles work very well is lots of situations, there are certain places that they cannot go such as across water, marshland, or heavy mud. The difference with a hovercraft is that the terrain over which it moves does not affect how it works. This means that a hovercraft can travel over areas that normal vehicles cannot. Our product is a more versatile vehicle because it can go over more various types of terrain than a wheeled vehicle and therefore be more useful. A boat could be used for some of the terrains that a wheeled vehicle cannot traverse; however, a hovercraft can traverse both types of terrain. A vehicle replacing multiple other vehicles and able to perform all their functions is a major advantage that can be used to obtain a large section of the market share. 7.2 Cost Analysis Table 2 takes into account the labor and parts costs and calculates the development cost of 2 prototypes combined. Table 2. Development cost of two prototypes. Parts 974 Labor 14,400 Fringe Benefits, % of Labor 3,600 Subtotal 18,974 Overhead, % of Matl, Labor & Fringe 9,627 Total Team Hovercraft (ECE4007L03) $28,601 12 Table 3 uses all calculated data to estimate a selling price and profit for 1000 units sold, as if it was mass produced. The analysis here would be potentially useful if the goal was mass production. Table 3. Selling price and profit analysis (based on 1000 units sold). Parts Cost Assembly Labor Testing Labor Total Labor Fringe Benefits, % of Labor Subtotal Overhead, % of Matl, Labor & Fringe Subtotal, Input Costs Sales & Marketing Expense Warranty & Support Expense Subtotal, All Costs Profit Profit Percentage Selling Price Total Revenue Total Profit 974 11 22 33 8 668 334 1,002 650 125 1,777 623 26% 2,400 $2,400,000 $623,000 Table 4 shows the cost of the various parts needed to build the hovercraft. These costs are determined from the literature for the various parts. The most expensive part is the eBox at $225. Team Hovercraft (ECE4007L03) 13 Table 4. Breakdown of parts cost for two prototypes. Part Quantity Unit Cost Total Cost Purchased Batteries 2 $30.00 $60.00 Thrust system 2 $12.00 $24.00 Hovercraft body 2 $100.00 $200.00 eBox 2 $225.00 $450.00 Camera 2 $20.00 $40.00 Cypress Controller Kit 2 $50.00 $100.00 Mounting, Cables, and Packaging 2 $50.00 $100.00 Total Material Cost $974 Table 5 shows the cost of labor for the 3 people in the group at $20 per hour for 192 hours. Fringe benefits are calculated as an estimated 25% of the total salary. Initial time estimations were vastly underestimated. Team Hovercraft (ECE4007L03) 14 Table 5. Breakdown of labor costs. Employee 8. Average hours per week Numbers of weeks* Total hours Rate per hour Fringe benefits (25%) $20 Total salary without fringe benefits $3840 $960 Total salary with fringe benefits $4800 Mitchell 12 16 192 Brandon 12 16 192 $20 $3840 $960 $4800 Justin 12 16 192 $20 $3840 $960 $4800 Total salary with fringe benefits $14400 SUMMARY Currently our project is in need of a few fixes. The first fix is to figure out is the grounding issue with the fans. The fans only work properly with the bench-top function generator and power supply and not with the battery and PSoC. After consulting several experts the motor problem could still not be solved. The other problem was the communication between the eBox and the PSoC. The RS-232 sent the signal as desired, however with the PSoC we were unable to make use of it. Potentially a few adjustments could be made to improve the hovercraft once the issues are solved. In the future the skirt could be made of a stronger more rigid material to help stabilize it. Another suggestion would be to implement the variable component of the propellers. Team Hovercraft (ECE4007L03) 15 REFERENCES [1] “iRobot SUGV300 Series,” [Online document], [cited 2009 Feb 1], Available HTTP: http://www.irobot.com/filelibrary/pdfs/gi/robots/iRobot_SUGV_300.pdf [2] “Military Hovercraft – Armed Forces International” [Online document], [cited 2009 Feb 1], Available HTTP: http://www.armedforces-int.com/categories/hovercraft/militaryhovercrafts.asp [3] “eBox-2300 Compact PC,” [Online document], [cited 2007 Sep 14], Available HTTP: http://www.embeddedpc.net/eBox2300/tabid/110/Default.aspx. [4] Compaq Computer Corporation, et al., Universal Serial Bus Specification, Revision 2.0, April 2000, Compaq, HP, Intel, Lucent, Microsoft, NEC & Philips. Team Hovercraft (ECE4007L03) 16 APPENDIX A: Gantt Chart Team Hovercraft (ECE4007L03) 17