OPEMAN1_REVIEWER

advertisement

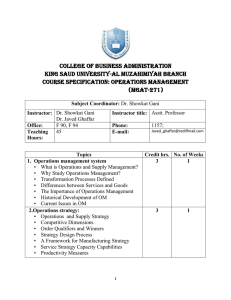

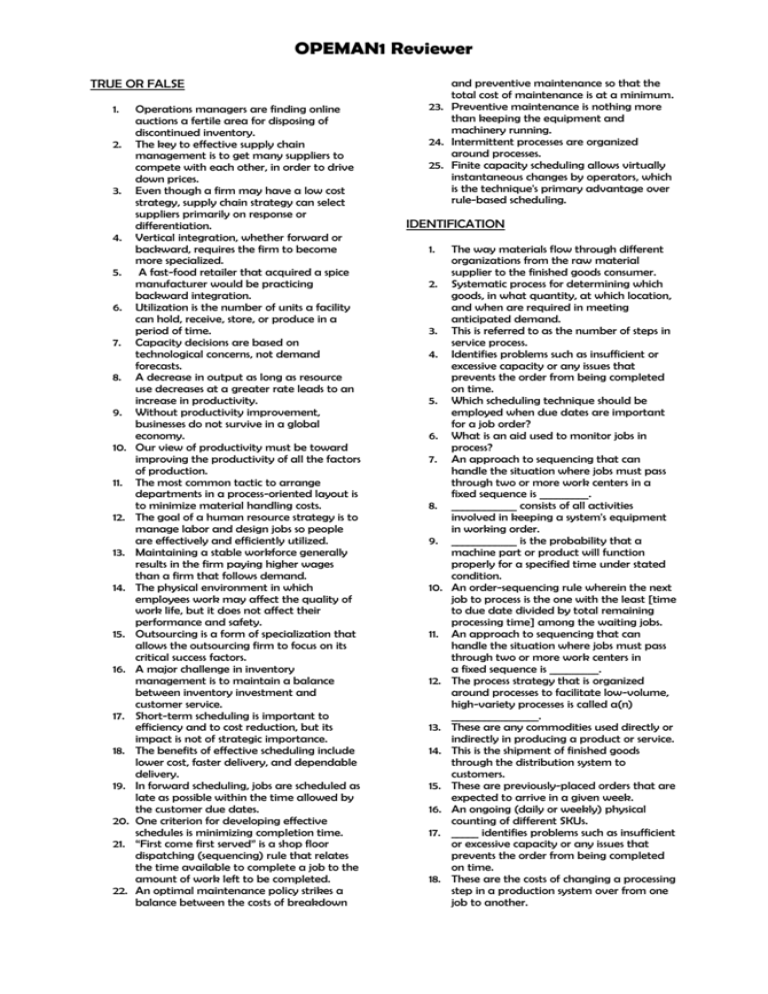

OPEMAN1 Reviewer TRUE OR FALSE 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. Operations managers are finding online auctions a fertile area for disposing of discontinued inventory. The key to effective supply chain management is to get many suppliers to compete with each other, in order to drive down prices. Even though a firm may have a low cost strategy, supply chain strategy can select suppliers primarily on response or differentiation. Vertical integration, whether forward or backward, requires the firm to become more specialized. A fast-food retailer that acquired a spice manufacturer would be practicing backward integration. Utilization is the number of units a facility can hold, receive, store, or produce in a period of time. Capacity decisions are based on technological concerns, not demand forecasts. A decrease in output as long as resource use decreases at a greater rate leads to an increase in productivity. Without productivity improvement, businesses do not survive in a global economy. Our view of productivity must be toward improving the productivity of all the factors of production. The most common tactic to arrange departments in a process-oriented layout is to minimize material handling costs. The goal of a human resource strategy is to manage labor and design jobs so people are effectively and efficiently utilized. Maintaining a stable workforce generally results in the firm paying higher wages than a firm that follows demand. The physical environment in which employees work may affect the quality of work life, but it does not affect their performance and safety. Outsourcing is a form of specialization that allows the outsourcing firm to focus on its critical success factors. A major challenge in inventory management is to maintain a balance between inventory investment and customer service. Short-term scheduling is important to efficiency and to cost reduction, but its impact is not of strategic importance. The benefits of effective scheduling include lower cost, faster delivery, and dependable delivery. In forward scheduling, jobs are scheduled as late as possible within the time allowed by the customer due dates. One criterion for developing effective schedules is minimizing completion time. “First come first served” is a shop floor dispatching (sequencing) rule that relates the time available to complete a job to the amount of work left to be completed. An optimal maintenance policy strikes a balance between the costs of breakdown and preventive maintenance so that the total cost of maintenance is at a minimum. 23. Preventive maintenance is nothing more than keeping the equipment and machinery running. 24. Intermittent processes are organized around processes. 25. Finite capacity scheduling allows virtually instantaneous changes by operators, which is the technique's primary advantage over rule-based scheduling. IDENTIFICATION 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. The way materials flow through different organizations from the raw material supplier to the finished goods consumer. Systematic process for determining which goods, in what quantity, at which location, and when are required in meeting anticipated demand. This is referred to as the number of steps in service process. Identifies problems such as insufficient or excessive capacity or any issues that prevents the order from being completed on time. Which scheduling technique should be employed when due dates are important for a job order? What is an aid used to monitor jobs in process? An approach to sequencing that can handle the situation where jobs must pass through two or more work centers in a fixed sequence is _________. ____________ consists of all activities involved in keeping a system's equipment in working order. ____________ is the probability that a machine part or product will function properly for a specified time under stated condition. An order-sequencing rule wherein the next job to process is the one with the least [time to due date divided by total remaining processing time] among the waiting jobs. An approach to sequencing that can handle the situation where jobs must pass through two or more work centers in a fixed sequence is _________. The process strategy that is organized around processes to facilitate low-volume, high-variety processes is called a(n) ________________. These are any commodities used directly or indirectly in producing a product or service. This is the shipment of finished goods through the distribution system to customers. These are previously-placed orders that are expected to arrive in a given week. An ongoing (daily or weekly) physical counting of different SKUs. _____ identifies problems such as insufficient or excessive capacity or any issues that prevents the order from being completed on time. These are the costs of changing a processing step in a production system over from one job to another. OPEMAN1 Reviewer 19. _____ means the amount of products or services produced with the resources used. 20. This refers to the process of estimating the amount of worker time required to produce one unit of output. 21. _____ refers to a hypothetical average situation ….. average or typical worker, material, machinery, environment, etc. 22. 23.