SECTION 16309 PRIMARY VOLTAGE CABLE INSTALLATION

advertisement

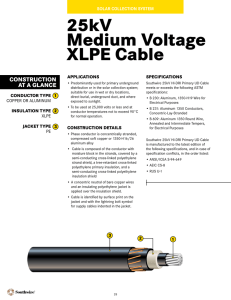

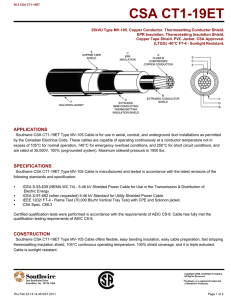

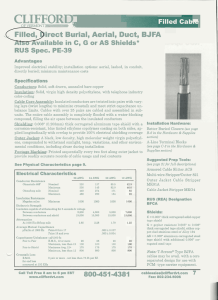

Stanford University – Facility Design Guidelines SECTION 16120 MEDIUM VOLTAGE POWER CABLE PART 1 1.1 GENERAL SCOPE This specification covers type MV-105, single-conductor, copper, medium-voltage (15 kV), shielded power cable, insulated with Ethylene Propylene Rubber (EPR), shielded and jacketed. This cable is intended for use in an underground distribution system. The same cable shall be used for both 12 kV and 4 kV installations. 1.2 RELATED WORK Section 16121: Medium Voltage Cable Installation. 1.3 SERVICE The cable shall be suitable for installation aerially, underground, through direct burial, in underground duct or conduit, in duct or conduit above ground, in raceway or in cable tray. The cable shall be capable of continuous operation in wet or dry environments at a conductor temperature of 105°C in normal operation, 140°C in emergency overload operation and 250°C in short circuit operation. 1.4 REFERENCE SPECIFICATIONS The cable shall meet the requirements of the following industry specifications: 1.4.1 Insulated Cable Engineers Association, Inc. (ICEA) ICEA S-93-639/NEMA WC74, 5-46kV Shielded Power Cable for Use in the Transmission and Distribution of Electric Energy ICEA S-97-682, Standard for Utility Shield Power Cables Rated 5-46 kV 1.4.2 The Association of Edison Illuminating Companies (AEIC) AEIC CS8, Specification for Extruded Dielectric Shielded Power Cables Rated 5 through 46 kV 1.4.3 Underwriters Laboratories UL 1072, Medium Voltage Power Cable, Type MV 105 1.4.4 ASTM International February 2014 Page 1 of 3 2015 FDG Section 16120 Stanford University – Facility Design Guidelines B496, Standard Specification for Compact Round Concentric-Lay-Stranded Copper Conductors 1.5 QUALITY ASSURANCE The manufacturer shall have a minimum of ten years experience manufacturing MediumVoltage Power Cable and shall submit a user reference list on request. A. The manufacturer shall ensure the cable core is virtually corona-free by applying the strand shield, insulation and insulation shield concurrently through a Triple Extrusion Single-Pass process. B. The manufacturer of the insulating and shielding material used shall minimize material contamination by filtering plant intake air and by processing and storing all materials in sealed containers not susceptible to rust and corrosion. Further, the manufacturing process shall be entirely computer controlled and employ state-of-the-art mixing and addition technology to maximize material uniformity. PART 2 2.1 PRODUCTS ACCEPTABLE MANUFACTURERS General Cable - UNIBLEND® (spec 6355) Okonite – Okoguard-Okoseal type MV-105 2.2 MATERIALS AND CONSTRUCTION A. CONDUCTOR The conductor shall be annealed compact stranded bare copper per per ASTM B496. B. STRAND SHIELD The strand shield shall be a black extruded semi-conducting thermoset compound applied directly over the conductor. It shall be free-striping from the conductor and be uniformly and firmly bonded to the EPR insulation. C. INSULATION The insulation shall be a high quality flexible thermoset Ethylene Propylene Rubber (EPR) compound that is heat, moisture, ozone and corona resistant. The compound shall be contrasting in color with the strand and insulation shields. The insulation level shall be 133%. D. INSULATION SHIELD February 2014 Page 2 of 3 2015 FDG Section 16120 Stanford University – Facility Design Guidelines The insulation shield shall be a black extruded semi-conducting thermoset compound applied directly over the insulation. It shall consist of a material compatible with insulation and the metallic shield and be free-striping. E. METALLIC SHIELD AND JACKET Metallic shields shall be an uncoated helically applied 5 mil bare copper tape with a minimum overlap of 12.5%, with a PVC or a flame-resistant semi-conducting Chlorinated Polyethylene (CPE) jacket. H. JACKET MARKING The following information shall be printed every twenty-four (24) inches on the outer jacket: 1. Manufacturer 2. Insulation thickness and type (shielded) 3. Jacket type 4. Conductor type and size (AWG or MCM) 5. Rated Voltage 6. Year of manufacture G. ENVIRONMENTAL REQURIEMENTS The outer jacket shall comply with EPA 40CFR, Part 261 for a leachable lead content of less than 5mg/L using the Toxicity Characteristic Leaching Procedure (TCLP). PART 3 3.1 EXECUTION TESTING OF COMPLETED CABLES Testing shall be done in accordance with the latest editions of ICEA S93-639 , UL 1072 and AEIC CS8. END OF SECTION February 2014 Page 3 of 3 2015 FDG Section 16120